33/124

33 /60

EN

This manual is the property of PIUSI S.p.A. Any reproduction, even partial, is forbidden.

Translated from Italian

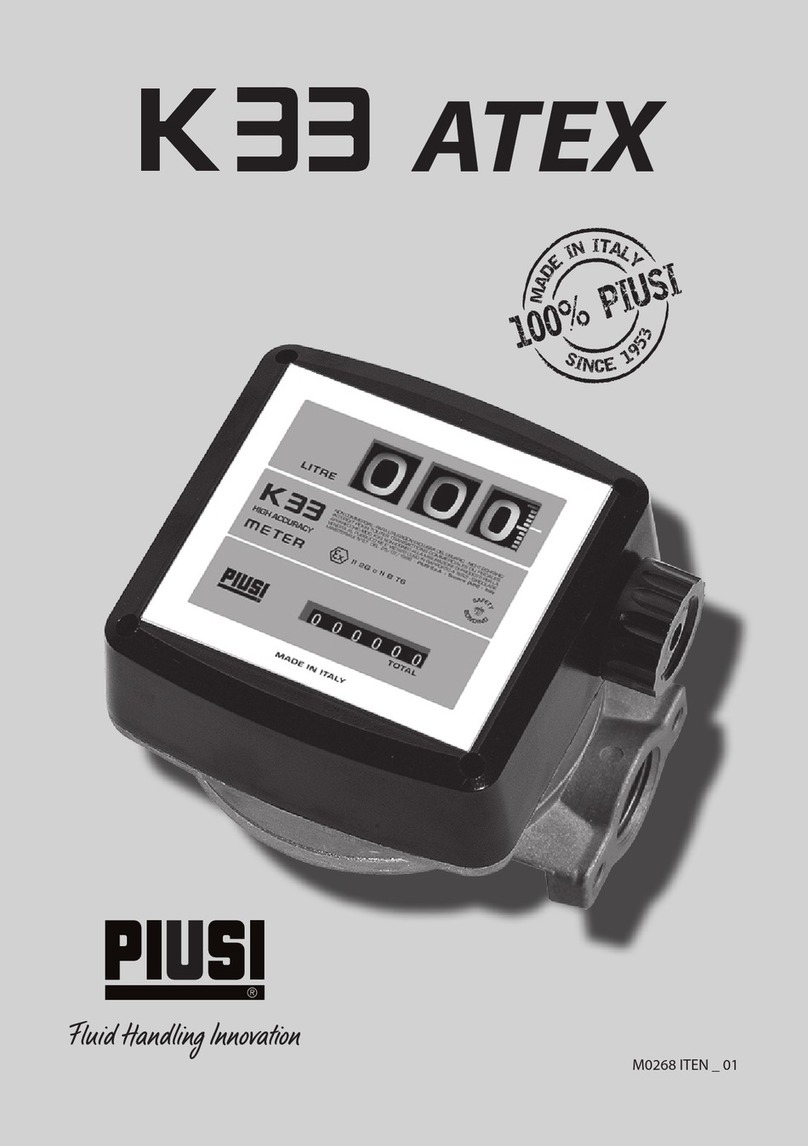

B DECLARATION OF CONFORMITY

The undersigned:

PIUSI S.p.AVia Pacinotti c.m. z.i.Rangavino

46029 Suzzara - Mantova - Italy

HEREBY STATES

under its own responsibility, that the equipment described below:

Descriprion: METER

Model: K900

Serial number: refer to Lot Number shown on CE plate affixed to productYear of manufacture: refer

to the year of production shown on the CE plate affixed to the productis in conformity with the legal

provisions indicated in the directives :

- Electromagnetic Compatibility Directive 2004/108/EC

The documentation is at the disposal of the competent authority following motivated request at Piusi

S.p.A.

or

following

request

sent

to

the

email

address:

[email protected] person

authorised

to

compile the technical file and draw up the declaration is Otto Varini as legal representative.

Suzzara, 01/01/2015 Otto Varini

legal representative.

C GENERAL WARNINGS

Important precau-

tions To ensure operator safety and to protect the pump from potential dam-

age, workers must be fully acquainted with this instruction manual before

performing any operation.

Symbols used in the

manual The following symbols will be used throughout the manual to highlight

safety information and precautions of particular importance:

ATTENTION

This symbol indicates safe working practices for operators and/or po-

tentially exposed persons.

WARNING

Thissymbolindicatesthatthere is risk ofdamagetothe equipment and/

or its components.

NOTE

This symbol indicates useful information.

Manual preservation his manual should be complete and legible throughout. It should remain

available to end users and specialist installation and maintenance techni-

cians for consultation at any time.

Reproduction rights

This manual belongs to Piusi S.p.A., which is the sole proprietor of all rights

indicated by applicable laws, including, by way of example, laws on copyrights. All

the rights deriving from such laws are reserved to Piusi S.p.A.: the reproduction,

including partial, of this manual, its publication, change, transcription and notifica-

tion to the public, transmission, including using remote communication media,

placing at disposal of the public, distri¬bution, marketing in any form, translation

and/or processing, loan and any other activity reserved by the law to Piusi S.p.A..