DGC DHT-100Plus User manual

INSTRUCTION MANUAL

HARDNESS TESTER DHT- 100Plus

V1.0.0

CONTENTS

1.Summary ...............................................................................1

2. Principle of Leeb hardness testing method ............................1

2.1 History of Leeb hardness testing method.................................. 1

2.2 Definition of Leeb hardness...................................................... 1

2.3 Available Functions .................................................................. 2

2.4 Symbol of Leeb’s hardness values............................................. 2

3. Pre-treatment of work piece .................................................3

3.1 Work piece surface .................................................................. 3

3.2 Weight of work piece ............................................................... 3

3.3 Work piece surface hardened layer .......................................... 3

3.4 No strong magnetism on the work piece surface....................... 4

4. Selection and performance of impact device .........................4

4.1 Selection of impact device........................................................ 4

4.2 performance of impact devices................................................. 4

5. Functions of DHT-100Plus......................................................5

5.1 Technical specifications............................................................ 5

5.2 Nomenclature of DHT-100Plus.................................................. 5

5.2.1 Main unit............................................................................................. 5

5.2.2 Display area......................................................................................... 6

5.2.3 Keypad ................................................................................................7

6. Operation instruction............................................................8

6.1 Power on ................................................................................. 8

6.2 Parameters setting................................................................... 8

6.3 Measure .................................................................................. 8

6.3.1 Impact direction settings .................................................................... 8

6.3.2 Material and hardness scales settings ................................................9

6.3.3 Average times settings......................................................................10

6.3.4 Tolerance ..........................................................................................10

6.3.5 Calibration......................................................................................... 10

6.3.6 Standards .......................................................................................... 10

6.4 Files management.................................................................. 12

6.4.1 New file settings................................................................................12

6.4.2 Storage settings................................................................................. 12

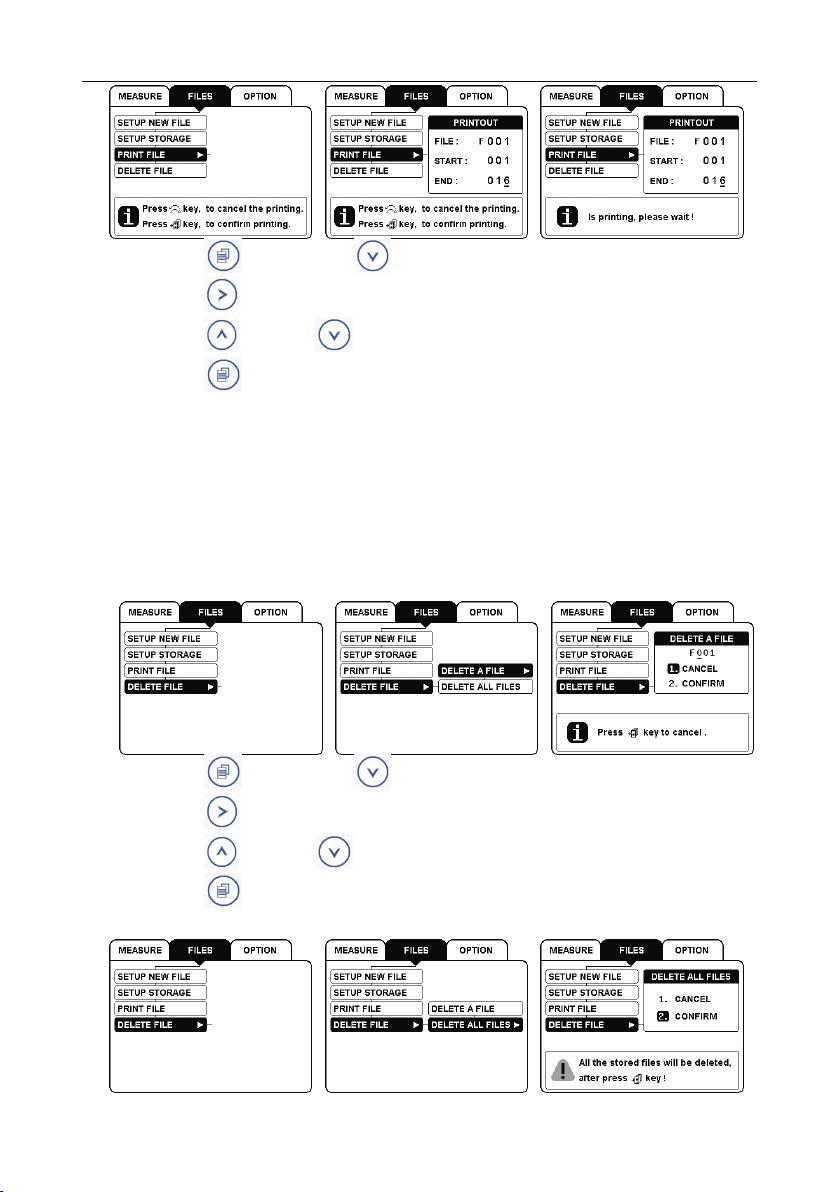

6.4.3 Print file settings ............................................................................... 13

6.4.4 Delete file settings ............................................................................14

6.5 Other settings ........................................................................ 15

6.5.1 Date and Time settings ..................................................................... 15

6.5.2 Auto shutdown settings .................................................................... 15

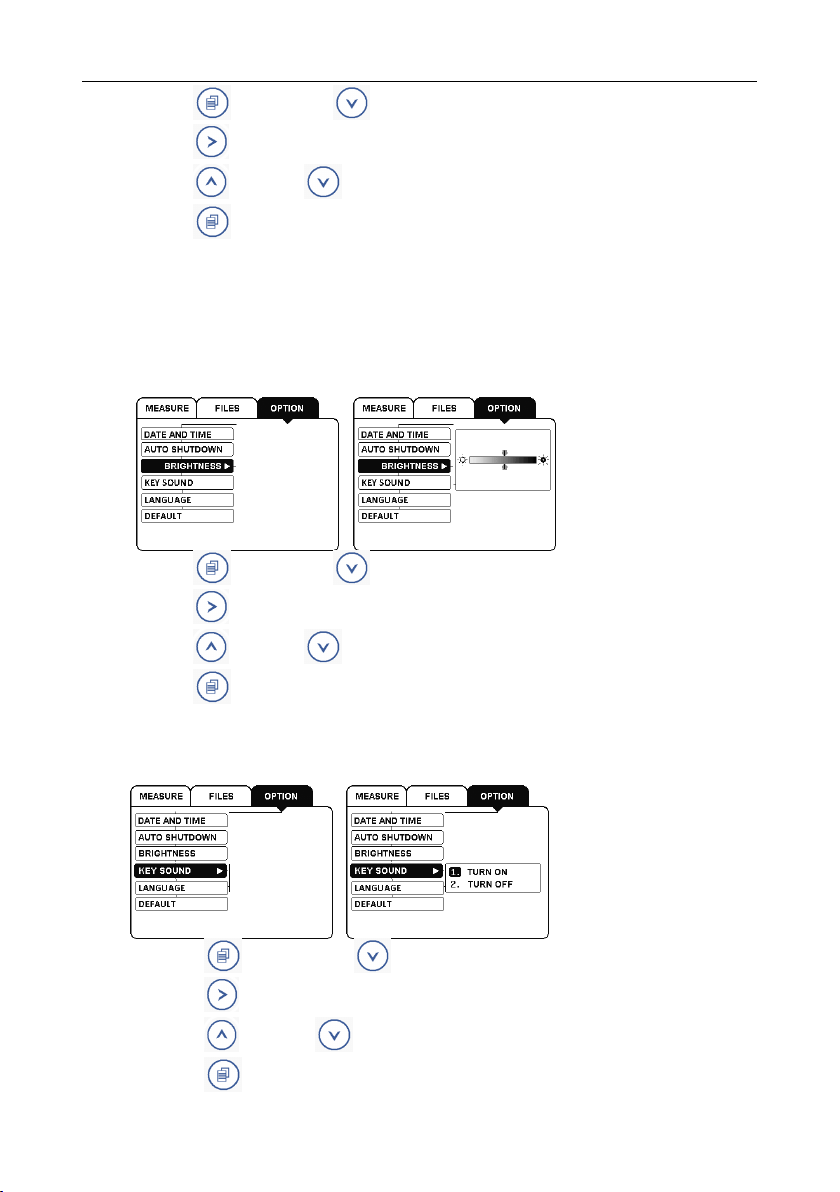

6.5.3 Brightness settings ............................................................................16

6.5.4 Key sound settings ............................................................................ 16

6.5.5 Language settings.............................................................................. 17

6.5.6 Default...............................................................................................17

6.6 Data output through USB to PC .............................................. 17

6.7Deleting of wrong measuring data.......................................... 18

7. Repairing and Maintenance................................................. 18

7.1 Maintenance of battery ......................................................... 18

7.2 Maintenance of impact body tip............................................. 18

7.3 Maintenance of impact device cable....................................... 18

7.4 Maintenance of printer .......................................................... 18

7.5 Maintenance of instrument.................................................... 19

8. Packing list.......................................................................... 19

9. Appendix ............................................................................ 20

Appendix 1:Measuring range: ...................................................... 20

Appendix 2: Features of impact devices ....................................... 21

Appendix 3:Material Applicable table .......................................... 21

Appendix 4: Supporting rings ....................................................... 22

Hardness Tester DHT-100 PLUS

1

1. Summary

DHT-100Plus Leeb hardness tester, based on the principle of Leeb theory, can

be used for hardness testing of various metals. With the feature of compact

size, it is suitable for working on various circumstances. The Leeb hardness

values can be easily converted to HRC, HRB, HV, HS and so on. In order to

operate the instrument correctly and properly, users are required to read this

instruction manual completely before using it.

2. Principle of Leeb hardness testing method

2.1 History of Leeb hardness testing method

The Leeb hardness testing method was first introduced by Dr. Leeb in 1978.

It is defined as the quotient of an impact body’s rebound velocity over its

impact velocity, multiplied by 1000. Hard materials produce a higher rebound

velocity than that of softer materials. For a specific group of material (e.g.

steel, aluminum. etc.), Leeb hardness value represents a direct relationship to

its hardness properties. For ordinary metal, conversion curves of hardness HL

versus other standard static hardness (HB, HV, HRC, etc.) are available,

enabling you to convert HL into other hardness values.

2.2 Definition of Leeb hardness

An impact body with a spherical test tip made of tungsten carbide is propelled

against the sample surface by a spring force and then rebounds back. At a

distance of 1mm from the sample surface, the impact and rebound velocity of

the impact body are measured by the following method: A permanent magnet

embedded in the impact body, when passing through the coil in its coil holder,

induces in the coil an electric voltage proportional to the velocities of the

magnet. The Leeb hardness values are expressed by the following formula:

HL=1000×( Vb / Va )

Where:HL is Leeb hardness values

Vbis the rebound velocity of the impact body

Vais the impact velocity of the impact body

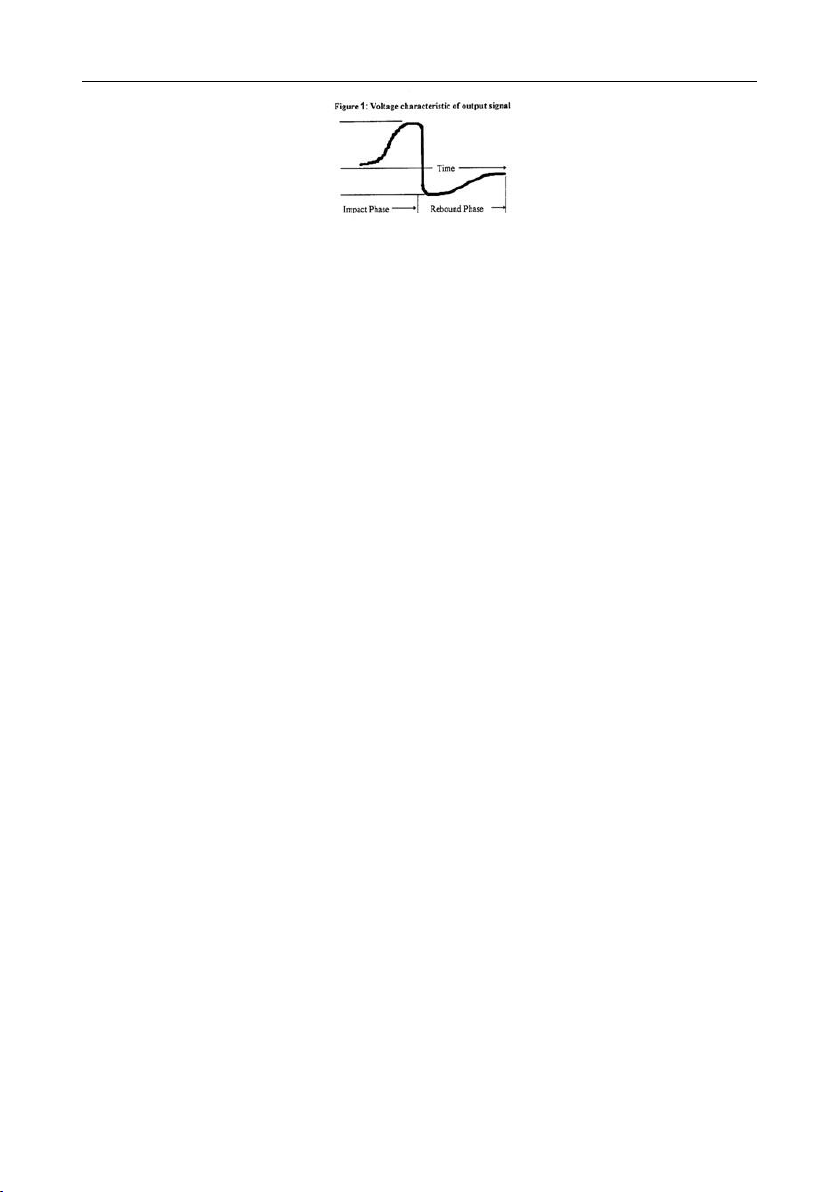

Figure 1 show the voltage produced during the impact and rebound of

impact body.

Hardness Tester DHT-100 PLUS

2

Figure 1 Voltage features of output signal

The Leeb hardness values can be converted to other hardness scales

directly, such as HV, HRC, HRB, HB and HS.

2.3 Available Functions

●320×240 matrix TFT Color LCD

●Auto connects to 32 bits / 64 bits computer system.

●100 files x 100 data can be stored.

●Auto identification of impact device D, DC, DL, D+15, C, G

●Quick entry of test numbers, test data, sample material type and impact

direction via the keypad.

●Multi-languages and Multi-hardness standards.

●Quick print out of all test results via optional Bluetooth printer or data

transfer without software.

●Auto converse to hardness value (HL, HRC, HRB,HB, HV, HSD)

●Low Battery Indicator

2.4 Symbol of Leeb’s hardness values

Just like the other hardness scales, users will get different hardness values

with different impact devices, for example:

720HLD≠720HLC.

Owing to different converting curves obtained from different hardness scale,

when converting from hardness scale L to another hardness scale, the

notation for the converted hardness value should include the impact device

used. For example: the Leeb hardness value 510HLD should be expressed as

below when it is converted to Rockwell hardness scales HRC: 510, 20 HRCLD in

which:510 Leeb hardness values

20 converted hardness values

HRC means the converted object

L means the measuring method

D means D impact device

Hardness Tester DHT-100 PLUS

3

3. Pre-treatment of work piece

To get the accurate measuring results, pre-treatment of work piece is

required.

3.1 Work piece surface

Temperature of work piece should be less than 80℃;

The surface roughness requirements are listed in table 3.1.1

Table: 3.1.1

Impact Device

Work piece of surface roughness

D, DC, D+15, DL

2um

G

7um

C

0.4um

The small support ring or non-conventional support rings are required for

work piece with curved surface radius less than 30mm, for details please refer

to appendix 4.

3.2 Weight of work piece

No support is required for work piece weight more than 5kg.

Work piece with weight of 2-5kg and also heavier work piece with

protruding parts or thin walls should be placed on a solid support. In such a

manner, they do not move or flex during testing.

Work piece less than 2 kg should be rigidly coupled with a non-yielding

support such as a heavy base plate.

Table 3.2.1 Work piece weight and thickness

Impact Device

Weight (KG)

Minimum thickness

of work piece (mm)

Need

coupled

Need

support

No

need

D\DC\DL\D+15

0.1-2

2-5

> 5

3

G

0.5-5

5-15

>15

10

C

0.2-0. 5

0.5-1.5

>1.5

1

3.3 Work piece surface hardened layer

If the work piece surface hardened layer is too thin, the impact force of

short duration will go through the layer and make the L-value incorrect. The

proper depth surface hardened layer is listed below:

Hardness Tester DHT-100 PLUS

4

Tale: 3.3.1

Impact device

Minimum depth of surface hardened layer

D, DC, D+15

0.8mm

C

0.2mm

3.4 No strong magnetism on the work piece surface

Strong magnetism will affect the circuit winding greatly, and affect the

accuracy of testing results, so it is required to avoid strong magnetism during

testing.

4. Selection and performance of impact device

4.1 Selection of impact device

Before testing, users should correctly select the proper impact devices

according to testing requirement, work piece size and shape. For details

please refer to appendix 1.

4.2 performance of impact devices

a) Loading

Press down the loading tube to lock the impact body.

b) Placement

Place the support ring on surface to be measured and make sure the

distance between two test points should be no less than 3mm.

c) Testing

Trigger the release button while the work piece and the impact body

are all stable, and the starting force coincides with the axis of the

impact body.

Hardness Tester DHT-100 PLUS

5

5. Functions of DHT-100Plus

5.1 Technical specifications

Display:

320×240 matrix TFT Color LCD display

Meas. Range:

HL 174-900 HRC 19.6-68.0

HRB 13.5-101.7 HS 32.5-99.5

HB 20-655 HV 80-940

Display accuracy:

Error 0.5%(HL=800), Repeatability 0.5%

Memory:

100 customized files X 100 data/each file

Power:

2 AA rechargeable batteries,

continuous work 8 hours

Auto turn off:

1Min./ 2Min./ 5Min. and off shutdown

Working Temp.:

-20℃—+40℃

Storing Temp.:

-30℃—+60℃

Dimension:

133×75×29mm

Weight:

260g (with battery)

5.2 Nomenclature of DHT-100Plus

5.2.1 Main unit

1

1

4

8

4. USB port/charging port

5. Impact device port

1. Shell

2. LCD display

3. Keypad

3

5

2

Hardness Tester DHT-100 PLUS

6

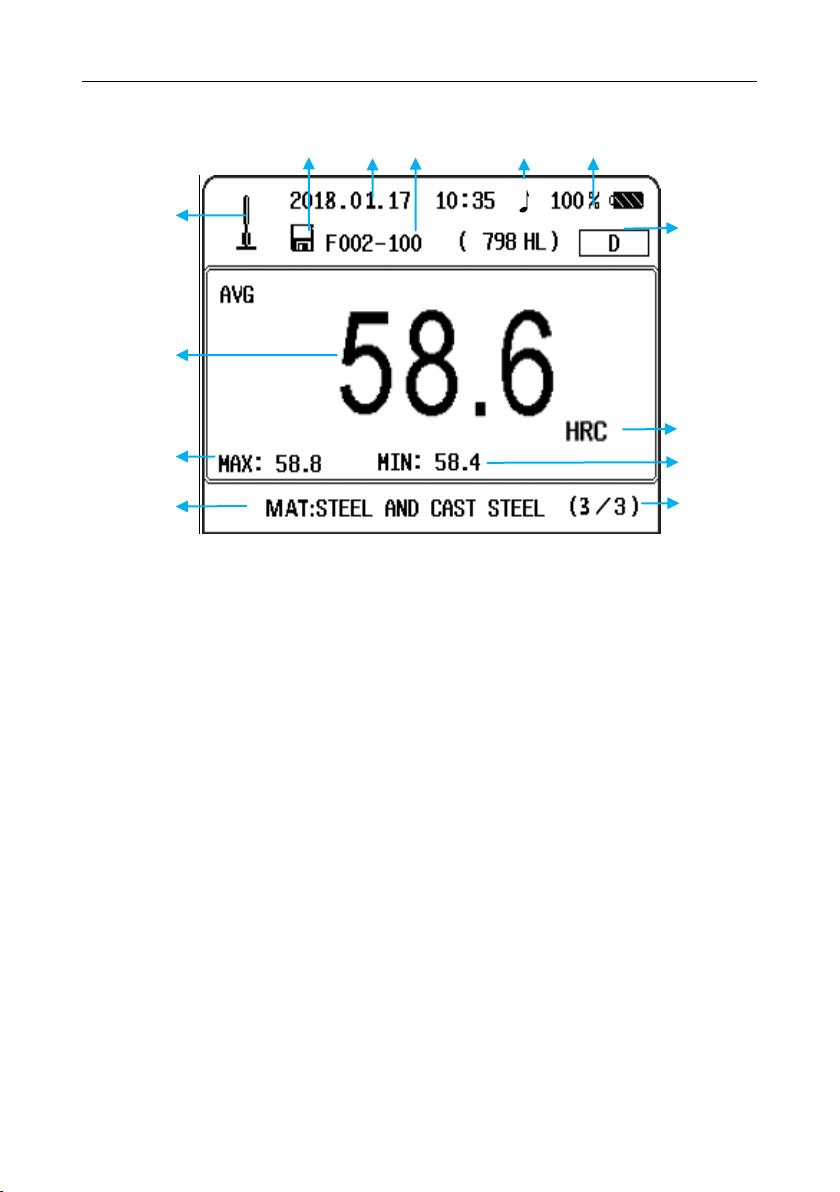

5.2.2 Display area

1

12

10

8

7

6

9

11

13

1Impact direction

2Auto save

3Date and time

4Current file

5Sound indication

6Power indication

7Impact device type

8Avg. value of testing result

9 Hardness scale

10 Max value of testing result

11 Min. value of testing result

12 Tested material

13 Test times

5

3

4

2

Hardness Tester DHT-100 PLUS

7

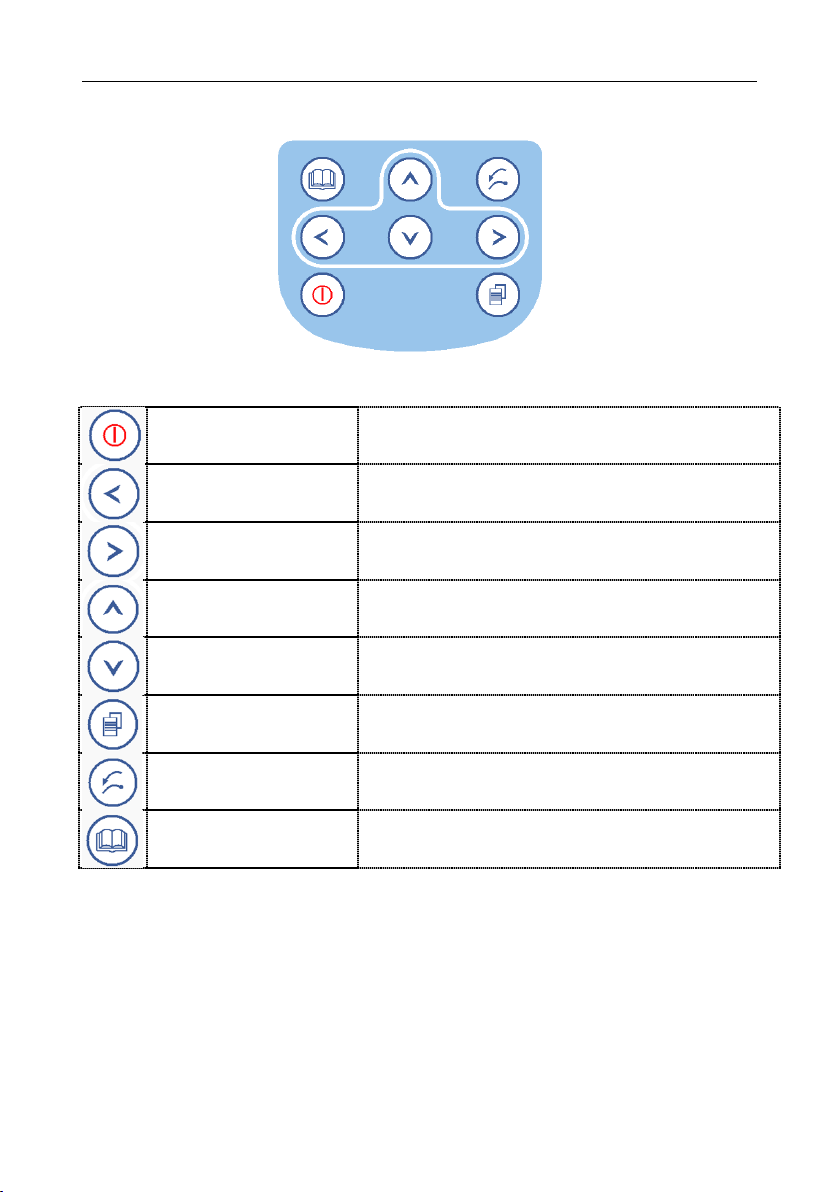

5.2.3 Keypad

1.Power key

1.Power on or off the instrument

1.Left Key

1.Adjust the menu items

1.Right key

1.Adjust the menu items

1.Up Key

1.Adjust the menu items

1.Down Key

1.Adjust the menu items;

1.Menu & confirm key

1.Enter into the menu and confirm the settings

1.Menu Esc.

2.Delete key

1.Exit menu

2. In measuring status, delete error values.

1.Preview key

1.Preview the saved files

Hardness Tester DHT-100 PLUS

8

6. Operation instruction

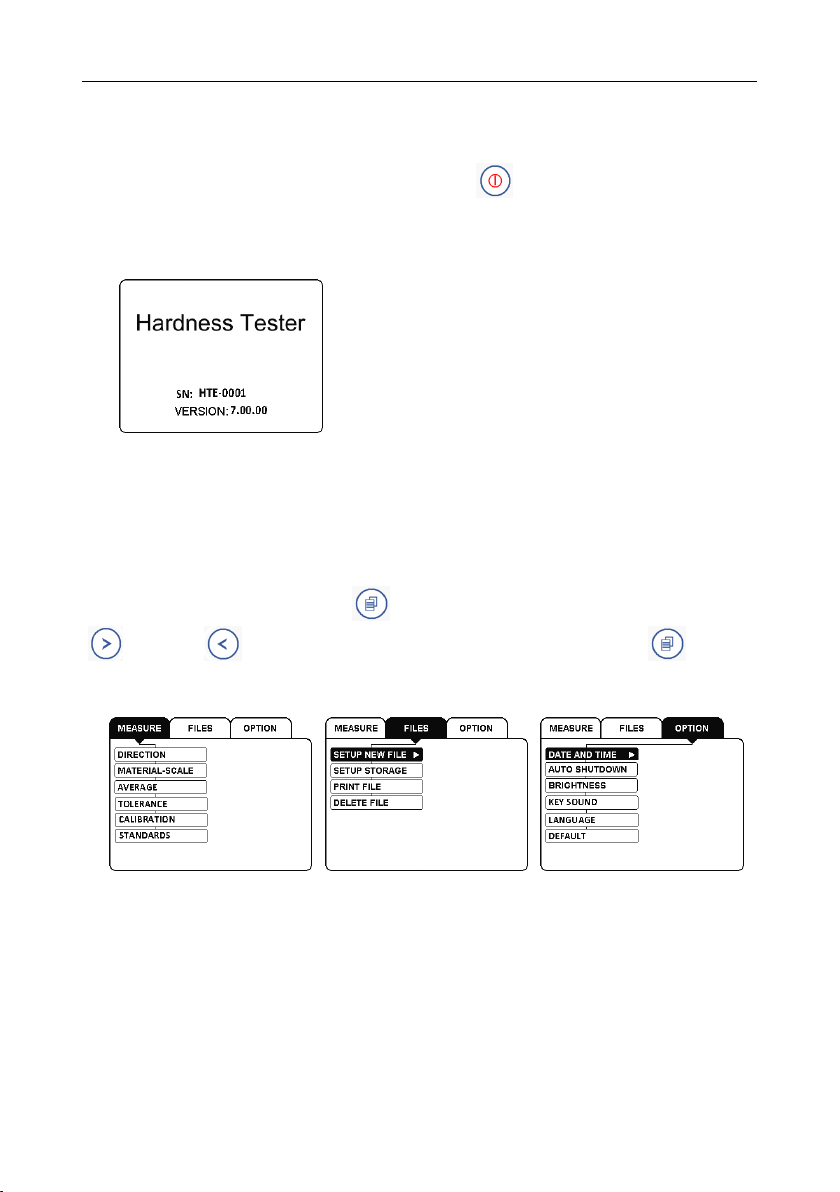

6.1 Power on

Fit on the impact device firstly, press key to power on. The following

information is displayed.

1. Series No., Software version

2. Parameters of last setting

Notice

:

If the impact device is not fitted properly, the instrument will not

be able to complete self-checking and will give out the Notice “Plug in the

impact device please”.

6.2 Parameters setting

Various parameter settings and management can be accomplished via the

instrument menu. Press the key to Enter the menu, and press the

key or key to select the setting items. Press the key to

confirm setting.

6.3 Measure

“Measure" is available for users to set basic parameters needed in

measurement. It can also be changed during the measurement operation.

6.3.1 Impact direction settings

DHT-100Plus can be used for hardness measuring in different directions,

but different direction meets different requirements, so it is very important to

select the proper impacting direction. Normally the direction is DOWN.

Hardness Tester DHT-100 PLUS

9

-Press the key and the key to enter MEASURE- DIRECTION.

-Press the key to enter this item,

-Press the key or key for setting,

-Press the key to confirm.

Notice: During measurements, the actual impacting direction must

conform to the one selected.

6.3.2 Material and hardness scales settings

During measurement performance, the material set must conform to the

actual measured material. DHT-100Plus hardness tester supplies 9 kinds of

materials for actual measurement. For each material, there is accordingly

different hardness scales. For details, please refer to appendix 2 and 3.

Before measurement, users should firstly confirm the measured materials

and the corresponding hardness scales. Set the proper materials and hardness

scales as following:

- Press the key and the key to enter MEASURE- MATERIAL-SCALE

- Press the key to enter this item,

- Press the key or key for setting,

- Press the key to confirm.

Keys and

for setting,key for

confirmation

Hardness Tester DHT-100 PLUS

10

6.3.3 Average times settings

It is extremely necessary to work out the average measuring values in leeb's

hardness testing. Different measuring times between 2~8 are selected

according to users’ different requirements.

- Press the key and the key to enter MEASURE—AVERAGE,

- Press the key to enter this item, use the key or key

to set the desired average times.

- Press the key to confirm.

Notice: 3~5 times are usually recommended in normal measurement.

6.3.4 Tolerance

During measurements, this function will be very useful for identifying

“checked out”. It is automatically turned on. The instrument will give alarming

sound and display the limits mark or on the left down corner

when some measuring values have got over the limits.

-Press the key and the key to enter MEASURE—TOLERANCE,

-Press the key to enter this item,

-Press the key or key for setting, press the or to

move the cursor,

-Press the key to confirm.

Keys and

for setting,key for

confirmation

Keys and

for setting,key for

confirmation

Hardness Tester DHT-100 PLUS

11

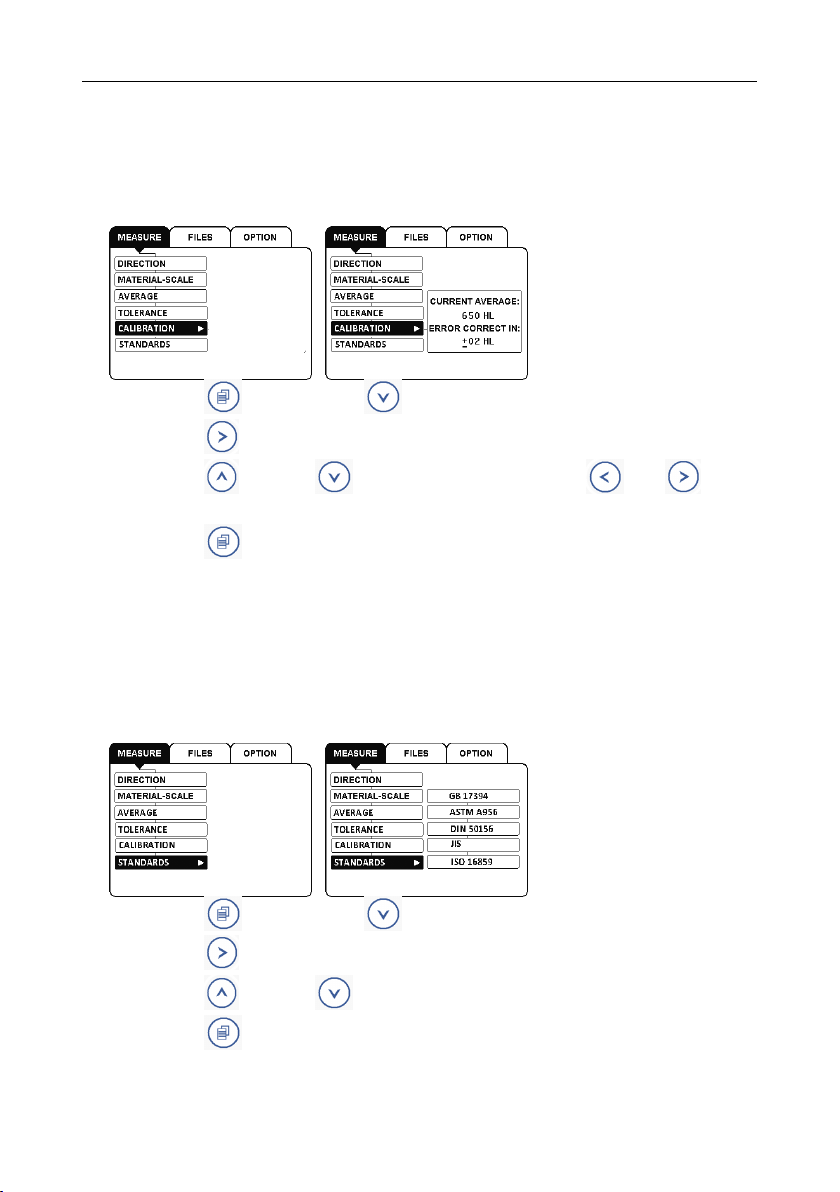

6.3.5 Calibration

Measuring error can be usually caused by impact device abrasion or

changing another impact device. So it is necessary to correct the error and get

more accurate value close to work piece. Hardness tester DHT-100Plus

supplies users with this function to correct the error mentioned above.

-Press the key and the key to enter MEASURE—CALIBRATION,

-Press the key to enter this item,

-Press the key or key for setting, press the or to

move the cursor,

-Press the key to confirm.

Notice: In actual measurement, adjust the range of within ±30HLD is

recommended. If the error is more than that, it is suggested to change the

impact body or repair the impact device.

6.3.6 Standards

There are 5 kinds of National Hardness Standards inside this main unit.

According to different requirements, users could set by themselves.

-Press the key and the key to enter MEASURE—STANDARDS,

-Press the key to enter this item,

-Press the key or key for setting,

-Press the key to confirm.

Keys and

for setting,key for

confirmation

Keys and

for setting,key for

confirmation

Hardness Tester DHT-100 PLUS

12

6.4 Files management

Via “file management”, users are allowed to set the file management ways.

For example, users can set the saved file codes according to their own

requirements.

6.4.1 New files settings

Via this sub-menu, users are allowed to set the number of files freely.

DHT-100Plus hardness tester supplies users 100 files, which are coded from

F001 to F100. Per each file, there is also 100 data storage, which is coded

from 001 to 100. For example it shows F001-099 on LCD display, it means the

99th test data in File No. 001.

Users are also allowed to build only one file. When the auto-save is turned

on, the indication mark appears on the screen, and the measured values

will be saved in the file in a series of codes. When the memory is full, it will

give a Notice and said that “please build another file” or “the memory is full”,

“please delete the data unused”. When a new file is built, the former one will

be closed automatically, and at the same time it is featured “read only”, which

means that users can only read or print out the former file but not write in.

-Press the key and the key to enter FILES--SETUP NEW FILE,

-Press the key to enter this item,

-Press the key or key for setting,

-Press the key to confirm.

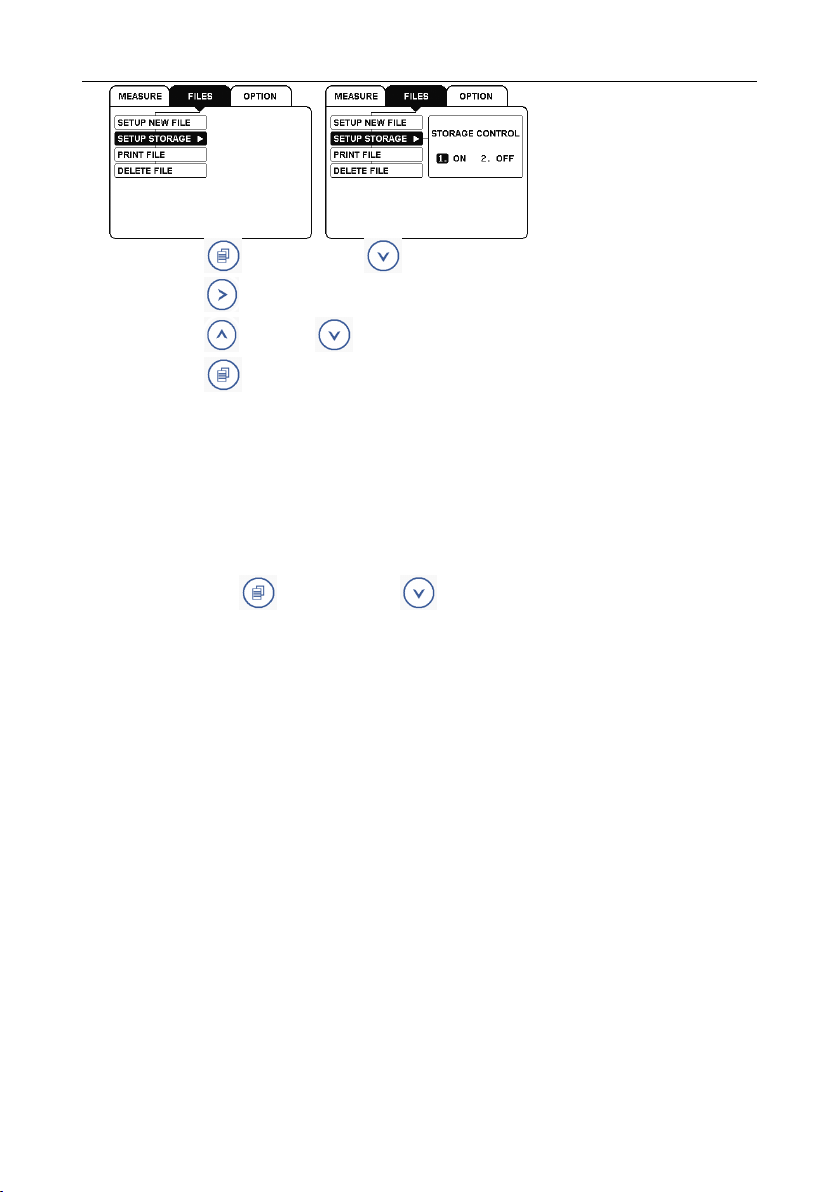

6.4.2 Storage settings

Set the data auto-saving state during measurement by turning on or off.

When data saving is set on “auto saving”, there will be a corresponding

indication mark on the screen, and the measuring values will be stored in

the file automatically, vice versa.

Keys and

for setting, key for

confirmation

Keys and

for setting,key for

confirmation

Hardness Tester DHT-100 PLUS

13

-Press the key and the key to enter FILES--SETUP STORAGE,

-Press the key to enter this item,

-Press the key or key for setting,

-Press the key to confirm.

6.4.3 Print file settings

Via this function, the saved data in instrument can be printed out through

optional Bluetooth printer. With this function, users are allowed to print out

data in a single file.

Before printing, users shall make pair between main unit and Bluetooth

printer. Procedure is like this:

1. Press the key and the key to enter PRINT—PRINTER PAIR,

choose “CONFIRM”. Meanwhile the main unit is searching for

Bluetooth printer automatically. At this time, please keep them as

close as possible,

2. When LCD shows “Please switch on printer”, please do accordingly,

3. If LCD shows “Pairing printer success”, it means users could printer out

data after setting at “Print out”,

4. If LCD shows “Pairing printer fails”, please repeat from step 1 again

until pairing printer success.

Notice: For successful connect between main unit and Bluetooth printer, it

is suggested that any Bluetooth function from any instruments is turned

off.

Then, users need to set the file code, start and end address of data

stored.

Keys and

for setting,key for

confirmation

Hardness Tester DHT-100 PLUS

14

-Press the key and the key to enter FILES--PRINT OUT,

-Press the key to enter this item,

-Press the key or key for setting,

-Press the key to confirm.

Notice: For safety of data stored in the main unit, it is suggested that

users should transfer all the saved data to PC or print them out after the

measurement.

6.4.4 Delete file settings

Via this function, the saved files and data can be deleted.

Both single file delete and all files delete are available.

Delete one file:This will delete all the information saved in one file.

-Press the key and the key to enter FILES—DELETE A FILE,

-Press the key to enter this item,

-Press the key or key for setting,

-Press the key to confirm.

Delete all files: It is used to delete all files saved in the instrument.

Keys and

for setting,key for

confirmation

Keys and

for setting,key for

confirmation

Hardness Tester DHT-100 PLUS

15

-Press the key and the key to enter FILES—DELET EALL FILES,

-Press the key to enter this item,

-Press the key or key for setting,

-Press the key to confirm.

Notice: The deleted files will never be able to come back, so please be

careful about your operation.

6.5 Other settings

Various optional settings are available for users in the “option” function.

6.5.1 Date and Time settings

Via this setting, users are allowed to set date and time, which will be saved

together with other data when transfer to PC or printed out.

-Press the key and the key to enter OPTION-DATE AND TIME,

-Press the key to enter this item,

-Press the key or key for setting,

- Press the key to confirm.

6.5.2 Auto shutdown settings

To avoid wasting of battery power, the instrument is equipped with various

kind of turning off functions.

Keys and

for setting,key for

confirmation

Keys and

for setting,key for

confirmation

Hardness Tester DHT-100 PLUS

16

-Press the key and the key to enter OPTION--AUTOSHUTDOWN,

-Press the key to enter this item,

-Press the key or key for setting,

-Press the key to confirm.

Notice: It is not suggested to use the function of “DISABLE”, which

consumes more power of batteries, even out of usage.

6.5.3 LCD brightness settings

DHT-100Plus supplies the function of brightness settings of LCD. Users can

adjust the brightness freely according to the operation circumstance.

-Press the key and the key to enter OPTION--BRIGHTNESS,

-Press the key to enter this item,

-Press the key or key for setting,

-Press the key to confirm.

6.5.4 Key sound settings

The key sound can be turned on or off by users.

-Press the key and the key to enter OPTION--SET KEY SOUND,

-Press the key to enter this item,

-Press the key or key for setting,

-Press the key to confirm.

Keys and

for setting,key for

confirmation

Keys and

for setting,key for

confirmation

Keys and

for setting,key for

confirmation

Hardness Tester DHT-100 PLUS

17

6.5.5 Language settings

Multi-languages are offered to clients for convenience in usage.

-Press the key and the key to enter OPTION--LANGUAGE,

-Press the key to enter this item,

-Press the key or key for setting,

-Press the key to confirm.

6.5.6 Default

It is used to renew the factory settings when some terrible parameter

settings error appears.

-Press the key and the key to enter OPTION--DEFAULT,

-Press the key to enter this item,

-Press the key or key for setting,

-Press the key to confirm.

6.6 Data output through USB to PC

DHT-100Plus Leeb hardness tester supplies users very powerful USB data

port for transferring saved data to PC.

1. Connect DHT-100Plus to PC with USB cable, in several seconds you will

find a new Disk is displayed.

Keys and

for setting,key for

confirmation

Keys and

for setting,key for

confirmation

Table of contents

Other DGC Test Equipment manuals