Dini Argeo 3590EGT Series Instruction manual

www.diniargeo.com

CONNECTION DIAGRAMS ENGLISH

3590ET / 3590EGT

Touch screen indicator

3

3590ET / 3590EGT

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

Table of contents

Introduction 4

Electrical warnings 5

Electrical precautions 5

Cable classification 5

Recommended distance between cables 6

Maximum permitted length of cables 6

Earthing system 7

Example of weighbridge earthing 8

Example of silos earthing 9

Motherboard 10

I/O expansion board 12

Optional internal board for rapid connection of multiple scales 13

RJ45 RS232 connector board 13

RS232 / RS485 to Ethernet / WIFI conversion board 14

USB support data saving board 16

RADIO communication board 17

PROFIBUS communication board 17

BLUETOOTH communication board 18

RADIO REMOTE CONTROL board 18

Circuit breaker against electrostatic loads 18

Analog output 19

Traffic light 20

RS485 20

RS485 opto-isolated board 21

Display board 21

4

3590ET / 3590EGT

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

Dear Customer,

Thank you for purchasing a DINI ARGEO product.

This manual contains all instructions for proper installation of the weight indicator with touch screen series 3590.

We thank you for purchasing this scale and we kindly ask you to take note of certain aspects of this manual:

This booklet provides useful information for proper operation and maintenance of the scale referred to herein. It is important to pay the

utmost attention to all the sections that illustrate the simplest and safest way to operate the device.

This publication, or portions thereof, may not be duplicated without written permission from the Manufacturer.

All information herein is based on the data available at the time of publication. The Manufacturer reserves the right to make changes

to its products at any time without notice and without incurring any penalty. We therefore recommend that you always check for any

updates.

N.B.: The individual in charge of operating the scale must ensure that all safety regulations in force in the country of use are applied,

ensuring that the appliance is used in accordance with the purpose it is intended for and to avoid any danger for the user.

The manufacturer declines any liability arising from any weighing operation errors.

We recommend carefully following the instructions when programming the weight indicator, as to do otherwise could jeopardise proper

scale operation.

This manual was written with the utmost care but we always welcome feedback on any inaccuracies you may find.

The instrument is covered by warranty and MUST NOT BE TAMPERED WITH BY THE USER for any reason.

Any attempt to repair or modify the device could expose the user to the risk of electrical shock and will render all warranty conditions

null, thus releasing the Manufacturer from all liability.

All problems with the unit or system must be communicated to the manufacturer or the dealer from which it was purchased. In any

case, DISCONNECT POWER before any operations.

Introduction

5

3590ET / 3590EGT

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

• Mains power supply adjusted within ± 10% of the nominal voltage

• Electrical protections (fuses, etc.) are to be provided by the installer.

• Comply with the minimum recommended distances between different categories of cables.

• The load cell or signal amplifier extension cables, which are used for serial port and analog output connection, must com-

ply with the maximum permitted lengths.

• The load cell or signal amplifier extension cables, which are used for serial port and analog output connection, must be

shielded and must also be inserted alone into the conduit or metal pipe.

• Cell or amplifier cable input into the electrical panel must be autonomous. If possible, they must be connected directly to

the indicator’s terminal board without passing through the conduit with other cables.

• Install an “RC” filter on coil contactors, solenoid valves and all devices that generate electrical interferences.

• If condensation can develop inside the scale’s transmitter, it is recommended to keep the equipment running.

• With regard to all shielded and non-shielded cables (cell cable, PC cable, power supply cable, etc.) that are connected to

the indicator, you must keep the cable as short as possible and make a minimum amount of the cables exit from the shield

in order to be connected to the terminal board;

• If the indicator is situated inside an electrical panel, you must also use a shielded cable for power supply and must keep

the cable as short as possible and far from the cables supplying coils, inverter, electromotive force, etc., and apply a

de-coupling transformer to supply the indicator only.

The various cables are classified according to the signals they transmit:

Category I

• Fieldbus , LAN network ( PROFIBUS, Ethernet, Devicenet...)

• Data shielded cables (RS232 ...)

• Shielded cables for analog digital signals < 25V (sensors, load cells.)

• Low-voltage power supply cables (<60V)

• Coaxial cables

Category II

• DC power supply cables with >60V and <400V

• AC power supply cables with >25V and <400

Category III

• Power supply cables with >400V

• Telephone cable

Category IV

• Any cables subject to lightning hazards

Electrical precautions

Cable classification

Electrical warnings

6

3590ET / 3590EGT

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

Electrical warnings

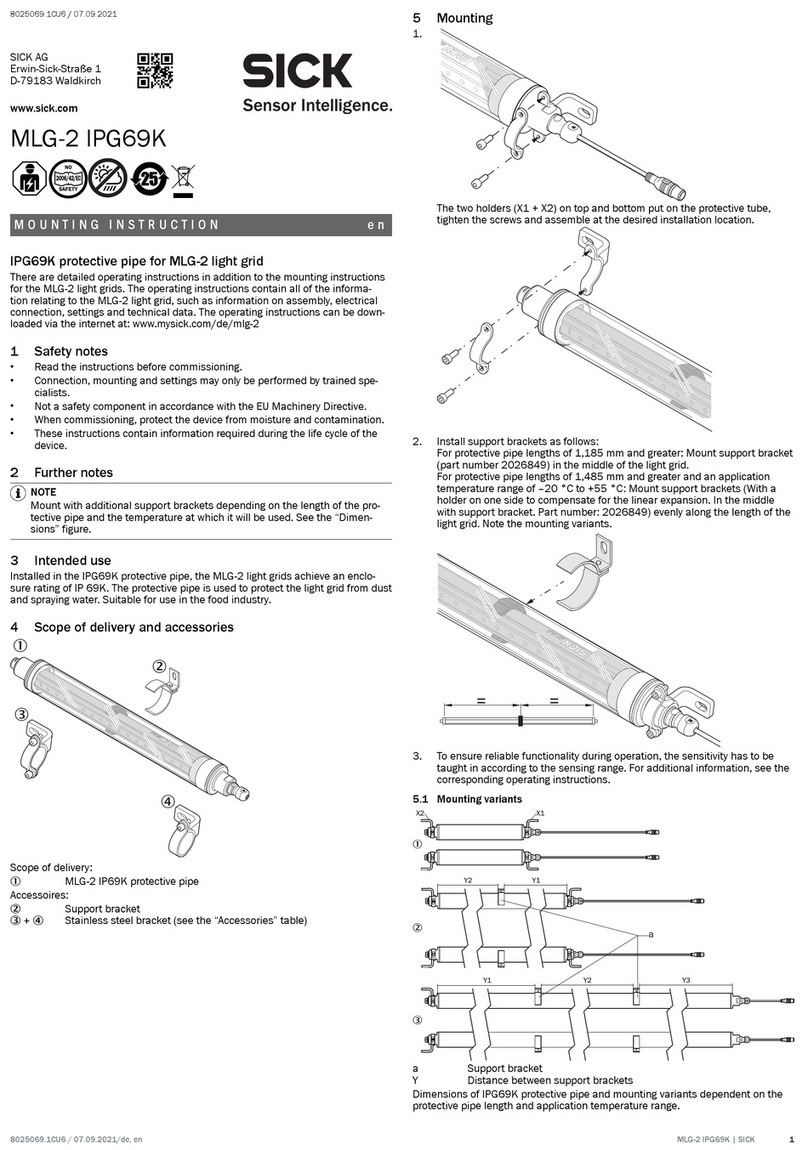

• When cables are laid parallel, they must be at the distances specified in the figure below

• These distances are intended in the air and are reduced if the housings are separated by metal boards connected to the

ground

• Cables from different categories can cross (90°)

LOAD CELL CONNECTION CABLE

The relative cable can reach the following maximum length from the line in order to connect the load cells:

• 50 metres with a 6 x 0.25 mm2cable

• 100 metres with a 6 x 0.5 mm2cable

RS232 CONNECTION CABLE

The relative cable can reach a maximum length of approximately 15 metres from the line for RS 232 connections, with a baud

rate of up to 19200.

RS485 CONNECTION CABLE

The relative cable can reach a maximum length of approximately 1200 metres from the line with a baud rate of up to 9600.

ANALOGUE OUTPUT CONNECTION CABLE

The maximum length for current analog output is:

• 100 metres with a 2 x 0.25 mm2cable

• 150 metres with a 2 x 0.5 mm2cable

• 300 metres with a 2 x 1 mm2cable

The maximum length for voltage analog output is:

• 50 metres with a 2 x 0.25 mm2cable

• 75 metres with a 2 x 0.5 mm2cable

• 150 metres with a 2 x 1 mm2cable

Category I Category II Category III Category IV

Recommended distance between cables

Maximum permitted length of cables

≥ 100 mm

≥ 200 mm

≥ 500 mm

≥ 100 mm

≥ 500 mm

≥ 500 mm

7

3590ET / 3590EGT

i

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

Electrical warnings

NOTES:

• ll earth cables must have a suitable length in order to obtain an overall resistance of the earthing system

below 1Ω.

• With regard to large and/or outdoor weighing system structures, such as a weighbridge:

- connection to earth must be carried out by connecting the earth cables to an earth bar, and the earth

bar to an earth pole with a minimum cable of 50 mm2.

- The cables must be larger (e.g. 50 mm2instead of 16 mm2and 100 mm2instead of 50 mm2) since the

voltage involved is higher (e.g. lightning);

- the earth pole must be situated at a minimum distance of 10 m from the weighbridge structure;

• You must open SENSE inside the indicator in order to compensate for the shift due to an increase in temperature.

• You must check and, if necessary, remove the connection between electrical installation earth and neutral.

For correct earthing and perfect system operation, you must connect the indicator, load cells, any junction boxes and weighing

structure to earth.

INDICATOR

Connect the container’s external earth terminal to earth with copper cables having a minimum dimension of 16 mm2.

LOAD CELLS AND JUNCTION BOX

Earthing must be carried out by connecting the earthing cables to the earth bar; the cables must have a minimum dimension of

16 mm2. Also, connect the earth bar to the earth pole with a minimum cable of 50 mm2.

• If the load cells are connected to the indicator via a junction box, you must connect the cable shield from the indicator and

the cell cable shields to the earth terminal of the junction box (refer to the junction box manual) and connect the latter to

earth by means of a copper cable having a minimum dimension of 16 mm2.

• If the load cells are connected directly to the indicator (without using a junction box), you must connect the cell cable

shields to the earthing point (or earth bar) inside the container.

• If the weighing system is for a large and/or outdoor structure, such as a weighbridge, and the junction box is connected to

the indicator with a cable longer than 10 m, or if there are interferences, connect the cable’s braiding from the indicator to

the earth terminal in the junction box and indicator and connect the two earth systems with an earth cable having a mini-

mum dimension of 16 mm2.

WEIGHING STRUCTURE

Connect the weighing structure and any other structures that are not connected (for example silos that leave material on the

weighing structure) to earth with cables having a minimum dimension of 16 mm2.

You must also connect the upper part of each cell with the lower part of the cell with a copper braid having a minimum dimen-

sion of 16 mm2. The upper part must be short circuited with the surface of the weighing structure and the lower part must be

connected to earth with a copper braid having a minimum dimension of 16 mm2.

SERIAL CABLES AND INSTRUMENTS CONNECTED

Connect the serial cable shield to the earthing point (or earth bar) inside the container (on the end part of the cable towards

indicator) and to the earth terminal of the connected instrument (on the end part of the cable towards the instrument connected),

and connect the earth terminal of the connected instrument to earth with copper cables having a minimum dimension of 16 mm2.

To avoid undesired effects, the earthing references of the connection cable and power supply of the instrument connection and

the indicator must have the same power.

Earthing system

8

3590ET / 3590EGT

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

Example of weighbridge earthing

Electrical warnings

Load cell

bypass U-bolt

Weighbridge

Weight indicator

Load cell

Earth cables

Ø 8-sec 50 mm2

Ø 11,3 - sec. 100 mm2

Earth pole placed

under or next to

the weighbridge

Copper perforated plate

placed on the coast wall

Junction box situated on

the coast wall of the ditch

Weighbridge

10

3590ET / 3590EGT

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

J1

CAL

J3

J2

EXC+

EXC-

SIG+

SIG-

GND

+5V

RX / CTS

-

-

TX

GND

+5V

RX

CTS

-

TX

GND

+5V

RX / CTS

-

-

TX

CH4 CH3 CH2 CH1

DISPLAY

POWER

DISPLAY

RS232

COM1 RS232

RS485

COM2

RS232

COM3

SENSOR

POWER IN:

12 ~ 24 Vdc

ORIGINAL BATTERY ONLY

AUXILIARY VOLTAGE OUT:

5,3 ~ 8 Vdc 400 mA max.

VOLTAGE OUT: 12Vdc

400 mA max.

Only if power supply is

connected.

Max. 48 Vac / 60 Vdc

Max. 150 mA

Max. 10 Ω

Max. 12 ~ 24 Vdc

Max. 20 mA

COM 1

Vin

GND

GND

+Vaux

OUT1

OUT2

OUT3

OUT4

IN1

IN2

TX1

RX1 / CTS

GND

CTS

TX2

RX2

GND

+Vdc

A(+)

B(-)

EARTH

SIG+

SIG-

SEN+

SEN-

EXC+

EXC-

+BAT

COM

COM

COM 2 4 / 6 wires load cell

connection

Load cell shield

connection

COM 3

OUT 1-2

SLOT OUT 3-4

SLOT

IN 1-2

SLOT

AUTO

SWITCH-ON

J 2 J 3

EXC+SEN+ SEN- EXC-

J 1

J 1

Legal

Internal use

ON

OFF

ON

OFF

RS485

RESISTORS

If “ON”, the instrument

turns on automatically. If “ON”, it enables the 120 Ω terminal resistors

between A(+) and B(-) connectors (22-23)

1 2 3 4 5 6 7 8 9 10

Vin

GND

GND

24Vdc

+Vaux

OUT1

OUT2

OUT3

OUT4

+BAT

COM

11 12 13 14 15 16 17 18

19

COM

IN1

IN2

TX1

RX1 / CTS

GND

CTS

TX2

RX2

24Vdc

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

Motherboard

INPUT AND OUTPUT CONNECTION

OUTPUT INPUT

12

3590ET / 3590EGT

SLOT1 SLOT2

COM

OUT5

OUT6

OUT7

OUT8

OUT9

OUT10

OUT11

OUT12

OUT13

OUT14

OUT15

OUT16

COM

IN3

IN4

IN5

IN6

IN7

IN8

GND

GPI0

I + (up to 20 mA)

COM - (0 mA / V)

V + (up to 10 V)

I + (up to 20 mA)

COM - (0 mA / V)

V + (up to 10 V)

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58

Max. 350 Ω

Max. 350 Ω

Min. 10 KΩ

Min. 10 KΩ

Max. 48 Vac / 60 Vdc

Max. 150 mA

Max. 10 Ω

Max. 12 ~ 24 Vdc

Max. 20 mA

SLOT 1 SLOT 2

EXPANSION

CPU

DISPLAY

1

2

31 32 33 34 35

24Vdc

OUT5

OUT6

OUT7

OUT8

COM

44 45 46 47 48 49 50

COM

IN3

IN4

IN5

IN6

IN7

IN8

24Vdc

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

I/O expansion board

installation integrated inside the scale. 12 OUT and 8 IN; enables expansion of scale power supply up to 8-40Vdc.

Connection:

INPUT AND OUTPUT CONNECTION

OUTPUT INPUT

13

3590ET / 3590EGT

i

SIG-

SIG+

EXC-

EXC+

SIG-

SIG+

EXC-

EXC+

SIG-

SIG+

EXC-

EXC+

SIG-

SIG+

EXC-

EXC+

CELL2

CELL3

CELL1

CELL4

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30

J1

CAL

J3

J2

GND

+5V

RX / CTS

-

-

TX

GND

+5V

RX

CTS

-

TX

CH4 CH3 CH2 CH1

POWER

DISPLAY

RS232

COM1 RS232

RS485

COM2

RS232

COM3

SENSOR

Vin

GND

GND

+Vaux

OUT1

OUT2

OUT3

OUT4

IN1

IN2

TX1

RX1

GND

CTS2

TX2

RX

GND

+Vdc

A(+)

B(-)

EARTH

SIG+

SIG-

SEN+

SEN-

EXC+

EXC-

+BAT

COM

COM

OUTPUT

1-2 SLOT OUTPUT

3-4 SLOT

INPUT

1-2 SLOT

AUTO

SWITCH-ON

J 1

J 1

Legal

Internal use

ON

OFF

ON

OFF

Se “ON”, lo strumento

si accende automaticamente.

CELL2

CELL3

CELL1

CELL4

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

RS232 RS232

RS232

ON

OFF

ON

OFF

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

Optional internal board for rapid connection of multiple scales

RJ45 RS232 connector board

Multi-scale fitting board Installation:

Motherboard

R/-to TX

T/+to RX TXD

RXD

GND

GNDGND

to motherboard

RXD

TXD

The AMP connector enables you to rapidly connect and supply the CPU board of the weighing indicator.

SIG-

SIG+

EXC-

EXC+

SIG-

SIG+

EXC-

EXC+

SIG-

SIG+

EXC-

EXC+

SIG-

SIG+

EXC-

EXC+

CELL2

CELL3

CELL1

CELL4

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30

J1

CAL

J3

J2

GND

+5V

RX / CTS

-

-

TX

GND

+5V

RX

CTS

-

TX

CH4 CH3 CH2 CH1

POWER

DISPLAY

RS232

COM1 RS232

RS485

COM2

RS232

COM3

SENSOR

Vin

GND

GND

+Vaux

OUT1

OUT2

OUT3

OUT4

IN1

IN2

TX1

RX1

GND

CTS2

TX2

RX

GND

+Vdc

A(+)

B(-)

EARTH

SIG+

SIG-

SEN+

SEN-

EXC+

EXC-

+BAT

COM

COM

OUTPUT

1-2 SLOT OUTPUT

3-4 SLOT

INPUT

1-2 SLOT

AUTO

SWITCH-ON

J 1

J 1

Legal

Internal use

ON

OFF

ON

OFF

Se “ON”, lo strumento

si accende automaticamente.

CELL2

CELL3

CELL1

CELL4

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

RS232 RS232

RS232

ON

OFF

ON

OFF

14

3590ET / 3590EGT

OFF ON

A+ B-

ETHERNET

RS485

SETTINGS

RS232

RS232

RX

TX

RX

TX

+VDC

-

-

GND

GND

DFLT

WIFI

ANTENNA

A

B

POWER

+Vdc

1 2

GND A(+)

3 4

B(-)

RX

6

TX

5 7

GND

SETHDIN

ETHERNET

RS485

RS232

WIFI

ANTENNA

A

B

i

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

Version for installation on a DIN bar

to A+

to RX

to A(+)

to B(-)

to RX

to GND

to motherboard

to TX

to GND

to TX

to 5÷12VDC

to GND

to 12÷24V

to GND

to RX

to TX

to B-

RS232 / RS485 to Ethernet / WIFI conversion board

Installation integrated inside the scale.

The AMP connector enables

you to rapidly connect and

supply the weighing indicator

CPU board.

RESET Jumper

Closing the DFLT jumper resets default settings of the operating

methods set via the dip switch:

• IP address: 192.168.16.205

• Subnet Mask: 255.255.255.0

• Baud rate and bit according to the type of combination of dip

switches

WIFI module

15

3590ET / 3590EGT

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

1

1

1

1

1

2

2

2

2

2

3

3

3

3

3

4

4

4

4

4

i

i

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

ETHERNET/WIFI conversion in «232/485» and vice-versa

Network between instruments on RS232

Port 485 available for simultaneous communication to other devices.

Set the serial ports to 115200 n-8-1.

Modbus RTU converter in Modbus TCP

Convert Modbus RTU protocol to Modbus TCP.

RS232 and RS485 communication ports cannot be used simultaneously.

Set the serial ports to 9600 n-8-2.

RS232 converter in «RS485» and vice-versa

ETHERNET/WIFI port disabled.

Set the serial ports to 9600 n-8-1.

Enable the option to configure the ethernet/wifi board via browser

Set the serial ports to 9600 n-8-1

WARNINGS:

RS232 and RS485 communication ports cannot be used simultaneously.

Set the serial ports to 9600 n-8-1.

SETTINGS:

It enables you to rapidly connect and supply the weighing indicator CPU board.

Attention:

every time you change the operating mode, the board resets the standard default settings.

16

3590ET / 3590EGT

SETTINGS

USB CABLE

RS232 (PRINTER)

to motherboard

to printer

RS232 (INDICATOR)

GND

5÷12Vdc

TX

RX

CTS

Vin

GND

CTS

TX

RX

OFF ON

1

2

3

4

USB UART

OFF ON

1

2

3

4

OFF ON

1

2

3

4

POWER

+Vdc

1 2

GND

RS232

TXD

3 4

RXD RTS

5 6

GND

USBDIN

i

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

SETTINGS:

Configure the baud rate, parity, bit number and stop bit:

• ON = 38400-E-8-1

• OFF = 9600-N-8-1

Enable CTS for a connected printer:

• ON = CTS managed

• OFF = CTS not managed

installation integrated inside the scale. Version for installation on a DIN bar

to RX

to RX

to TX

to TX

to GND

to GND

to Vin

to CTS

to CTS

LED description:

RED LED:

ON = Print in progress

Flashing = USB not detected

GREEN LED:

Slow flashing = Ready

Quick flashing = USB or printer not detected

The AMP connector enables you to rapidly connect

and supply the CPU board of the weighing indica-

tor

USB support data saving board

to 5÷12V

to GND

17

3590ET / 3590EGT

i

i

RADIO

MODULE

TX

GND

5÷12V

RX

RADIO

MODULE

TTL

5V

GND

TX

RX

POWER RS232 RS485

+Vdc

1 2 3 4 5 6 7 8 9

GND TX RX GND B(-) A(+) SHD EARTH

PROFIBUS

PROFI232

A-LINE

GND B-LINE

+5VBUS

5 4 3 2 1

6789

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

Version for installation on a DIN bar

to GND

to GND

to GND

to B(-)

to A(+)

to SHD

to EARTH

to GND

to 5÷12V

to 12÷24V

to 5V

to TX

to motherboard

to TX

to TX

to RX

to RX

to RX

RADIO communication board

PROFIBUS communication board

The AMP connector enables you to rapidly connect and supply the CPU board of the weighing indicator .

It is possible to connect the

indicator to RS232 or RS485

installation integrated inside the scale TTL version

18

3590ET / 3590EGT

GND

5V

RX

TX

TLR -1

RX

TX

-

5V

ANTENNA

-

GND

SHIELD

CELL

SIDE

INDICATOR

SIDE

DIGITAL CELL

ANALOG CELL

EXC-

EXC+

SEN-

SEN+

SIG-

SIG+

SHIELD

SHIELD

EXC-

EXC+

SEN-

SEN+

SIG-

SIG+

GND

+Vdc

B(-)

A(+)

GND

+Vdc

B(-)

A(+)

i

i

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

to GND

to 5V

to TX

to RX

BLUETOOTH communication board

RADIO REMOTE CONTROL board

Circuit breaker against electrostatic loads

Installation integrated inside the scale.

installation integrated inside the scale.

Installation integrated inside the scale.

The AMP connector enables you to rapidly connect and supply the

CPU board of the weighing indicator.

Connect the module to the indicator’s COM2 via a strip connector

situated on the board with a wire or directly to the CPU board with a

tulip connector situated under the board.

19

3590ET / 3590EGT

1

ANALOG

OUTPUT

EXPANSION

CPU

DISPLAY

SLOT1 SLOT2

ANALOG

OUTPUT

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58

EXPANSION

CPU

DISPLAY

SLOT1 SLOT2

1

ANALOG

OUTPUT

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58

1

2

EXPANSION

CPU

DISPLAY

SLOT1 SLOT2

ANALOG

OUTPUT

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58

EXPANSION

CPU

DISPLAY

SLOT1 SLOT2

1

ANALOG

OUTPUT

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58

TECH_MAN_SCHEMES_3590_ENG_vX_17.06

Analog output

Installation integrated inside the scale. 0-4mA/0-10Vdc.

Assemble the board facing towards the indicator’s CPU.

Other manuals for 3590EGT Series

1

This manual suits for next models

1

Table of contents

Other Dini Argeo Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Aalborg

Aalborg XFM Series operating manual

Extech Instruments

Extech Instruments 461700 user guide

Emerson

Emerson Rosemount 8600D Series Reference manual

Hengstler

Hengstler tico 734 operating instructions

Sontex

Sontex Supercal 739 Instruction guide

Thies CLIMA

Thies CLIMA First Class Advanced X Instructions for use