diagenode Bioruptor Pico User manual

Bioruptor® Pico

Sonication System

Version 3 01_2020

USER GUIDE

Guarantee

Limited 5 years global warranty

Diagenode guarantees the Bioruptor Pico from any manufacturing defects as we rigorously test it to

meet strict quality standards. Diagenode warrants that all standard components of the instrument

will be free of defects in materials and workmanship for a period of five (5) years or for maximum

210 hours of total running time* from the date that the warranty period begins, unless the original

quotation or accompanying documentation states a different warranty period. The warranty period

begins on the date of delivery and apply only to the first purchaser of the product. The warranty

period expires when one of the two above conditions ends (5 years or 210 hours of total running

time*). If a manufacturing defect arises and a valid claim is received within the warranty period,

Diagenode, at its discretion, will repair or replace the product in accordance with the warranty

terms and conditions stated herein. In case of repair or replacement of a product under warranty,

Diagenode will cover the expenses to return the repaired or replacement product.

This warranty covers only manufacturing defects and does not cover any damage caused by misuse,

lack of compliance to recommendations stated in the manual, neglect, accidents, abrasion, or

exposure to extreme temperatures, chemical solvents, or acids. Improper or incorrectly performed

maintenance or repairs will void the warranty.

*The total running time corresponds to total sonication time ON + total sonication time OFF

that compose the cycles of the shearing process.

Technical assistance & ordering information

For the rest of the world, please contact Diagenode s.a.

https://www.diagenode.com/en/pages/support

Diagenode s.a.

BELGIUM | EUROPE

LIEGE SCIENCE PARK

Rue Bois Saint-Jean, 3

4102 Seraing (Ougrée)

Belgium

Tel: +32 4 364 20 50

Fax: +32 4 364 20 51

Diagenode Inc.

USA | NORTH AMERICA

400 Morris Avenue, Suite

#101

Denville, NJ 07834

USA

Tel: +1 862 209-4680

Fax: +1 862 209-4681

Diagenode Co., Ltd.

JAPAN

1-1-25, Arakawa

Toyama 930-0982

Japan

Tel: +81 76-482-3110

Fax: +81 76-482-3211

Looking for the manual of the previous version? Follow this link :

https://www.diagenode.com/files/products/shearing_technology/bioruptor/Bioruptor_pico_

cooler_manual.pdf

3

Contents

BIORUPTOR® PICO

Critical steps for maintenance and efficient shearing 6

Introduction 7

Technical specifications 8

Getting to know you Bioruptor Pico System 9

Equipment installation 12

Installation 13

System Operation 14

Tube holders & tubes 20

BIORUPTOR® COOLER

Safety 23

Design and functions 26

Operation 36

Maintenance 38

Disposal 43

Technical data 44

BIORUPTOR® PICO

6 BIORUPTOR® PICO MANUAL

Critical steps for maintenance

and efficient shearing

General warnings

Sonication bath temperature

• Optimal temperature for sonication is 4°C. Sample temperature should not exceed 8°C.

• The Bioruptor Cooler (Cat. No. B02010010, B02010011, B02010012) has to be used to guarantee the

automatic temperature control of the sonication bath during the entire sonication process.

Validated tubes for the Bioruptor® Pico

• DNA shearing: 0.2 ml (Cat.No. C30010020) and 0.65 ml (New Cat. No. C30010011; Old Cat. No. WA-005-

0500) Bioruptor® Microtubes for DNA shearing.

• Chromatin shearing: 0.2 ml (Cat.No. C30010020) and 1.5 ml (Cat.No. C30010016) Bioruptor® Microtubes

and 15 ml (Cat.No. C01020031) Bioruptor® Tubes & sonication beads.

Fitting tubes in the tube holder

• Place the tubes in the corresponding tube holder. Never leave empty spaces in the tube holder. Fill the

empty spaces with tubes containing the same volume of water. Screw the lid on the tube holder without

over-tightening it.

• Carefully place the tube holder on the holding plate.

• During sonication, samples must remain at the bottom of the tube. If needed, briefly centrifuge samples

during sonication after pausing the run.

DON’T

Turn on the instrument without water

Exceed 30 min of total sonication

Tilt the sonication unit

DO

Change water at least once every month

Use deionized or distilled water

QC your system with our DNA QC Kit

7

Introduction

Diagenode’s Bioruptor Pico uses a gentle method of sonication to retain the integrity of

DNA and/or biological complexes, including chromatin, protein-protein binding, protein-

DNA complexes and other biochemical and biological assay systems. The Bioruptor Pico

sonication system uses a sonication bath to generate indirect sonication waves, which

emanate from an ultrasound element below the water tank. Because the system is gentler

than other sonicators, the Bioruptor Pico produces better and more consistent results than

with harsher sonication methods. Up to 16 closed tubes can be sonicated in parallel and the

continuous rotation of tubes allows even distribution of the energy for efficient sonication.

The Bioruptor Pico enables automation of sonication, guaranteeing higher reproducibility of

results.

The effect of ultrasound on biological sample

The Bioruptor Pico sonication system uses

ultrasound to create focused mechanical stress to

shear chromatin or DNA, remove paraffin from FFPE

samples, disrupt cells and homogenize tissue, or

disperse chemical component, or reduce the size

of liposomes. Ultrasound waves pass through the

sample expanding and contracting the liquid. During

expansion, negative pressures pull the molecules

away from one another to form a cavity or bubble. This process is called cavitation. The bubble

continues to absorb energy until it can no longer sustain itself and implodes. This produces

intense focused shearing forces, that disperse and break biomolecules. The fragmentation

of chromatin or DNA takes place as a consequence of this mechanical stress or shear. With

the Bioruptor Pico, the entire volume of water present in the sonication bath is exposed to

ultrasound, allowing all the samples to be efficiently sonicated in parallel.

Use of Bioruptor® Pico by pregnant women

Exposure to 20-60 kHz sound waves has not been shown to be harmful to human health.

However, we would recommend avoiding unnecessary exposure. Diagenode recommends

that pregnant women should not be exposed to 20-60 kHz wave lengths for a long period of

time.

8 BIORUPTOR® PICO MANUAL

BIORUPTOR® PICO

Input Voltage Range 100 - 240 V

Input Frequency Range 50 - 60 Hz

Maximum Electrical Consumption 4.2 A

Ultrasonic Wave Frequency 20 - 60 kHz

Unit Dimensions

• The sonicator

• The cooler

380 (W) x 315 (D) x 275 (H) mm

200 (W) x 390 (D) x 495 (H) mm

Weight

• The sonicator

• The cooler

9 kg

26.9 kg

Placement Indoor areas

Ambient Temperature Range 15 – 25°C

Maximum Relative Humidity

80%

Altitude Up to 2,000 meters

Degree of protection IP31

Shearing Accessories

• Tube holder for 0.2 ml tubes

Cat. No. B01201144

• Tube holder for 0.65 ml tubes

Cat. No. B01201143

• Tube holder for 1.5 ml tubes

Cat. No. B01201140

• 15 ml sonication accessories

Cat. No. B01200016

Shearing Consumables

• 0.2 ml Bioruptor Pico Microtubes Cat. No. C30010020

• 0.65 ml Bioruptor Pico Microtubes Cat. No. C30010011

• 1.5 ml Bioruptor Pico Microtubes Cat. No. C30010016

• 15 ml Bioruptor Pico Tubes

Cat. No. C30010017

• 15 ml Bioruptor Pico Tubes & sonication beads

Cat. No. C01020031

Throughput

• 0.2 ml microtubes – 16 samples

• 0.65 ml microtubes – 12 samples

• 1.5 ml microtubes – 6 samples

• 15 ml tubes – 6 samples

Sample Volume Range

• 0.2 ml microtubes – 20-100 µl

• 0.65 ml microtubes – 100 µl

• 1.5 ml microtubes – 100-300 µl

• 15 ml tubes – 500 µl – 2 ml

Fragment Length Range Achievable 150 – 1,000 bp

Working Temperature Range 2 - 20°C

Variable Parameters Time ON, Time OFF,

# cycles, level of frequency

User Interface Touchscreen with Bioruptor Pico software

Bioruptor Pico technical specifications

9

Getting to know your Bioruptor Pico system

Bioruptor Pico components overview

Bioruptor Cooler (detailed instructions page 21)

Power cable (EU) Power cable (US)

Sonication unit

Sonication bath

Motorized lid

Tube holder

10 BIORUPTOR® PICO MANUAL

Sonication bath

The sonication bath is a critical component of the instrument. The generators below the

tank produce ultrasonic waves which are then transferred through water. The sonication

bath requires special handling and care as described below.

Handling

The sonication unit must remain upright at all times, especially when moved. Tilting the

sonication unit or handling roughly may damage the ultrasound emitter component,

resulting in a substantial drop in sonication efficiency. If transportation of the apparatus is

required after initial set-up, it is imperative to keep the sonication unit at a right angle to the

ground during the transport at all times.

Water quality

The water bath must be filled with purified water according to specification (see table) to

the fill line. Change water at least every month and clean sonication tank with a soft tissue.

Water temperature

The water in the sonication bath must be kept at 4°C. Ultrasonic waves produced by the

Bioruptor Pico generate heat. Drop off in sonication efficiency will occur above 8°C. To

ensure preservation of the samples and to prevent damage to the instrument, it is necessary

to start the sonication process with cold water and to keep it at 4°C during the sonication

process.

Automatic temperature control

The Bioruptor Cooler (Cat. No. B02010010, B02010011, B02010012) to guarantee the

automatic temperature control of the sonication bath during the entire sonication process.

The cooling system produces a regular water flow to maintain a constant water level in the

GRADE OF WATER COMPATIBILITY

WITH THE BIORUPTOR

Ultrapure water Type 1 or Type 1+ No

Deionized water Type 2+ or Type 2 Yes

Distilled water Type 3 Yes

Tap water N/A No

11

tank. The integrated regulating valve ensures that water will only be replaced during the off

cycle to avoid any interference between the water flow and the sonication process.

Motorized lid

The motorized lid, along with the gear plate accessory, keeps the sample

tubes in constant rotation and ensures optimal position in the sonication

bath during sonication. Avoid the immersion of the motor into the water.

Tube holders

Several sizes of tubes can be used with the Bioruptor Pico.

The minimum and maximum sample volume to be used with each tube is given in the table

below.

TUBE SIZE MINIMUM MAXIMUM

0.2 ml 20 µl 100 µl

0.65 ml 100 µl 100 µl

1.5 ml 100 µl 300 µl

15 ml 500 µl 2 ml

Bioruptor® Cooler Sonication unit

12 BIORUPTOR® PICO MANUAL

Equipment installation

The following pages contain information on installing your particular Bioruptor Pico model.

This equipment must only be installed by personnel after reading this section. Consider all

hazards even though no particular hazards have been identified during installation. Before

starting installation work, turn the main switch off and secure the unit against being re-

energized. No special tools are required. One square meter is needed to set-up the Bioruptor

Pico.

Devices are designed to be safe under the following conditions:

Installation overview

• Indoor use

• Altitude up to 2,000 meters

• Operating external temperature 15°C to 25°C

(do not install the Bioruptor in a cold room)

• Maximum relative humidity 80%

• Transient overvoltage typically present on the

MAINS supply

• Degree of protection: IP31

• Power plug must be grounded

• POLLUTION DEGREE 2 (Normally only

non-conductive pollution occurs. However,

occasionally a temporary conductivity caused

by condensation is expected)

• Never install this equipment in a place where

environmental conditions and warnings

mentioned above are infringed

Fig. Schematic installation overview of the Bioruptor Pico System in combination with the Bioruptor Cooler.

13

Installing the Bioruptor Pico system

Before starting the installation, turn the main switches off and make sure that the unit is not

plugged into an electrical outlet.

1. Open the boxes and unpack all components.

2. Place the Bioruptor on a bench.

• Important Note: Please make sure that the Bioruptor Pico is always placed on a level surface.

3. Place the Bioruptor Cooler on the bench or below the Bioruptor.

4. Connect the Bioruptor Pico to the Bioruptor Cooler with the cooling long red and blue

isolated tubing by inserting them into the connectors (Optional: Cut the length you need

for the output and input flow. Make sure there is enough slack).

5. Fill the tank of the Bioruptor Cooler with 2 - 3 liter and the sonication bath of the

Bioruptor with 700 ml.

6. Plug the valve connection cable into the outlet on the back side of the Bioruptor Cooler

and on the Bioruptor Pico.

7. Plug the power cord into the outlet and switch on the power switch on the back side of

the sonication unit.

8. Plug the power cord into the outlet of the Bioruptor Cooler.

9. Press main switch on the front side of the Bioruptor Cooler.

10. Set the temperature to 4°C.

11. Detailed operating instructions for the Bioruptor Cooler are available at page 21.

Bioruptor® CoolerBioruptor® Pico

14 BIORUPTOR® PICO MANUAL

System operation

Touch screen: Allows the user to easily program the sonication of samples.

15

LED LIGHT BAR

The LED light bar allows the tracking of the processing of your samples.

The blue light means the system is waiting for the operator.

The progressive green light indicates the progression of the shearing process.

The green light indicates the end of the shearing process.

The orange light means the protocol is on pause.

The red light indicates an alert message.

Technical Support: Diagenode contact

information for technical questions

User Protocols: Record your protocol

Diagenode dots: Go back to the top

menu

Commercial Support: Diagenode contact

information for commercial questions

Guidelines: Read Diagenode

recommendations for your applications

Go & Shear: Start a new shearing

protocol

Good Practices: Critical steps for

Bioruptor maintenance and efficient

shearing

Settings: Visualize and change the

parameters of your Bioruptor Pico

Information: General information about

your Bioruptor Pico

Edit: Edit the parameter

Question mark: Some notes to guide you

Sound: Adjust the sound level

Maintenance: Access for administrators

Language: Choose your voice language

Brightness: Adjust the brightness of the

screen

INTERFACE

16 BIORUPTOR® PICO MANUAL

START SHEARING EXPERIMENT

1. Click on ‘Protocols’ icon of the top menu.

2. Click on ‘Go & Shear’ icon to start a new

protocol or click on ‘User Protocols’ icon to

find your pre-recorded shearing protocol.

3. Select your mode. Find validated parameters

on the Easy Mode or optimize your protocol with

different levels of frequency on the Advanced

Mode.

ENTER PARAMETERS

1. Enter the sonication time ON, the sonication

time OFF and the number of cycles. These

are the parameters controlling the shearing

process:

- the time ON is the time during which there is

sonication;

- the time OFF is the time during which there

is no sonication but water circulation;

- the cycle is made up of a time ON and a time

OFF.

2. If Easy Mode was selected, select the tube type

you plan to use. The Bioruptor will automatically

swap to the correct frequency for optimal

shearing of your samples. If Advanced Mode

was selected, choose your level of frequency

that is the most convenient for your application.

PROTOCOLS

GO AND SHEAR

Choose validated

protocols

Choose your level

of frequency

GO AND SHEAR (easy mode)

30

seconds

seconds

cycles

30

10

10

min seconds

00

17

PREPARE SAMPLES

1. Fill the sonication tubes with same volume of sample.

Use the recommended tubes and sample volumes

for optimal shearing efficiency. Visit our Guidelines

folder for more information.

2. Vortex and then spin your samples.

3. Fill all positions of the tube holder with your samples

(or with water of same volume) and place it on the

motorized lid.

4. Close the lid to start the run. The sonication only

starts when the cover is closed. The cover also

prevents from any noise disturbance.

18 BIORUPTOR® PICO MANUAL

START PROCESSING & MONITOR PROGRESS

1. Click “Go” to start the shearing process. You

will then be asked to check water temperature

and right setting of your samples.

2. Once the run started, the running screen

appears. The running screen indicates

the elapsed time ON, time OFF and the

number of cycles. A progress bar and the

remaining time will be displayed on the

screen. The led indicator lights up in green.

You can pause or interrupt the shearing

process by pressing the button pause or stop,

respectively. If the cover will be opened during

a run the sonication will automatically pause.

Once the cover is again closed the machine

continues with the sonication process.

3. You will get a notification on the screen once

the shearing process ends successfully. Click

“OK” to go back to the menu.

SHEARING PROCESS

Remaining:

11:25

Remaining Time:

Sonication ON:

Sonication OFF:

Number of cycles:

25

seconds

30

seconds

13

cycles

GO AND SHEAR (easy mode)

30 seconds

seconds

cycles

30

10

10 min seconds

00

19

15 ml sonication

accessories

(Cat. No. B01200016)

1.5 ml Bioruptor®

Microtubes

(Cat. No. C30010016)

0.2 ml Bioruptor®

Microtubes

(Cat. No. C30010020)

0.65 ml Bioruptor®

Microtubes

(Cat. No. C30010011)

Tube holder for 0.2 ml tubes

(Cat. No. B01201144)

Tube holder for 0.65 ml

tubes

(Cat. No. B01201143)

Tube holder for 1.5 ml tubes

(Cat. No. B01201140)

15 ml Bioruptor® Tubes

(Cat. No. C30010017)

15 ml Bioruptor® Tubes &

sonication beads

(Cat. No. C01020031)

Tube holder

Dock

Tube holders & tubes

The holder is made up of a tube holder and its specific

dock.

To guarantee homogeneity of chromatin or DNA shearing,

the tube holders should always be completely filled with

tubes. Never leave empty spaces in the tube holder. Fill

the empty spaces with tubes containing the same volume

of distilled water.

Other manuals for Bioruptor Pico

2

Table of contents

Other diagenode Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Isotech

Isotech ORION 796 Maintenance manual

J.P. SELECTA

J.P. SELECTA CENTRO-8 BL instruction manual

3D Histech

3D Histech Pannoramic 250 user guide

Novatech Instruments

Novatech Instruments 1450B instruction manual

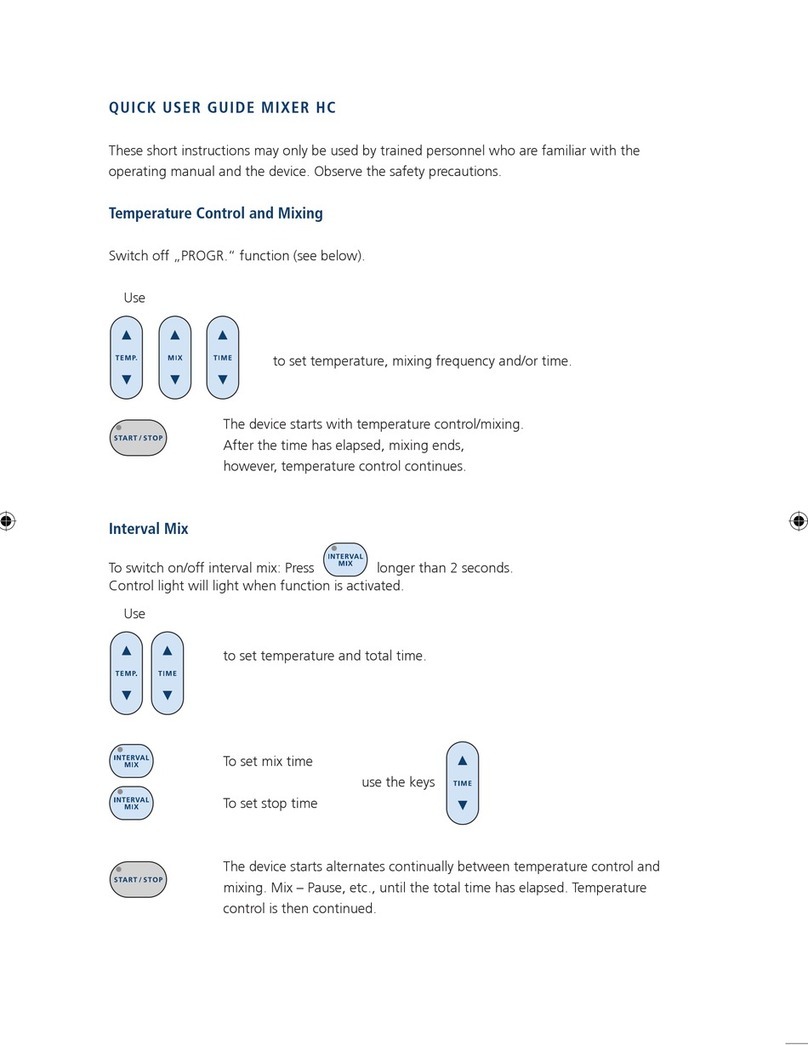

Star Lab

Star Lab Mixer HC Quick user guide

TAN Bead

TAN Bead Maelstrom 8 Autostage user manual