DEWALT 14000 Generator 7

Item Part No. Description Qty.

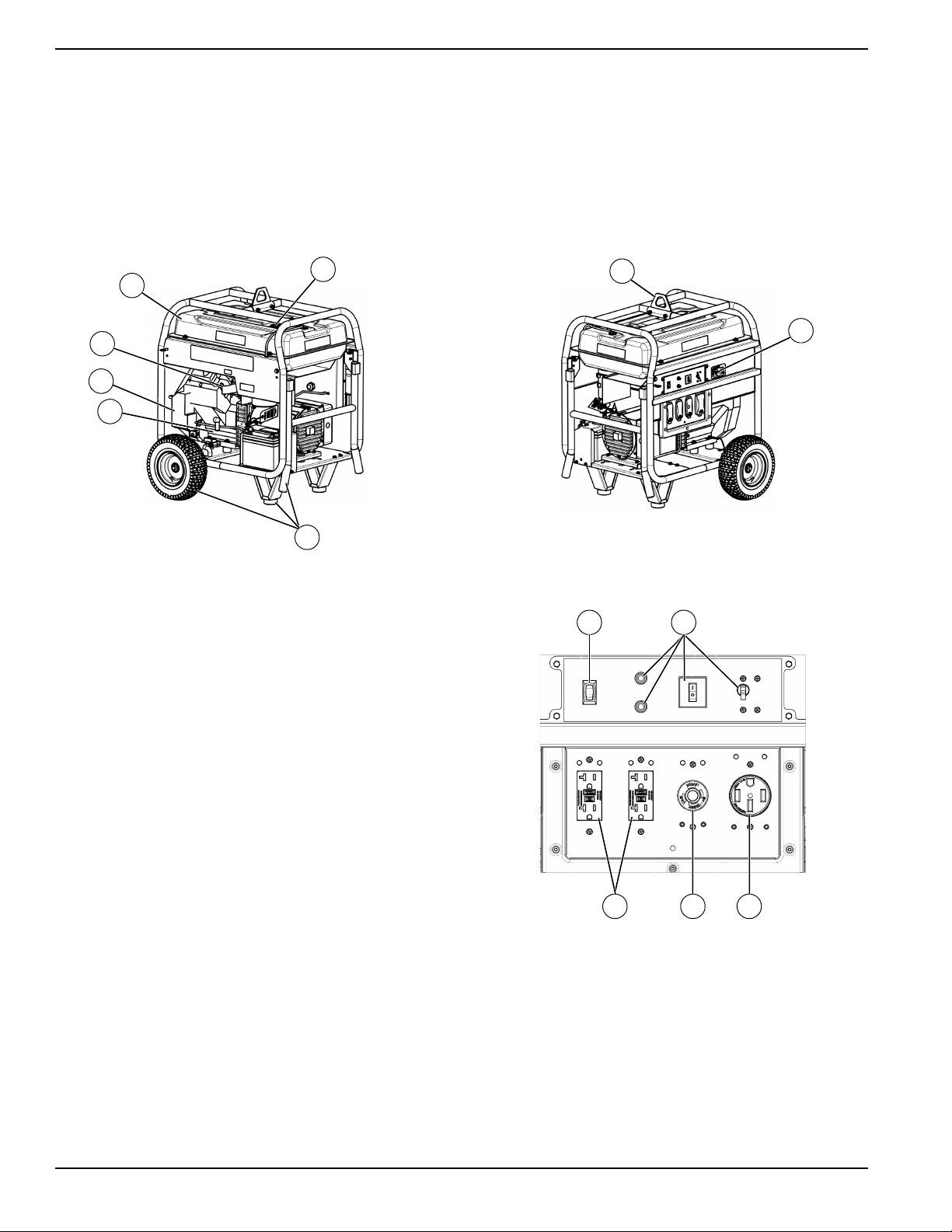

10L11140ST03 CARRIER DXGN14000

BLACK

1

20L0992 WIRED PANEL DXGN14000 1

310000023679 FUEL TANK ASSEMBLY,

DXGN14000

1

4EHB200CB03Y ENGINE G36 GX630R VXE2

AIR_3

1

50L0442 HEX FLANGED NUT (5/16-

18 SERR ZP)

8

60L0949 CAP FUEL 1

70L0878 BATTERY POST COVER

ELL-TRON 47

1

80L09950ST03 STATOR BRACKET

DXGN14000 BLK

1

90L0829 WASHER (42 X 1.5 X .25) 2

10 0L1014 HONDA MUFFLER X630

DXGN14000

1

11 0L0845 FILLER ON/OFF

FLOOTOOL #720104

1

12 0L0947 FLAT WASHER (5/16 1.13

OD ZP)

2

13 0L2472 CHAIN RING ATTACHMENT 1

14 0L1031 BOLT WHZ (3/8-16 X 1.00

GR5 ZP)

4

15 0L0767 BLK WIRE ASSEMBLY 8GA

19.25 RING/R

1

16 0L0715 RED WIRE 8GA 17.25

RING/R

1

17 0L2477 VINYL HOSE (1/2 ID X 6 LG) 1

18 0L0856 WORM HOSE CLAMP SAE6 1

19 0L0859 FITTING (3/8NPT X 1/2

BARB STR

1

20 0L0858 BALL VALVE 3/8 NPT M/F 1

21 0L0926 OIL DRAIN FITTING GX630 1

22 0L1032 HEX HEAD BOLT (M6-1.0 X

30MM BLK ZDC)

4

23 0L0366 WIRE GREEN/YELLOW

12GA 5.50 GR

1

24 0L2407B FUEL HOSE 8MM X 8 LG 1

25 0L0803 SCREW HSW #10-32 X .50

ZP (NAS

1

26 0L0446 HEX HEAD BOLT(5/16 - 18

X 1.5)

8

27 0L0805 NYLOC NUT (5/16 - 18) 4

28 0L0974 RELEASE PIN (5/16OD X

1.00LG BL)

2

29 0L0809 FLAT WASHER 5/16 W ZP 12

30 0L0711 HEX HEAD BOLT (5/16-18 X

1.00 GR5 ZP)

9

31 0L0440 LOCK WASHER (5/16 ZP

(NASP)

9

32 0L0437 ISOLATOR 7

33 0L0462 STAR WASHER (5/16 EXT

(NASP)

6

34 0L0403 FUEL FILTER 1

35 0L1104 FUEL TANK METAL MOUNT

INSERT

4

36 0L0405 BEZEL FUEL GAUGE W/

PRINTED LEV

1

37 0L0924 SPARK ARRESTOR KIT V-

TWIN

1

38 0L0937 GFCI RECEPTACLE

COVER

2

39 0L1071 RECEPTACLE COVER

TWISTLOCK

1

40 0L0948 COVER RECEP 50A 1

41 0L1102 RUBBER MOUNTING

GROMMET

4

42 0L1116 CARBON CANISTER

BRACKET 1200CC

1

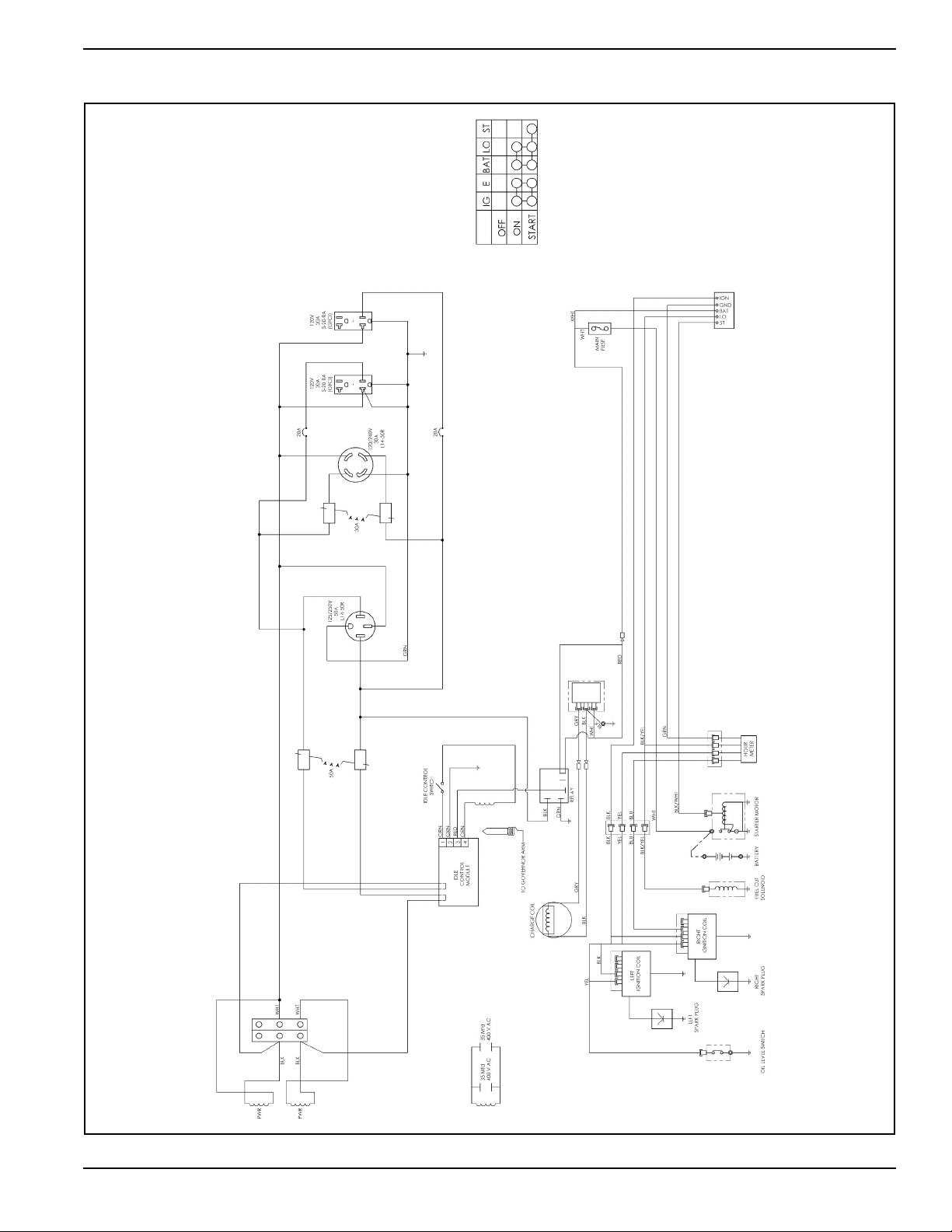

43 0L0396 CIRCUIT BREAKER 20A

125V

2

44 0L0625 CIRCUIT PROTECTOR 30A

DUAL

1

45 0L0846 CIRCUIT BREAKER 50A 1

46 0L1037 IC MODULE ASSEMBLY

DXGN 14000

1

47 0L0808 STRAIN RELIEF FASTENAL 1

48 0L0423 ROCKER SWITCH SPDT 1

49 0L0809 FLAT WASHER (5/16 W ZP) 7

50 0062552SRV MANIFOLD GASKET 2

51 0061393SRV NUT WHZ 8MM 4

52 0L0868 NYLON LANYARD 3/16 2

53 0L10000ST03 WELDED HANDLE ASSEM-

BLY DXGN140 BLK

1

54 0L0822 VINYL J CLAMP 1/2 1

55 0L0870 HANDLE GRIP 2

56 0L0973 HEX HEAD BOLT (3/8 - 16 X

1.75 GR5 BL)

2

57 0L10390ST03 HEAT SHIELD ASSY

DXGN14000 BLK

1

58 0L0854 GROMMET(.88 ID X 1.5OD) 1

59 0L1035 WIRE HARNESS ASSY

DXGN14000

1

60 0062554SRV RECTIFIER 1

61 0L1032 HEX HEAD BOLT (M6-1.0 X

30MM BLK ZDC

1

62 0L0444 HEX HEAD BOLT (5/16-18 X

1.25 GR5 ZP)

1

63 0L0807 BOLT WHZ 5/16-18 X .50 ZP

(NAS)

2

64 0L1111 WHEEL ASSEMBLY12 FLAT

FREE

2

65 0L10110ST03 WHEEL BRACKET ASSY

DXGN140 BLK

2

66 0L10100ST03 FOOT BRACKET

DXGN14000 BLK

2

67 0L0945 RUBBER FOOT 2

68 0L09960ST03 BATTERY HEAT SHIELD

DXGN14 BLACK

1

69 0L0976 COTTER PIN (1/8 X 1.25) 2

70 0L0871 WHEEL SPACER 2

71 0L0980 HEX HEAD BOLT (5/16 - 18

X 2.00 UNC B)

4

72 0L1086 CONNECTOR HOSE 1

73 0L1063 FUEL VALVE HOLDER

INSERT V2

1

74 0L0813 FUEL VALVE 1

75 GU0151 SCREW (M6 X 20 TF) 4

Item Part No. Description Qty.