8

English

OPERATING PROCEDURES

WARNING:

Donotattempttounclog(backflush)thespraygun

bysqueezingthetriggerwhileholdingyourfingerinfrontof

the fluid nozzle.

CAUTION:

Pressure may vary according to viscosity of material

used.Maximumworkingpressureofthegunis60PSI.Donot

exceedpressurelimitofgunoranyothercomponentinsystem!

CAUTION:

Prior to daily operation, make certain that all

connections and fittings are secure. Check hose and all

connections for a weak or worn condition that could render system

unsafe.Allreplacementcomponentssuchashoseorfittingsmust

haveaworkingpressureequaltoorgreaterthansystempressure.

Prior to shipment, this spray gun was treated with an anticorrosive

agent. Before use, make sure that it is carefully flushed with thinner.

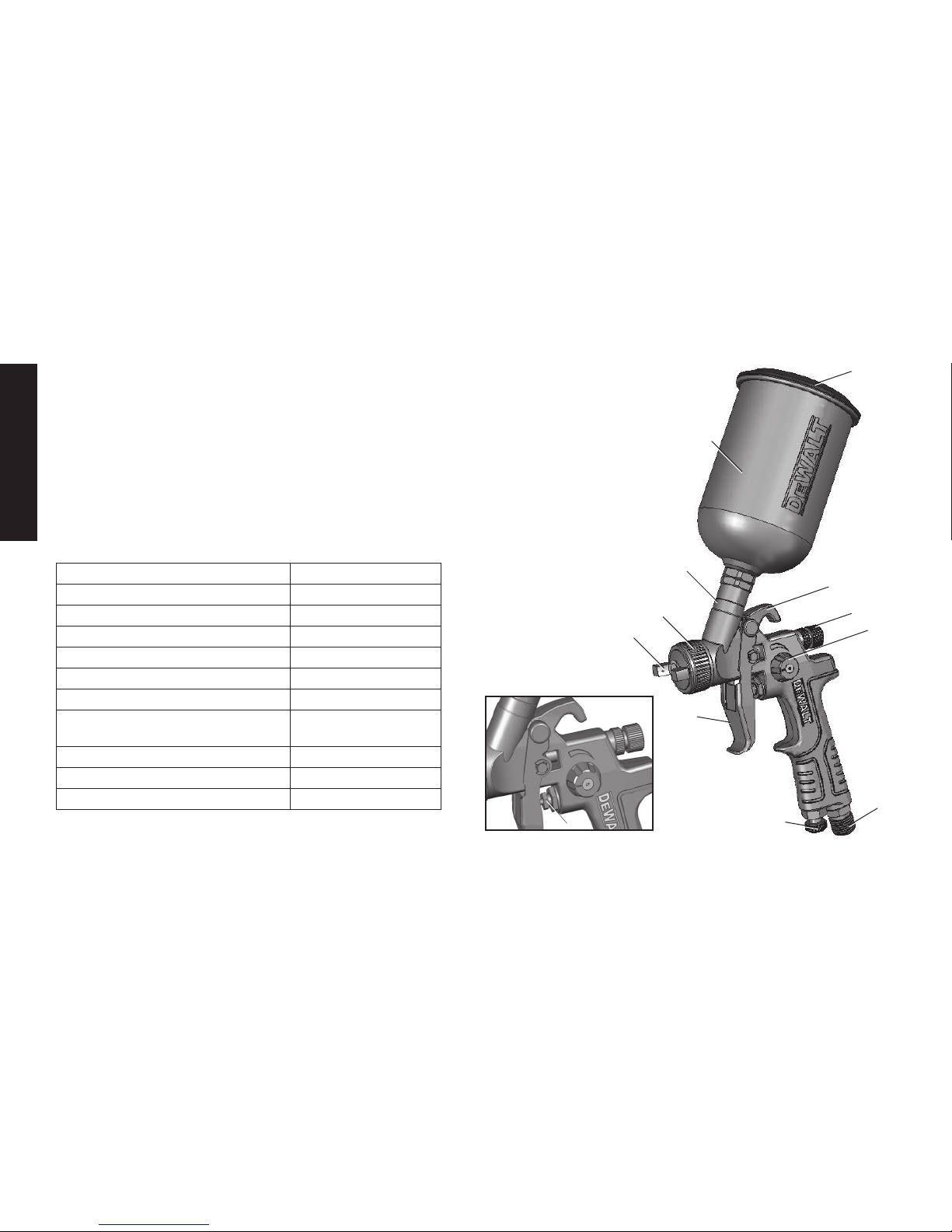

1. Loosen the air cap (C) and rotate the horns (D) to achieve

the desired spray pattern. Tighten the air cap.

2. Attach spray gun cup (A) to the gun handle.

NOTE: The (B) filter supplied is optional to protect against

contaminants and small particles. See parts list for

filter orientation.

CAUTION:

donotuselatexorotherheavypaints

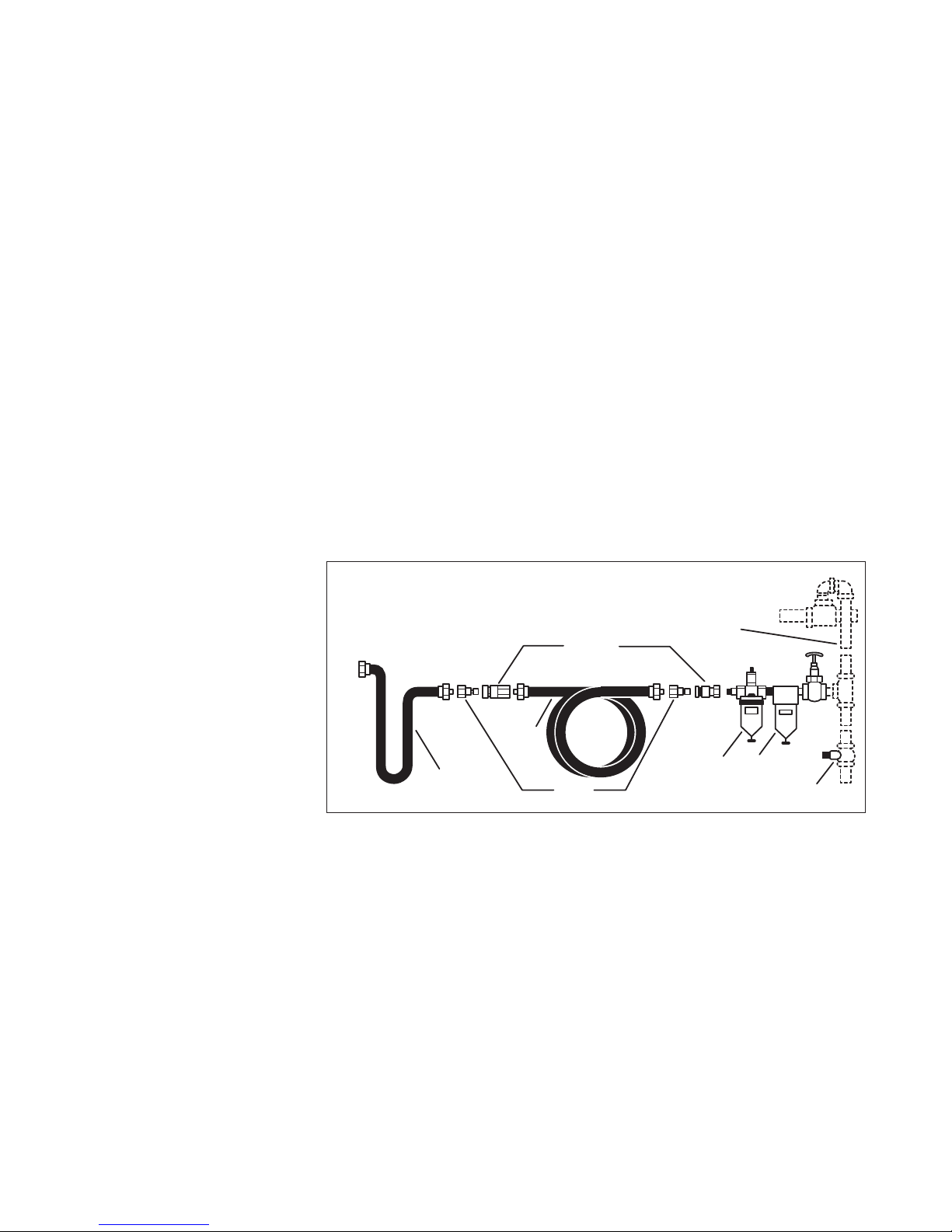

3. Attach air supply line to 1/4" NPS air inlet.

CAUTION:

NEVER point spray gun at self or any other person.

Accidentaldischargeofmaterialmayresultinseriousinjury.

4. Adjust air pressure on the air compressor.

CAUTION:

DONOTexceed60PSI.

5. Depress the spray gun trigger (E) fully to spray material.

NOTE: Depressing the trigger partially will cause only air

to be released.

ADJUST SPRAY GUN:

1. Turn the fluid control knob (I) counterclockwise to increase

the amount of material released, or clockwise to decrease.

2. Turn the pattern control knob (H) counterclockwise to

increase the width of the “fan spray”, or clockwise to decrease

the width of the spray.

3. Turn the air volume control knob (F) counterclockwise

to increase the air quantity, or clockwise to decrease

the air flow.

CAUTION: Care should be exercised when handling spray gun

to avoid damage to the orifice of the air cap and tip of fluid nozzle.

Damagetothesepartsresultsinirregularspraypatterns.

MAINTENANCE

WARNING: Shut off air compressor, release all pressure

by depressing trigger, and disconnect power source before

disassembly or removal of any part of the gun or attached

components.

CAUTION: Alwaysexerciseextremecarewhenusinganysolvent

orthinner.Nevercleanthegunnearfire,flame,oranysourceofheat

or sparks. Properly dispose of used cleaning materials.

CAUTION: DONOTsoaktheentiresprayguninsolventor

thinner for a long period of time as this will destroy lubricants

and possibly impair operation. NEVERuselyeorcausticalkaline

solution for cleaning. Such solutions will attack aluminum alloy

parts of the gun.