when:

- the equipment is set on the lowest temperature

- the equipment is positioned in an ambient with higher

temperature or relative humidity than above indicated

- the amount of displayed goods exceeds the maximum

recommended and the proper air circulation is prevented.

In those cases the goods are kept at higher temperatures, the

refrigerating unit has to run non-stop and ice may form on the

evaporator. It is necessary therefore to turn the equipment off to

allow the complete melting of the ice. During this phase do not

use any kind of sharp object to make the melting of the ice quicker,

because you could cause big damages to the equipment. Once the

ice is completely melted, switch the equipment on through the

ON/OFF switch (as indicated in paragraph 12).

17) DEFROSTING

The defrosting takes place automatically during the running of the

unit. The defrosting cycles are 6 a day and last for about 25’ each.

During the defrosting phase the temperature of the unit could be

altered, but when this cycle is over, in a short time the working

temperature will return to normal.

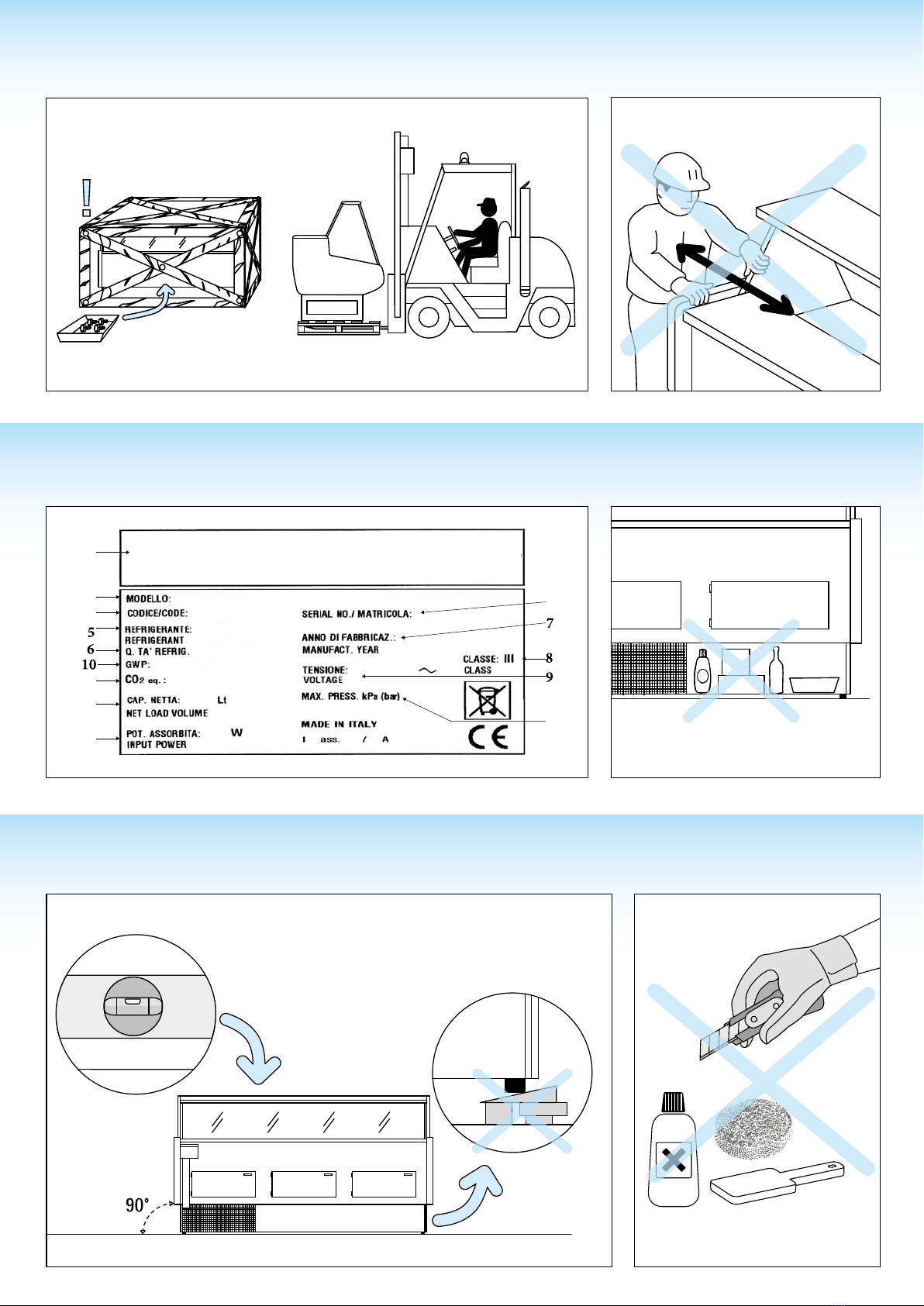

OBLIGATION

The water from defrost is collected in a drip tray that has

to be emptied manually when necessary. The plastic tray is

supplied with the counter and has to be placed below the

drain on the right side seen from the service side, as shown

in picture P.

It is possible to order the counter with electric evaporation

(optional).

18) PERIODICAL MAINTENANCE AND

CLEANING

We suggest to carry out a daily/weekly cleaning of the external

parts of the equipment and a monthly thorough cleaning of the

internal parts of the refrigerated cabinet for the good working, the

good preservation of the food and the aesthetics preservation of

the equipment. The cleaning has to be made by qualified people,

who should know the procedure described in this paragraph.

Attention! Before starting any cleaning operation it is

necessary to turn off the equipment by the on/off red

switch and to unplug or disconnect the equipment by the general

power security switch of your shop.

OBLIGATION

IMPORTANT – DURING THE WHOLE CLEANING

OPERATION USE WORKING GLOVES OF CLASS

II TO PROTECT YOUR HANDS ALL THE TIME

AND THE PERSONAL PROTECTIVE EQUIPMENT

ACCORDING TO THE LAW OF YOUR COUNTRY.

Remove all goods from the refrigerated unit and keep them in a

fridge or in a refrigerated ambient suitable for their preservation.

Carefully and thoroughly clean the display surface, the glasses,

the aluminium profiles, the door gaskets (if presents) with specific

cleaners for any surface.

PROHIBITION

Do not use acid and alkaline detergents, chemical / organic

solvents, unknown chemical composition detergents.

During the maintenance and cleaning it is forbidden to use

abrasive substances and/or sharp tools which can damage

the unit (fig. N).

After every cleaning operation it is necessary to rinse with warm

water and dry the unit with a soft and clean cloth.

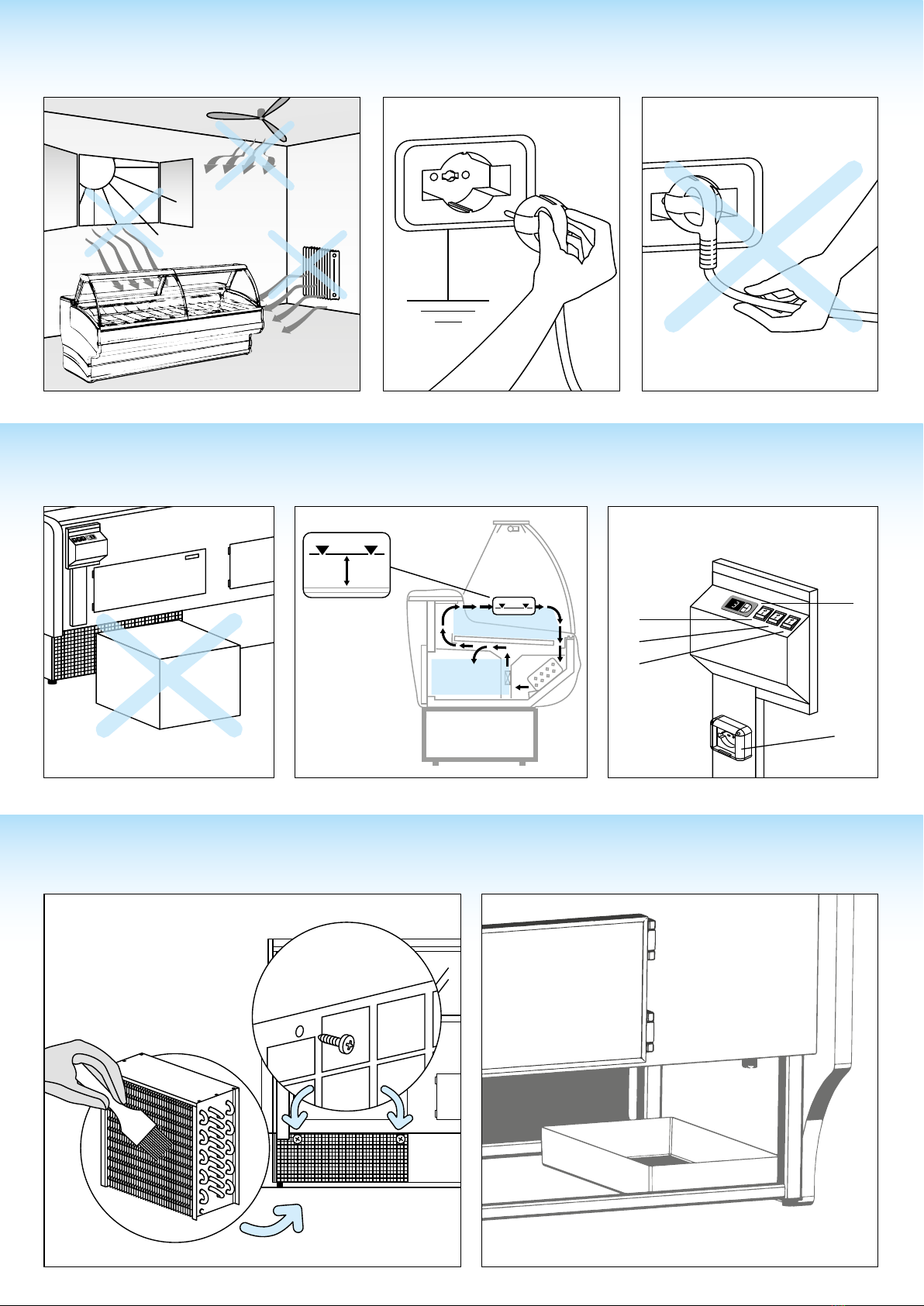

Clean the condenser, after having removed the cover grid (fig.

O), with a dry paint brush (do not use iron brushes - fig. N) or a

vacuum cleaner, removing all dust and possible deposits on the fins.

ATTENTION

During the maintenance and cleaning pay attention not to

bend or damage the fins and the whole refrigerating unit.

Never neglect this operation, as it is basic for the good working of

the unit and to avoid possible breakings. When you have finished

this operation, fit the cover grid in its original position.

When the cleaning operation is over, make sure that everything

is clean and dry before connecting the equipment to the power

supply again. When the unit reaches the correct working

temperature, it is possible to reload it. In case of long absences (i.e.

holidays etc.) the unit has to be unplugged, emptied completely,

cleaned and dried. Make sure to leave the doors open to prevent

bad smells.

A correct maintenance of the equipment can considerably prolong

its life.

19) TECHNICAL ASSISTANCE (servicing)

ATTENTION

If the equipment does not run properly or does not work

at all, in your own interest before calling for servicing, we

suggest to check the following points:

- if the plug is well inserted in the socket;

- if the power reaches the socket to which the equipment is

connected;

- if the thermostat is set as recommended;

- if the network voltage is the same as requested for the

equipment (+-6%);

- if the evaporator is covered with ice (in this case proceed

as indicated at paragraph 16);

- if the condenser is clean (paragraph 18);

- if there are air draughts, if the cabinet is installed in the

correct position (see paragraph 9) and if the ambient tem-

perature is as indicated (see paragraph 7).

20) REPLACEMENT OF LAMPS

The replacement and the substitution of lamps must be made by

qualified technician and when the unit is disconnected from the

power net.

Before replacing the lamp disconnect the equipment by the general

power supply. During the whole replacement operation use proper

working gloves.

21) EMERGENCY SITUATIONS

Devices to be used in case of fire: powder-extinguishers or liquid-

extinguishers complying with the current legislation.

22) DISMANTLING THE UNIT

OBLIGATION

The unit must be disposed of in accordance with your coun-

try’s waste management legislation.

ATTENTION

This equipment contains HFC, a coolant with a high green-

house effect potential (GWP).

The components of the refrigeration circuit must never be

cut and/or separated. They must be returned intact to a

specialized centre for the refrigerant recovery.

This appliance is hermetically sealed and the coolant load is

less than 3 kg.

OBLIGATION

IN CASE OF REQUEST FOR SERVICE, CONTROL

AND/OR REPLACEMENTS YOU WILL HAVE TO

CONTACT THE SUPPLIER WHERE THE CABI-

NET WAS BOUGHT.