DHC BT2000EV User manual

Model BT2000EV

GOLF CART MAINENANCE BATTERY ANALYZER

OWNER’S MANUAL

READ ENTIRE MANUAL BEFORE USING THIS PRODUCT

- 1 -

MODEL NO. BT2000EV

GOLF CART MAINTENANCE BATTERY ANALYZER

TEST PROCEDURES / OPERATING INSTRUCTIONS

IMPORTANT:

1. For testing 6 volt, 8 volt, and 12 voltbatteries

2. Suggested operation range 32℉(0℃) to 122℉(50℃) in ambient

temperature.

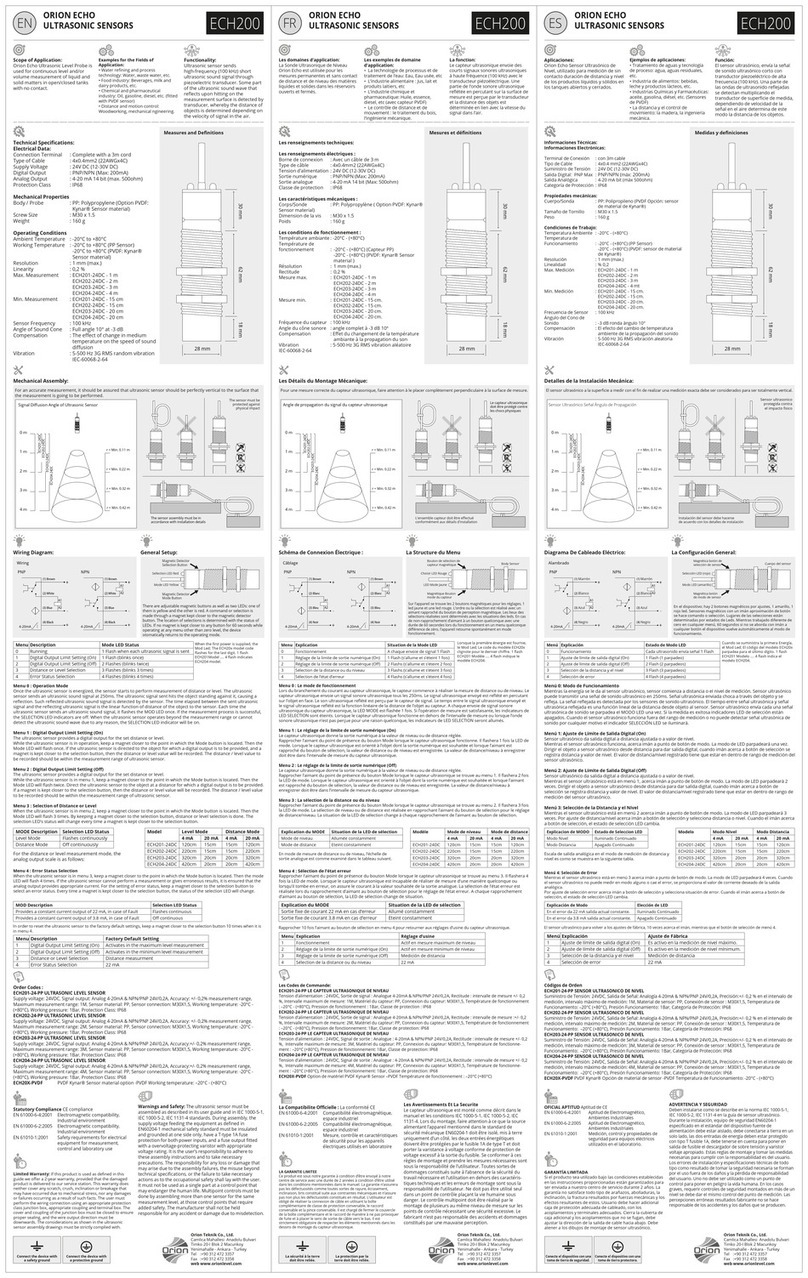

1

2

1

Printer

2

Display

3

DirectionalKeys

4 3

4

USB Port

5

Volt Probe Jack

6

Amp Clamp Jack

6 5

- 2 -

WARNING:

Pursuant to California Proposition 65, this product contains chemicals

known to the State of California to cause cancer and birth defects or

other reproductive harm. Wash hands after handling.

1. Working in the vicinity of a lead acid battery is dangerous.

Batteries generate explosive gases during normal battery operation.

For this reason, it is of utmost importance, if you have any doubt,

that each time before using your tester, you read these instructions

very carefully.

2. To reduce risk of battery explosion, follow these instructions and

those published by the battery manufacturer and manufacturer of

any equipment you intend to use in the vicinity of the battery.

Observe cautionary markings on theseitems.

3. Do not expose the tester to rain orsnow.

PERSONAL SAFETYPRECAUTIONS:

1. Someone should be within range of your voice or close enoughto

come to your aid when you work near a lead acid battery.

2. Have plenty of fresh water and soap nearby in case battery acid

contacts skin, clothing oreyes.

3. Wear safety glasses and protectiveclothing.

4. If battery acid contacts skin or clothing, wash immediately with

soap and water. If acid enters eye, immediately flood eye with

running cold water for at least ten minutes and get medical attention i

mmediately.

5. NEVER smoke or allow a spark or flame in vicinity of battery or

engine.

6. Be extra cautious to reduce risk of dropping a metal tool onto the

battery. It could spark or short-circuit the battery or other electrical

parts and could cause anexplosion.

7. Remove personal metal items such as rings, bracelets, necklaces

and watches when working with a lead acid battery. It can produce a

short circuit current high enough to weld a ring or the like to metal

causing a severeburn.

- 3 -

PREPARING TO TEST:

1. Be sure area around battery is well ventilated while battery is

being tested.

2. Clean battery terminals. Be careful to keep corrosion from coming

in contact with eyes.

3. Inspect the battery for cracked or broken case or cover. If battery

is damaged, do not usetester.

4. If the battery is not sealed maintenance free, add distilled water in

each cell until battery acid reaches level specified by themanu

-facturer. This helps purge excessive gas from cells. Do not overfill.

5. If necessary to remove battery from vehicle to test, always remove

ground terminal from battery first. Make sure all accessories in the

vehicle are off to ensure you do not cause anyarcing.

OPERATION & USE:

1. Remove the cover at the backside bottom of the battery tester.

2. Insert the connectors which contain black-white pairand

yellow-red pair in one end of the lead wire into the sockets which can

be found when you remove the cable cover. Be sure to make colors

matched between the connectors and sockets as shown below.

BT2000EV backside

INSERTION OR REPLACEMRNT OF LEAD WIRE

black

white

yellow

red

- 4 -

1. Before you test a battery in a vehicle, turn off the ignition, all

accessories andloads.

2. Make sure you have put 6 AA 1.5V batteries into the battery

chamber. Oxyride batteries are not recommended because of the

initial 1.7 Volt output. If the internal 1.5V batteries run out of power,

the display will show “POWER LOW”. Replace those 6 AA 1.5V

batteries before starting a newtest.

Note that nothing will be seen on the display until the tester is

connected to a battery.

3. Make sure the battery terminals are clean. Wire brush them if

necessary. Connect the red clamp to the positive battery terminal

post; connect the black clamp to the negative battery terminal post.

For the most accurate results, clamp the lead part of the terminal

only. Attaching to the fixture rather than directly on the terminal will

lead to the unstable testresults.

4. Paper load:

a. Open the clearcover.

b. Place a new paper roll in thecompartment.

c. Pull a short length of paper from the

compartment and press down the clear cover

to close.

BATTERY TEST

- 5 -

5. Press the ◄ ► key to select Battery Test. Press «ENTER» button.

6. Select the number of batteries from pack to test.

7. Select the battery brand you are going to test.

You can find the following battery lineup.

JCI / TROJAN / US BATTERY / EXIDE / DEKA

8. Confirm the model number.

9. Testing battery.

10. When the test is completed, the display shows the result, SOC,

and SOH (Press the directional keys to select STATE OF HEALTH or

STATE OF CHARGE.)

One of the five results will be displayed.

The battery is good & capable of holding a charge.

The battery is good but needs to be recharged.

Battery is discharged. The condition cannot be

determined until it is fully charged. Recharge & retest the battery.

GOOD & RECHARGE

GOOD & PASS

RECHARGE & RETEST

# OF BATTERY

1/2/3/4/5/6/7/8

BATTERY BRAND:

JCI

BATTERY MODEL:

EGC8

GOOD & PASS

XX.XXV

GOOD & RECHARGE

XX.XXV

RECHARGE & RETEST

XX.XXV

- 6 -

LOAD ERROR

MEMORY FULL

WILL OVERWRITE

MEMORY

PRESS ENTER

MEMORY ERROR

REFER TO MANUAL

PRESS ENTER

The battery will not hold a charge. It should be

replaced immediately.

The battery has at least one cell short circuit. It

should be replaced immediately.

11. A code will be generated to each test result.

Use the Decoder to get the test result at PCend.

12. Press the ◄ ► key to select result printing:

YES or NO. Press «ENTER» to confirm your

choice.

NOTE that there might be some message displayed to different

circumstances as below.

The tested battery is bigger than the defaulted

threshold. Or the clamps are not connected properly.

The tester can record 1000 test results, which will

be overwrote when the record is above 1,000times.

MEMORY ERROR

Tester cannot store the result properly. Please use

the CLEAR MEMORY function. The stored test data will be deleted.

MEMORY FULL

BAD & REPLACE

BAD CELL & REPLACE

LOAD ERROR

BAD & REPLACE

XX.XXV

BAD CELL & REPLACE

XX.XXV

CODE

XXXXXXXXXXX

PRINT RESULT?

YES

- 7 -

LANGUAGE SELECT

1. Hook the tester up to a battery.

2. The tester defaults to the BATTERY TEST display. Press the

directional keys to get to the LANGUAGE SELECTdisplay.

3. Press ENTER and the display will show the language options.

Press the directional keys to select the language you want the tester

to display.

4. Press ENTER and the display returns to BATTERY TEST.

SETTING THE DATE AND TIME

1. Hook the tester up to a battery.

2. The tester defaults to the BATTERY TEST display. Press the

directional keys to get to the CURRENT DATE/TIME display.

3. Press ENTER and the display will show the ADJUST YEAR.Press

the directional keys to change thesetting.

4. Press ENTER and the display will show the ADJUSTMONTH.

Press the directional keys to change thesetting.

5. Press ENTER and the display will show the ADJUST DAY. Press

the directional keys to change thesetting.

6. Press ENTER and the display will show the ADJUSTHOUR.

Press the directional keys to change thesetting.

7. Press ENTER and the display will show the ADJUSTMINUTE.

Press the directional keys to change thesetting.

8. Press ENTER and the display will show the ADJUSTSECOND.

Press the directional keys to change thesetting.

9. Press ENTER and the display returns to BATTERY TEST.

ADJUST THE DISPLAY BRIGHTNESS

1. Hook the tester up to a battery.

2. Get to the BRIGHTNESS display.

3. Press the directional keys to adjust the brightness of thedisplay.

SETTINGS AND INFORMATION RETRIEVAL

- 8 -

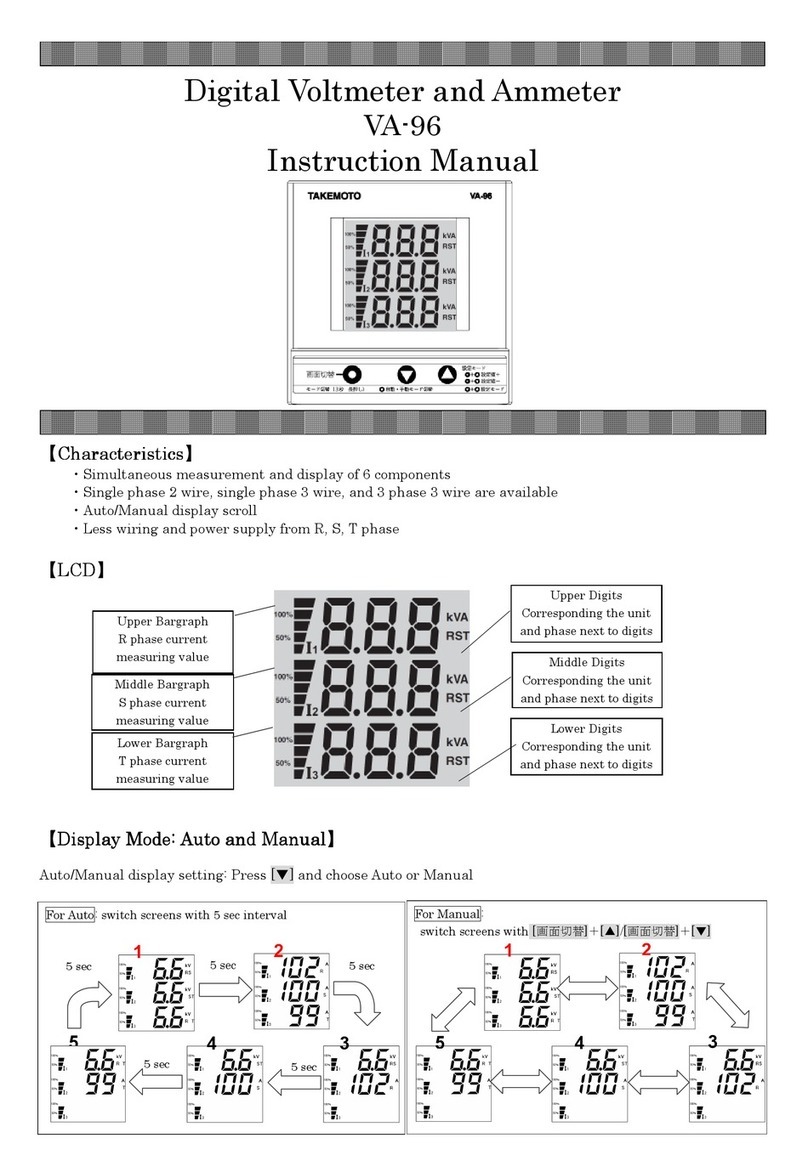

Press LEFT / RIGHT buttons to select the following functions when the unit is turned on.

TEST FLOW

CLEAR MEMORY

BATTERY TEST

XX.XX V

TEST COUNTER

BAT. TEST: XXXX

LANGUAGE

SELECT

INFORMATION

VOLTMETER

2000 / 01 / 01

xx : xx : xx

BRIGHTNESS

AMMETER

- 9 -

PC NAVIGATION GUIDE

Each BT2000EV comes with a CD, including the drive of the

software installation and its user guide. You can follow the instruction

to install the specific software for the diversedemand.

SOFTWARE INSTALLATION

LIST

REVIEW TEST RESULT DOWNLOAD TESTRESULT

Review the test data stored in thetester. Connect BT2000EV to PC

through the supplied USB lead.

UPGRADE SOFTWARE DELETE TEST RESULT

Add new battery algorithm

to BT2000EV

Delete test data from BT2000EV

BATTERY

BATTERY

- 10 -

Any battery tester defective in material or workmanship will be

repaired or replaced according to published defective return test

repair procedures. The existence of a defect shall be determined by

the seller in accordance with published procedures. The published

test procedures are available upon request.

This warranty does not cover any unit that has been damaged due to

accident, abuse, alternation, use for a purpose other than that for

which it was intended, or failure to follow operating instructions. This

warranty is expressly limited to original retail buyers. This warranty is

not assignable or transferable. Proof of purchase is required for all

alleged claims. Warranty cannot be authorized without proof of

purchase. Warranty claims must be sent pre-paid with dated proof of

purchase. Damage incurred during shipment is the responsibility of

the shipper (customer returning unit) If the returned unit qualifies for

warranty, the shipper will only incur shipping cost. The seller reserves

the right to substitute or offer alternative warranty options at its

discretion.

The sole and exclusive remedy for any unit found to be defective is

repair or replacement, at the option of the seller. In no event shall the

seller be liable for any direct, indirect, special, incidental, or

consequential damages (including lost profit) whether based on

warranty, contract, tort, or any other legal theory.

RETURN GOODS

Pack with sufficient over-pack to prevent damage during shipment.

Damage incurred during return is not covered under this warranty.

Repair costs for such damages will be charged back to shipper.

REMARK

WHEN RETURNING GOODS, PLEASE SHOW “RETURN GOODS”

ON ALL INVOICES & RELATED SHIPPING DOCUMENTS TO

PREVENT ANY EXTRA CHARGE.”

WARRANTY

Table of contents

Other DHC Measuring Instrument manuals