IKA T 65 D User manual

Other IKA Laboratory Equipment manuals

IKA

IKA RV 10 control User manual

IKA

IKA C 7010 User manual

IKA

IKA RCT basic safety control User manual

IKA

IKA MS 450 Swirler User manual

IKA

IKA Mini MR standard User manual

IKA

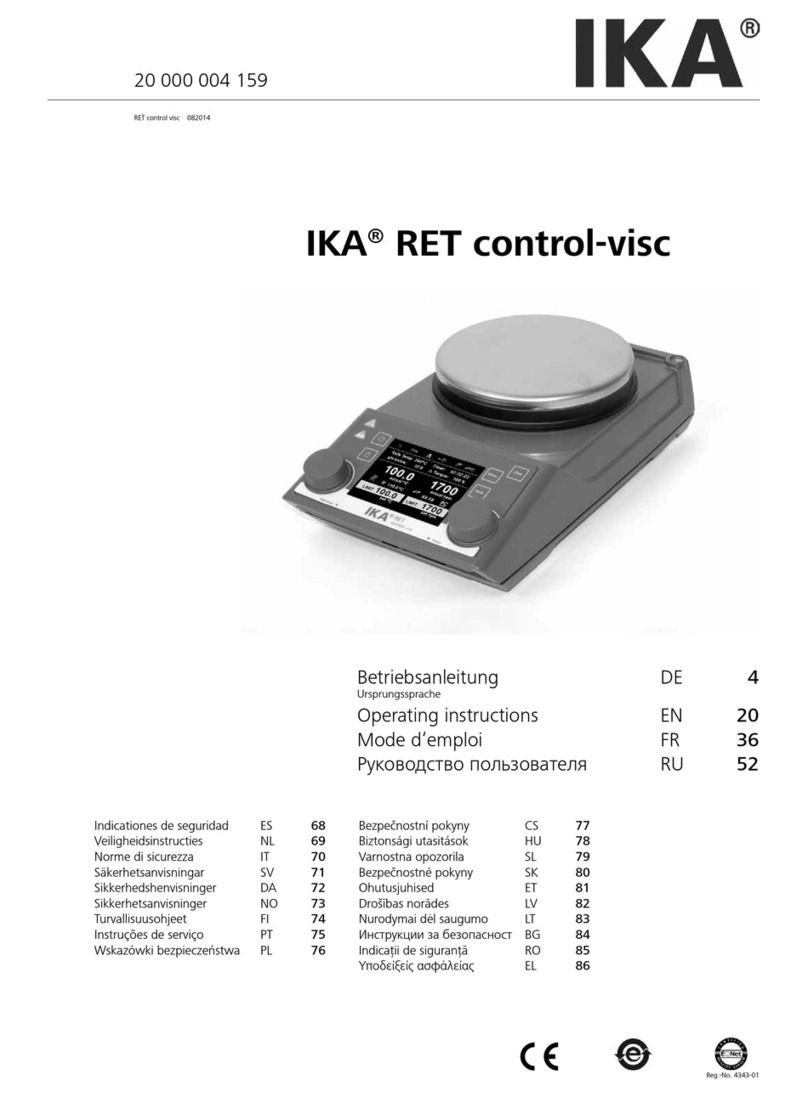

IKA RET control-visc User manual

IKA

IKA Topolino Mobil User manual

IKA

IKA HB 10 User manual

IKA

IKA AOD 1.1 User manual

IKA

IKA Color Squid User manual

IKA

IKA RH basic User manual

IKA

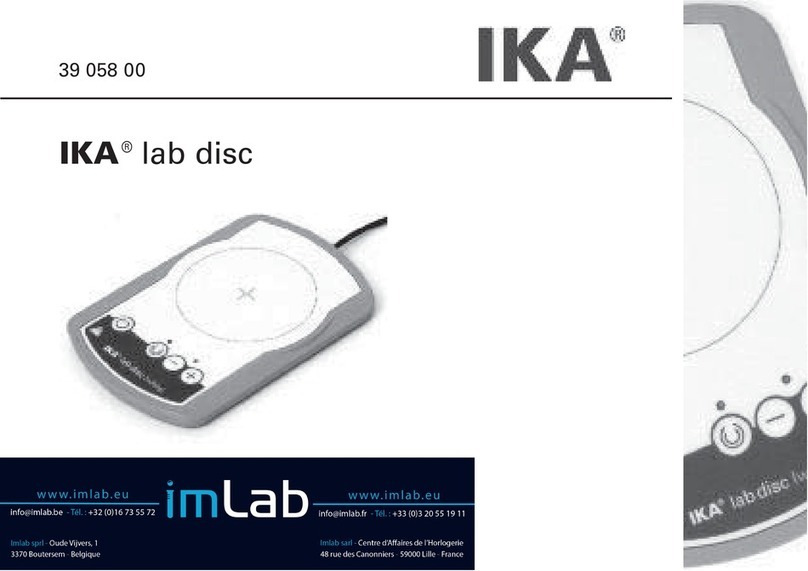

IKA Lab disc User manual

IKA

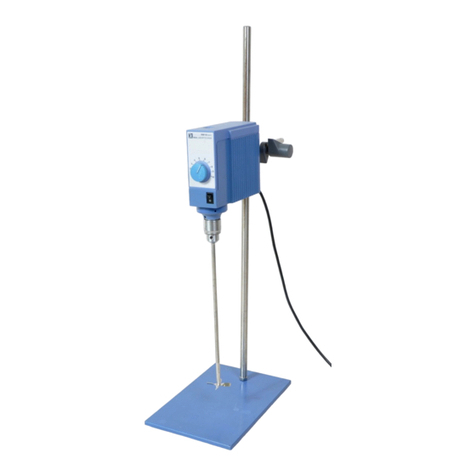

IKA RW 16 basic User manual

IKA

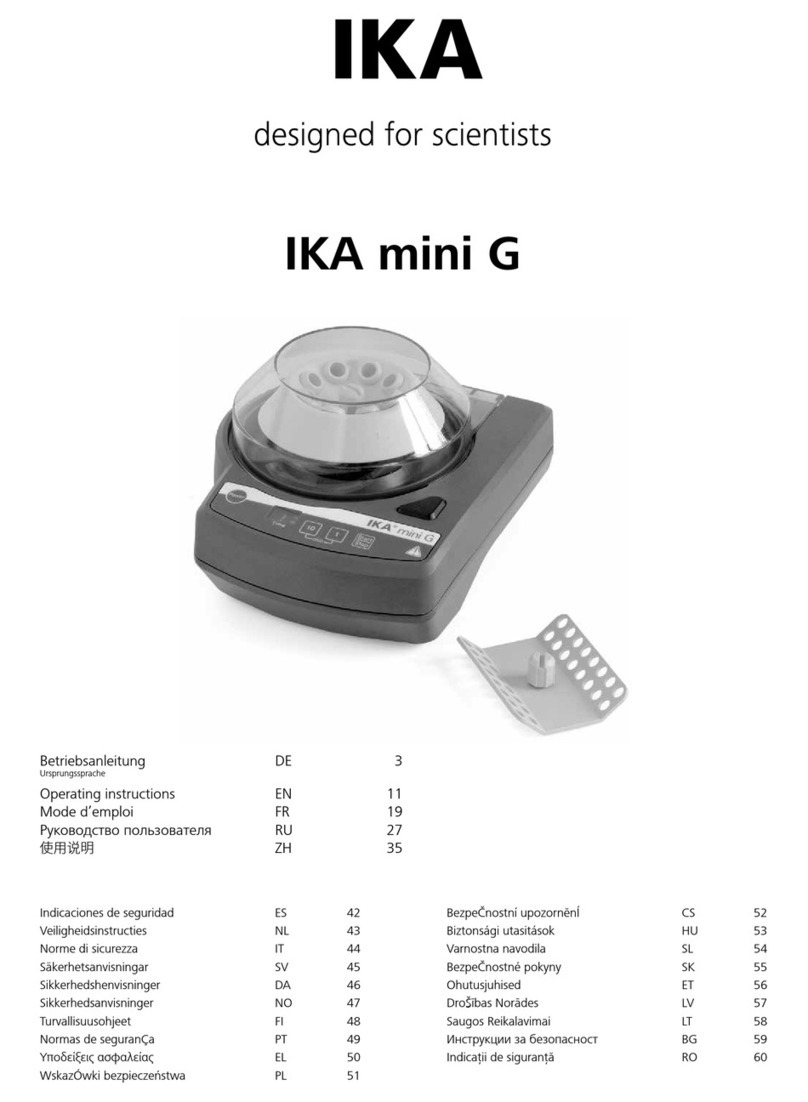

IKA mini G User manual

IKA

IKA Mini MR standard User manual

IKA

IKA ULTRA-TURRAX T 65 basic User manual

IKA

IKA RW 16 basic User manual

IKA

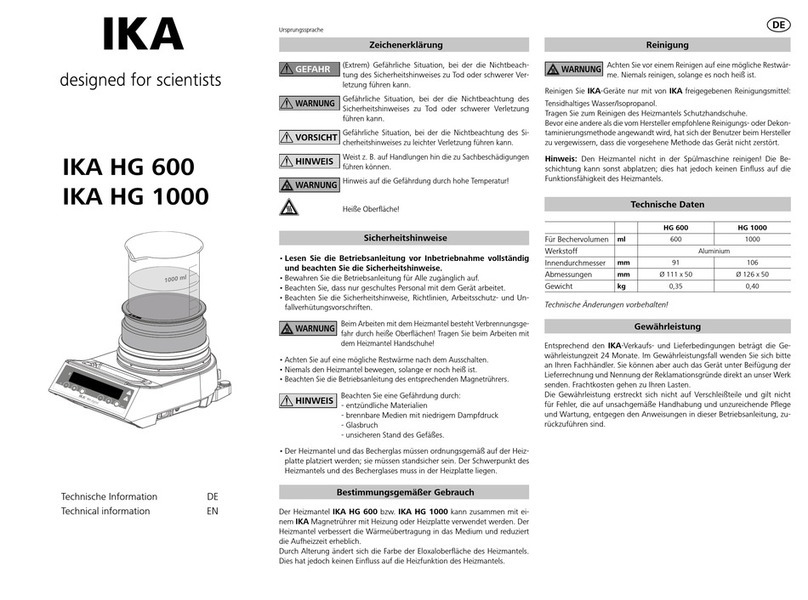

IKA HG 600 Manual

IKA

IKA EUROSTAR digital User manual

IKA

IKA HRC 2 control User manual

Popular Laboratory Equipment manuals by other brands

Qiagen

Qiagen DML 3000 user manual

Queensgate

Queensgate NANOSCAN OP400 Quick start instructions

Conviron

Conviron GEN1000-GE Operator's manual

Parr Instrument

Parr Instrument 4560 Operating instructions manual

Integra

Integra DOSE IT operating instructions

Agilent Technologies

Agilent Technologies 5800 ICP-OES user guide

Endress+Hauser

Endress+Hauser Cleanfit CPA875 operating instructions

NI

NI PXI-5422 CALIBRATION PROCEDURE

Collomix

Collomix Aqix operating instructions

SPEX SamplePrep

SPEX SamplePrep 6875 Freezer/Mill Series operating manual

Ocean Insight

Ocean Insight FLAME-NIR+ Installation and operation manual

Parker

Parker ALIGN-MG-NA Installation, operation and maintenance manual