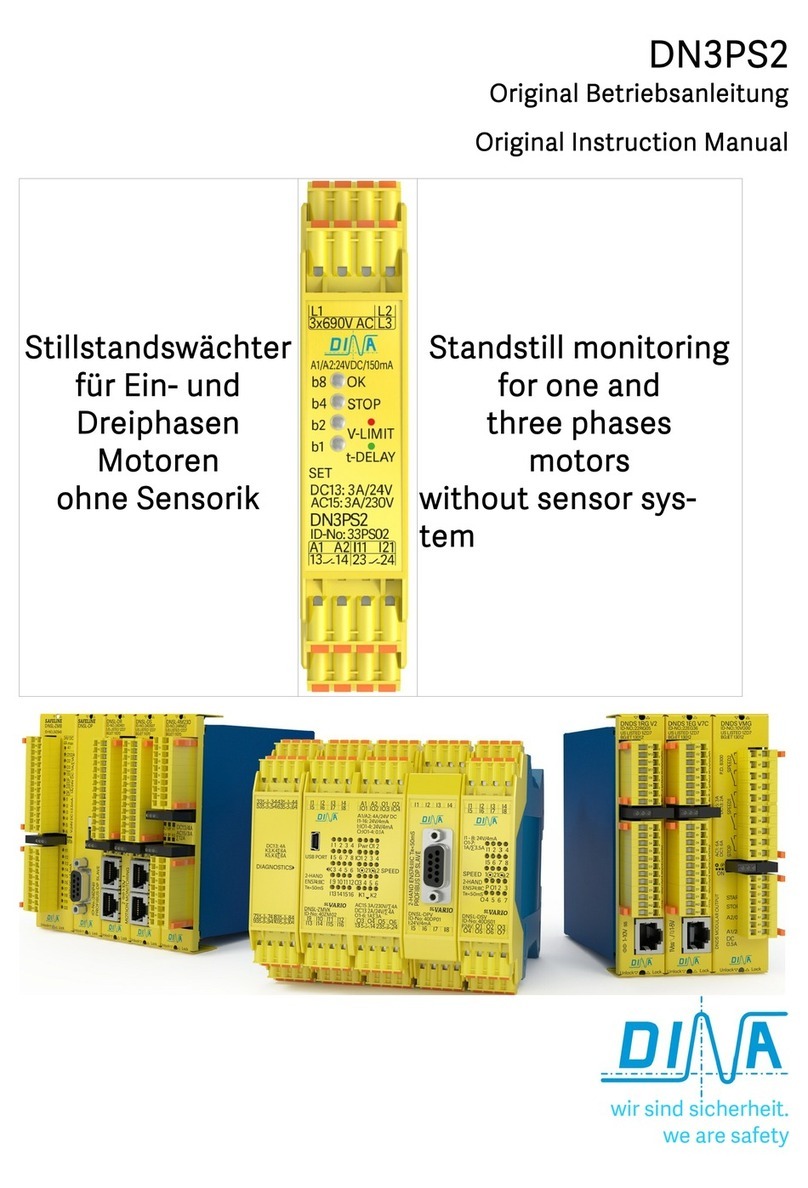

DINA DN3PD1 User guide

DN3PD1

Original Instruction Manual

valid for ID-No: 33PD02

Safety switchgear

to monitor the speed of three-phase and

single-phase motors without sensor

we are safety.

18-09-27 / 33pd02-V0743 3

EU-Konformitätserklärung

EC-Declaration of Conformity

DINA Elektronik GmbH

Esslinger Str. 84

72649 Wolfschlugen

Germany

Phone +49 7022 95170

Fax +49 7022 9517700

info@dina.de

www.dina.de

Wir erklären, dass folgendes Produkt die einschlägigen Harmonisierungsrechtsvorschriften der Union erfüllt.

We declare that the following product is in conformity with the relevant Union harmonization legislation.

Produkt/ product

Beschreibung/ Description

DN3PD1

Sicherheitsschaltgerät zur sensorlosen Drehzahlüberwa-

chung bei Ein- und Dreiphasen Motoren

Safety switchgear unit to monitor the speed of 3-phases

and single phase motors without sensor

EU-Richtlinien/ EC- directives

Angewandte Normen/ Applied standards

2006/42/EG Maschinenrichtlinie/ Machinery-Directive

2014/30/EU EMV-Richtlinie/ EMC-Directive

2011/65/EU RoHS Richtlinie/ RoHS-Directive

EN ISO 13849-1: 2015

IEC 62061: 2015

IEC 61800-5-2: 2016

IEC 61508: Parts 1-7:2010

EN 50178: 1997

EN 60204-1: 2006 + A1:2009 + AC:2010

EN 60947-5-1:2010

EN 61326-1: 2013

EN 61326-3-1: 2008 + Entwurf 2015 SIL3

GS-ET-20: 2016-10

Notifizierte Stelle

Notified Body

EG Baumusterprüfbescheinigung

EC Type Test

TÜV Rheinland Industrie Service GmbH

Am Grauen Stein

51105 Köln

Germany

NB 0035

Reg.-Nr.: /No.: 01/205/5650.01/18

Wolfschlugen, 24.07.2018

Dirar Najib

CEO

DN3PD1

Inhaltsverzeichnis

418-09-27 / 33pd02-V0743

Content

1Intended Use 6

Approvals 6

Safety parameters 6

Ordering data 6

2Safety regulations 7

3Important information and validation 7

4Function description 8

Switching threshold 8

Start-up monitoring 8

Minimum switch-off time 8

Acknowledge function 8

Functional diagram 9

Schematic, operating element and display 10

Terminal description 10

5Applications 11

Motor with frequency converter 11

Motor with star-delta circuit 11

Single-phase motor 11

6Mounting and removal 11

Wiring 12

Commissioning 12

Example of application 12

7Parameterization of the switching thresholds 13

Important notes for parameterization 13

Table of frequencies 13

Configuration of the switching threshold and acknowledgement 14

Example for configuration 15

8Diagnostics 16

Error report 16

9Technical data 17

Ambient conditions 17

Input data 17

Output data 17

General data 17

Connection data 17

Relay load curve 18

10 Dimensions 18

DN3PD1

18-09-27 / 33pd02-V0743 5

Always read the additional applicable online documentation before working on/with the safety

switchgear. Make sure you always work with the valid documentation. This is available online at

http://www.dina.de/downloads/

Dispose of the device according to the national environmental regulations.

Symbol and Notes:

WARNING

Observe the safety regulations and installation notes in the corresponding section.

INFO

Observe the notes in the corresponding section.

Version overview / Change history

Version

Date

valid for ID-No

Innovations / changes

0743

2018-09-27

33PD02

DN3PD1

Intended Use

618-09-27 / 33pd02-V0743

1Intended Use

•Safety switchgear to monitor the speed of three-phase and single-phase motors without sensor.

•Two speed thresholds are possible: minimum speed and maximum speed.

•The unit meets Cat. 4/ PL e acc. to ISO 13849-1, SIL (CL) 3 acc. to IEC 62061 and IEC 61508.

•Usage in safety current circuit according to VDE 0113 T.1

Approvals

Safety parameters

The unit meets Cat. 4/ PL e and SIL (CL) 3.

Parameter

Value

Note

PFH

1,56 E-09 1/h

1,6 % von SIL 3

MTTF

d

553 a

HIGH

DC

avg

95%

(HIGH)

table 1-1: Safety parameters

Ordering data

Description

Type

ID-No.:

Speed monitoring, sensorless 0-600Hz, 2 contact outputs,

start-up monitoring DN3PD1 33PD02

DN3PD1

Safety regulations

18-09-27 / 33pd02-V0743 7

2Safety regulations

•The device may only be installed and commissioned by an electrician or trained persons who are familiar

with these operating instructions and the applicable regulations regarding work safety and accident pre-

vention.

•Observe the VDE, EN and local regulations, particularly with respect to the protective measures.

•Failure to observe the regulations may result in death, severe bodily injury or extensive property damage.

•For emergency-stop applications, either the integrated function for restart interlock must be used or au-

tomatic restarting of the machine must be prevented by means of a higher-level control.

•During transport, storage and operation, adhere to the conditions specified in EN 60068-2-1, 2-2!

•Unauthorized modifications shall render any warranty null and void. Dangers may thereby arise that

could result in severe injuries or even death.

•Install the device in a control cabinet with a protection class of at least IP54! Dust and moisture may oth-

erwise result in impaired functions. Installation in a control cabinet is mandatory.

•Ensure adequate protection circuits at output contacts for capacitive and inductive loads!

•The device is to be installed taking into account the distances required per DIN EN 50274, VDE 0660-514.

•During operation, switching devices carry dangerous voltage. Do not remove protective covers.

•Replace the device after the first malfunction.

•Properly dispose of the device at the end of its service life.

•If these regulations are not adhered to or in the event of improper use, DINA Elektronik GmbH accepts

absolutely no liability for the resulting property damages or personal injury.

•Save this product information!

3Important information and validation

•The product described here was developed to perform safety-related functions as part of a complete

system.

•The complete system consists of sensors, evaluation and message units as well as concepts for safe

shutdowns.

•It is the responsibility of the manufacturer of a system or machine to ensure the proper overall function.

•The manufacturer of the system is required to test and to document the effectiveness of the

implemented safety concept within the complete system.

In this case, it must be checked whether the release contacts open when exceeding or falling below the

thresholds.

•This verification is to be performed after every modification to the safety concept or to safety parameters.

•DINA Elektronik is not in the position to guarantee the properties of a complete system that was not

designed by DINA.

•DINA Elektronik GmbH also accepts no liability for recommendations that are given or implied by the fol-

lowing description.

•No new guarantee, warranty or liability claims that extend beyond DINA's general delivery conditions can

be derived on the basis of the following description.

•To avoid EMC disturbances, the physical environmental and operating conditions at the installation

location of the product must comply with section EMC of DIN EN 60204-1.

•When using contact outputs, the safety function must be requested once a day at PL e and once a year at

PL d according to IEC 61800-5-2.

•Observe the general technical data at the end of this operating manual.

DN3PD1

Function description

818-09-27 / 33pd02-V0743

4Function description

The two-channel evaluation unit of the safety switchgear module measures the frequency of the effective rotat-

ing field of the motor at the measuring terminals L1, L2, L3.

If the parameterized switching threshold frequencies are exceeded or undershot (V-LIMIT 1 and V-LIMIT 2), or an

internal or external fault exists, the enabling current paths 13/14, 23/24 open immediately. The device is in safe

switching state.

The monitoring of V-LIMIT 1 can be deselected. Then the output contacts remain closed at standstill.

Asynchronous motors have a load-dependent slip between the motor speed and the rotating field frequency. This

must be observed by the configuration of the switching threshold (V-LIMIT 1 and V-LIMIT 2).

Switching threshold

Two switching thresholds are configurable.

V-LIMIT 1: minimum speed

If V-LIMIT 1 is undershot, the output contacts (13-14 / 23-24) switch off.

They switch on again after the acknowledgment via the acknowledgment input Q.

Depending on the acknowledgment mode, the switch-on-conditions differ. Please note the chapter

"Function diagram".

V-LIMIT 2: Maximum speed

If V-LIMIT 2 is exceeded, the output contacts (13-14 / 23-24) switch off.

They switch on again after the acknowledgment via the acknowledgment input Q, if V-LIMIT 2 (minus hysteresis)

is undershot.

Switching on takes place at the earliest after 0.5 seconds. (see chapter minimum switch-off time)

Start-up monitoring

The startup monitoring tAis a time limit within which the actual speed must be greater than V-LIMIT 1. If the mini-

mum speed is not reached during this time, the enable current path opens again.

The start-up monitoring time is fixed and is 60s. It is not retriggerable, it cannot be restarted while it is running.

The start-up monitoring time starts

•In case of manual acknowledgment: with the falling edge of the acknowledge signal

•In case of automatic acknowledgment: if the actual speed is> 1Hz

The startup monitoring is omitted if V-LIMIT 1 has been deselected.

Minimum switch-off time

The minimum switch-off time tmin is the time that the enable current path is at least open after triggering before it

switches on again. It is 0.5s.

Acknowledge function

•With the acknowledgment function, the enable current path is switched on again after a shutdown due to

underspeed or overspeed.

•The acknowledgment takes place via the input Q.

•Automatic or manual acknowledgment is possible.

•With automatic acknowledgment, the Q input must always be connected to 24V DC.

•A manual acknowledgment takes place after a falling signal edge at the input Q (tQ ≥ 200ms and ≤ 10s).

DN3PD1

Function description

18-09-27 / 33pd02-V0743 9

•Signal that is longer than10s does not cause a reset.

•For parameterization of the acknowledgment function see chapter " Configuration of the switching

threshold and acknowledgement".

Functional diagram

Automatic acknowledgement V-LIMIT 1 and V-LIMIT 2

(V-LIMIT 1 must be at least 1.1Hz!)

Manual acknowledgment V-LIMIT 1 and V-LIMIT 2

1

Start-up monitoring time starts if f>1Hz

1

Start-up monitoring time starts with the falling

edge of the acknowledgement signal.

2

Start-up monitoring time is expired. Enabling

current path remains closed because f>V-LIMIT

1.

2

Start-up monitoring time is expired. Enabling

current path remains closed because f>V-LIMIT

1.

3

Enabling current path opens because f<V-LIMIT

1.

3

Enabling current path opens because f<V-LIMIT

1.

4

Enabling current path closes, if f<0,5Hz.

4

Start-up monitoring time starts with the falling

edge of the acknowledgement signal.

5

Start-up monitoring time starts if f>1Hz.

5

Start-up monitoring time is expired. Enabling

current path opens because f < V-LIMIT 1.

6

Start-up monitoring time is expired. Enabling

current path opens because f < V-LIMIT 1.

6

Start-up monitoring time starts again.

7

The setpoint speed was reached outside of the

minimum switch-off time. Enabling current path

closes.

7

Start-up monitoring time is expired. Enabling

current path remains closed.

8

The setpoint speed was reached within the min-

imum switch-off time. Enabling current path

closes after 0.5s.

8

Enabling current path closes because

V-LIMIT 1<f<V-LIMIT 2.

Hysteresis

f

Q-autom.

V-LIMIT2

13/14, 23/24

1 Hz

0,5 Hz

V-LIMIT1

Hysteresis

t

A

>t

min

<t

min

t

A

1 2 3 54 6 7 8

Hysteresis

f

Q-manuell

V-LIMIT2

13/14, 23/24

V-LIMIT1

Hysteresis

t

A

t

A

t

A

1235

467 8

DN3PD1

Function description

10 18-09-27 / 33pd02-V0743

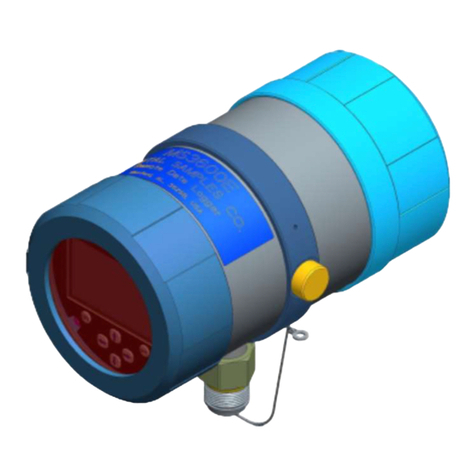

Schematic, operating element and display

OK

SPEED

24 V DC

A1 A2 O1 O2

L1

13 14 23 24Q

b8

L3 L2

b4

b2

b1

SET

L1, L2, L3

Measuring inputs

A1 Power supply

+24V DC

A2 0V

Q Acknowledgment in-

put

O1, O2 Diagnostics outputs

13-14/23-24 Enabling contacts

SET Configuration button

b1, b2, b4, b8 parameter 1-15

OK Ready for operation

SPEED Speed Status

Terminal description

A1/ A2 Power supply 24V DC

L1, L2, L3 Measuring inputs are to be connected directly to the motor, without switching contacts between.

Q Acknowledgment input can be parameterized, manually or automatically

13/14, 23/24 Enabling contacts (2 NO-contacts). These switch off immediately if the parameterized speeds are

undershot or exceeded or internal or external errors.

13/14, 23/24 are to be used in such a way that the intended safety function, e.g. emergency stop is

executed.

O1, O2 Digital positive switching semiconductor outputs for the transmission of switching states to a

higher-level control for diagnostic tasks.

DN3PD1

Applications

18-09-27 / 33pd02-V0743 11

5Applications

Motor with frequency converter

The operation on electric power drive systems with adjustable

speed is possible. (Frequency converter)

L1

L2

L3

U1V 1W1

24V DC

Test?

FU/ FC

M

V1U2

U1

W2 W1

V2

3

L1

L2

L3

A1

A2

Q 13

14O1

23

24O2

DN3PD1

b1

b2

b4

b8SET

Motor with star-delta circuit

Operation on motors with star-delta connection or pole

changeover is possible. For pole-changing motors, please note

that DN3PD1 detects the frequency and not the speed!

The measuring inputs L1 and L3 are bridged and directly con-

nected to W1 on the motor.

The measuring input L2 is directly connected to W2 on the mo-

tor.

3M

L1

U1

U2

V 1

V 2 W 2

W 1

L2 L3

24V DC

L1

L2

L3

A1

A2

Q 13

14O1

23

24O2

DN3PD1

b1

b2

b4

b8 SET

Single-phase motor

Operation on a single-phase motor is possible.

The measuring inputs L1 and L3 are bridged and directly con-

nected to U1 on the motor.

The measuring input L2 is directly connected to U2 on the mo-

tor.

1

M

L

N

U1 U2

Test? 24V DC

L1

L2

L3

A1

A2

Q 13

14O1

23

24O2

DN3PD1

b1

b2

b4

b8 SET

6Mounting and removal

Mounting on 35mm DIN rail according to EN 60715

For the removal pull the lock device using a screwdriver

Required distances according to DIN EN 50274, VDE 0660-514 must be observed

No strong magnetic fields in the installation vicinity. (Magnetic fields < 30 A/m). These can interfere with the unit.

Mounting

70-75mm

70-75mm (1) (2) (3)

(1) DIN rail

(2) lock device

(3) cable channel

Removal

DN3PD1

Mounting and removal

12 18-09-27 / 33pd02-V0743

Wiring

•Conductor cross-section of 1.5 mm² must not be undercut.

•Use Copper wires approved up to 60°C/75°C.

•For of wire end sleeve is recommended.

•Loads connected to the measuring wires are not allowed.

•The placing of the measuring wires has to avoid a cross connection or short. Laying in cable channel.

•The regulations according to EN 60204-1 are to be followed.

•Use effective protective circuits parallel to an inductive load to avoid a shortcut of the output contacts.

•The arrangements of the overcurrent protective mechanism are to consider.

•Overvoltage > 32V DC destroys the unit.

•Use power supply with max. 32V output voltage also with fault..

Commissioning

•Switch off the unit befor you start working.

•Wire the unit according to intended use

•Connect the power supply 24V DC to A1 and 0V to A2.

•Self-test follows. After faultless self-test the unit is in function. The LED OK is green

Example of application

Application: Output contacts connected in parallel

L1

L2

L3

U1V 1W1

24V

L1

L2

L3

A1

A2

Q 13

14O1

23

24

O2

DN3PD1

14

NC

FU/ FC

Test?

b1

b2

b4

b8 SET

≤ 3A

≤ 3A

∑6A

M

V1

U2

U1

W2W1

V2

3

24

14

24

Application: Output contacts connected in series

L1

L2

L3

U1 V 1 W1

24V

L1

L2

L3

A1

A2

Q 13

14O1

23

24O2

DN3PD1

NC

FU/ FC

Test?

b1

b2

b4

b8 SET

2323

≤ 3A

M

V1U2

U1

W2 W1

V2

3

DN3PD1

Parameterization of the switching thresholds

18-09-27 / 33pd02-V0743 13

7Parameterization of the switching thresholds

Important notes for parameterization

•Use a VDE-insulated screwdriver according to EN 60900 to press the SET button.

•The switching threshold and acknowledgement must be set correctly in order to ensure safe operation;

this responsibility lies with the user.

•To determine the switching thresholds, the number of pole pairs must be taken into account:

•f [Hz]= n [U/min] / 60 x number of pole pairs

•Example: 5000 rev/min x 3 (number of pole pairs) / 60 = 250Hz

•During parameterization, the output contacts are switched-off.

•The parameters are not saved by voltage break or break of the parameterization for longer than 20s.

•Frequency of (V-LIMIT 2 -10%) must be higher than (V-LIMIT 1).

•On automatic acknowledgement must be V-LIMIT 1 ≥ 1,1Hz .

•The monitoring of a minimum speed can be deselected. In this case, the lowest frequency for V-LIMIT 1

should be selected. There is no distance to keep to V-LIMIT 2. The output contacts remain closed at

standstill.

Table of frequencies

These frequencies can be set as switching thresholds.

Level x.1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Level x.2

1

0,15

1,26

1,96

3,05

4,8

7,4

11,5

18,0

28,00

43,6

68,0

104

159

255

396

2

0,20

1,29

2,02

3,14

4,9

7,6

11,9

18,5

28,8

44,9

70,0

106

163

263

408

3

0,30

1,33

2,08

3,24

5,04

7,9

12,2

19,1

29,70

46,3

72,1

109

167

270

418

4

0,40

1,37

2,14

3,33

5,2

8,1

12,6

19,6

30,6

47,7

74,3

112

172

278

431

5

0,50

1,41

2,20

3,43

5,35

8,3

13,0

20,2

31,5

49,1

76,5

116

178

287

443

6

0,60

1,46

2,27

3,54

5,5

8,6

13,4

20,8

32,5

50,6

78,8

119

181

295

458

7

0,70

1,50

2,34

3,64

5,7

8,8

13,8

21,5

33,4

52,1

81,1

123

187

304

471

8

0,80

1,55

2,41

3,75

5,8

9,1

14,2

22,1

34,4

53,7

83,6

126

291

314

485

9

0,90

1,59

2,48

3,86

6,0

9,4

14,6

22,8

35,5

55,3

86,1

130

196

323

500

10

1,00

1,64

2,55

3,98

6,2

9,7

15,1

23,5

36,5

56,9

88,7

134

214

333

514

11

1,05

1,69

2,63

4,10

6,4

10,0

15,5

24,2

37,6

58,6

91,3

138

221

342

529

12

1,10

1,74

2,71

4,22

6,6

10,3

16,0

24,9

38,8

60,4

94,1

142

227

353

544

13

1,15

1,79

2,79

4,35

6,8

10,6

16,5

25,6

39,9

62,2

97,5

147

234

363

560

14

1,18

1,85

2,88

4,48

7,0

10,9

17,0

26,4

41,1

64,1

100

150

240

374

575

15

1,22

1,90

2,96

4,61

7,2

11,2

17,5

27,2

42,0

66,0

102

155

247

385

594

DN3PD1

Parameterization of the switching thresholds

14 18-09-27 / 33pd02-V0743

Configuration of the switching threshold and acknowledgement

The current settings can be checked by briefly pressing the SET button. The LEDs show the parameters binary

coded in five steps (Level). Two levels each determine V-LIMIT 1 and V-LIMIT 2 (see frequency table), the fifth level

indicates the type of acknowledgment.

The permanent pressing of the SET button starts the parameterization mode and the levels can be run through.

Releasing the button allows you to change this level parameter. The configuration can be adjusted by a short

touch of the button. The new setting is saved again by pressing the button permanently.

Each level can be recognized by its flashing rhythm or the LED color.

V-LIMIT 1

V-LIMIT 2

Acknowledgement

1.1: column 1.2: row 2.1: column 2.2: row autom./manual

SET

b8

b4

b2

b1

Adjusting by briefly pressing the SET button

Save: press SET button >1s

Press SET button for >2s until all LED flash green.

Adjust V-LIMIT 1, Level 1.1 binary coded by short key press (column of the table 7-1)

Keep the SET button pressed: The value is saved and displayed as continuous light.

Keep the SET button pressed until the blinking rhythm of all LEDs changes.

Adjust V-LIMIT 1, Level 1.2 binary coded by short key press (row of the table 7-1).

Keep the SET button pressed: The value is saved and displayed as continuous light.

Keep the SET button pressed until the color of all LEDs changes.

Adjust V-LIMIT 2, Level 1.1 binary coded by short key press (column of the table 7-1)

Keep the SET button pressed: The value is saved and displayed as continuous light.

Keep the SET button pressed until the blinking rhythm of all LEDs changes.

Adjust V-LIMIT 2, Level 1.2 binary coded by short key press (row of the table 7-1).

Keep the SET button pressed. The value is saved and displayed as continuous light.

Keep the SET button pressed until the LED flash in pairs.

Adjust the acknowledgement*) by short key press

Keep the SET button pressed: The value is saved and displayed as continuous light.

Release the button. The configuration is completed. The unit is ready for operation, if the OK LED shows

green.

*) Adjust the acknowledgement

b8

b4

b2

b1

-

b8

b4

b2

b1

manual SET automatic

The set thresholds must be validated as follows:

Checking the set parameters in the display mode (short pressing of the SET key) and verification of

the correct safety functions by checking the shutdown speeds, e.g. by comparison with the speed dis-

played on the frequency converter or use of other suitable speed measuring equipment.

Level

DN3PD1

Parameterization of the switching thresholds

18-09-27 / 33pd02-V0743 15

Example for configuration

V-LIMIT 1 = 1,0 Hz V-LIMIT 2 = 297,9 Hz

Acknowledgement

Level 1.1

Level 1.2

Level 2.1

Level 2.2

manual

column 1

row 10

column 14

row 6

b8

b4

b2

b1

b8

b4

b2

b1

b8

b4

b2

b1

b8

b4

b2

b1

b8

b4

b2

b1

DN3PD1

Diagnostics

16 18-09-27 / 33pd02-V0743

8Diagnostics

The 2-color LEDs (b1, b2, b4, b8) indicate operational readiness, switching status, internal and external errors.

The semiconductor output O1 is switched on when the frequency is within the parameterized range. See Fig. 8-1

The semiconductor output O2 indicates the operational readiness. This switches off in case of an error.

LED OK

LED SPEED

O1

O2

13/14, 23/24

Status

green

green

24V

24V

acknowledged

in range

green

off

0V

24V

not acknowledged

out of range

green

flashing green

0V

24V

acknowledged

out of range

green

off

24V

24V

not acknowledged

in range

flashing red

off

0V

0V

error

see error report

Fig. 8-1

Error report

The red flashing LED OK signals an error condition.

The flashing variations for different causes of faults are shown below.

flashing variation

possible cause

remedy

1s

1x 1x 1s 1x

incorrect power supply

UB < 20V or > 32V UB=20.5V-26,5V DC

1s

… 2x … 2x 1s … 2x

(V-LIMIT 2) < (V-LIMIT 1)

(V-LIMIT 2 – 10%) > (V-LIMIT 1)!

1s

… 3x … 3x 1s … 3x

incorrect acknowledge signal

Q < 200ms or > 10s Q ≥200ms, <10s

1s

… 4x … 4x 1s … 4x

open-circuit on L1, L2, L3

check on

short circuit

cross-connection

wire break

1s

… 5x … 5x 1s … 5x

single-channel measuring

check on

short circuit

cross-connection

wire break

1s

… 6x … 6x 1s … 6x

relay error

check on external error

switch off, switch on

exchange

1s

… ≥7x … ≥7x 1s … ≥7x

internal error switch off, switch on

exchange

DN3PD1

Technical data

18-09-27 / 33pd02-V0743 17

9Technical data

Ambient conditions

Ambient temperature (operation)

-20 to +55°C DIN IEC 60068-2-3

Ambient temperature (storage)

-40 to +85°C DIN IEC 60068-2-3

Maximum altitude

max. 2000m (above sea level)

Vibration resistance 3 axis

Sinus 10–55Hz, 0,35mm, 10 cycles, 1 octave/min

Air and creepage distances

DIN EN 50178, safe isolation

Protection class

Installation in a closed cabinet, min. IP54

Input data

Operating voltage UB

24V DC -15 % / +10 %, reverse protection

Current draw at 24V DC

typ. 80mA

Current draw at L1, L2, L3

0,35mA at 690V AC

Input voltage at L1, L2, L3

90 to 690V AC

Input frequency at L1, L2, L3

≤ 600 Hz

Switching hysteresis

10%

Power consumption at A1/ A2

typ. 1,9W

Status display

4 x LED 2-color

Protection wiring

Overvoltage/ inverse polarity protection

Output data

Contact type

2 enabling NO-contacts

Contact material

AgSnO

2

Operating voltage

24V DC / 230V AC

Minimum switching current

3 mA/ 24V DC

Maximum switching current

6A / 24V DC/ 230V AC

Short-circuit strength

1000A SCPD 6A gL/gG

Mechanical life

107switching cycles

Reaction time

Up to 30 Hz: 1 period (reciprocal value of the set frequency) + 10ms

Over 30 Hz: 3 x 1 period + 10ms

Output fuse

6 A gL/gG

B10d values acc. to

DIN EN 61810-2-1, 01.2012

AC15: 5A/230V AC, >2x105,

AC1: 6A/230V AC, >2x105

DC13: 4A/24V DC, >3x105

DC1: 6A/ 24V DC, >7x105switching cycles

Total current 13-14 and 23-24

with parallel connection: 6A

with serial connection: 3A

Outputs O1, O2

≤ 100mA( UB-1V) shot-circuit and overload protection

General data

Nominal operating mode

100 %

Protection class

IP20

Mounting position

vertical or horizontal

Housing material/ Type

Polyamide PA not increased/ ME/ Phoenix Contact

Dimensions

B x H x T/ 22,5 x 114 x 111 mm

Degree of pollution

2

Overvoltage category

III

Connection data

Terminals/ Material

Push-in, pluggable/ PA

Screw, pluggable /PA

Number of pins

4

5

3

Rated surge voltage

4kV

2,5kV

8kV

Rated insulation voltage

320V

160V

1000V

Conductor cross-section, flexible

with wire end sleeve

0,25 - 2,5mm2

0,25 - 1,5mm2

0,25 - 2,5mm2

Conductor cross section AWG

24…12

24…16

24…12

Connection wire

60/75°C Copper

Tightening torque min/max

-

-

0,5Nm/0,6Nm

DN3PD1

Dimensions

18 18-09-27 / 33pd02-V0743

Relay load curve

L / R = 0 ms

4610

5

3

2

1

0.5

0.4

0.30.1 0.2

1000

300

10

DC Spannung / DC voltage

DC Schaltstrom (A) / DC Switching current (A)

200

100

50

40

30

20 L / R = 40 ms

ohmic load L/R = 0ms

inductive load L/R = 40ms

WARNING

Loads with high capacitive component can destroy the output contacts because the switching cur-

rent is very high.

10 Dimensions

111

114

22.5

we are safety.

DINA Elektronik GmbH

Esslinger Str. 84

D72649 Wolfschlugen

Phone +49 7022 95170

Fax +49 7022 9517700

www.dina.de

Other manuals for DN3PD1

1

Table of contents

Other DINA Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

SIRETTA

SIRETTA SNYPER-LTE graphyte user manual

ADCMT

ADCMT 4601 I-V Meter Operation manual

AeroDiode

AeroDiode Cool & Control Series operating manual

ELECTROMATIC

ELECTROMATIC Check-Line RH1 Calibration guide

Pfeiffer Vacuum

Pfeiffer Vacuum IKR 261 operating instructions

Envira IOT

Envira IOT Nanoenvi IAQ user manual