CHESTER DB7VS User manual

DB7VS

LATHE

Manual

Chester UK Lt

d

Clwyd Close

Hawarden Industrial Par

k

Hawarden

Chester CH5

3PZ

Tel: 01244

531631

sales@chesterma

ch

i

n

etools.com

www.

ch

esterma

ch

i

n

etools.com

Safety guidelines

Personnel working with any machine tools are required to follow the safety instructions stated below in order to

prevent any accident that may occur.

• Appropriate personal protective equipment (such as safety glasses, dust coat, shoes etc..) must be worn

whilst operating the machine.

• Long hair or ties must be tightened up.

• Hand gloves should never be used.

• Workpieces and cutting tools must be properly clamped.

• Chuck keys must be removed when not in use.

• Do not leave any loosened parts on the machine table.

• Ensure you know how to operate the machine before switching on.

• Machine guards must be put in position when in use.

• Keep hands away from any rotating objects.

• Cutters used should be correctly ground and in good condition.

• Use the correct cutting speed, feed rate, and depth of cut from time to time.

• Spilled oil or cutting fluid must be swiped off immediately.

• Never use a hand file or emery cloth for finishing lathe work pieces.

• Do not leave a running machine unattended.

Index

1 Safety ……………………………………………………………................................................................... 3

1.1 Proper use ………………………………………………………………………………………………….. 3

1.2 Possible dangers caused by the lathe …………………………………………………………………… 4

1.3 Individual protection gear ………………………………………………………………………………….. 4

1.4 For your own safety during operation …………………………………………………………………….. 4

1.4.1 Disconnecting the lathe and making it safe ……………………………………………………….. 5

2 Unpacking and connecting ……………………………………………………………………………………... 6

2.1 Extent of supply ……………………………………………………………………………………………... 6

2.2 Installation and assembly …………………………………………......................................................... 6

2.2.1 Requirements of the installation site ………………………………………………………………... 6

2.2.2 Load suspension point ………………………………………........................................................ 6

2.2.3 Fixing …………………………………………………………………………………………………... 6

2.3 First Use ……………………………………………………………………………………………………… 7

2.3.1 Cleaning and greasing ……………………………………………………………………………….. 7

2.3.2 Optional accessories …………………………………………....................................................... 8

3 Operation …………………………………………………………………………………………………………. 9

3.1 Safety …………………………………………………………………………………………………………. 9

3.2 Control and indicating elements ………………………………………………………………………….... 9

3.3 Clamping the tool …………………………………………………………………………………………… 10

3.4 Clamping a workpiece into the lathe chuck ………………………...................................................... 11

3.4.1 Replacing the clamping jaws on the lathe chuck …………………………………………………. 12

3.4.2 Head spindle seat ……………………………………………………………………………………. 12

3.5 Switching ON/OFF ………………………………………………........................................................... 12

3.5.1 Changing-over switch ………………………………………........................................................ 13

3.6 Adjusting the speed ………………………………………………………………………………………… 13

3.6.1 Changing the speed range ………………………………………………………………………….. 13

3.7 Turning short tapers with the top slide ……………………………...................................................... 13

3.8 Turing between centres ……………………………………………........................................................13

3.9 Adjusting feeds and threads pitches ………………………………...................................................... 14

3.9.1 Switching on the feed …………………………………………………………………………… ..… 14

3.10 General working notes ……………………………………………………………………………………. 15

3.10.1 Coolant ……………………………………………………………………………………………... 15

4 Maintenance ……………………………………………………………………………………………………… 16

4.1 Safety ………………………………………………………………………………………………………… 16

4.2 Inspection and maintenance ………………………………………....................................................... 16

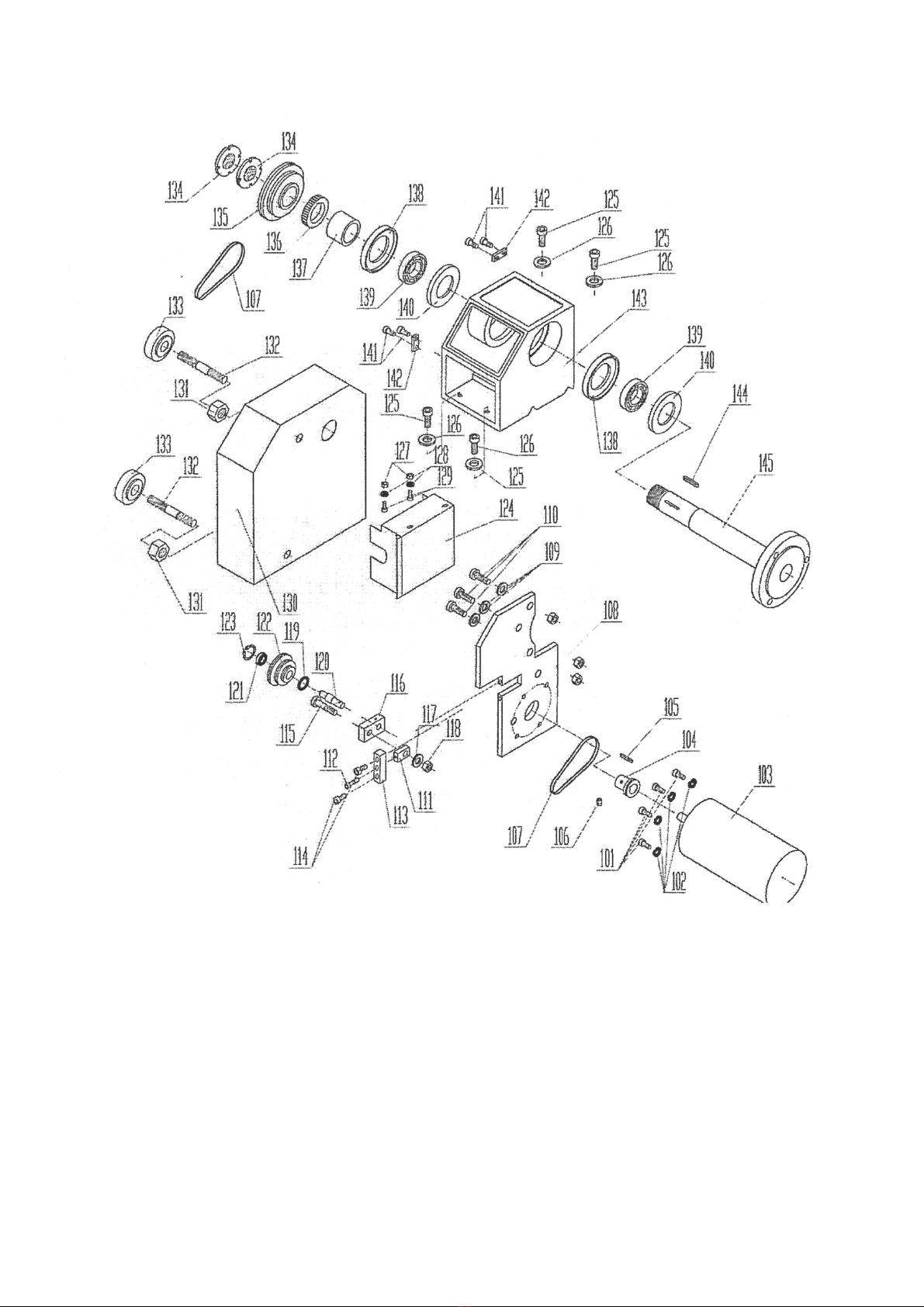

4.3 Spare parts drawing drive …………………………………………........................................................ 17

4.4 Spare parts drawing top slide and compound slide ……………………………………………………... 18

4.5 Spare parts drawing lathe slide ……………………………………………………………………………. 19

4.6 Spare parts drawing engine bed …………………………………………………………………………... 19

4.7 Spare parts drawing tailstock ………………………………………………………………………………. 20

4.8 Spare parts list …………………………………………………………………………………………… 21-23

5 Technical data……………………………………………………………………………………………………. 24

1 Safety

This part of the operating manual:

• Explains the meaning and use of the warning references contained in the operating manual

• Explains how to use the lathe properly

• Highlights the dangers that might arise for you or others if these instructions are not obeyed

• Tells you how to avoid dangers

In addition to this manual, please observe:

• Applicable laws and regulations

• Legal regulations for accident prevention

• The prohibition, warning, and mandatory signs as well as the warning notes on the lathe

Always keep this document close to the lathe for future reference.

1.1 Proper use

Warning!

In the event of improper use, the lathe

• Will endanger personnel

• Will endanger the machine and other material property of the operator

• May affect proper operation of the machine

The machine is designed and manufactured to be used in environments where there is no potential danger of

explosion.

The lathe is designed and manufactured for straight turning and facing round or regularly shaped three, six, or twelve

square workpieces in cold metal, castings and plastics or similar materials that do not constitute a health hazard or do

not create dust, such as wood, Teflon, etc..

The lathe must only be installed and operated in a dry and well-ventilated place.

Improper Use.

The lathe must only be used in any other way than described above, modified without our authorization, or operated

with different process data, then the lathe is being used improperly.

We do not take any liability for damage caused by improper use.

We would like to stress that any modifications to the construction, or technical or technological modifications that have

not been authorized by us will also render the guarantee null and void.

It is also part of proper use that

• The maximum values for the lathe are complied with

• The operating manual is observed

• Inspection and maintenance instructions are observed

In order to achieve an optimum cutting performance, it is essential to choose the right turning tool, feed tool, feed, tool

pressure, cutting speed, and coolant.

Warning!

It is forbidden to make any modifications or alterations to the operating values of the lathe.

1.2 Possible dangers caused by the lathe

The lathe has been designed and built using the latest technological advances, nonetheless, there remains a residual

risk since the machine operates with

• High revolutions

• Rotating parts

• Electrical voltage and currents

We have used construction resources and safety techniques to the minimize the risk to personnel resulting from these

hazards.

If the lathe is used and maintained by personnel who are not duly qualified, there may be a risk resulting from

incorrect operation or unsuitable maintenance.

All personnel involved in operation and maintenance must

• Be duly qualified

• Follow this operating manual

In the event of improper use

• There may be a risk to personnel

• There may be a risk to the machine, and other material property

• Correct functioning of the lathe may be affected

Remove the mains plug of the machine whenever you change gears, speed range, or clean the lathe.

There are additional requirements for work on the following machine parts:

• Electrical components or equipment. This work must only be carried out by a qualified electrician or person

working under the instructions and supervision of a qualified technician.

Warning!

Remove the protective cover of the headstock only after the mains plug has been removed.

1.3 Individual protection gear

For certain work individual protection gear is required.

Protect your face and eyes; during all work and especially work during which your face and eyes are exposed to

hazards. A safety helmet with guard should be worn.

Use protective gloves when handling pieces with sharp edges.

Wear safety shoes when transporting the lathe.

Use ear protection if the noise level (inmission) in the workpiece exceeds 80 dB(A).

Before starting work, make sure that the appropriate individual protection gear is available in the workplace.

1.4 For your own safety during operation

Before activating the lathe, ensure that this will not:

• Endanger other people

• Cause damage to equipment

Avoid unsafe working practices

• Make sure that your work does not endanger anyone

• Clamp the workpiece tightly before switching the lathe on

• Mind the maximum chuck opening

• Use protective goggles

• Do not removing turning chips by hand. To remove chips, use a chip hook and or a handbrush

• Clamp the turning tool at the correct height and with the least possible overhang

• Turn off the lathe before measuring the workpiece

• The instructions in this manual must be observed during assembly, handling, maintenance, and repair

• Do not work on the lathe if your concentration is reduced, for example, because you are taking medication

• Observe the rules for preventing accidents

• Stay at the lathe until all rotating parts have come to a halt

• Use the prescribed protection gear. Make sure to wear a well-fitting work suit, and if necessary, a hairnet.

1.4.1 Disconnecting the lathe and making it safe

Pull the mains plug before beginning any maintenance or repair work. All machine components and hazardous

voltages and movements must have been disconnected.

2 Unpacking and connecting

The lathes come preassembled. When the lathe is delivered, check immediately that it has not been damaged during

shipping, and that all components are included. Also, check that no fastenings have come loose.

2.1 Extent of supply

Compare the parts supplied with the information on the packing list.

2.2 Installation and assembly

2.2.1 Requirements of the installation site

Operation, maintenance and repair in the work area must not be hindered.

The mains plug of the lathe must be freely accessible.

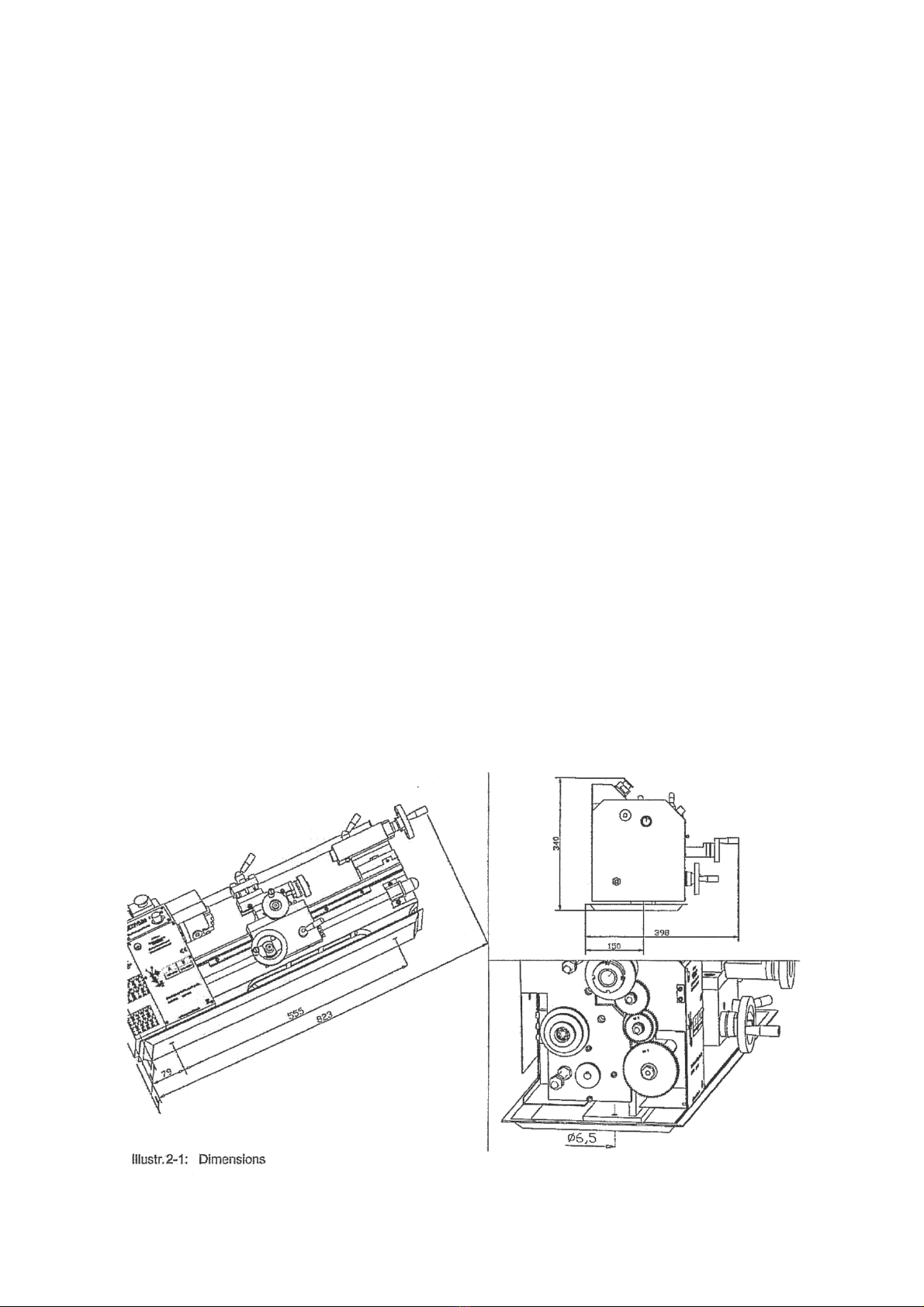

2.2.2 Load suspension point

Proceed extremely carefully when lifting, assembling and mounting the machine.

Take notice of the weight of the lathe when assembling. The weight amounts to 60kg.

Wear safety shoes

• Fasten the load suspension gear around the lathe bed

• Clamp the tailstock firmly before transporting the lathe

• Make sure that no add-on pieces or varnished parts are endangered due to the load suspension

2.2.3 Fixing

• Control the foundation of the lathe using a spirit level for horizontal orientation

• Make sure that the means of transport and the foundation on which the lathe is being placed can withstand

the load

• Place the lathe onto the provided foundation

• Screw the machine > Fix the lathe with the provided bore holes (2 pieces) together with the chip pan and the

provided foundation

Insufficient rigidity of the foundation leads to the superposition of vibrations between the lathe and foundation (natural

frequency of components). Insufficient rigidity of the entire lathe assembly also rapidly causes the lathe to reach

critical speeds, with unpleasant vibrations, leading to bad turning results.

2.3 First use

2.3.1 Cleaning and greasing

Cleaning the machine

Remove the anticorrosive agent applied to the lathe for transport and storage purposes. We recommend the use of

stove distillate.

Do not use any solvents, thinners, or other cleaning agents which could corrode the varnish on the lathe. Follow the

specifications and indications of the manufacturer of the cleaning agent.

Lubricate all bright machine parts with non-corrosive lubricating oil.

Grease the lathe using the lubrication chart (under “Inspection and maintainance”).

Control the function of movable and fixed parts

Check smooth running of all spindles.

Ensure the fastening screws of the lathe chuck are firmly tightened.

Clamp a workpiece into the lathe chuck, or bring the clamping jaws of the lathe chuck completely together before the

switch the lathe on.

Make sure that the current supply is working correctly

Connect the electrical supply cable (safety plug with earthing).

Warning!

Do not stand directly in front of the lathe chuck when you turn the machine on for the first time.

2.3.2 Optional accessories

4 jaw chuck 100mm

Flange for 4-jaw chuck

Face plate

Follow rest

Steady rest

Set of collet chucks, 1-16mm, 15 pieces (ER25)

ER25 Toolholder

Quick change tool holder AA

Single toolholder WAAD

Set of lathe tools, 10mm, 7 pieces

Set of tipped tools, 8mm, 11 pieces

3 Operation

3.1 Safety

Use the lathe only under the following conditions:

• The machine is in proper working order

• The lathe is used as prescribed

• The operating manual is followed

All abnormalities should be eliminated immediately. Stop the lathe immediately in the event of any abnormality in

operation and make sure it cannot be started up accidentally or without authorization.

3.2 Control and indicating elements

Warning!

Please be aware that the machine should only be run at low revs and high loads for a limited amount of time, then run

and unloaded at full speed to allow the motor to cool.

3.3 Clamping the tool

Clamp the turning tool into the tool holder.

The tool must be clamped firmly and with the least possible overhang in order

to absorb well and make sure that the cutting force is reliably generated during

the chip formation.

The maximum height between the supporting surface of the quadruplicate

toolholder and the center of the lathe chuck amounts to 10mm (11mm from

year of manufacture).

Adjust the height of the tool. Use the tailstock with the center point in order to

determine its required height.

If necessary, put the steel washers beneath the tool to achieve the required

height.

The blade of the tool must be exactly adjusted to the height of centers in order

to produce a shoulder-free front face. By facing, plain faces are being

produced which are rectangular to the axis of rotation of the workpiece. Here it

is distinguished between cross-facing, cross-slicing, and longitudinal facing.

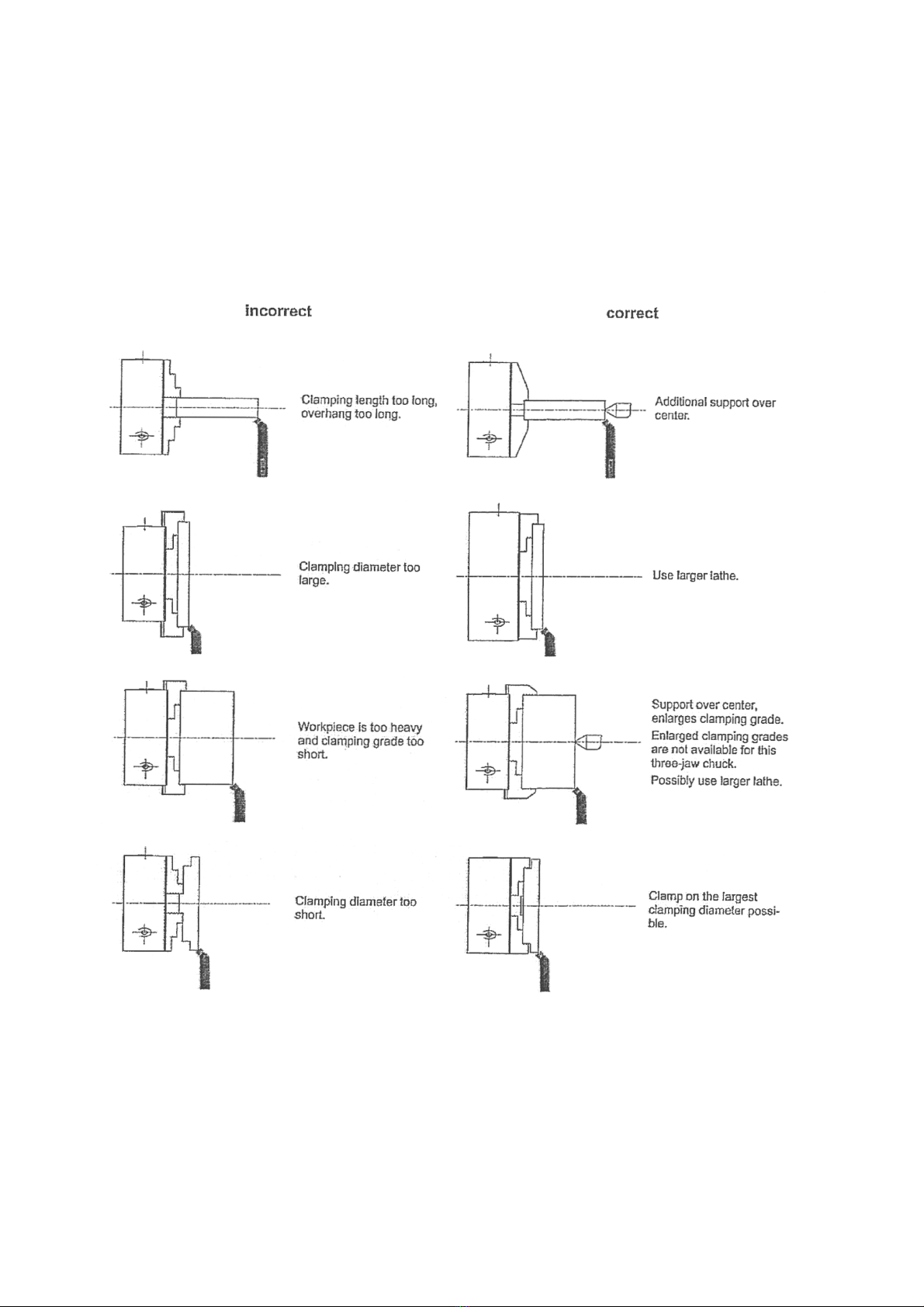

3.4 Clamping a workpiece into the lathe chuck

When the workpiece is being improperly clamped, there is a risk of injury as the workpiece may fly off or the jaws may

break. The following examples do not show all possible risks of danger.

The workpiece should be clamped safely and tightly on the lathe before starting operation. The clamping force should

be dimensioned in a way that ensures the workpiece is securely driven and that there are no dangers or deformations

in the workpiece.

Do not clamp any workpieces that exceed the permitted chucking capacity of the lathe chuck. The clamping force is

too low if its capacity is exceeded, the jaws may also come loose.

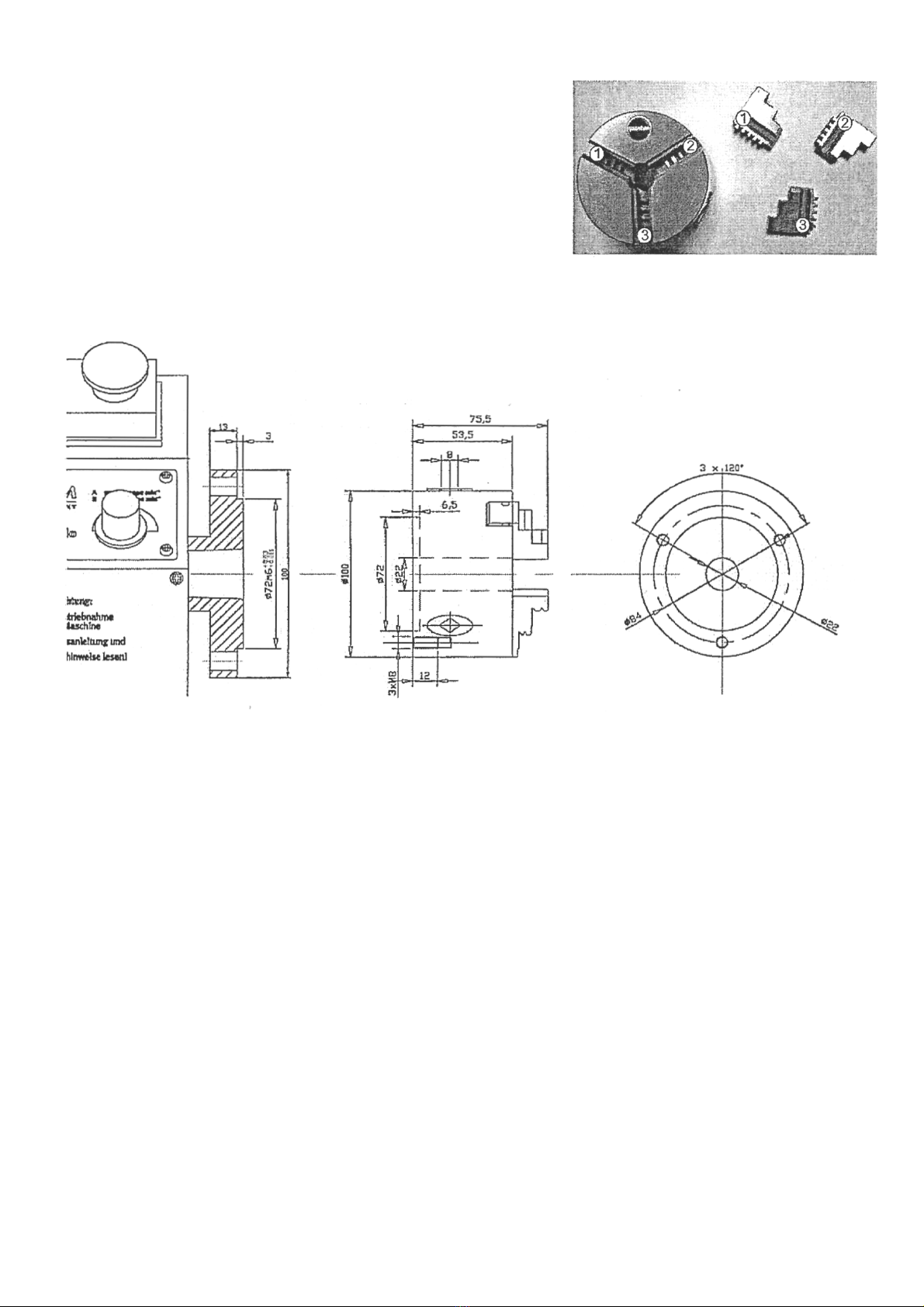

3.4.1 Replacing the clamp jaws on the lathe chuck

The clamping jaws and the three-jaw chuck are equipped with numbers.

Insert the clamping jaws at the correct position and in the right order into

the three-jaw chuck.

After replacement, bring the jaws completely together in order to ensure

that they are inserted correctly.

3.4.2 Head spindle seat

Optional accessory for this machine.

When disassembling the work support, it may fall on the engine bed and damage the guide rails. Place a wooden

plank or another adequate part on the engine bed in order to avoid damage.

• Disconnect the machine from the electrical supply

• Block the revolutions of the spindle. For instance, by inserting the square seat of the lathe chuck. Also ensure

that the engine bed is not damaged by the arm of the lever

• Loosen the three nuts on the flange of the lathe chuck to disassemble the work support

• Remove the work support to the front

• If required, loosen the work support by knocking it slightly with a plastic tip or rubber mallet

3.5 Switching on / off

Check that the engaging lever is not activating when cutting threads.

By switching the lathe on with high-speed setting and activating engaging lever, the lathe slide will move with high

speed.

Before switching the lathe on, turn the potentiometer for speed setting to a low-speed setting.

The electronics may be damaged if the machine is switched on at a full speed setting.

The machine can be switched on with the ON / OFF switch. The lathe may only be switched on when the change-over

switch is in the position of R or L.

3.6 Change-over switch

The sense of rotation of the lathe is performed by the change-over switch.

• The R marking means right-handed rotation. The lathe chuck turns anti-clockwise

• The L marking means left-handed rotation. In the left-handed rotation for instance, the lathe slide is being

reversed for thread cutting. In the position 0 the engine is switched on.

Wait until the lathe has come to complete halt before inverting the turning direction using the control levers. Changing

the turning direction during operation may cause damage to components.

3.6 Adjusting the speed

Adjust the speed with the potentiometer.

In order to use another speed range, you must change the position of the

synchronous belt on the pulleys.

Unplug the shockproof cover of the lathe before opening the protective

cover of the headstock.

3.6.1 Changing the speed range

• Unplug the shockproof cover from the mains

• Detach the protective cover of the headstock

• Loosen the fastening nut of the shim with a 14mm fork wrench

• Screw in the hexagon socket screw, reducing the tension of the

synchronous belt

• Lift the upper synchronous belt onto the required wheel diameter

• Proceed the other way around to tighten the synchronous belt. The correct

tension of the belt has been reached when you can still bend it

approximately 3mm with your index finger

Make sure the tension of the synchronous belt is correct. Excessive or insufficient

tension may cause damage.

3.7 Turning short tapers with the top slide

To turn short tapers the top slide is to be adjusted according to the required angle.

• Loosen the fastening screws

• Swivel the top slide

• Clamp the top slide again

• Clamp the top slide

3.8 Turning between centers

For the operation between centers check the clamping of the tailstock or

spindle sleeve.

Screw the safety screw at the end of the lathe bed in order to avoid

unintentional pulling of the tailstock out of the lathe bed.

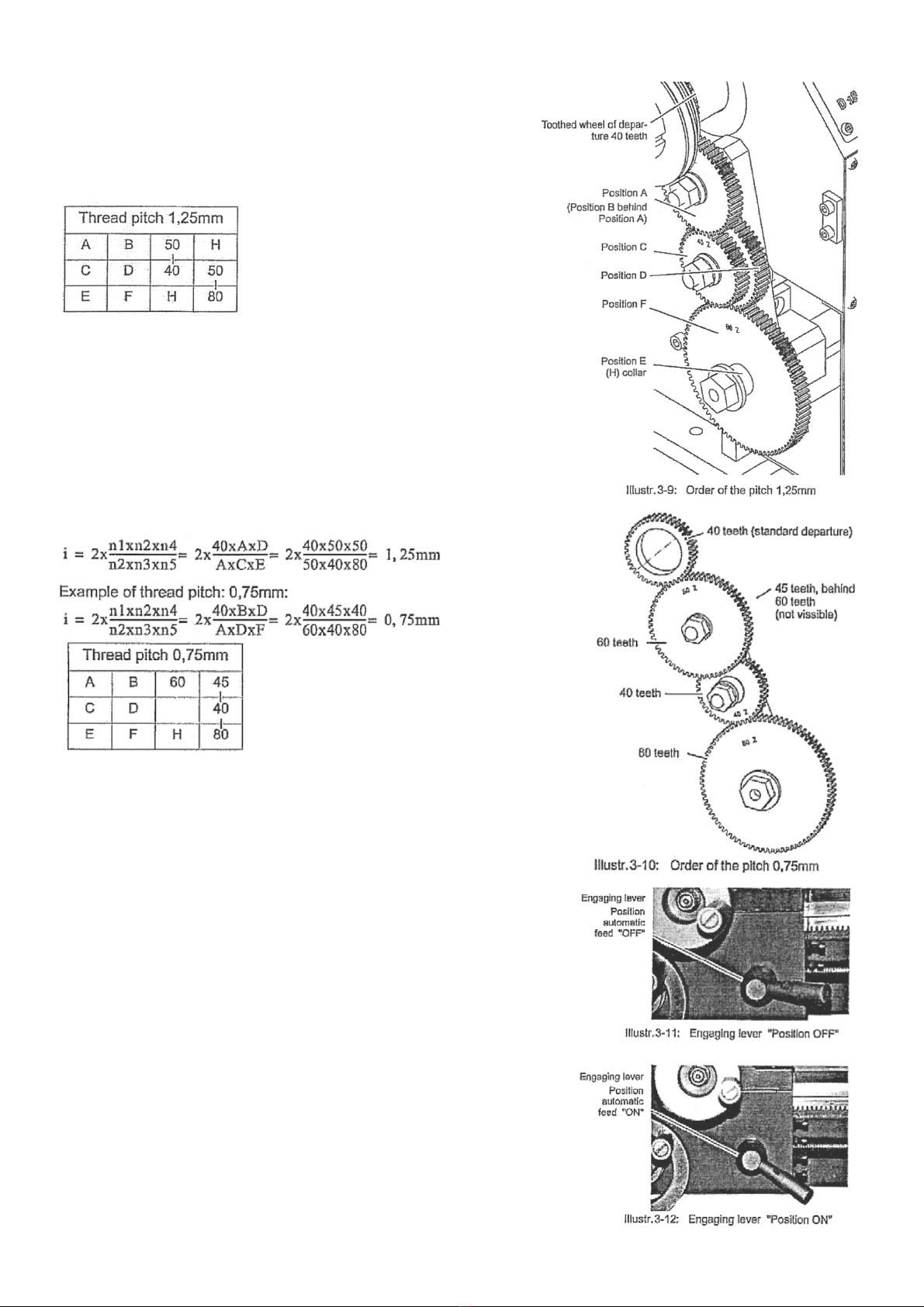

3.9 Adjusting feeds and thread pitches

In order to achieve a change of feed of a certain thread pitch, the

changes wheels are to be changed according to the table. You will

find the complete table on the lathe.

For example:

• The toothed wheel of departure with 40 teeth cams in the

toothed wheel A

• The toothed wheel A cams in the toothed wheel C

• The toothed wheel D cams in the toothed wheel F

• H means the vacuity (collar). You may as well use a smaller

toothed wheel which does not cam in with any other

toothed wheel

Example of transmission ratio:

The thread pitch of the leading spindle amounts to 2mm.

The toothed wheel of departure with 40 teeth cams in the toothed wheel A

The toothed wheel B cams in the toothed wheel D

The toothed wheel D cams in the toothed wheel F

Metrical threads are indicated as thread pitch. In the example above, the

lathe saddle moves by 1.25mm during one turn of the lathe chuck. Inch

threads are indicated as number of threads on the length of one inch. The

length of one inch amounts to 25.4mm.

3.9.1 Switching on the feed

When switching on the lathe with high revolution setting and the engaging

lever activated, the lathe saddle moves at a high speed.

If you switch on the lathe for instance at full speed of 2500min with the

order of the toothed wheels for thread pitch 1.25mm, the lathe saddle will

travel a distance of 52mm within one second.

Threads are always cut with the least possible speed.

3.10 General working notes

3.10.1 Coolant

Friction during the cutting processes causes high temperature at the cutting edge of the tool.

The tool should therefore be cooled during the cutting process. Cooling the tool with a suitable cooling lubricant

ensures better working results and a longer edge life of the cutting tool.

Use a water soluble and non-pollutant emulsion as a cooling agent. This can be acquired from authorized distributors.

Make sure that the cooling agent is properly retrieved. Respect the environment when disposing of any lubricants and

cooling agents. Follow the manufacturers disposal instructions.

4 Maintenance

In this section you will find important information about

• Inspection

• Maintenance

• Repair

Properly performed regular maintenance is an essential prerequisite for

• Safe operation

• Faulty-free operation

• Long service life of the lathe and

• The quality of the products you manufacture

Installations and equipment from other manufacturers must be in optimum condition.

4.1 Safety

The consequences of incorrect maintenance and repair work may include

• Very serious injury to users working on the lathe

• Damage to the lathe

Only qualified users should carry out maintenance and repair work on the lathe.

4.2 Inspection and maintenance

The type and extent of wear depends to a large extent on individual usage and service conditions. For this reason, all

intervals are only valid for the authorized conditions.

Interval

Where?

What?

How?

Every

Week

Machine Bed

Lubricate

Lubricate all blank steel parts with a non-corrosive oil

Headstock

Inspection

Control the tension of the synchronous belts

Lubricate

Slightly lubricate the change wheels and the leading

spindle with a lithium grease.

4.3 Spare parts drawing. Drive

4.4 Spare parts drawing. Top slide and compound slide

4.5 Spare parts drawing. Lathe slide

4.6 Spare parts drawing. Engine bed

Table of contents

Other CHESTER Lathe manuals

CHESTER

CHESTER Cobra Mill User manual

CHESTER

CHESTER Coventry Pro User manual

CHESTER

CHESTER Crusader User manual

CHESTER

CHESTER Craftsman User manual

CHESTER

CHESTER CONQUEST SUPER User manual

CHESTER

CHESTER DB8VS User manual

CHESTER

CHESTER Centurion Series User manual

CHESTER

CHESTER DB8VS User manual

CHESTER

CHESTER Voyager Lathe User manual

CHESTER

CHESTER 920 User manual

Popular Lathe manuals by other brands

Grizzly

Grizzly G0776 owner's manual

Jet

Jet CL-1640ZX operating instructions

Far Tools

Far Tools ML 400B Original translation

Carbatec

Carbatec WL-B1220H instruction manual

Carbatec

Carbatec WL-B1420P instruction manual

woodmizer

woodmizer Sawmill LT20 AC MH Series Safety, Setup, Operation & Maintenance Manual