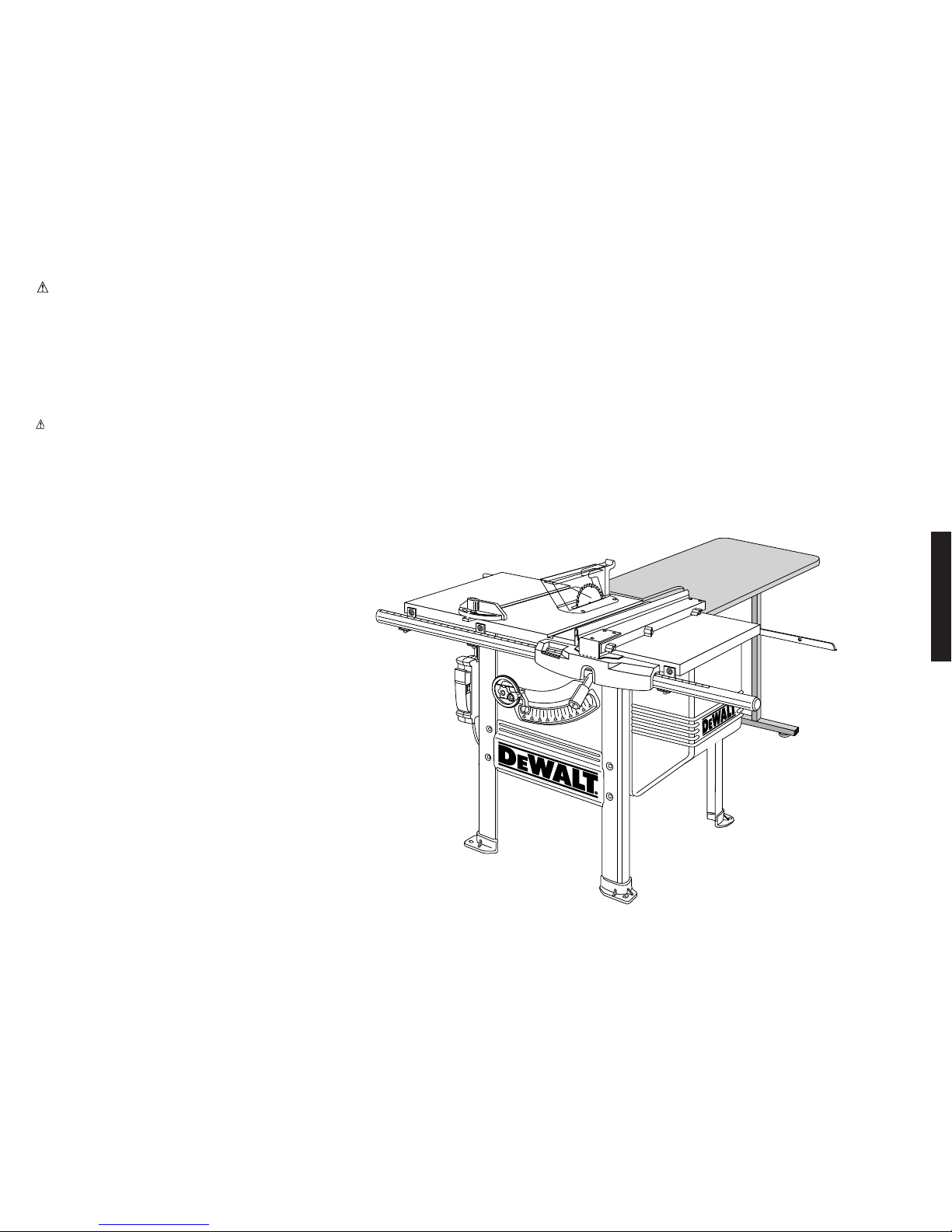

Français

ÉTAPE 8. Déballez le carton des rails (contenant les rails frontal

et dorsal) et celui de la table de sortie.

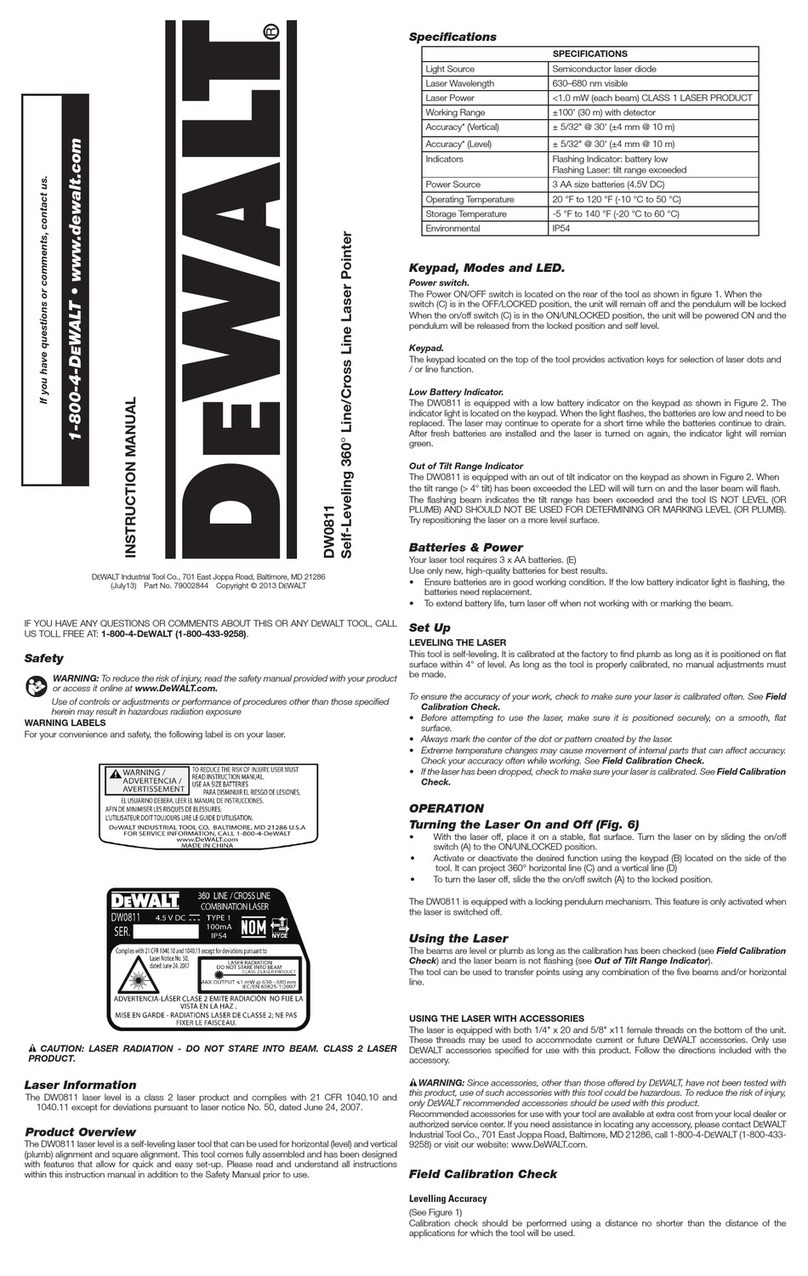

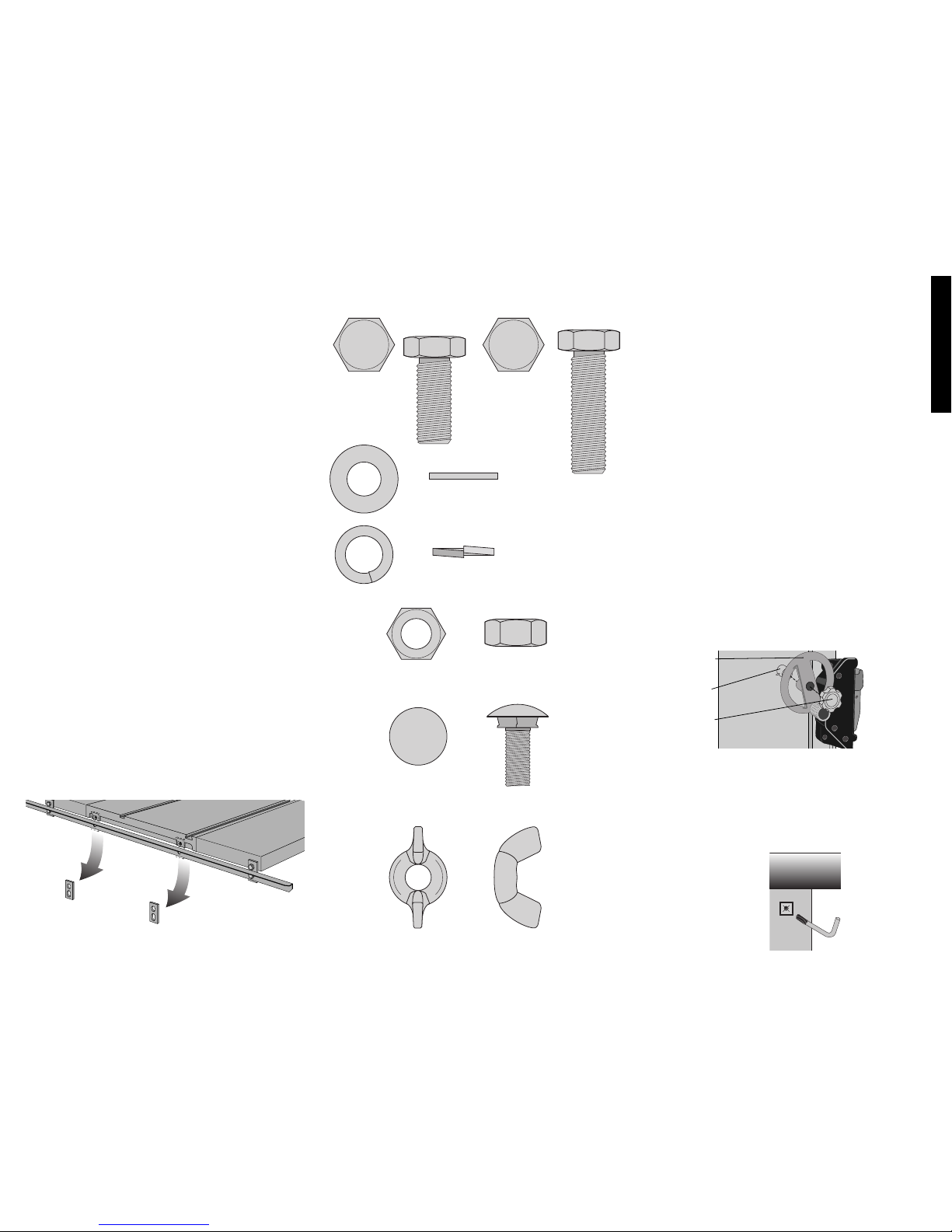

ÉTAPE 9. Monter le rail frontal et les fixations (Fig. 4).

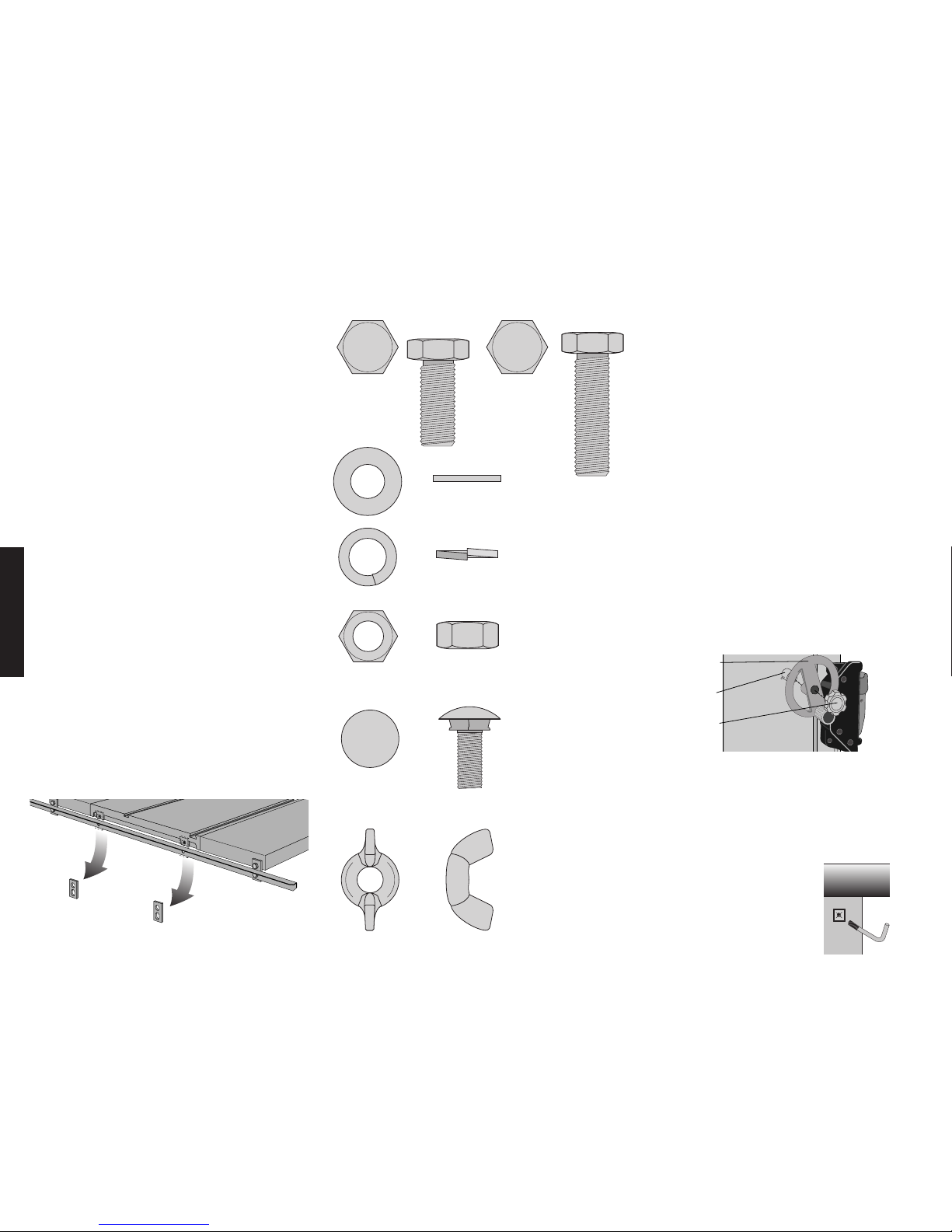

Vous aurez besoin de :

4 –boulons de carrosserie 8 mm (3 si vous

ajoutez une table coulissante)

4 –rondelles d’arrêt 8 mm

4 –écrous 8 mm

Montez les boulons de carrosserie, les rondelles et les écrous

sur les fixations du rail frontal (juste quelques pas de vis).

Mettez la tête des boulons de carrosserie dans les fentes

dans le rail frontal et faites glisser pour enclencher la partie

carrée du boulon . Vissez manuellement l’écrou pour le ser-

rer et répétez la procédure pour les trois autres fixations (si

vous ajoutez aussi une table coulissante, la fixation àl’ex-

trême gauche du rail frontal est inutile). Pendant la fixation

des fixations sur le rail, le rail doit être positionnéde manière

que l’échelle longitudinale ait le côtédroit vers le haut. Les 4

fixations doivent aussi toutes regarder dans la même direc-

tion.

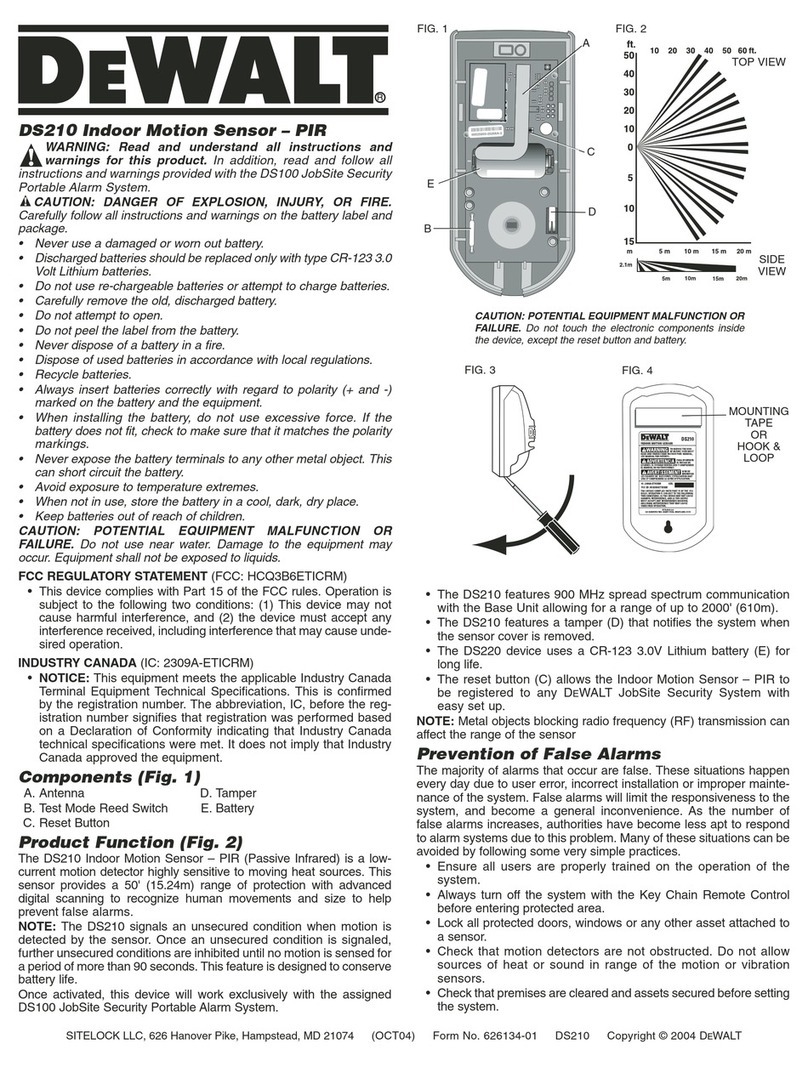

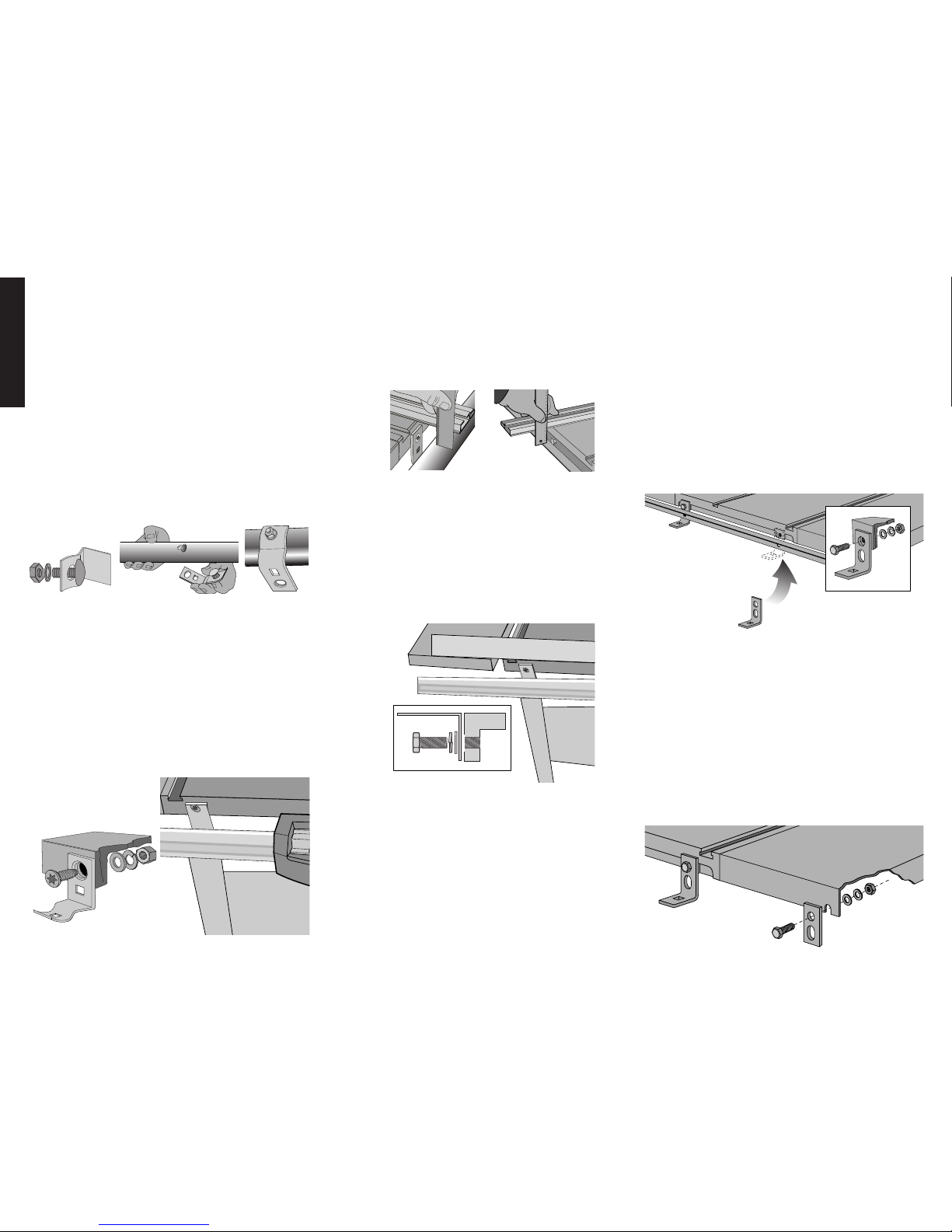

ÉTAPE 10. Attacher le rail frontal avec les fixations au

dessus de la table (Fig. 5).

Vous aurez besoin de :

2 –vis àtête plate 10 x 30 mm

2 –rondelles plates 10 mm

2 –rondelles d’arrêt 10 mm

2 –écrous 10 mm

Fixez chaque vis àtravers le trou supérieur dans les fixations

centrales en positionnant la rondelle plate, la rondelle d’arrêt

et l’écrou sur le côtéinterne de la table. Serrez pour ajuster

mais pas trop. Serrez les écrous de 8 mm des fixations cen-

trales du rail, en conservant le seul serrage manuel pour les

plus extérieures.

FIG. 4

FIG. 5

FIG. 6

FIG. 7

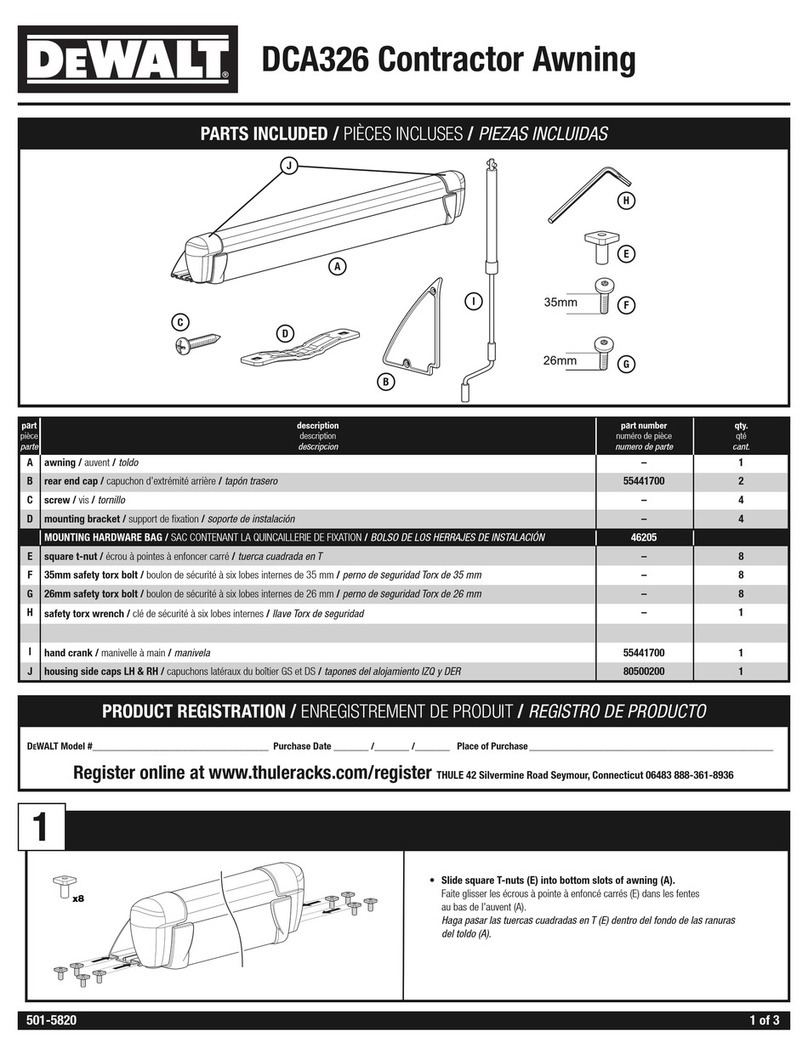

ÉTAPE 11 Placer le rail frontal parallèlement au dessus de la

table de la scie (Fig. 6). En utilisant le devant du guide ou

une règle de vérification pour prolonger la surface de la table

par dessus le rail, assurez-vous que la distance du haut de la

table de la scie au haut du rail est la même du côtédroit et du

côtégauche de la table. Si le rail n’est pas correctement

aligné, desserrez légèrement les vis de montage et tapotez

sur le rail avec un marteau mou ou un marteau régulier et un

bloc en bois jusqu’à ce que les distances soient identiques.

Serrez àfond les articles de quincaillerie.

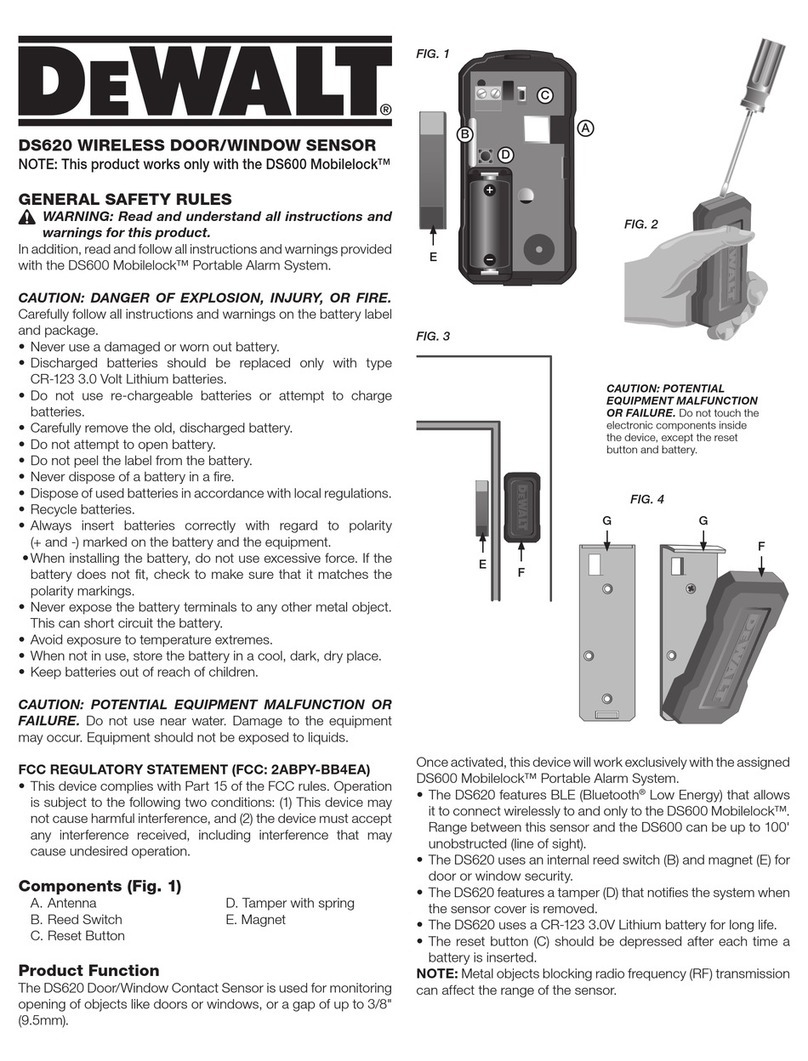

ÉTAPE 12. Attacher les tables de support droite et gauche (Fig.

7). Vous aurez besoin de :

6 –boulons àtête hexagonale 10 x 25 mm

6 –rondelles plates 10 mm

6 –rondelles d’arrêt 10 mm

La table de support n’étant pas en place, installez 3 écrous de

chaque côtéavec des rondelles comme montréen main-

tenant un espace de 1/4 po (6,36 mm). Faites reposer la table

de support sur les écrous, en l’encastrant dans les encoches.

En utilisant le guide comme une règle de vérification, faites

araser la table de support avec le bord de la table de la scie

et ajustez le boulon frontal. Répétez ce procédépour le

boulon dorsal et le boulon central. Serrez tous les articles de

quincaillerie. Répétez pour l’autre côté.

ÉTAPE 13. Attacher la fixation du rail frontal aux tables de

support (Fig. 4). Vous aurez besoin de :

2 –vis àtête plate 10 x 25 mm

2 –rondelles plates 10 mm

2 –rondelles d’arrêt 10 mm

2 –écrous 10 mm

Alignez la fixation frontale avec la table de support et serrez

l’écrou de la fixation au rail. Attachez les tables de support àla

fixation extérieure de support du rail frontal en positionnant les

rondelles et l’écrou sur le côtéinterne de la table. En utilisant

le devant du guide comme une règle de vérification, assurez-

vous que le coin extérieur frontal de la table de support est de

niveau avec le coin interne et la surface principale de la table.

Serrez tous les articles de quincaillerie, y compris l’écrou de

la fixation de support du rail 8 mm. Répétez cette procédure

pour l’autre table de support.

ÉTAPE 14. Attacher les fixations pour suspendre à la table de

la scie (Fig. 8). Vous aurez besoin de :

2 –boulons àtête hexagonale 10 x 35 mm

2 –rondelles plates 10 mm

2 –rondelles d’arrêt 10 mm

2 –écrous 10 mm

Fixez un boulon àtravers le trou carrédans chaque fixation

avec pour chacun une rondelle plate, une rondelle d’arrêt et

un écrou en positionnant les rondelles et l’écrou sur le côté

interne de la table. Pendant le serrage des écrous, maintenez

les fixations àl’équerre avec la table. (Si un autre accessoire

est en place, assurez-vous que les fixations pour suspendre

sont placées entre le rail dorsal et la table de la scie.)

ÉTAPE 15. Attacher les deux fixations de support dorsal (Fig.

9). (Si d’autres accessoires sont en place, les fixations de

support dorsal sont inutiles. Le rail dorsal s’attachera directe-

ment àl’accessoire).

Vous aurez besoin de :

2 –boulons àtête hexagonale 10 x 25 mm

2 –rondelles plates 10 mm

2 –rondelles d’arrêt 10 mm

2 –écrous 10 mm

Fixez un boulon àtravers le trou rond dans chaque fixation

avec pour chacun une rondelle plate, une rondelle d’arrêt et

un écrou en positionnant les rondelles et l’écrou àl’intérieur.

Assurez-vous que ces articles se trouvent en haut de chaque

fente au dos de la (les) table(s) de support et serrez. Alors que

vous serrez, maintenez les fixations àl’équerre avec la table.

FIG. 8

FIG. 9