Page4

SB-2-552-D

3.

Pull

gun

trigger until activator begins

spraying

out

of

the

air

cap horns.

4.

Afteractivator

flow

has stabilized,

lower

the activator flow by closing the

flow

meter

adjustment knob clockwise. Ad-

just

until afine mist comes

out

of

the

air

cap horn holes.

Notes

Activator flow must overcome back

pressure created

by

air cappressure.

You

may have

to

Increase actfvator

tank pressure slightly

to

overcome

this back pressure. The amount

of

back pressure Is dependent

upon

the

air cap pressure.

On

new

guns, it may require higher

air pressure

to

the

gun

to

Initially

actuate

the

activator valve. Refer

to

Page 7, "Break-In" procedure (new

guns).

APPLICATION

Normal application of contact adhesive ·is

equal

to

approximately 7 gramspersquare

foot. Thiswill

not

resultin acontinuousfilm.

Rather, a coarse, random spot atomization

pattern

will

resultwhich is desirable. Apply

this

~pebbled"

film to both sutfaces. Follow

themanufacturer'sinstructionsfortacktime

before bonding. Some adjustments

to

acti-

vator concentration may

be

required.

Adjustments

to

the adhesive pressure

will

require re-calibration

of

both components.

CLEAN

UP

Refer

to

the manufacturer's instructions.

DeVilbiss recommends

each

component be

slowly pushed out

of

both hoses using a

lukewarm water and soap solution recom-

mended

by

the supplier. Do

not

attempt

to

blow

components back. Clean

out

from

supply source forward only.

If adhesive and activator are flushed

out

daily, DeVilbiss recommends all liquid lines

be

kept filled

with

the clean out water solu-.

tion, until system is used again.

Ifsystem is notflushed daily, DeVilbiss rec-

ommends the following:

1.

Turn

off

supply ball valve at activator

source.

2.

Turn

off

supply ball valve at adhesive

source.

3.

Removeanyadhesiveaccumulationfrom

the

air

cap surfaces

(see

PREVENTIVE

MAINTENANCE

for

cleaning instruc-

tions).

4.

Removeadhesiveaccumulationfromface

of

fluid tip.

5.

Wipe exterior

of

baffle with a wet rag

to

remove activator. Clean baffle and re-

taining ring threads.

6.

Store gun

with

nozzle pointed down-

ward, preferably in a shallow container

of

clean water.

The activatorflow

can

be

affected byfluctu-

ating supply pressures, increasing

or

de-

creasing atomizing air, adjustment to the

fan pattern,aplugged activatorfilterscreen,

or

aplugged.020"

(.5

mm)orificefitting (36).

If there appears to

be

no

reason

for a re-

ducedactivatorflow, removepressurefrom

supply. Check for blockage in the .020"

(.5

mm) orifice fitting

(36)

located at the

activator valve. Inspect filter screen. If

acoumulation

is

present clean or replace

screen

(46),

or

orifice fitting

(36).

PREVENTIVE

MAINTENANCE

A gun lube sample

(1.5

ml) is included in

each

gun

package.

SSL-10

gun lube is also

availablein 2

oz.

(66

ml)bottles

(see

ACCES-

SORIES

section

on

Page

11)

and

can

be

ordered from your DeVilbiss distributor.

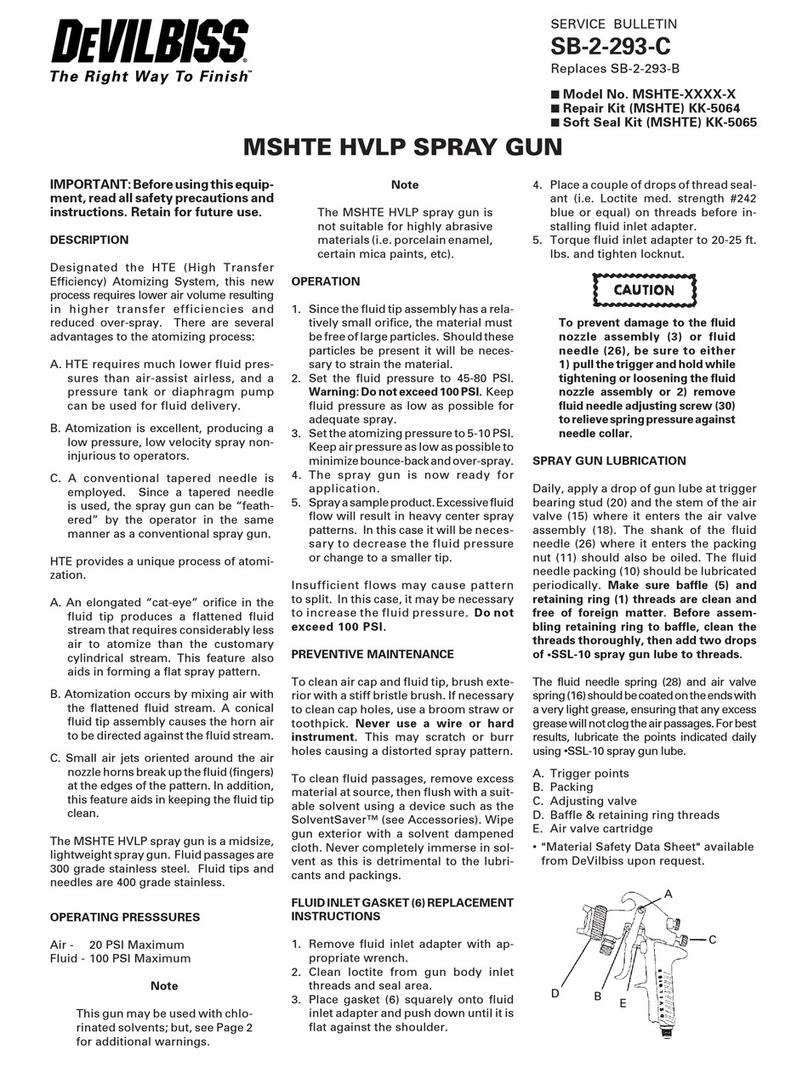

Additional lubrication pointson the gun

are

shown.

A. Trigger points

B.

Needle

Packing

C.

Adjusting screw

threads

D.

Baffle and retaining ring threads

E.

Air

valve cartridge

The

needle spring

(12)

and airvalve spring

(17) should

be

coated

with

a light grease.

Make sure that any excess grease does not

clog the air

passages.

For best results,

lubricate the points indicated daily using

SSL-10 gun lube.

Air

Cap

-Remove air

cap

from gun and

brush exteriorwith bristle brush and appro-

priate cleaning agent. Blow dry with com-

pressed air.

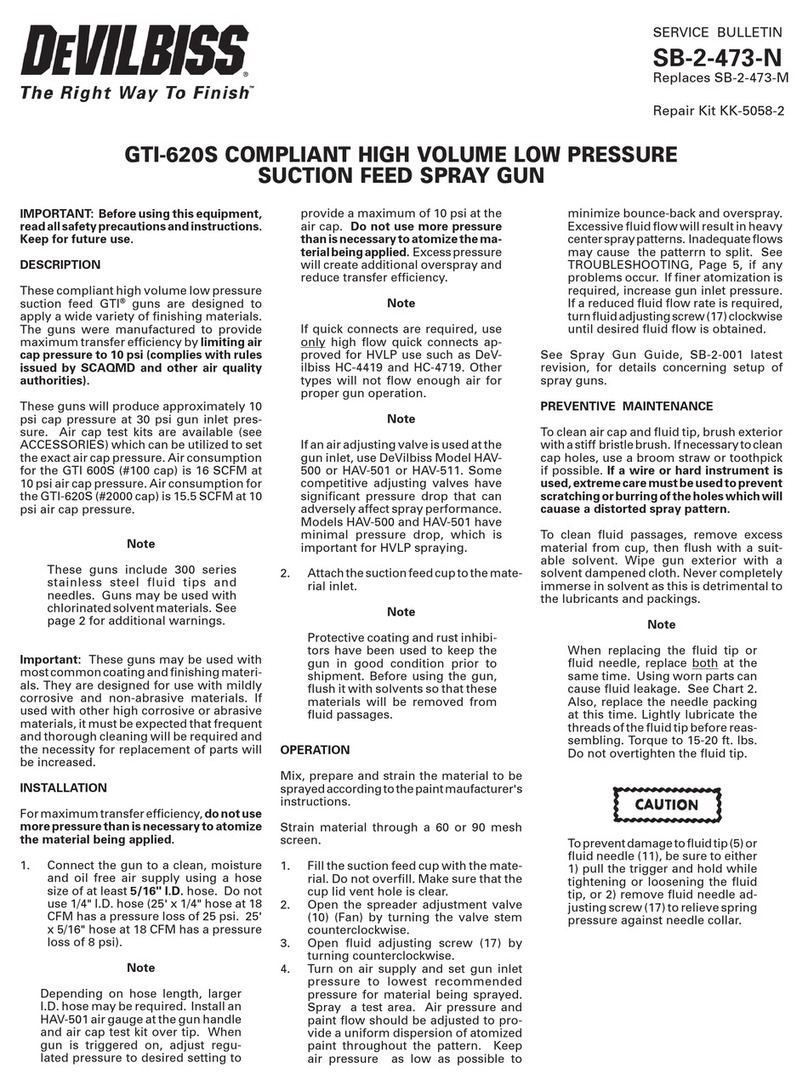

Ifsmallholesin

the

aircap becomeplugged,

soak cap

in

cleaning agent. Ifreaming holes

is

necessary,

use

a toothpick, broomstraw

or

some other soft implement (Figure

6).

Cleaning holes with a wire, nail

or

similar

hard object may damage cap by enlarging

jets, resulting in adefective spray pattern.

Figure 6 Cleaning Air

Cap

PARTS REPLACEMENT

To

prevent

damage

to

the

fluid

tip

(3A)

or

needle(38),

be

sure

to

either

1)

pull

the

trigger

and

hold

while

loosening

or

tightening

the

fluid

tip;

or

2) remove needle

adjusting

screw

(13)

to

relieve

spring

pressure.

When

replacing

the

fluid

tip

or

fluid

needle,

both

should

be

replaced

as a

lapped set

to

prevent leakage.

When installing the

new

fluid

tip,

tighten

to

a

torque

of20-25

ft.lbs.

(27.2-

34 N•m).

Fluid

Inlet

Gasket (27)

Replacement

Instructions

1.

Removefluid inletadapter

with

appro-

priate wrench.

2.

Clean Loctite

from

gun

body

inlet

threads, threads

of

inlet

fitting

(29),

and

seal area.

3.

Place gasket (27) squarely

onto

the

fluid

inlet adapter and push

it

down

until

it

is flat against

the

boss.

4.

Place a couple

of

drops

of

thread seal-

ant

(i.e.LoctiteMed.Strength242, Blue)

on

threads before installing fluid inlet

adapter.

5.

Torque

fluid

inlet

adapter

25-30

ft.lbs.

(34-

41

N•m) and tighten locknut until

snug.