DISCO DFD-2S/8 User manual

DFD-2S/8

INTRODUCTION

INSTALLATION

STRUCTURAL SECTIONS AND THEIR FUNCTIONS

CIRCUIT DIAGRAM

PRINCIPLES OF OPERATION

CHECKING PROCEDURES FOR TROUBLESHOOTING

ILLUSTRATION AND PARTS LIST

MAINTENANCE AND REGULAR INSPECTIONS

ACCESSORIES

BLADE BREAKAGE DETECTOR

A

B

C

D

E

F

G

J

H

i

920610

DFD-2S/8

CONTENTS

Page

INTRODUCTION

A INSTALLATION

I Installation Environment ................................................................................................ A-1

II Necessaries for Installation ........................................................................................... A-2

III Other Notice ................................................................................................................... A-2

IV Installation Leveling ....................................................................................................... A-2

V Wiring Connection ......................................................................................................... A-4

VI Transportation ................................................................................................................ A-6

B STRUCTURAL SECTIONS AND THEIR FUNCTIONS

I Structures ....................................................................................................................... B-1

II Functions ........................................................................................................................ B-2

1 X-axis Section .......................................................................................................... B-2

2 Y-axis Section .......................................................................................................... B-3

3 Z-axis Section .......................................................................................................... B-4

4 θ-axis Section ......................................................................................................... B-6

5 Spinner Section ....................................................................................................... B-9

6 Elevator Section ...................................................................................................... B-10

7 Transfer Section ...................................................................................................... B-12

8 Microscope Section ................................................................................................. B-13

9 Main Body Section ................................................................................................. B-18

10 Electrical System...................................................................................................... B-20

(1) Construction ........................................................................................................ B-20

(2) Power Supply Section ........................................................................................ B-24

(3) Main Control Section ......................................................................................... B-32

(4) Sub-control Section ............................................................................................. B-53

(5) Attachment Section ............................................................................................ B-62

ii

920610

DFD-2S/8

C CIRCUIT DIAGRAM

Block Diagram 1 (Main) (for DFD-2S/8) ............................................................................ C-1

Block Diagram 1 (Main) (for DFD-2D/8) ........................................................................... C-1A

Block Diagram 2 (Main) ....................................................................................................... C-2

Block Diagram 3 (Main & Sub) (for DFD-2S/8) ................................................................ C-3

Block Diagram 3 (Main & Sub) (for DFD-2D/8) ............................................................... C-3A

MainAC Power Circuit (for DFD-2S/8) ............................................................................. C-4

MainAC Power Circuit (for DFD-2D/8) ............................................................................. C-4A

Main BoxAC Power Source ................................................................................................. C-5

Main Box DC Power Source ................................................................................................. C-6

Sub Control Power Circuit (for DFD-2S/8) ........................................................................ C-7

Sub Control Power Circuit (for DFD-2D/8) ....................................................................... C-7A

Main Control Signal Diagram ............................................................................................. C-8

Sub Control Box Wiring Diagram (Y-axisAC Servo) ...................................................... C-9

Sub Control Box Wiring Diagram (Y-axis Pulse Motor) (for DFD-2S/8) ...................... C-10

Sub Control Box Wiring Diagram (Y-axis Pulse Motor) (for DFD-2D/8) ..................... C-10A

ALU Block Diagram .............................................................................................................. C-11

Hard Disk Wiring Diagram ................................................................................................. C-12

Floppy Disk Wiring Diagram .............................................................................................. C-13

Main-Sub/ALU (S I O) Wiring Diagram ............................................................................ C-14

SI/O Wiring Diagram ............................................................................................................ C-15

MCN1 Wiring Diagram (for DFD-2S/8) ............................................................................. C-16

MCN1 Wiring Diagram (for DFD-2D/8) ............................................................................ C-16A

MCN2 Wiring Diagram (for DFD-2S/8) ............................................................................. C-17

MCN2 Wiring Diagram (for DFD-2D/8) ............................................................................ C-17A

MCN3 Wiring Diagram (for DFD-2S/8) ............................................................................. C-18

MCN3 Wiring Diagram (for DFD-2D/8) ............................................................................ C-18A

MCN4 Wiring Diagram (for DFD-2S/8) ............................................................................. C-19

MCN4 Wiring Diagram (for DFD-2D/8) ............................................................................ C-19A

MCN5 Wiring Diagram ........................................................................................................ C-20

MCN6 Wiring Diagram (for DFD-2S/8) ............................................................................. C-21

MCN6 Wiring Diagram (for DFD-2D/8) ............................................................................ C-21A

MCN7 Wiring Diagram ........................................................................................................ C-22

MCN9 Wiring Diagram ........................................................................................................ C-23

iii

920610

DFD-2S/8

CNS Wiring Diagram ............................................................................................................ C-24

Camera & TV Monitor Wiring Diagram (for DFD-2S/8) ................................................ C-25

Camera & TV Monitor Wiring Diagram (for DFD-2D/8) ................................................ C-25A

SCN1 Wiring Diagram (for DFD-2S/8) .............................................................................. C-26

SCN1 Wiring Diagram (for DFD-2D/8) .............................................................................. C-26A

SCN2 Wiring Diagram (for DFD-2S/8) .............................................................................. C-27

SCN2 Wiring Diagram (for DFD-2D/8) .............................................................................. C-27A

SCN4 Wiring Diagram .......................................................................................................... C-28

SCN5 Wiring Diagram .......................................................................................................... C-29

SCN6 Wiring Diagram (for DFD-2S/8) .............................................................................. C-30

SCN6 Wiring Diagram (for DFD-2D/8) .............................................................................. C-30A

SCN7 Wiring Diagram .......................................................................................................... C-31

Outside Relay P.C.B. Circuit Diagram ............................................................................... C-32

Set Up P.C.B. Circuit Diagram ............................................................................................ C-33

PCB (Axis) ............................................................................................................................... C-34

Signal Tower I/F P.C.B. Circuit Diagram .......................................................................... C-35

Spinner Control P.C.B. Circuit Diagram ............................................................... ........... C-36

Spinner Circuit Diagram .......................................................................................... ........... C-37

D PRINCIPLES OF OPERATION

I Linear Scale .................................................................................................................. D-1

1. Main Components .................................................................................................... D-2

2. Block Diagram .......................................................................................................... D-3

3. Principles ................................................................................................................... D-4

4. Scale Specifications .................................................................................................. D-5

E TROUBLESHOOTING GUIDE

I Spinner Pump Problems and Remedies ................................................................... E-1

II Feedback Unit Problems and Remedies ................................................................... E-4

III Checking Procedures for Troubleshooting of Electrical System ............................. E-6

(1) POWER ................................................................................................................ E-6

(2) Servomotor/driver ............................................................................................... E-8

(3) PM motor/driver ................................................................................................. E-10

IV Error Code .................................................................................................................... E-12

iv

920610

DFD-2S/8

1. General ......................................................................................................................... E-12

2. Error Code Tables ...................................................................................................... E-12

3. Details of Error Code ................................................................................................. E-24

F ILLUSTRATION AND PARTS LIST

EXPLODED VIEW OF MAIN BODY (A) .............................................................. F-1

EXPLODED VIEW OF MAIN BODY (B) .............................................................. F-2

EXPLODED VIEW OF MAIN BODY (C) .............................................................. F-3

EXPLODED VIEW OF MAIN BODY (D) .............................................................. F-4

EXPLODED VIEW OF MAIN BODY (E) .............................................................. F-5

EXPLODED VIEW OF MAIN BODY (F) .............................................................. F-6

EXPLODED VIEW OF X-AXIS (A) ........................................................................ F-7

EXPLODED VIEW OF X-AXIS (B).......................................................................... F-8

(NotAssigned) ........................................................................................................................ F-9

EXPLODED VIEW OFY-AXIS (A) ......................................................................... F-10

EXPLODED VIEW OFY-AXIS (B) ......................................................................... F-11

EXPLODED VIEW OFY-AXIS (C) ......................................................................... F-12

EXPLODED VIEW OFY-AXIS (D) ........................................................................ F-13

EXPLODED VIEW OF y-AXIS (A) (DFD-2D/8 ONLY) ........................................ F-13A

EXPLODED VIEW OF y-AXIS (B) (DFD-2D/8 ONLY) ........................................ F-13B

EXPLODED VIEW OF Z-AXIS (A) (DFD-2S/8 ONLY) ........................................ F-14

EXPLODED VIEW OF Z-AXIS (B) (DFD-2S/8 ONLY) ........................................ F-14A

EXPLODED VIEW OF Z-AXIS (C) (DFD-2S/8 ONLY) ........................................ F-14B

EXPLODED VIEW OF Z-AXIS (D) (BLADE BREAKAGE DETECTOR)

(DFD

-2S/8 ONLY) (OPTION) .................................................................................... F-14C

EXPLODED VIEW OF Z-AXIS (E) (DFD-2D/8 ONLY) ........................................ F-15

EXPLODED VIEW OF Z-AXIS (F) (DFD-2D/8 ONLY) ........................................ F-15A

EXPLODED VIEW OF Z-AXIS (G) (DFD-2D/8 ONLY) ....................................... F-15B

EXPLODED VIEW OF Z-AXIS (H) (DFD-2D/8 ONLY) ....................................... F-15C

EXPLODED VIEW OF MICROSCOPE ................................................................. F-16

EXPLODED VIEW OF θ-AXIS (A) ....................................................................... F-17

EXPLODED VIEW OF θ-AXIS (B) ....................................................................... F-18

EXPLODED VIEW OF LOADING/UNLOADING (A) ......................................... F-19

EXPLODED VIEW OF LOADING/UNLOADIING (B) ....................................... F-20

v

920610

DFD-2S/8

EXPLODED VIEW OF LOADING/UNLOADIING (C) ....................................... F-21

EXPLODED VIEW OF TRANSFER (A) ................................................................ F-22

EXPLODED VIEW OF TRANSFER (B) ................................................................ F-23

EXPLODED VIEW OF TRANSFER (C) ................................................................ F-24

EXPLODED VIEW OF TRANSFER (D) ................................................................ F-25

EXPLODED VIEW OF TRANSFER (E) ................................................................ F-26

EXPLODED VIEW OF TRANSFER (F) ................................................................. F-27

EXPLODED VIEW OF SPINNER (A) .................................................................... F-28

EXPLODED VIEW OF SPINNER (B) .................................................................... F-29

EXPLODED VIEW OF SPINNER (C) .................................................................... F-30

EXPLODED VIEW OF PNEUMATIC PIPING (A) .............................................. F-31

EXPLODED VIEW OF PNEUMATIC PIPING (B) .............................................. F-31A

EXPLODED VIEW OF PNEUMATIC PIPING (C) .............................................. F-32

EXPLODED VIEW OF PNEUMATIC PIPING (D) .............................................. F-33

EXPLODED VIEW OF PNEUMATIC PIPING (E) .............................................. F-34

EXPLODED VIEW OF PNEUMATIC PIPING (F) .............................................. F-35

EXPLODED VIEW OF PNEUMATIC PIPING (G) .............................................. F-36

EXPLODED VIEW OF PNEUMATIC PIPING (H) .............................................. F-37

EXPLODED VIEW OF WATER PIPING (A) ......................................................... F-38

EXPLODED VIEW OF WATER PIPING (B) (DFD-2S/8 ONLY) ........................ F-39

EXPLODED VIEW OF WATER PIPING (C) (DFD-2D/8 ONLY) ....................... F-39A

EXPLODED VIEW OF WATER PIPING (D) ........................................................ F-40

EXPLODED VIEW OF WATER PIPING (E) (DFD-2S/8 ONLY) ........................ F-41

EXPLODED VIEW OF WATER PIPING (F) (DFD-2D/8 ONLY) ........................ F-41A

EXPLODED VIEW OF N2PIPING (A) .................................................................. F-42

EXPLODED VIEW OF N2PIPING (B) .................................................................. F-42A

EXPLODED VIEW OF N2PIPING (C) .................................................................. F-43

EXPLODED VIEW OF N2PIPING (D) .................................................................. F-44

EXPLODED VIEW OF N2PIPING (E) .................................................................. F-45

INDEX

vi

920610

DFD-2S/8

G MAINTENANCE AND REGULAR INSPECTIONS

I Maintenance ................................................................................................................. G-1

1 Cleaning ................................................................................................................... G-1

2 Consumables Replacement .................................................................................. G-2

II Regular Inspections ..................................................................................................... G-18

Daily Inspection .................................................................................................. G-18

Weekly Inspection .............................................................................................. G-19

Semiannual Inspection ...................................................................................... G-20

H ACCESSORIES

1 Tape Frames ............................................................................................................ H-1

2 Cassettes .................................................................................................................. H-3

3 Chuck Tables ........................................................................................................... H-3

4 Type MR Flange Set .............................................................................................. H-4

J BLADE BREAKAGE DETECTOR (OPTIONAL)

I Construction ................................................................................................................. J-1

1 Components .................................................................................................................J-1

II Installation ..................................................................................................................... J-4

1 Detection Unit Mounting Position (Component ⑤in Section I) .................. J-4

2 Photo-amplifier Mounting Position (Component ④in Section I) ................ J-4

III Fiber Installation ........................................................................................................... J-5

IV Connection ................................................................................................................... J-8

VOperating Procedures ................................................................................................. J-9

1 Preparation for Power ON .................................................................................. J-9

2 Power ON ................................................................................................................. J-9

3 Adjustment .............................................................................................................. J-9

4 Idling ......................................................................................................................... J-10

5 Breakage Detection FunctionActivation and Reset ........................................ J-11

6 Total Loss Detection FunctionActivation and Reset ....................................... J-11

7 DIP Switch Setup ................................................................................................... J-12

8 Rotary Switch Setup .............................................................................................. J-13

VI Precautionary Concerns ............................................................................................. J-14

VII Maintenance ................................................................................................................. J-14

INTRODUCTION

DFD-2S/8

910228

INTRODUCTION

This manual provides an guide to the identification and repair of malfunctions of the DISCO

MODEL DFD-2S/8 and DFD-2D/8 FULLY AUTOMATIC DICING SAW.

Familiarity with its contents will enable you to obtain the years of dependable service that the

MODEL DFD-2S/8 and DFD-2D/8 FULLYAUTOMATIC DICING SAW is designed to deliver.

CAUTION:

This manual uses lint free paper. Since this paper is weakened by heat, do not place

near heat. Also when rubbing strongly with something such as an eraser, since the

printing will become thin and contaminated. Please take adequate precautions in

handling.

DFD-2S/8

A INSTALLATION

DFD-2S/8

A

A-1

910228

DFD-2S/8

A. INSTALLATION

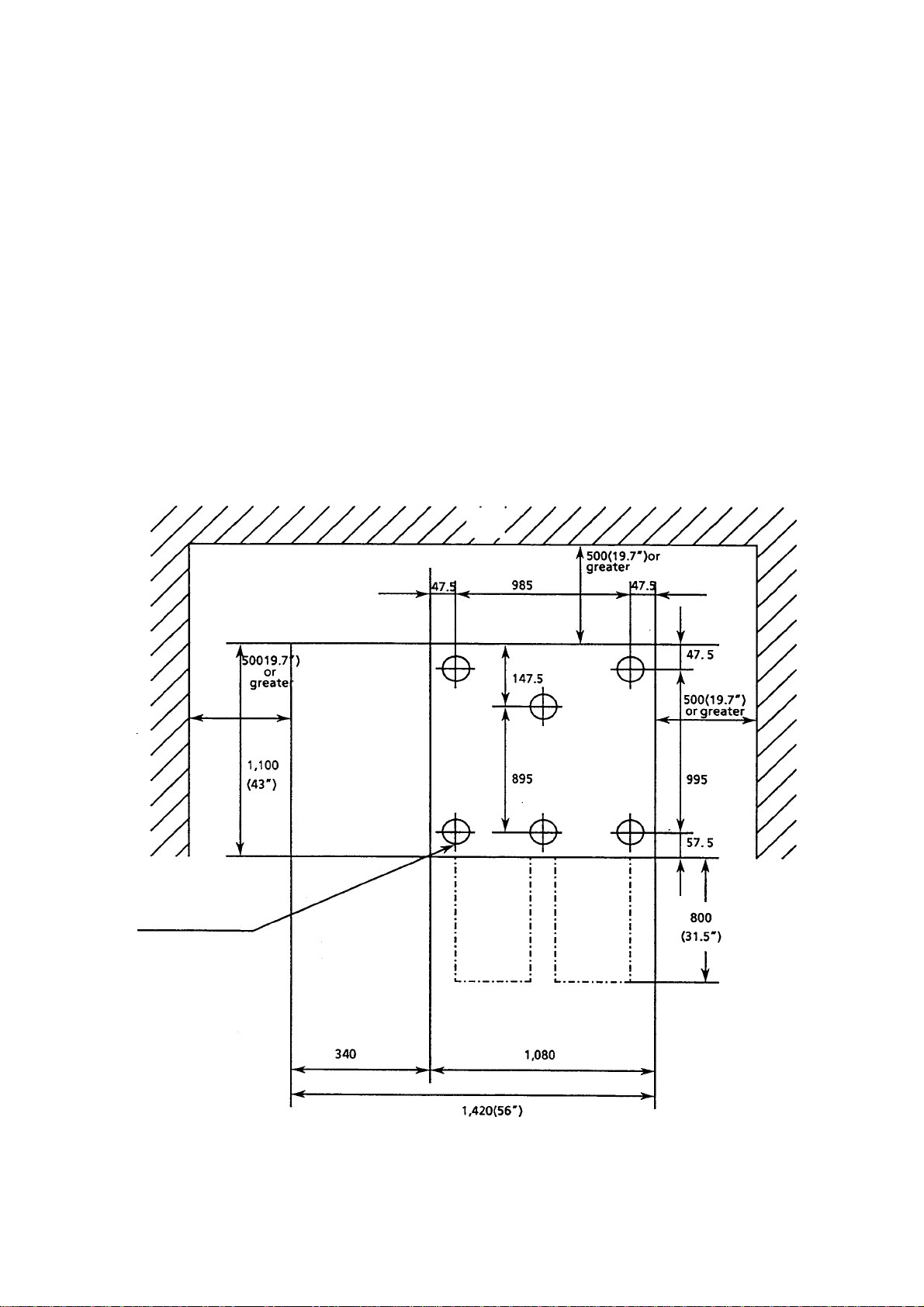

I Installation Environment

(1) Required space for this machine is 1,420mm (56″) (W)×1,100mm (43″) (D).

(2) Installation place should be determined by considering ease of operation and ease of

maintenance.

(3) Keep away from where temperature changes abnormally. Appropriate temperature is 20~25℃

±1℃(68~69.5°F±1.8°F) and humidity is 55±15%.

(4) Do not use a power source which flucturates frequently. Appropriate power is 200V±10%.

(5) Do not use a power source which emits noise. Permitted noise is less than 2,000V and its pulse

width is less than 500n/sec.

(6) Keep away from where the shock and/or sensible vibration are observed.

Fig. A

-

--

-

1

Wall

Jack sheet

Space

need

electronics

drawer

(Loading, Unloading) (Main body)

A-2

910228

DFD-2S/8

II Necessaries for Installation

(1) Power supply cord

(2) Piping hose

A hose provided as a standard accessory is 2m (79″) long. If you need a longer one, please tell

us previously. When you use other hoses, select those which have sufficient durability against

the proper fluids.

(3) Precision level

Asmall sized one.

(4) Tools

Supplied with the machine.

III Other Notice

(1) Install where floor has enough strength.

(2) Install where air, water, drain pipes, and power etc. can be supplied nearby.

(3) Connect piping hoses after cleaning their inside.

(4) Use dry air that’s filter is 0.003PPMWT/wt and its dew point is below than -15℃(5°F).

(5) Be sure to ground the machine.

(6) During installation do not load shock and /or use excessive force against the machine.

(7) After installation, remove all the hanging fittings and metal fittings for fixing.

(8) After installation, check that all the wiring terminals and piping joints are connected safely.

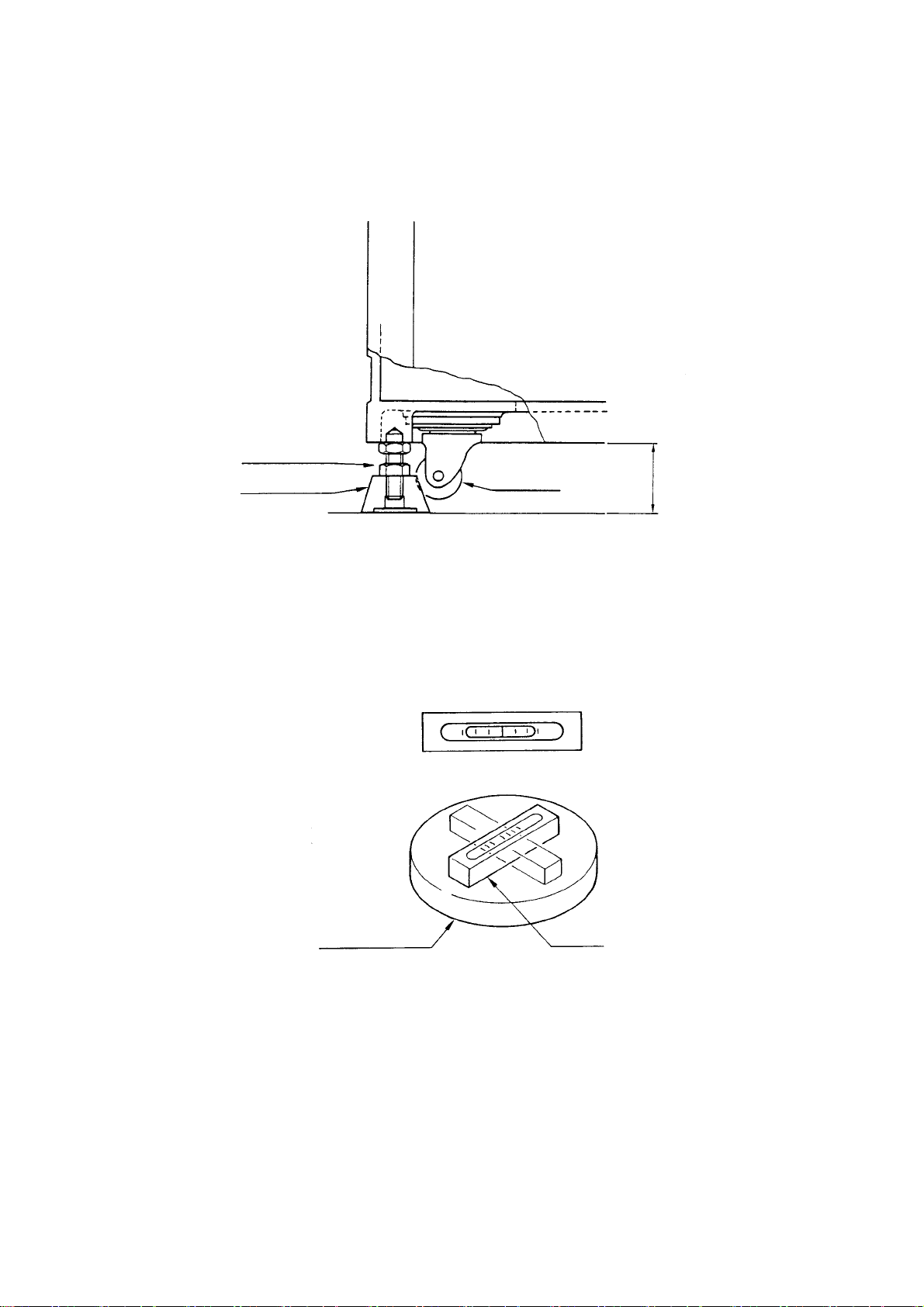

IV Installation leveling

Level the machine using the jack provided within the machine.

(1) Patch a jack sheet under the six jack bolts. Raise up equally until all casters are above the

floor.

(2) Place a level on a chucktable.

(3) Adjust level for four directions (before and behind, left and right) by turns shifting the jack

bolt.

(4) Set the level within 1 scale (0.02mm/1m)(0.0008″/39″) for all four directions.

(5) Check and confirm that all the jack bolts touch the jack sheet.

A-3

910228

DFD-2S/8

Illustration Of Installed Bearing

Fig. A

-

--

-

2

Fig. A

-

--

-

3

Jack bolt

Jack

sheet

Caster

Chuck table Level

90mm

(3.5")

A-4

910228

DFD-2S/8

V Wiring Connection

(1) The following illustration shows the piping points and junction points at the rear of the

machine.

(2) Please verify the coupling connections.

(3) Be sure to connect the power source cord.

(4) The power source cord for the monitor is to be connected to a 100V table tap within the

machine through the cover.

(5) Signal cables for the monitor and for the signal lamp are to be linked to each connecter by the

cords leading from the machine.

A-5

910228

DFD-2S/8

Fig. A

-

--

-

4

NO Name Remarks NO Name Remarks

1 Main drain Duct hose 50

MSTDH50T 8 Cooling water out Blade hose ID15

MSTBH22X15C

2 Main duct Duct hose 100

MSTDH100T 9 Exhaust drainage

(chuck table) Blade hose ID12

MSTBH18X12C

3 Spinner duct Duct hose 100

MSTDH100T 10 DI water Blade hose ID15

MSTBH22X15C

4 Spindle exhaust Junron tube8×5 11 N2Blade hose ID15

MSTBH22X15C

5 Cooling water in Blade hose ID15

MSTBH22X15C 12 Rinse Blade hose ID15

MSTBH22X15C

6 Water for cutting Blade hose ID15

MSTBH22X15C 13 Spinner drainage Blade hose ID32

MSTBH41X32C

7 Air Blade hose ID15

MSTBH22X15C 14 Exhaust

drainage (spinner) Blade hose ID32

MSTBH41X32C

A-6

910228

DFD-2S/8

VI Transportation

(1) Take off all piping and wiring.

(2) Draw water out of the machine.

(3) Take off the monitor.

(4) Take off the monitor base, the signal lamp, and the upper cover.

(5) Fix the Y-axis and the Z-axis with proper fittings.

(6) Fix the transfer arm with a thin string.

(7) Put on a hanging fittings for transportation.

(8) Run a pole through the hanging fitting and raise the machine with a crane.

(9) Notes for craning:

●Pay attention that ropes, etc. do not touch the machine.

●Do not shock the machine.

●Do not incline the machine excessively.

●Do not weigh on the cover.

(10) After raising up the machine, all the jack bolts are to be pulled in to the utmost. If they

remain below the casters, it is possible to break them when the machine is placed on the

ground the next time.

A-7

910228

DFD-2S/8

Illustration Of Transport Method

Fig. A

-

--

-

5

B STRUCTURAL SECTIONS AND THEIR FUNCTIONS B

DFD-2S/8

B-

--

-1

910228

DFD-2S/8

B. STRUCTURAL SECTIONS AND THEIR FUNCTIONS

I. Structures

The DFD-2S/8 or DFD-2D/8 consists of the X-axis, Y-axis, y-axis (only for the DFD-2D/8),

Z-axis,θ-axis, spinner, elevator, transfer, microscope, main body, and electrical sections.

Elevator section Spinner section Transfer section Z-axis section

Fig. B

-

--

-

1

θ-axis section

Main body section Electrical section X-axis section Y-axis section

B-2

910228

DFD-2S/8

II. Functions

1. X-axis Section

This section consists of the base (1), leadscrew (2), and cover (3) sections.

Fig. B

-

--

-

2

(1) Base Section

With theθ-axis section mounted on the table that slides on the straight rails, the base section

performs work transport, rightward/leftward feed for alignment, and reciprocating cutting

movements.

(2) Leadscrew Section

This section moves the slide table by means of the ball -bearing leadscrew coupled direct to the

AC servomotor.

(3) Cover Section

The splash cover, bellows cover, and water drain duct are provided to discharge the cutting

water out from the machine, protecting the mechanism against water.

Cover section

Screw section

Base section

This manual suits for next models

1

Table of contents