4) Do not pull the electrical cable or the unit to unplug the equipment from the

socket (g. E).

5) Pay attention that the power supply cable is laid in such a way as to prevent it

from being damaged or becoming hazardous to people and things.

6) In case the power supply cable is damaged, it should be replaced only by a

qualied technician.

8) OPERATION START

After the refrigerated equipment has been installed and cleaned, the power supply

voltage has been checked and the plug has been connected, switch on the unit.

When the unit has reached the working temperature, put in the products already

cooled. Do not exceed the 2/3 of the available room with the product’s level. Leave

some room between the displayed products in order to allow a good airow and

never obstruct the air intake situated on the front side.

9) PERIODICAL

MAINTENANCE

We suggest to carry out a

thorough cleaning of the

counter once a month for

the good working, the good

preservation of the food and

the aesthetics preservation of

the equipment.The periodical

cleaning can be made by

qualied people, who should

know the procedure described

in this paragraph. Attention!

Before starting any cleaning

operation it is necessary to

turn off the equipment by

the on/off red switch and to unplug or disconnect the equipment by the general

power security switch of your shop.

IMPORTANT – DURINGTHE WHOLE CLEANING OPERATION USE

WORKING GLOVES OF CLASS II TO PROTECTYOUR HANDS ALL

THETIME.

Remove all goods from the refrigerated unit and keep them in a fridge or in a

refrigerated ambient suitable for their preservation.

Carefully and thoroughly clean the display surface, the shelves, the glasses, with

specic cleaners for any surface. Never use abrasive substances, metal pads or

other stuff which can damage the unit.

After every cleaning operation it is necessary to rinse with warm water and dry the

unit with a soft cloth.

Clean the condenser, after having removed the cover grid, with a dry paint brush

(g. G) or a vacuum cleaner, removing all dust. Pay attention not to bend or damage

the ns, the tubes or the blades of the fans. Never neglect this operation, as it is

basic for the good working of the unit and to avoid possible breakings.When you

have nished this operation, t the cover grid in its original position.

When the cleaning operation is over, make sure that everything is clean and dry

before connecting the equipment to the power supply again.When the unit reaches

the correct working temperature, it is possible to reload it. In case of long absences

(i.e. holidays etc.) the unit has to be unplugged, emptied completely, cleaned and

dried to prevent bad smells.

10) DEFROSTING

The defrosting takes place automatically during the running of the unit.The

defrosting cycles are 4 a day and last for about 30’ each and are controlled by the

thermostat in the electric control panel.

During the defrosting phase the temperature of the unit could be altered, but when

this cycle is over, in a short time the working temperature will return to normal.

The water from defrost is collected in a drip tray equipped with automatic

evaporation.

11) EL ECTRONIC THERMOSTAT

TEMPERATURE MODIFICATION

The thermostat is already set at the factory. In case the temperature is altered, the

manufacturer will not take any responsibility.Any modication will have to be made

by qualied people.

- Press

for 5 seconds to display the selected parameter value; press

or

to

reach the required temperature;

- Press

to conrm.

12)TEMPERATURE

The thermostat regulates the temperature into

the equipment and the working temperature is

already preset at the factory.

A lower performance must be expected from

the refrigerated unit when:

- the equipment is set on the lowest temperature

- the equipment is positioned in an ambient with higher temperature or relative

humidity than above indicated

- the amount of displayed goods exceeds the maximum recommended and the

proper air circulation is prevented.

In those cases the goods are kept at higher temperatures, the refrigerating unit has

to run non-stop and ice may form on the evaporator. It is necessary therefore to

turn the equipment off to allow the complete melting of the ice.

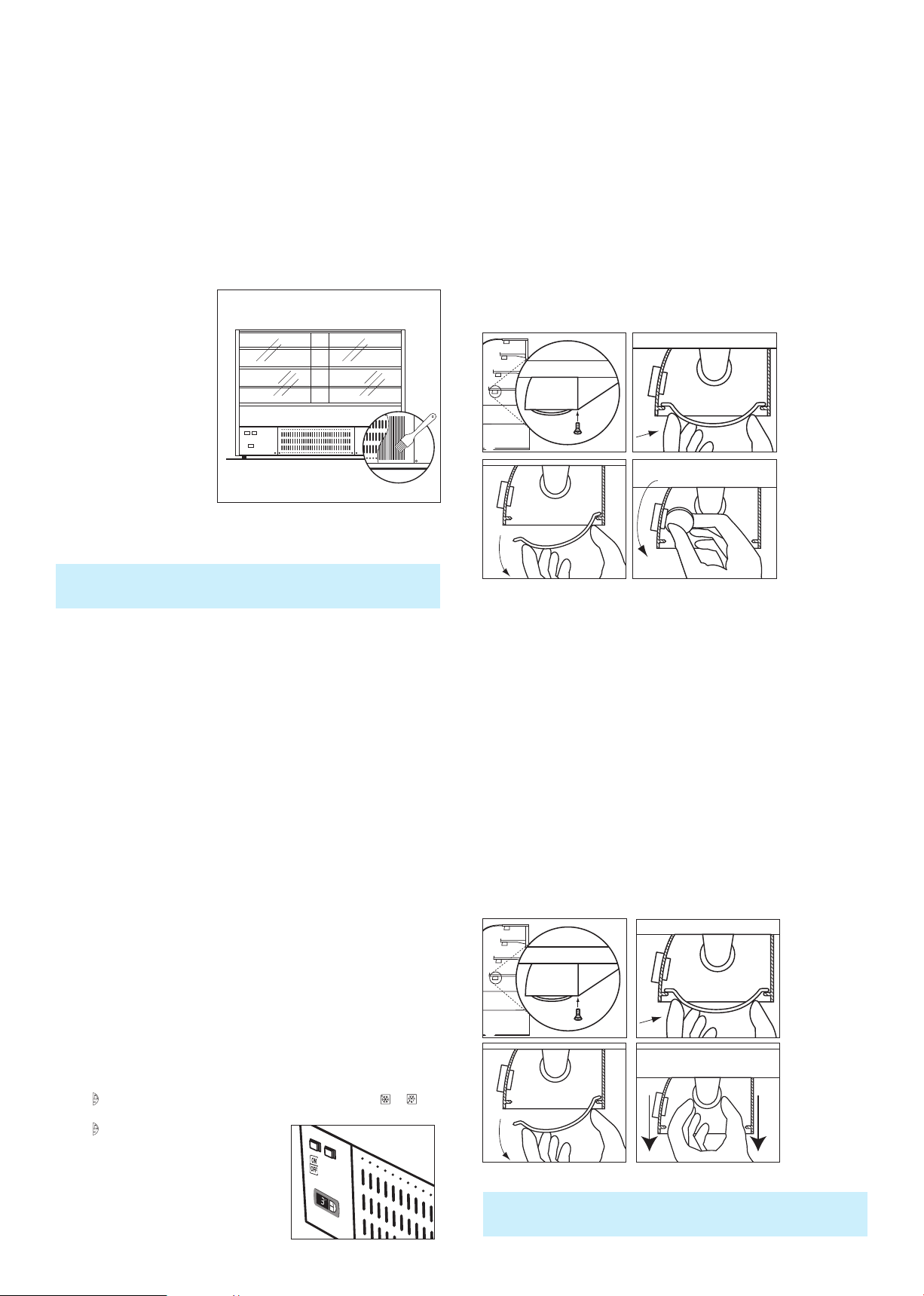

13) REPLACEMENT OFTHE THERMOMETER BATTERY

Before replacing the thermometer battery it is necessary to turn off the equipment

by the on/off red switch and to unplug or disconnect the equipment by the general

power supply.

1) Unscrew the screws of the plastic cover.

2-3) Press the plastic cover on the front part ant let it turn downwards.

4) Using a coin unscrew the battery cover and replace the battery.

5) For the assembling repeat the operation on the contrary way.

14)TECHNICAL ASSISTANCE (servicing)

If the equipment does not run properly or does not work at all, in your own

interest before calling for servicing, we suggest to check the following points:

1) if the plug is well inserted in the socket;

2) if the power reaches the socket to which the equipment is connected;

3) if the thermostat is set as recommended;

4) if the network voltage is the same as requested for the unit (+-6%);

5) if the evaporator is covered with ice (in this case proceed as indicated at

paragraph 12);

6) if the condenser is clean (see paragraph 9);

7) if there are air draughts, if the cabinet is installed in the correct position (see

paragraph 5) and if the ambient temperature is as indicated (see paragraph 4).

15) REPLACEMENT OF LAMPS (neon tube)

The replacement and the substitution of lamps must be made by qualied technician

and when the unit is disconnected from the power net.

1) Before replacing the lamp disconnect the equipment by the general power supply.

2-3) Unscrew the screws of the plastic cover and take it out by pressing it on the

front part.

4) Unfasten the neon tube from the steel hook and take the neon tube out.

5) For the assembling repeat the operation on the contrary way.

IN CASE OF REQUEST FOR SERVICE, CONTROL AND/OR

REPLACEMENTSYOU WILL HAVE TO CONTACTTHE SUPPLIER

WHERETHE CABINET WAS BOUGHT.

G

43

2

1

23

43