3

Grain Flow

TABLE OF CONTENTS

*IMPORTANT! Itis veryimportantforthe dealerand/or the person(s) installingthe Grain Flow

(withDry Grain Control for the Calc-U-Dri) togo throughthe Start-UpChecklistProcedure.

Failure to do so will invalidate warranty.

SAFETYGUIDELINES........................................................................................................... 4 - 8

DECALLOCATIONS .............................................................................................................9 - 11

Introduction ............................................................................................................................... 12

OverallDimensions-Grain Flow................................................................................................ 13

GrainFlow Installation Instructions......................................................................................14 -25

GrainSamplerInstallation ............................................................................................ 21

Straight Out SwivelBoot Installation ....................................................................................25 - 26

GimbalSwivelBoot Installation ...........................................................................................26 - 27

VerticalAugerInstallation ....................................................................................................28 - 30

VerticalAuger Optional Equipment ............................................................................................ 31

Take-AwayAuger ControlBox Installation ................................................................................. 31

InclinedAuger ........................................................................................................................... 31

MainControl Box Installation...............................................................................................32- 33

OperationsFlowChart................................................................................................................ 34

Start-UpChecklist ...............................................................................................................35 - 36

OperatingSuggestions........................................................................................................37 - 39

DryingGuideChart.................................................................................................................... 40

ControlFunctions.................................................................................................................41-43

FusesandThermal Unit Chart................................................................................................... 44

Parts List & Exploded Views

Control Box - 230V, 1 PH .......................................................................................46 - 47

Control Box - 230V, 3 PH .......................................................................................48 - 49

Control Box - 440V, 3 PH .......................................................................................50 - 51

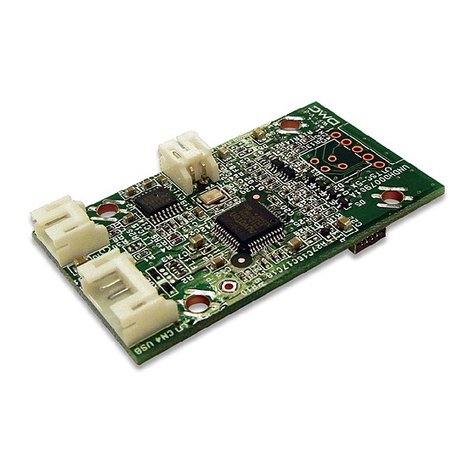

ControlModule .......................................................................................................52 - 53

Discharge& Power Unit .........................................................................................54 - 55

Center Sump & Gear BoxAssembly ......................................................................56 - 57

Take-AwayAugerControl Box ................................................................................58 - 59

VerticalAuger.........................................................................................................60 - 61

VerticalAugerAccessories .....................................................................................62 - 63

OptionalEquipment................................................................................................64 - 65

Dual Center Gear Box (mfg. by Hub city)................................................................66 - 67

DualCenter Gear Gox (mfg. byCurtis) ...................................................................68 - 69

WiringDiagrams .................................................................................................................70 - 73

ElectricalHook-Ups ............................................................................................................74 - 80

AnnualStart-UpChecklist ......................................................................................................... 81

CircuitBoardRemoval............................................................................................................... 82

Stirring Equipment...............................................................................................................83 - 84

TroubleShooting .................................................................................................................85 - 87

Calc-U-DriSupplementforNECOandShivvers....................................................................88 - 93

AppendixA(Dip Switch Settings) .............................................................................................. 94

AppendixB(Sampling).............................................................................................................. 95