PG7307™ OPERATION AND MAINTENANCE MANUAL

© 2002 - 2007 DH Instruments, a Fluke Company Page 14

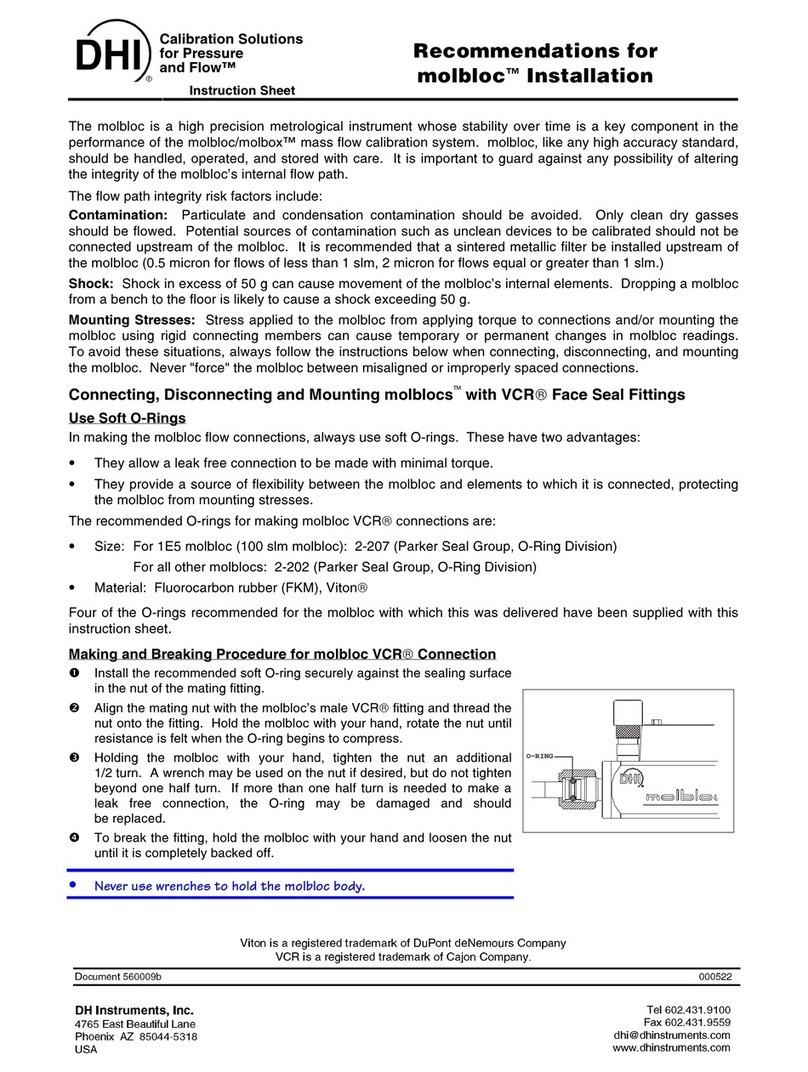

To assemble and disassemble a PG7307 piston cylinder module, proceed as follows:

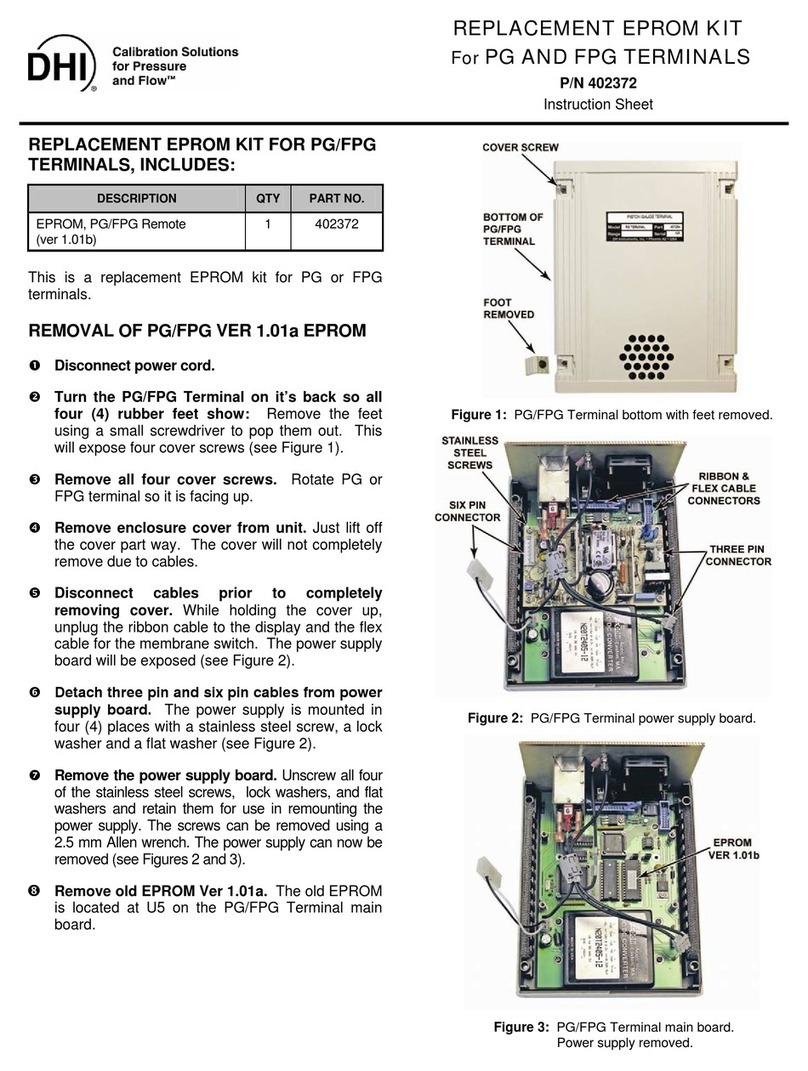

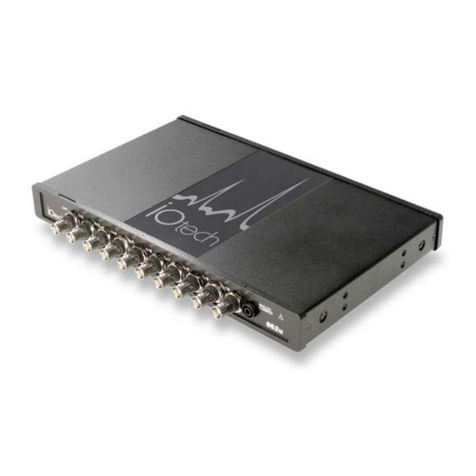

Figure 3. Oil Piston-Cylinder Module (Exploded View)

nScrew the piston-cylinder module into the base of its

bullet case (PVC shipping and storage case) and

place the base and module on a clean stable

surface with the piston cap (2) up.

oUsing a 3 mm Allen tool, loosen the two socket

head sleeve retaining screws (5) from the opposing

sides of the main module housing (4).

In reassembly, after the two sleeve retaining

screws (5) are installed, sleeve assembly

(9+13+18) must still have a small amount of

freedom to move and rotate within the main

module housing (4).

pWhile firmly holding down the cap (2), use a 5 mm Allen

tool, to loosen the socket head cap retaining screw

(1). Turning the screw pushes the piston head (6)

straight out of the piston cap (2) ensuring that no

sideways torque is applied to the piston (7). The

cap retaining screw will not fully disengage from the

piston cap due to the adjustment mass (3). Gently

remove the cap and screw from the assembly. Use

caution to be sure the piston head is out of the cap

so as NOT to apply torque to the piston (7) when

removing the cap.

When installing the piston cap during

reassembly, remember to reinstall the

adjustment mass (3). Take great care to

slip the piston cap (2) straight onto the

piston head (6) and not to apply torque to

the piston (7).

qUnscrew the main module housing (4) from the

bullet case leaving the piston-cylinder and sleeve

assembly (9+13+18) behind in the bullet case base.

Carefully reinstall the piston cap (2) onto the piston

head (6) taking care not to apply sideways torque

on the piston (7). Using the cap as a handle, slide

the piston straight out of the cylinder.

Remove the cylinder and sleeve assembly (8 + 9 +

13) from the bullet case base. Turn over the

assembly and place it on the sturdy surface with the

O-ring assembly (18) up.

Stop here if you are doing a simple cleaning of

the piston-cylinder. The cylinder (11) can be

cleaned within the sleeve assembly (9+13+18)

by flushing with clean oil. The O-ring assembly

(18) is NOT intended to be regularly

disassembled. Do not proceed with the next

step of disassembly unless it is suspected

that a repair is required. Do not proceed with

the next step of disassembly if you do NOT

have a new set of O-rings (10, 12, 14, 15, 17) and

anti-extrusion ring (16) to use in reassembly.

It is imperative that new parts be used in

reassembly (not all modules have an anti-

extrusion and all the O-rings (see Table 2)).

sUsing a 2 mm Allen tool, loosen the two O-ring

assembly retaining screws (21). Lift off the O-ring

assembly (18) and the retaining screws. Remove

O-rings (14, 17) and the anti-extrusion ring (16)

(PC-7307-200 and -100 do NOT have an

anti-extrusion ring).

In reassembly use new O-rings and

anti-extrusion ring only and take special care

to center the anti-extrusion ring on the

shoulder of part (18).

tHolding the cylinder (11) in the open end of the

cylinder sleeve (13), turn the cylinder sleeve over

and allow the cylinder to gently slide out. Remove

O-ring (10). Using a 3 mm Allen tool, loosen the

cover retaining screws (8). Remove the cover (9)

and remove the O-ring (12).

In reassembly use new O-rings. The end of

the cylinder marked with the serial number

must be upwards (towards the cover (9)).

The orientation of the piston on the cylinder is important. The end of the cylinder that is marked with

the serial number should be upwards (against the sleeve cover (9)). Installing the cylinder with the

wrong orientation may lead to out of tolerance measurements.