1 Version 4.2 ©2001 - 2005 DMC Co., Ltd.

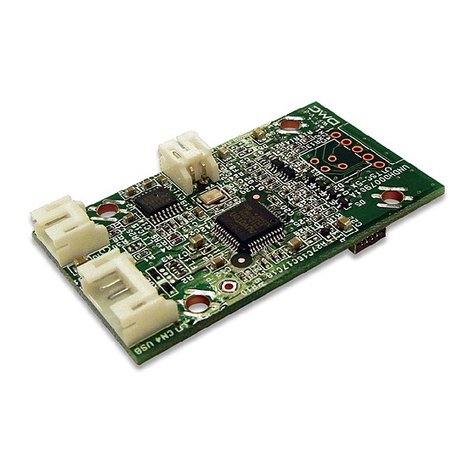

TSC-10/IC Product S

ecification

Table of Contents

1. PRODUCTS OUTLINE.......................................................................................................................... 2

1-1. Scope of Application ..........................................................................................................................2

1-2. Outline................................................................................................................................................2

1-3. Features .............................................................................................................................................3

1-4. General specification..........................................................................................................................3

2. Pin layout and representation ................................................................................................................ 4

3. Pin functions.......................................................................................................................................... 5

4. Initial setting .......................................................................................................................................... 6

4-1. EEPROM setting ................................................................................................................................6

4-2. Communication mode setting.............................................................................................................6

4-3. Configuration in USB mode................................................................................................................7

4-4. Panel ID setting (USB mode) .............................................................................................................7

5. Data sheet............................................................................................................................................. 8

5-1. Absolute maximum rating...................................................................................................................8

5-2. Recommended operational conditions ...............................................................................................9

5-3. Timing requirement ..........................................................................................................................10

5-4. DC standards ...................................................................................................................................12

6. Packaging Specification....................................................................................................................... 13

6-1. Outline..............................................................................................................................................13

6-2. Notes on storage/handling ...............................................................................................................13

6-3. Basic packaging ...............................................................................................................................13

6-4. Small group packaging.....................................................................................................................14

6-5. Tray specification .............................................................................................................................15

6-6. Product name label specification......................................................................................................15

7. Storage Specification........................................................................................................................... 16

7-1. Storage Conditions...........................................................................................................................16

7-2. Baking ..............................................................................................................................................16

8. Implementation Temperature Specification .......................................................................................... 17

1. Reflow method (Infrared reflow, air reflow, VPS reflow) ......................................................................17

2. Wave soldering method (Flow soldering, solder dip method) ..............................................................17

3. Soldering iron (Manual soldering)........................................................................................................18

4. Reflow method (Infrared reflow, air reflow: When lead-free solder is used) ........................................18

5. Wave soldering method (Flow soldering, solder dip method when lead-free solder is used) ..............18

9. Changes and improvements ................................................................................................................ 19

9-1. Version history .................................................................................................................................19

10. Warranty............................................................................................................................................ 21

10-1. Warranty Period .............................................................................................................................21

10-2. Warranty Target .............................................................................................................................21

10-3. Warranty Exceptions ......................................................................................................................21

11. Notes on use ..................................................................................................................................... 22

11-1. Overall handling .............................................................................................................................22

11-2. Others ............................................................................................................................................22

Dimensional Drawing

Circuit Diagram

Part List