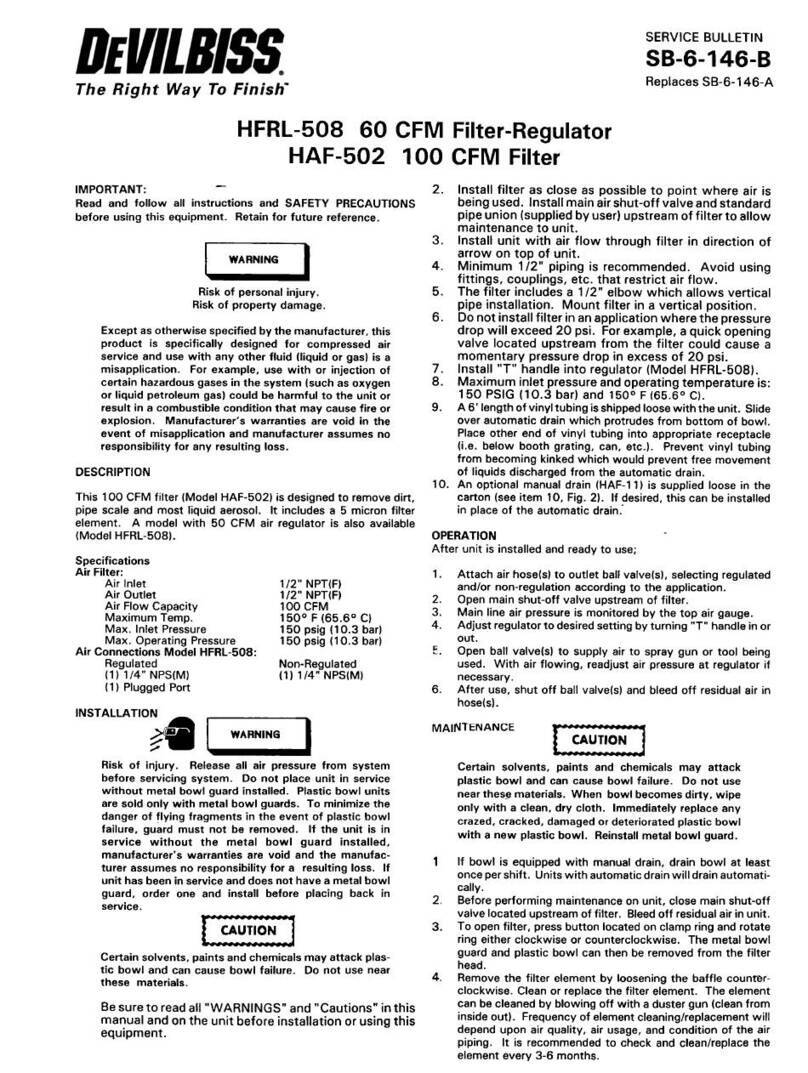

Tamper

Resistant

•T-handle must be

ordered separately.

Air

Pilot

1

2

3

4

1/8”-27

NPT(F)

9

15 lb./in.

(1.6 N-m)

8

6 lb./in.

(.07 N-m)

14

15

16

18

19

PTFE, (smooth

gray surface)

must face

wetted section

17

20 21

22

23

24

Apply QH-130

Loctite to threads.

25

26

27

120 lb./in.

13.5 N-m) 1/8-27

NPT(F)

Inlet

Non-Circulating

Port

Circulating Port

120 lb./in.

13.5 N-m)

12

13

11

15 lb./in.

(1.6 N-m)

8

6

5

7

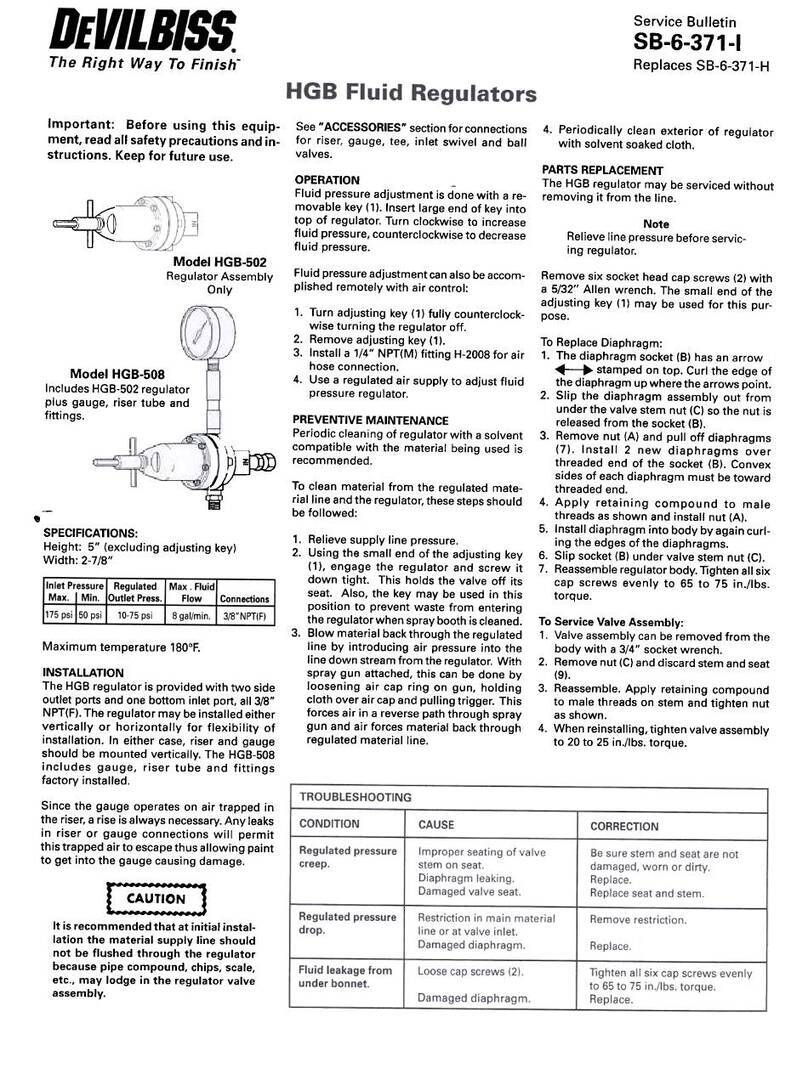

DESCRIPTION

The KK-4456 HGS uid regulator repair kit

is recommended for replacement of the

diaphragm and seating components when

repairing the regulator. It is designed to

be used with all HGS regulators.

DISASSEMBLY

Shut off and relieve pres-

sure before disconnecting

hoses from uid regulator.

Pressurized parts cause

a risk of injury to person-

nel if disassembled under

pressure.

1. Remove all pressure from regulator.

2. Remove regulator and clean.

Note

Refer to HGS Fluid Regulator Ser-

vice Bulletin SB-6-403 for general

service and cleaning procedures.

3. Remove six cap screws (8).

4. Remove bottom plug (25) circulating

regulators; or plug (27) non-circu-

lating regulators.

5. Remove and discard O ring (24) from

plug.

6. Remove stem (23) by inserting a blad-

ed screwdriver into slot and turning

counterclockwise while holding hex

nut (14).

7. Remove and discard upper plate (15),

gasket (16), diaphragm (17) and

PTFE washer (18) from valve stem

(23). Remove and save at washer

(19).

8. Remove and discard PTFE valve seat

(22) from body (20 or 21).

9. Clean all parts to remove any trace of

contaminates.

ASSEMBLY

1. Insert valve seat (22) into body (20

or 21) so that the at surface of

the valve seat is ush with the at

surface of the body.

2. Insert stem (23) through seat (22) so

it extends through body (20 or 21).

3. Install flat washer (19) and PTFE

washer (18) onto valve stem (23).

Note

PTFE washer (18) must be posi-

tioned between the at washer

(19) and diaphragm (17).

4. Place diaphragm (17) onto valve stem

(23) so that threaded portion of stem

protrudes through diaphragm.

5. Apply a couple of drops of QH-130 to

threads of valve stem (23).

6. Place upper plate (15) over threads of

stem against diaphragm and secure

in place with hex nut (14). Torque to

proper torque specication.

7. Install gasket (16) and bonnet (10 or

11) and secure in place with six cap

screws (8). Torque to proper torque

specications.

8. On circulating regulators, Install O

ring (24) and plug (25); on non-

curculating regulators, install O-ring

(24) and plug (27); and if equipped,

install spacer (26). Torque to proper

torque specication.

9 Reinstall uid regulator into the system.

PROP 65 WARNING

WARNING: This product

contains chemicals

known to the State of

California to cause

cancer and birth defects or other

reproductive harm.

CA PROP

65

Ref.

No. Description

Ind.

Parts

Req'd.

1 T-handle Kit •

2 Adjustment Screw 1

3Lock 1

4 Guard 1

5 Cap Nut 1

6 Nut 1

7 Allen Set Screw 1

8 Cap Screw 6

9 Connector 1

10 Bonnet 1

11 Bonnet 1

Ref.

No. Description

Ind.

Parts

Req'd.

12 Adjustment Seat 1

13 Regulator Spring 1

14* Hex Nut 1

15* Upper Plate 1

16* Gasket 1

17* Diaphragm, PTFE 1

18* Washer, PTFE 1

19 Flat Washer 1

20 Regulator Body 1

21 Regulator Body 1

22* Valve Seat, PTFE 1

Ref.

No. Description

Ind.

Parts

Req'd.

23 Valve Stem 1

24* O-ring, PTFE 1

25 Plug 1

26 Spacer 1

27 Plug 1

* QH-130 Loctite 1

•T-handle must be ordered separately.

*These parts are included in the KK-4456

Regulator Repair Kit.

PARTS LIST

KK-4456 FLUID REGULATOR REPAIR KIT

SI-6-41-1-R1 (3/2018) 1 / 2 www.carlisleft.com

EN

SERVICE MANUAL