Service Instructions

BYC-069-A

Description

The SGK-600PR spray gun has Transtec HVLP technology and is gravity fed.

It is a high production spray gun, ideal for spraying finishing materials, with

exception of corrosive and abrasive ones. It renders paint economy, less

overspray and ,consequently, reduces costs.

Installation

Connect the spray gun to a clean air source, free of humidity and oil, by using

at least a 5/16” internal diameter hose. Depending on the length of the hose, a

bigger internal diameter may be necessary. Press the spray gun trigger and

adjust the inlet air pressure at the handle of the gun to approximately 25 psi.

Operation

Prepare the material to be sprayed according to the manufacturer’s

instructions. Filter the material through a 100 mesh screen.

Regulate the air pressure at the DeVilbiss filter regulator

Make a spray test.

Regulate the spray pattern by opening or closing the spray pattern valve

knob (10)

Spray a small area to adjust the work speed and desired finishing. If

finishing is too dry or rough, the amount of material is too small in relation

to the air pressure. Turn the fluid adjustment knob (18) counter clockwise,

or decrease the air pressure at the filter regulator.

Keep the spray gun always perpendicular to the surface being painted.

Do not move your hand in an arch. The arch movement produces a non-

uniform paint layer.

We recommend the spray gun be kept at a distance of 6 to 8 inches from

the surface.

The position of the air cap determines the position of the pattern. Turn the

air cap according to requirements.

Maintenance and Cleaning

We recommend cleaning be done after using equipment:

1. Disconnect the spray gun from the air line.

2. Clean the cup and put clean solvent in same.

3. Open totally the fluid adjustment knob, press the trigger and let the solvent

flow through the fluid passage until it comes out completely clean.

4. Clean the gun body with a cloth wet with solvent, avoid waste of cotton

5. Remove the air cap and wash it in solvent using a brush or soft bristle

brush. Then dry it with an air jet.

6. If necessary, clean the air cap hole with a bristle or toothpick. NEVER

USE steel wire or hard instrument for this may damage the hole causing a

distorted spray pattern.

7. To avoid damaging the needle, make sure to pull the trigger and keep it

pulled while you are tightening or releasing the fluid tip, or remove the

fluid adjustment knob (18) to release the spring pressure.

8. Only remove the fluid tip when changing same or when there is internal

clogging.

9. For routine cleaning it is not necessary to remove the cup.

10. The recommended tightening of the tip is 150-180 lbf/inch.

Note: To replace both U-cup seal (11) and air valve seat (12) see the procedure

described in Service Instructions of the K-5029 kit.

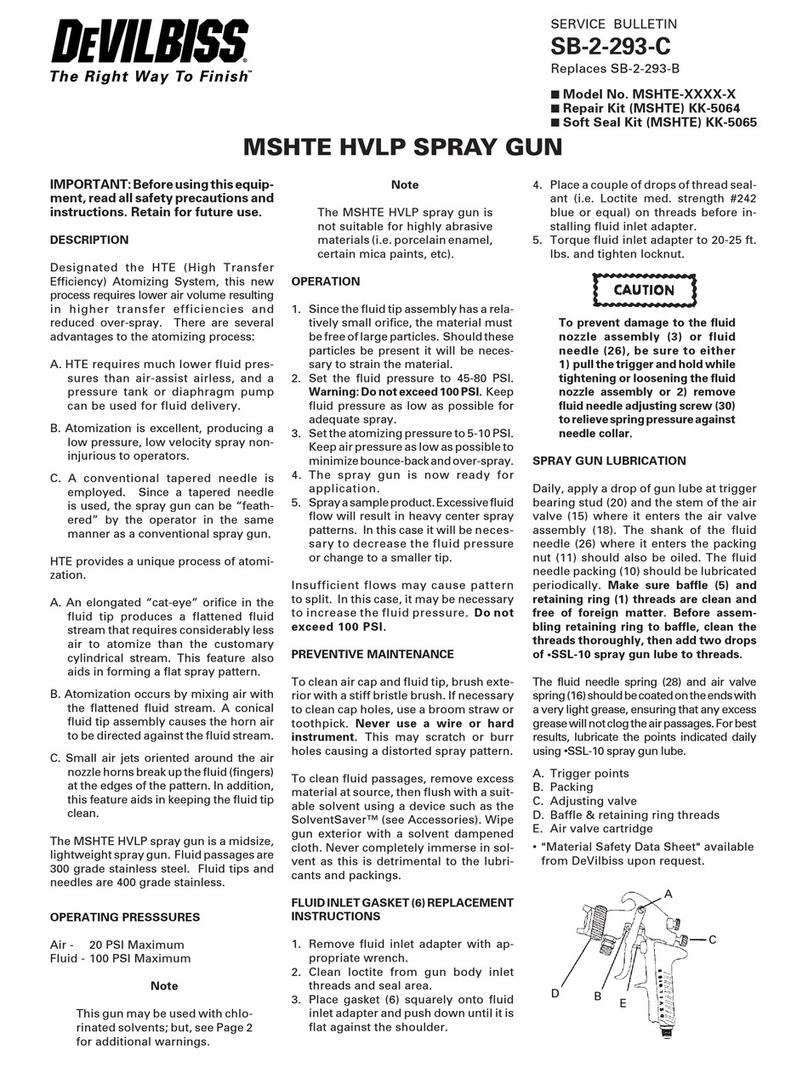

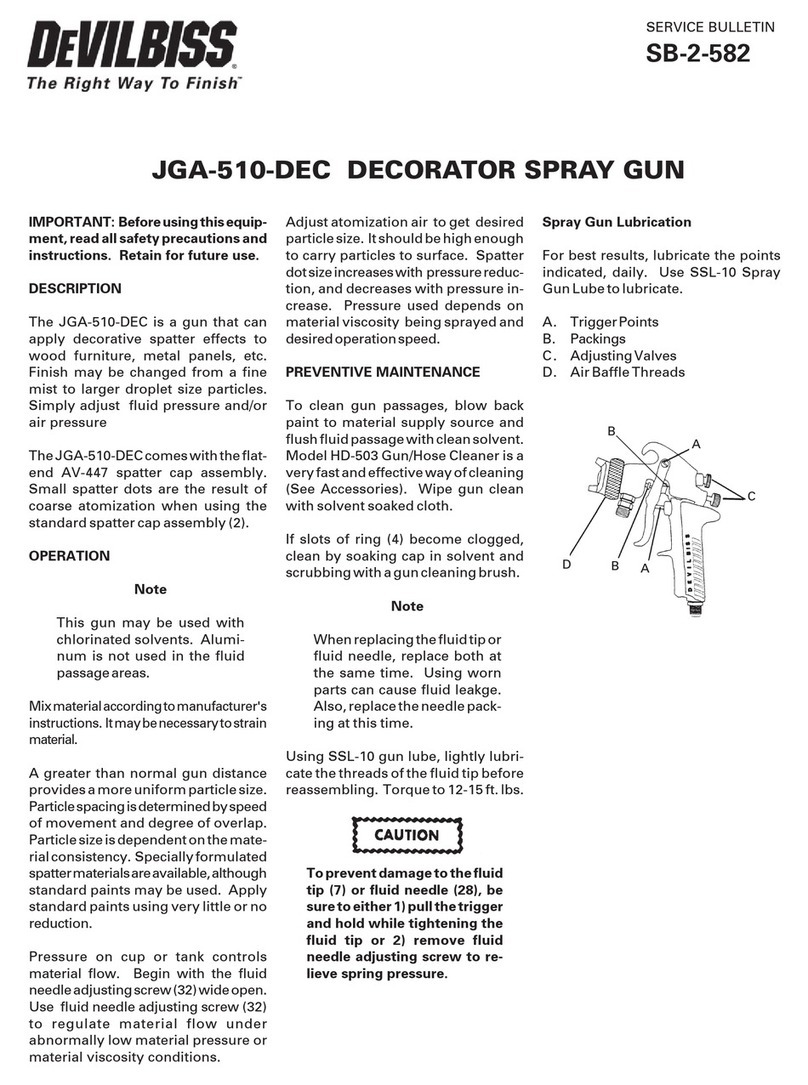

Lubrication

For best results, oil the indicated points daily

We recommend the use of the SSL-10 DeVilbiss oil.

A. Trigger areas

B. Needle gasket

C. Adjustment valves

D. Retaining ring

E. Air valve

Service Check

Defect Causes Correcting

a. Material buildup at air cap. a. Remove air cap and wash it with solvent.

Heavier spray on top or

below. b. Partial obstruction of air cap horn holes or

central holes.

b. Remove air cap and wash it with solvent (see

maintenance and cleaning).

c. Material buildup at the fluid tip or partial

obstruction of same.

c. Remove the tip and wash it with solvent.

Defective configuration in

curve shape. d. Damaged fluid tip. d. Replace the tip and needle assembly.

a. Excess material. a. Reduce the material flow by closing the fluid

adjustment knob.

Heavy spray in the center

b. Very thick material. b. Dilute the material.

a. Air pressure too high. a. Reduce air pressure at DeVilbiss filter regulator.

Split spray. b. Lack of material. b. Increase material flow opening fluid.

a. Lack of material. a. Refill paint recipient.

b. Obstructed fluid passage. b. Clean fluid passage.

Jerky or fluttering spray.

c. False entrance of air in paint line. c. Check paint line.

a. Low air pressure at spray gun. a. Check air line or increase pressure.

b. Fluid regulating knob closed. b. Open fluid adjustment knob (see Operation).

c. Material is too thick. c. Dilute material.

d. Air cap is loose. d. Tighten air cap.

Will not spray.

e. Material buildup in between tip and air cap. e. Clean tip externally and the central air cap hole.

a. Fluid tip or needle worn or damaged. a. Change the tip and needle assembly (see item 7 in

Maintenance and Cleaning).

Dripping or material leakage

through the tip. b. Gasket holding the needle. b. Lubricate the gasket (item 6) when new, or change it,

lubricate and adjust.

With 14 psi at spray gun inlet air cap pressure is 10 psi.

DeVilbiss maintains the right to modify the characteristics of its products without previous notice.

Warranty

DeVilbiss equipment has a six month warranty from the date of purchase. This warranty will be limited to material, manufacturing and workmanship defects; bad use or repairs effected by non authorized people imply

in automatic loss of the warranty;

When repairs are necessary, take your equipment to a DeVilbiss Authorized Distributor where the repair will be effected by specialized technical people and only charged if equipment it outside warranty.