dispomed MODUFlex COAXIAL User manual

805-0975-025

2DISPOMED Ltd. / 1 800 363-1746 / [email protected] / www.dispomed.com

TM/MC

TABLE

OF CONTENTS

User Responsibility .......................... 3

Standard and Optional Features ............... 4

Receiving , Assembly and Instructions .........5-9

Assembled View ............................10

Optional accessories Assembly Instructions ...11-14

Assembled View With Optional Accessories .....15

Daily Leak Check Procedure ............... 16-17

Moduflex Elite ..............................18

Annual Maintenance.........................19

Consumable Materials List...................20

Warranty...................................21

Order Part Numbers ..................... 22-23

ModuflexTM is a trademark of Dispomed Ltd.

805-0975-025 3

TM/MC

Read this manual before operating the unit. Pay special attention to all

warnings and cautions.

• This product will perform in conformity with the description

contained in this operating manual when assembled,

operated, maintained and repaired in accordance with the

instructions provided.

• This product must be verified periodically.

• A defective product should not be used.

• Parts that are broken, missing, plainly worn, distorted or

contaminated should be replaced immediately.

• Should a repair or replacement become necessary, Dispomed

recommends placing a request by phone or in writing to the

nearest Dispomed regional service center.

• This product, or any of its parts, should not be repaired other

than in accordance with written instructions provided by

Dispomed and by Dispomed trained personnel.

• The product may not be altered without prior written approval

from Dispomed.

• The user of this product shall have the sole responsibility

for any malfunction which results from improper use, faulty

maintenance, improper repairs, damage or alteration by

anyone other than a Dispomed trained technician.

USER

RESPONSIBILITY

805-0975-025

4DISPOMED Ltd. / 1 800 363-1746 / [email protected] / www.dispomed.com

TM/MC

The Moduflex Coaxial is the first machine to incorporate a CO2 absorber with an integrated Coaxial

breathing circuit. This reduces clutter, eliminates the possibility of a disconnection, and reduces heat

loss by preheating the inhaled gasses with the exhaled gasses. The Moduflex Elite is the same as the

Moduflex Coaxial, but with the traditional “Y” connections.

STANDARD FEATURES

• 0.1 to 4 LPM O2 flowmeters (up to 2 flowmeters

can be installed).

• Rotary float and large scale for easy readability.

• Recessed flush valves to prevent accidental

activation.

• Quick connect fresh gas outlet for easy and

secure switching between breathing circuits.

• SELECTATECTM compatibility manifold for easy

and quick installation of vaporizer

• 1500 ml CO2 absorber with integrated coaxial

breathing circuit reduces patient heat loss, helps

to humidify the inspired gas and reduce clutter.

• Condensation trap to prevent water build-up in

soda lime. Easy and efficient gas sealing.

• Momentary closed features incorporated into

pop-off valve.

• Convenient anesthesia monitor shelf.

• 2.5 meter oxygen supply hose (D.I.S.S.).

• 5-year warranty.

OPTIONAL FEATURES

• Small cylinder holder

• Bain circuit adaptor

• 0-1 LPM O2 flowmeter

• Up to 2 flowmeters can

be installed

• Circuit pressure alarm

• Extra large monitor shelf

THE COAXIAL

ANESTHESIA MACHINE

805-0975-025 5

TM/MC

Your Moduflex Coaxial or Elite anesthesia ma-

chine requires some assembly before use. The

Moduflex Elite is the same as the Moduflex

Coaxial, but with the traditional “Y” connec-

tions.

RECEIVING

In order to reduce the possibility of damage to

a minimum during shipping, the head assembly

and other breathing circuit components have

been detached from the unit. These compo-

nents are packed separately within the ship-

ping crate.

INSPECTION

On receipt of your unit, inspect the shipping

container and the enclosed components for

signs of damage. Check your Materials List to

ensure that all the necessary components are

included.

RECEIVING AND ASSEMBLY

INSTRUCTIONS

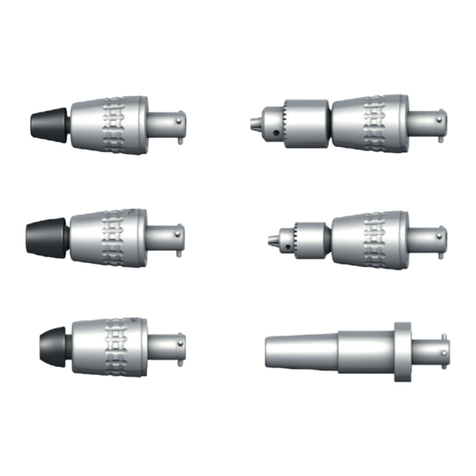

x1

x1

x1

x1 x1 x1

x1

x1 x1

OR

x4

x1

OR

x1 x1

x1

Coaxial Elite

Coaxial Patient Circuit

Y Patient Circuit for Elite unit

x1

805-0975-025

6DISPOMED Ltd. / 1 800 363-1746 / [email protected] / www.dispomed.com

TM/MC

Carefully remove the head assembly from the

box (caution: do not use the shelf assembly as

a carrying handle, damage to the shelf may oc-

cur) and slide the U-channel onto the post of the

base assembly (the absorber connections face

the same way as the locking castors).

RECEIVING, ASSEMBLY

INSTRUCTIONS CONTINUED

Remove the base assembly from the box and

place it upright on the floor with locking castors

at the front and slide the post onto the base with

threaded holes positioned as illustrated.

21

805-0975-025 7

TM/MC

Insert and tighten the four levelling screws at

the top and the bottom of the post.

Remove the accessories from the bag.

RECEIVING, ASSEMBLY

INSTRUCTIONS CONTINUED

3 4

805-0975-025

8DISPOMED Ltd. / 1 800 363-1746 / [email protected] / www.dispomed.com

TM/MC

Install the breathing tube to the CO2 absorber

connection with a small twisting motion.

When connecting a Universal F circuit

(not included) pay attention to the inspiration

and expiration outlets to hook them up

correctly.

5a. Install the oxygen supply tubing to the oxy-

gen supply inlet at the back of the machine. 5b.

Connect the other end of the oxygen tube to a

50 p.s.i. (3 bars) oxygen supply.

Inspiration

Expiration

Universal F

Breathing Circuit

SKU: 940-12U6006

RECEIVING, ASSEMBLY

INSTRUCTIONS CONTINUED

5a

5b

6 Coaxial

6 Elite

Inspiration

Expiration

a

b

805-0975-025 9

TM/MC

Connect the fresh gas hose from the fresh gas

outlet to the CO2 fresh gas inlet.

CAUTION: Always depress locking mechanism

while inserting and removing fresh gas connec-

tion.

Install the breathing bag on the swivel bag

mount.

RECEIVING, ASSEMBLY

INSTRUCTIONS CONTINUED

7 8

805-0975-025

10 DISPOMED Ltd. / 1 800 363-1746 / [email protected] / www.dispomed.com

TM/MC

Install the gas evacuation tube to the back of the

machine.

1. Loosen the absorber sealing screw and re-

move the soda lime canister. 2. Affix Soda Lime

expiration label to the Soda Lime container. 3.

Fill the canister with absorbent using loose-fill

granules. (Caution: do not overfill the canister;

leave approximately ¼” (5 mm) from the top

empty.) 4. Reinstall the canister and tighten the

sealing screw.

RECEIVING, ASSEMBLY

INSTRUCTIONS CONTINUED

9 10

1

2

805-0975-025 11

TM/MC

1500 ml CO2

Absorber Canister

Flowmeter

Flush valve

Vaporiser Manifold

ASSEMBLED

VIEW 1

805-0975-025

12 DISPOMED Ltd. / 1 800 363-1746 / [email protected] / www.dispomed.com

TM/MC

OPTIONAL ACCESSORIES

ASSEMBLY INSTRUCTIONS

BAIN CIRCUIT ADAPTOR

VAPORIZER

1

1

2

2

1. Insert the vaporizer into the bracket. 2. Secure

the vaporizer in place with the locking mecha-

nism.

1. Screw the Bain adapter holder onto the anes-

thesia machine. 2. Insert the Bain adapter into

the bracket previously attached to the unit.

*Bain type open circuit on an anesthesia machine

gives you better control during surgery. The

breathing bag is always inflated, no need to wait

for it to have reached a certain size before venti-

lating the patient. Moduflex Bain is equipped with

a pressure gauge that gives you the possibility to

check the animal’s lung pressure. The Bain adap-

tor is equipped with a momentary valve to avoid

forgetting the valve in a closed position, which

could cause pulmonary trauma to the animal.

805-0975-025 13

TM/MC

OPTIONAL ACCESSORIES

ASSEMBLY INSTRUCTIONS

Screw the interface to anesthesia unit using the

screws provided in the package. Install the scav-

enger interface as per interface instructions.

During surgery unused gas should be evacuated

outside of the building to avoid it being inhaled

by your employees and patients. Connected to

a gas evacuation ventilator, the scavenger inter-

face controls the flow of suction and maintains

the balance with the quantity of unused gas.

CIRCUIT ALARMSCAVENGER INTERFACE

1

2

IMPORTANT: Always refer to the user manual of the

option you are installing for more detailed instruc-

tions.

1. Screw the circuit alarm holder on the anes-

thesia machine. 2. Screw the circuit alarm to the

support previously screwed to the device.

During assisted ventilation, the alarm will alert

you if the predetermined pressure level is

reached. For example, if you forget the evacua-

tion valve in a closed position, the circuit alarm

will alert you with a warning sound at the prede-

termined pressure.

805-0975-025

14 DISPOMED Ltd. / 1 800 363-1746 / [email protected] / www.dispomed.com

TM/MC

OPTIONAL ACCESSORIES

ASSEMBLY INSTRUCTIONS

IMPORTANT : Always refer to the user manual of

the option you are installing for more detailed

instructions.

1. Place and screw the two sections of the

holder around the post of the anesthesia ma-

chine. 2. Connect the hose to the appropriate

connections.

The cylinder holder can be helpful in many situ-

ations. It can be very useful when there is a lack

of oxygen in the central system. In the occasion-

al case where you need to move an anesthetized

animal to a room where there are no oxygen out-

lets, the cylinder holder enables you to keep the

patient in an ideal condition.

E-TANK HOLDER

1

2

805-0975-025 15

TM/MC

ASSEMBLED VIEW

WITH OPTIONAL ACCESSORIES

Bain Circuit Adaptor

965-0500-000

Installation on page 12

Patient Circuit Alarm

987-0010-000

Installation on page 13

Vaporizer

990-VI5P-SVEEZ

Installation on page 12

Cylinder Holder

975-0300-400

Installation on page 14

Scavenger Interface

985-0200-000

Installation on page 13

805-0975-025

16 DISPOMED Ltd. / 1 800 363-1746 / [email protected] / www.dispomed.com

TM/MC

Connect the circuit to be verified to the fresh

gas outlet of the anesthesia machine.

Obstruct the patient’s circuit outlet with a plug

or your thumb.

Open flowmeter to approximately 200 ml. Close the gas evacuation valve.

The unit’s integrity should be verified every day, and at each re-

placement of patient circuit components such as breathing bags,

tubes, etc. A properly maintained anesthesia machine reduces gas

consumption and operating room pollution.

Prerequisites:

Oxygen supply of 40 to 60 psi

(3 bars) Breathing circuit and

bag.

DAILY LEAK

CHECKS PROCEDURES

2

3 4

1

805-0975-025 17

TM/MC

If you encounter an excessive leak, it is recom-

mended that you proceed by elimination to find

the source of the problem by replacing a single

component at a time. The most frequent leaks

can be found at the fresh gas outlet o’ring, the

patient circuit and the bag.

Once the leak is identified, dispose of the de-

fective item to avoid it being reused by error.

At the end of each day, it is recommended that

you close the oxygen tank and fill the

anesthetic agent vaporizer.

8

Press oxygen flush button and hold until the

pressure on the manometer indicates approxi-

mately 30 cm H2O.

Check the manometer. The pressure must not

drop (but it can increase). If the pressure drops,

replace the patient circuit and the bag and try

again.

Caution: Open the evacuation valve before us-

ing the anesthesia machine again.

DAILY LEAK

CHECKS PROCEDURES

5 6

7

805-0975-025 18

TM/MC

ANNUAL

MAINTENANCE

845-S019 x2

845-S019 x2

845-S010 x2

845-S106 x2

845-S113 x2

845-S011 x1

845-S113 x1

980-0200-055 x2

980-0300-100 x1

980-0300-105 x1

Prerequisite:

Preventative maintenance kit

# 975-0900-900

The maintenance kit contains

all the necessary parts to per-

form the annual maintenance.

Refer to this technical draw-

ing the replacement parts are

identified. Perform the daily

leak check procedure (page

17) once after the mainte-

nance is done.

980-0300-300 x1

Moduflex Elite Only

# 940-3704-800

Y PATIENT CIRCUIT

805-0975-025

19 DISPOMED Ltd. / 1 800 363-1746 / [email protected] / www.dispomed.com

TM/MC

CONSUMABLE MATERIALS

LIST

0.5 liter: # 940-0200-005

1 liter: # 940-0200-010

2 liters: # 940-0200-020

3 liters: # 940-0200-030

Moduflex Coaxial Only

# 940-0200-200

1.6 liters: # 905-8855-000

18.9 liters: # 905-8862-000

REBREATHING BAGS

KRYTOX

COAXIAL PATIENT

CIRCUIT

GAS EVACUATION TUBING

CARBON DIOXIDE

ABSORBENT

7g : # 850-0052-000 152.4cm / 5’ :

# 985-0065-000

805-0975-025 20

TM/MC

Dispomed Ltd. guarantees that the Moduflex

Compact anesthesia machine is free from

manufacturing defects for a period of five

(5) years from the date of delivery to the

customer, provided that it is used according

to the instructions provided and that the

prescribed maintenance and service are

performed.

Dispomed shall not be held liable for

damage, injury or loss arising out of the

use of the product, whether as a result of a

defect in the product or otherwise, if, prior

to such damage, injury or loss, the product

was:

• Damaged, misused or misapplied;

• Repaired, altered or modified by a

person other than a Dispomed Ltd.

technician or approved service people;

• Not installed in strict compliance with

the instructions provided by Dispomed

or with the applicable codes and

ordinances in place;

• Cleaned using alcohol or other

damaging products.

Plastic, rubber and consumable items are

guaranteed to be free of defects at the date

of delivery to the customer.

Any product which proves to be defective in

workmanship or material will, at Dispomed’s

discretion, either be repaired or replaced.

Dispomed Ltd. is not responsible for

deterioration, wear or abuse of this unit.

This warranty shall be void for any product

on which the serial number has been

altered, defaced or removed.

Shipping charges for any unit repaired

or replaced is the responsibility of the

customer. Leaner units are available while

your unit is being repaired.

SERVICE AND INFORMATION CENTER

Dispomed Ltd is proud to offer its customers

an online or telephone service to answer

any questions or concerns regarding its

products.

Contact us at:

T: 1-800-363-1746

T: 1 450 759-9395

F: 1 450 759-8181

Email: [email protected]

Website: www.dispomed.com

Facebook: www.facebook.com/dispomed

Youtube: www.youtube.com/dispomedltd

DISPOMED

WARRANTY

Table of contents

Other dispomed Medical Equipment manuals