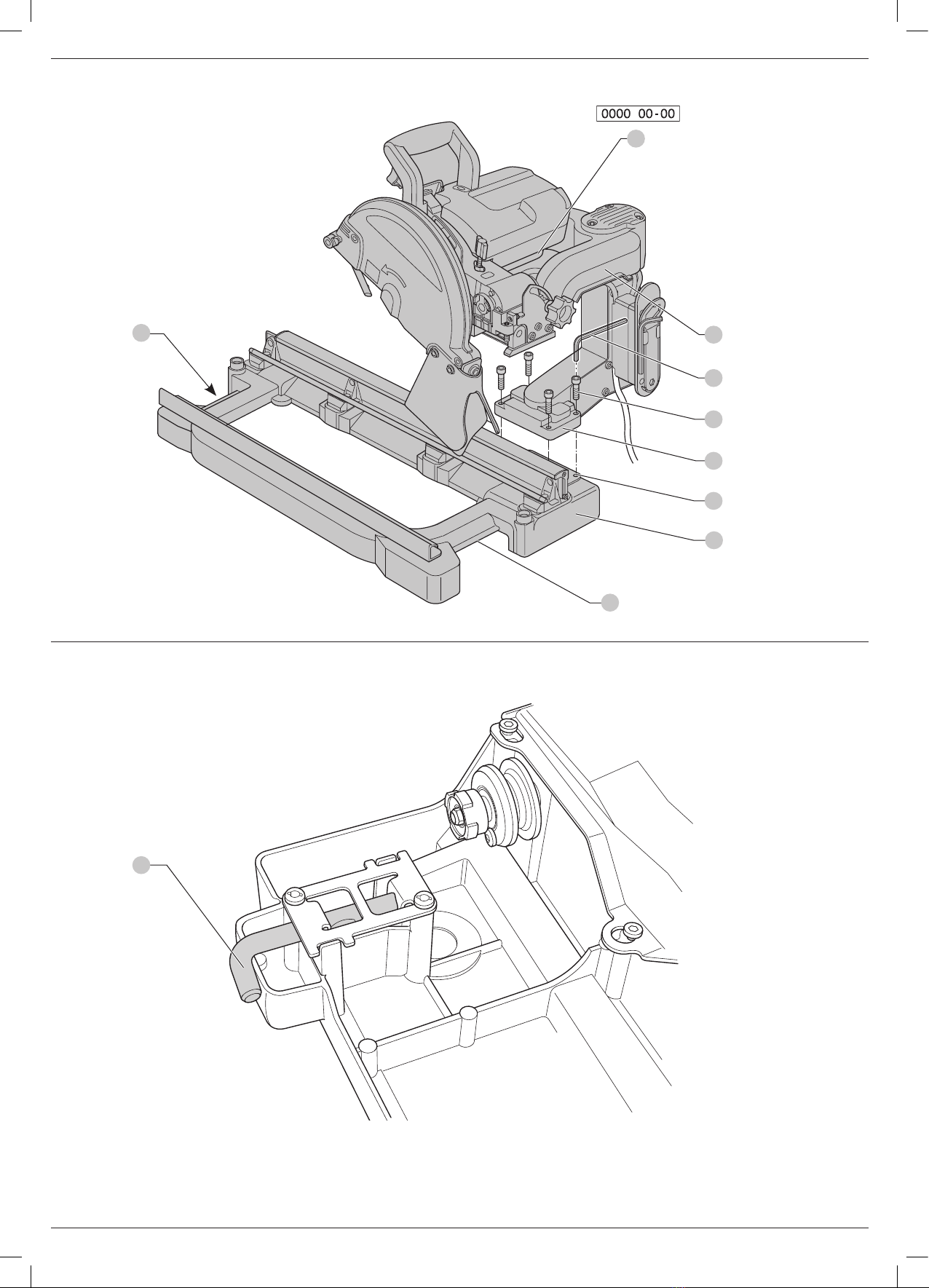

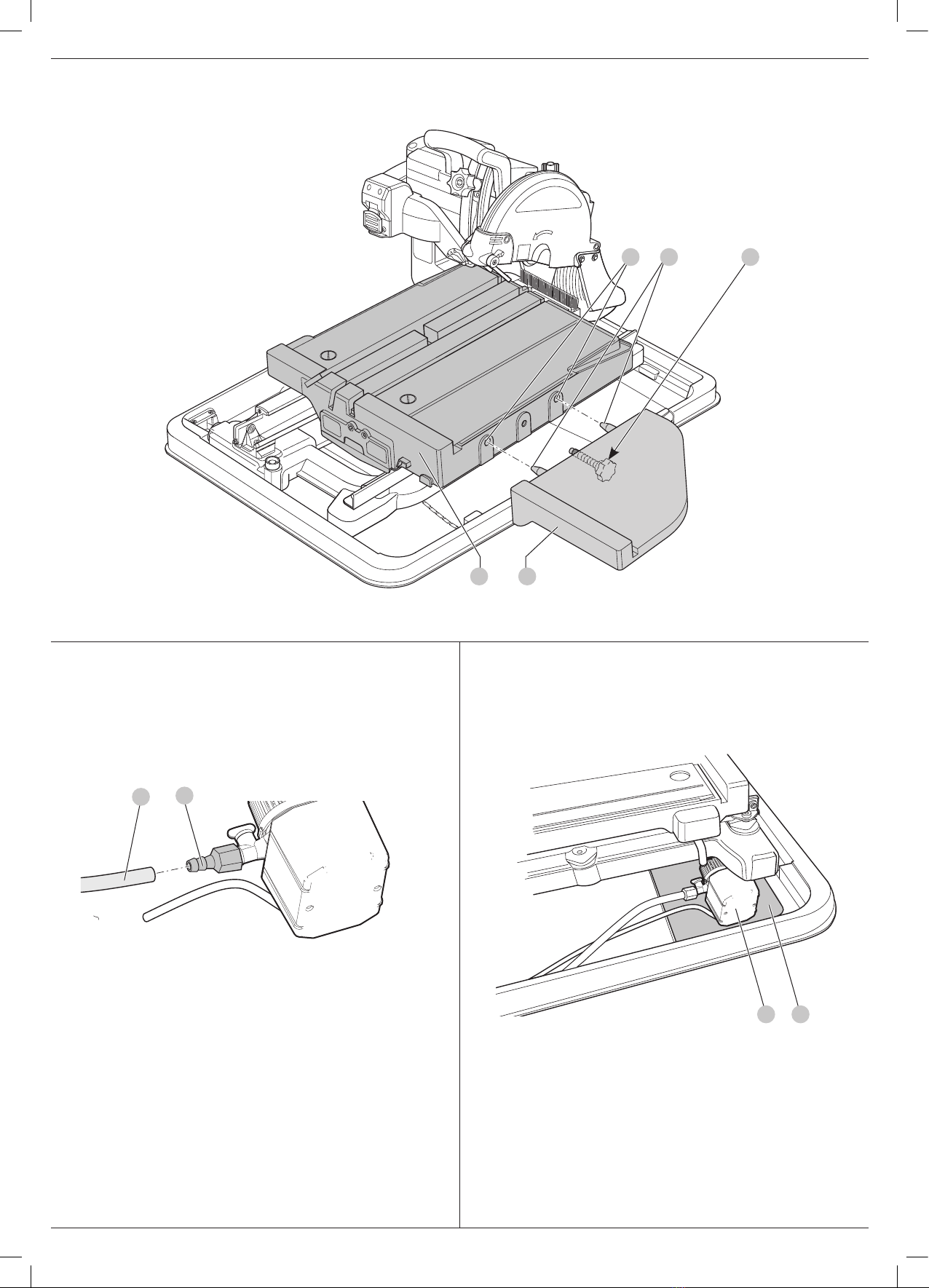

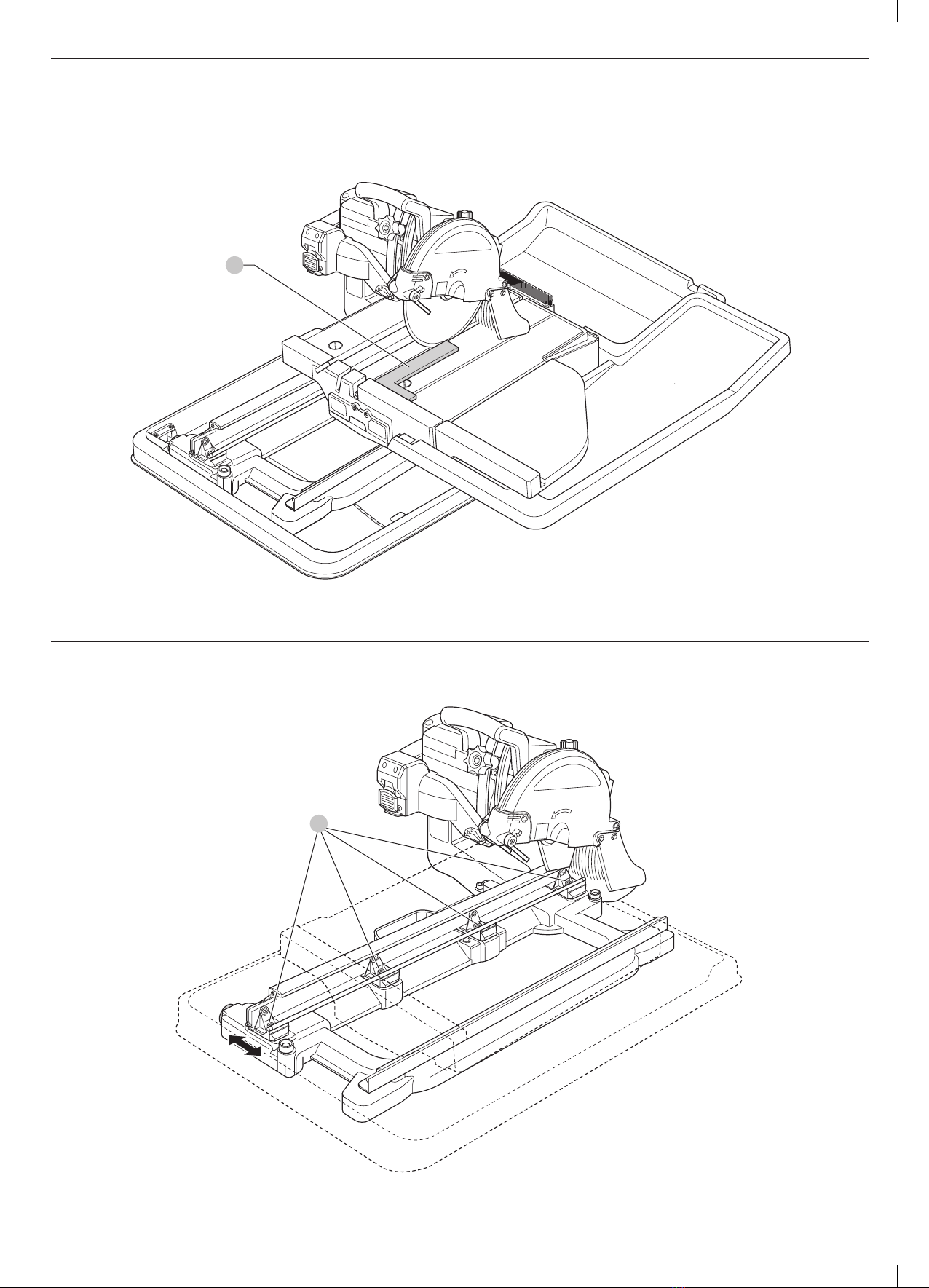

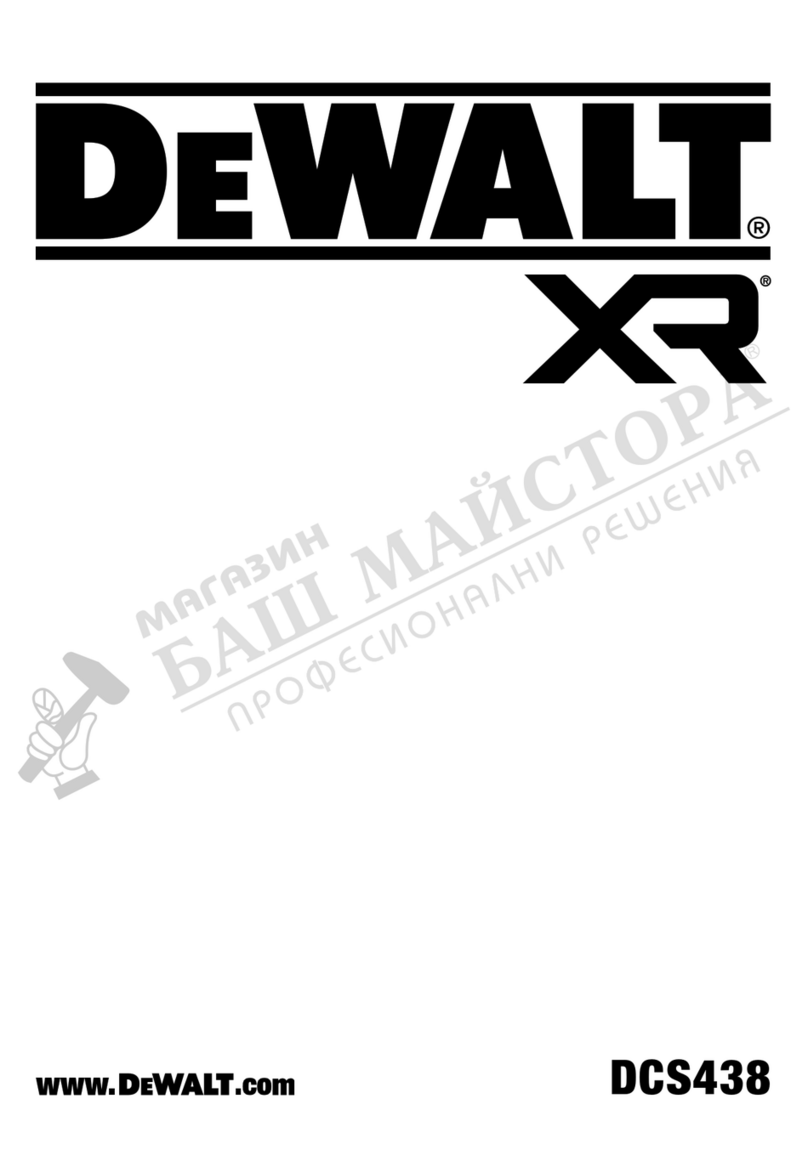

DeWalt D24000 User manual

Other DeWalt Cutter manuals

DeWalt

DeWalt DCS690N User manual

DeWalt

DeWalt Klein Tools BAT20-G Series User manual

DeWalt

DeWalt XR DCS438 User manual

DeWalt

DeWalt DCS350 User manual

DeWalt

DeWalt XR DCS551N-XJ User manual

DeWalt

DeWalt DCS551 User manual

DeWalt

DeWalt DCS438N User manual

DeWalt

DeWalt DCS438 User manual

DeWalt

DeWalt Impact Connect DWAPVCIR User manual

DeWalt

DeWalt DC550 User manual

DeWalt

DeWalt DCE555D2 User manual

DeWalt

DeWalt XR DCS438 User manual

DeWalt

DeWalt DCE555 User manual

DeWalt

DeWalt DCE155 User manual

DeWalt

DeWalt DW660 User manual

DeWalt

DeWalt DWE46144N User manual

DeWalt

DeWalt DW862 User manual

DeWalt

DeWalt DW660 User manual

DeWalt

DeWalt DWE46125 User manual

DeWalt

DeWalt DC550 User manual

Popular Cutter manuals by other brands

Milwaukee

Milwaukee HEAVY DUTY M12 FCOT Original instructions

SignWarehouse.com

SignWarehouse.com Bobcat BA-60 user manual

Makita

Makita 4112HS instruction manual

GEISMAR STUMEC

GEISMAR STUMEC MTZ 350S manual

Hitachi

Hitachi CM 4SB2 Safety instructions and instruction manual

Dexter Laundry

Dexter Laundry 800ETC1-20030.1 instruction manual