4/5

Operation – Input and Output Signals

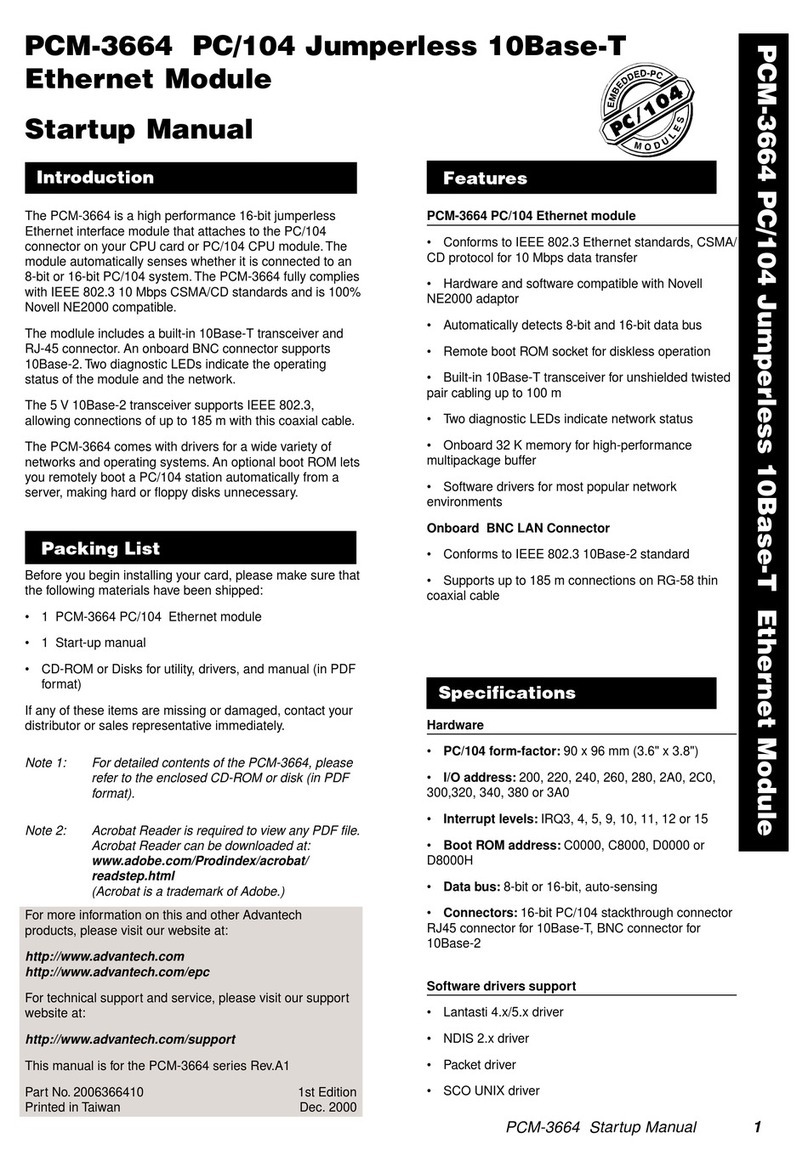

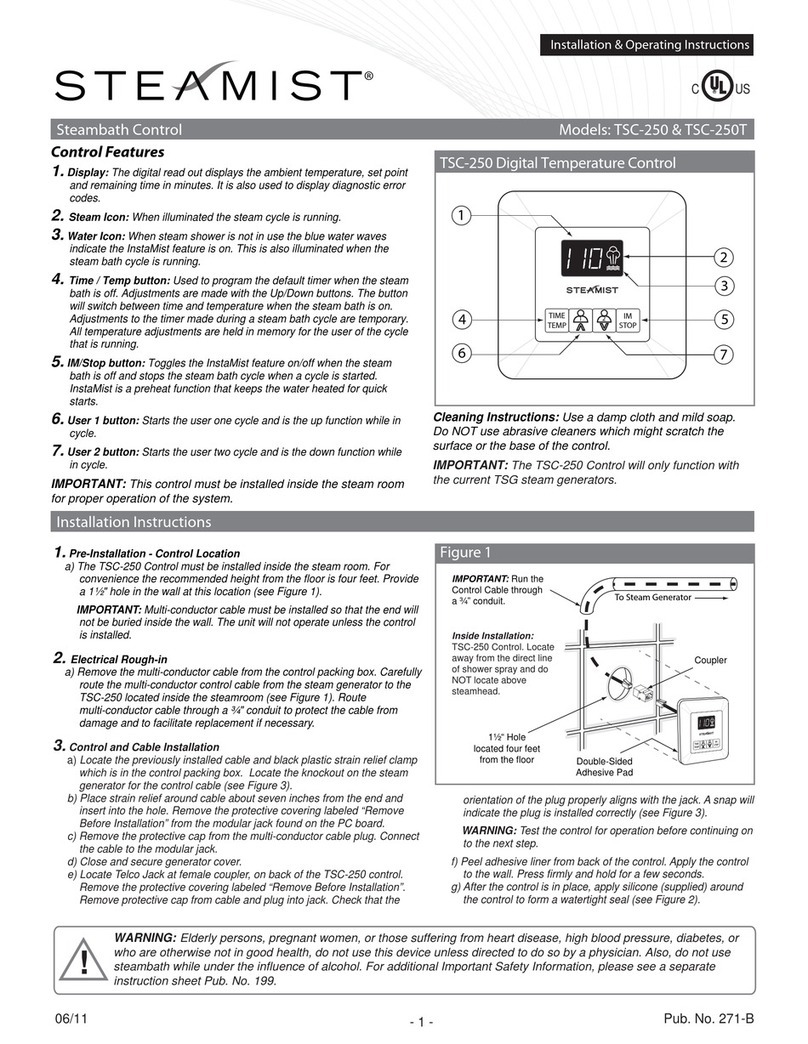

The input signal type is selected with the 4 position DIP switch labeled INPUT SELECT. The available input signal types and DIP switch positions are

shown in the chart below.

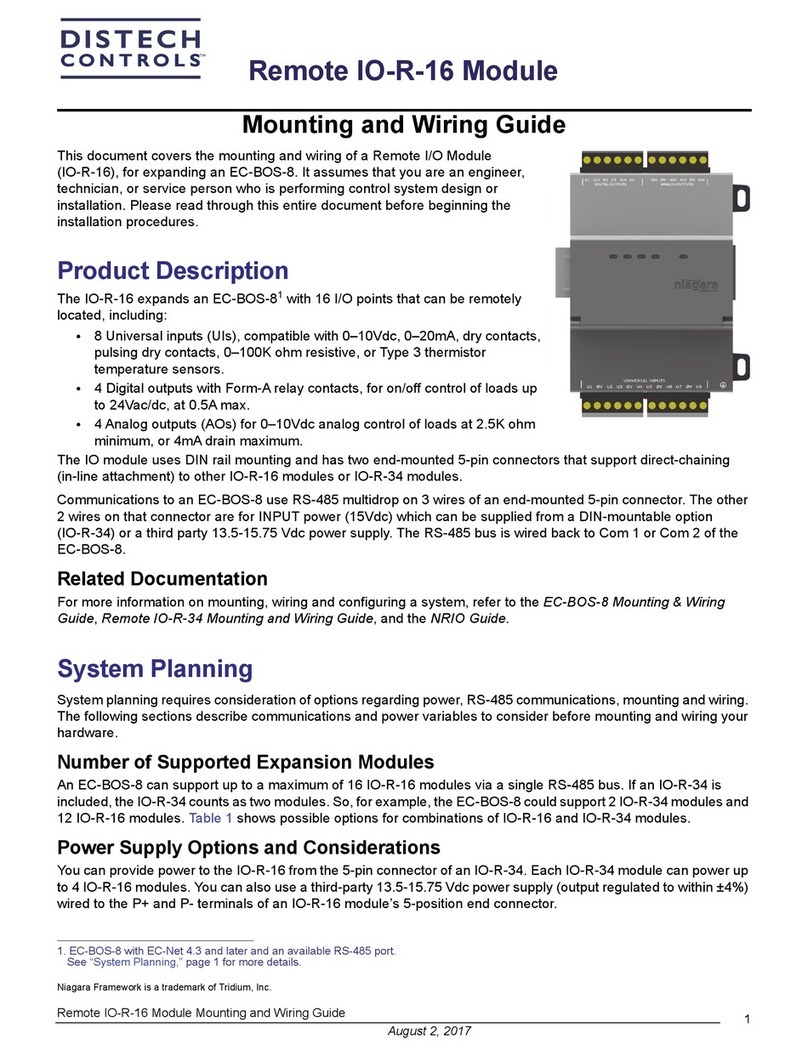

Figure 6 Input and Output Signals

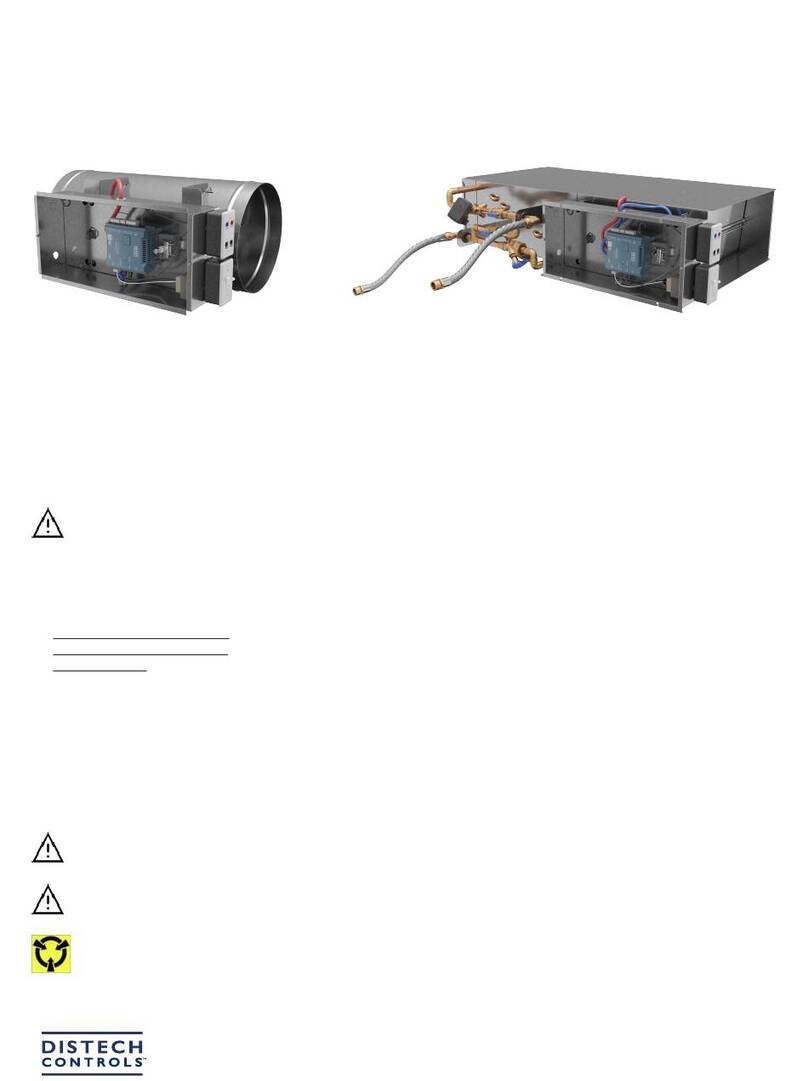

Figure 7 Applications of Operation Input Output Signals

The ranges shown in the chart are all pre-calibrated such that 0-100% of the input signal will cause the output resistance from W to R to change from the

pot minimum to the maximum value.

Upon power up, the wiper will start at the W position but will immediately sample the input signal and move to the resistance value proportional to the input

signal and the selected input range.

For example, for a 0-5 Vdc input signal and a 0-135 Ω pot, the resistance between W (min) and R (wiper) will be 0 Ω for 0 Vdc input and the resistance

between B (max) and R (wiper) will be 135 Ω. As the input signal increases from 0 to 5 Vdc, the resistance between W and R will increase and the

resistance between B and R will decrease until the input signal is 5 Vdc. At 5 Vdc the W-R resistance will be 135 Ω and the B-R resistance will be 0 .

The resistance output has a minimum and maximum value and does not wrap around. In the above example with 0-5 Vdc input signal, the W-R resistance

will increase to 135 Ω and will stay at 135 Ω even in 6 Vdc is applied to the input.

Voltage input signals are referenced to the COM terminal and have an input impedance of >10 KΩ.

Current input signals are also referenced to COM and have an input impedance of 250 Ω. The current input is a sinking type signal, the controller must

source the 0-20 mA signal.

The signal interface features a micro-controller for highest accuracy and includes input filtering and hysteresis to prevent relay chatter or hunting for the

correct output resistance value. The output resistance is controlled with a 256 bit resolution.

Operation – Failsafe Input

The signal interface OUTPUT terminals are connected to the resistance values through a DPDT relay that is used to control the failsafe function. During

normal operation with power applied to the signal interface, the pot resistance is connected to the OUTPUT terminals.

In the event of a power loss, the failsafe relay will disconnect the OUTPUT terminals from the pot value and instead connect the OUTPUT terminals directly

to the FAILSAFE terminals.

This is useful in several ways, for example, discreet resistor may be connected to the W (min) and R (wiper) terminals of the FAILSAFE connector to set

a minimum resistance value on power failure. If the signal interface is controlling a damper actuator, then the resistance would set a minimum open position

on power failure.

To failsafe to the minimum signal interface resistance value, connect a wire jumper between the W and R terminals of the FAILSAFE connector.

To failsafe the maximum signal interface resistance value, connect a wire jumper between the B and R terminals of the FAILSAFE connector.

A manual potentiometer may also be connected to the FAILSAFE connector to allow manual control. The PCB has a MAN / AUTO jumper that can be

used to force the failsafe mode. For normal operation the jumper is placed in the AUTO position. To test the system, place the jumper in the MAN position

and the OUTPUT terminals will immediately connect to the FAILSAFE terminals so an external pot can be used to manually control the device connected

to the signal interface output.

Return the jumper to the AUTO position for normal operation.