The Formwork Experts

4999771002 - 08/2008 Ü

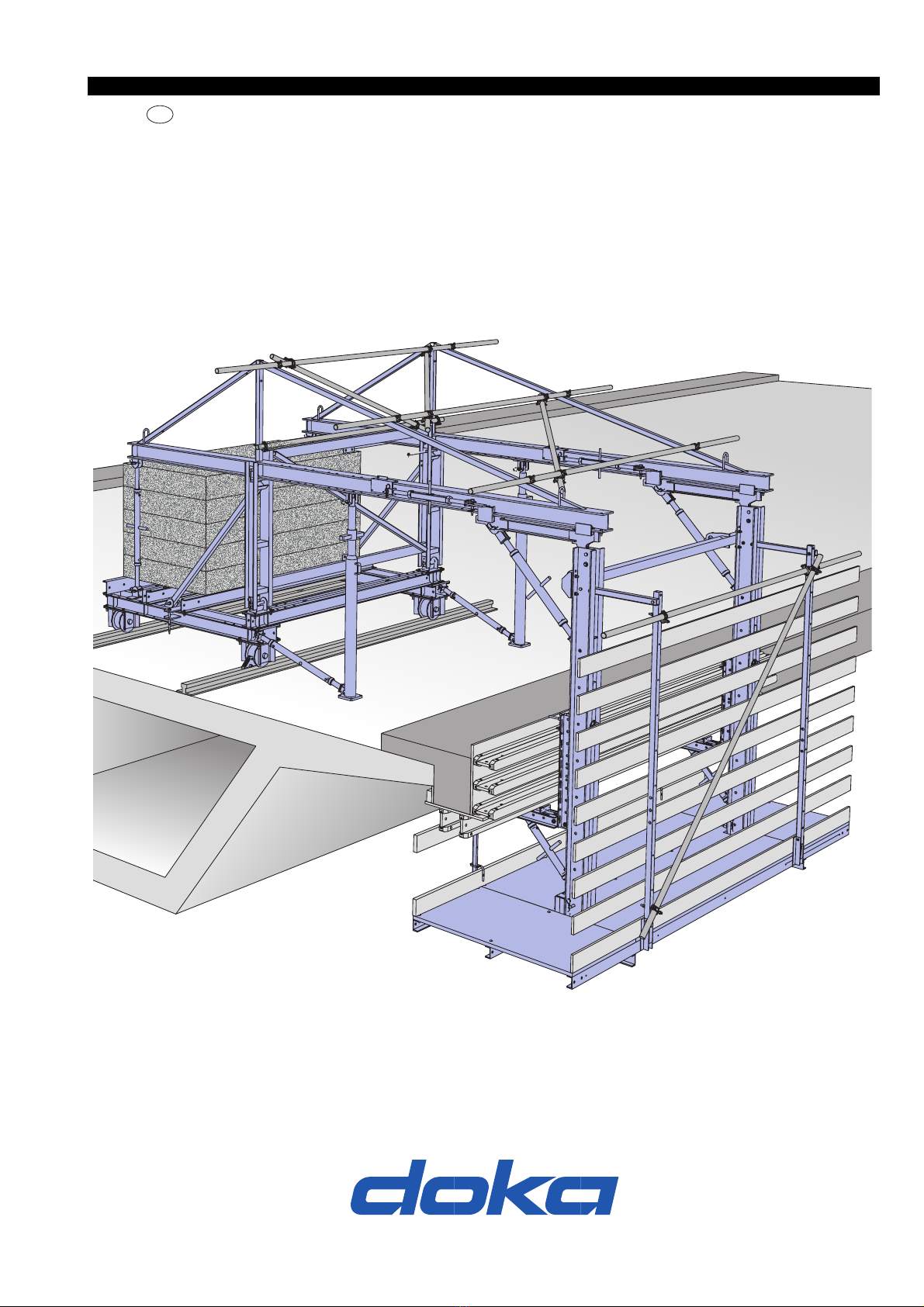

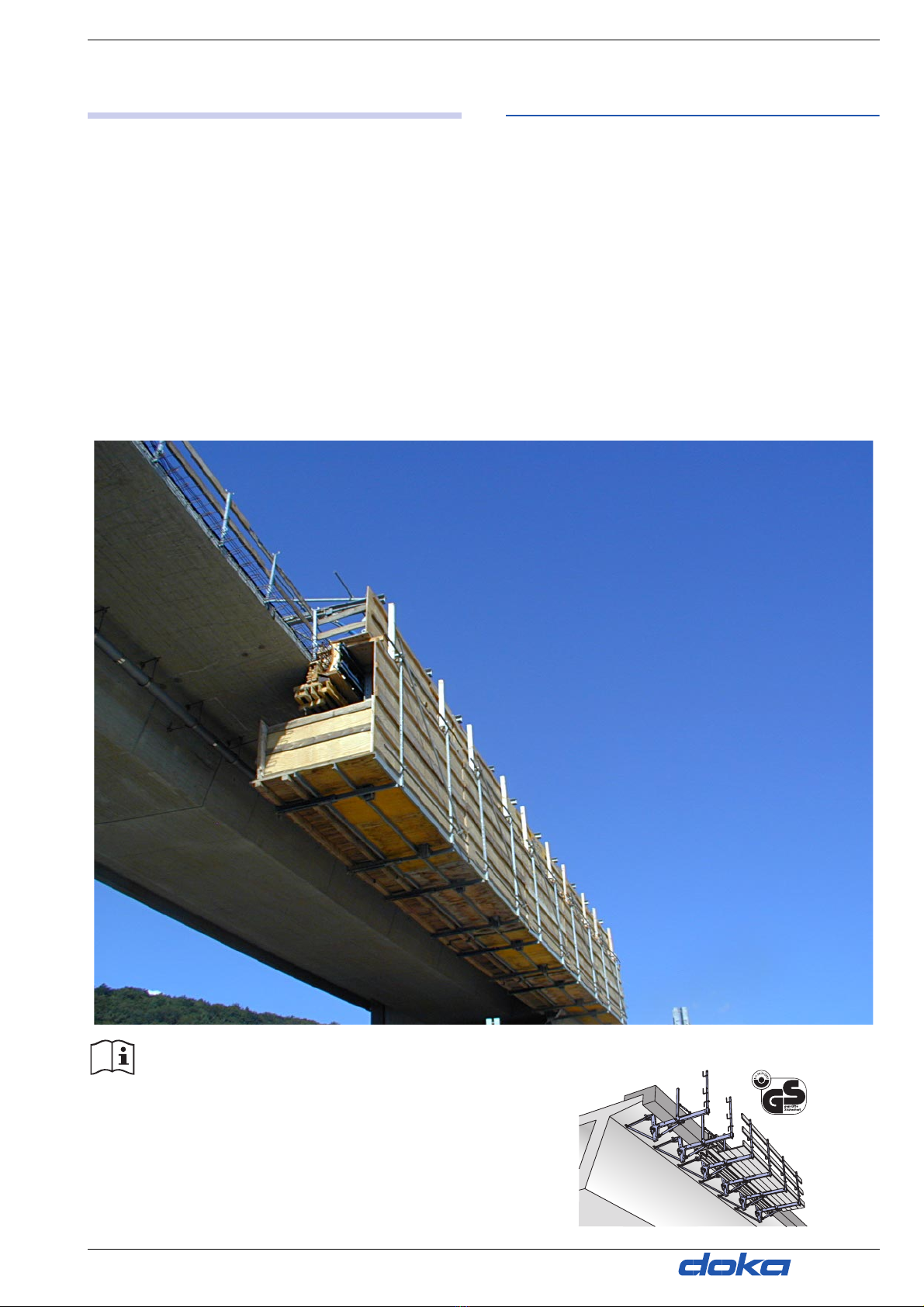

Introduction User information Doka forming wagon T

Elementary safety warnings

User target groups

●This User Information booklet (Method State-

ment) is aimed at everyone who will be working

with the Doka product or system it describes. It

contains information on how to set up this sys-

tem, and on correct, compliant utilisation of the

system.

●All persons working with the product described

herein must be familiar with the contents of this

manual and with all the safety instructions it con-

tains.

●Persons who are incapable of reading and under-

standing this booklet, or who can do so only with

difficulty, must be instructed and trained by the

customer.

●The customer is to ensure that the information

materials provided by Doka (e.g. User Informa-

tion booklets, Instructions for Assembly and Use,

Operating Instruction manuals, plans etc.) are

available to all users, and that they have been

made aware of them and have easy access to

them at the usage location.

Remarks on this document

●This User Information booklet can also be used

as a generic method statement or incorporated

with a site-specific method statement.

●Many of the illustrations in this booklet show the

situation during formwork assembly and are

therefore not always complete from the safety

point of view.

●Further safety instructions, especially warnings,

will be found in the individual sections of this

document!

Planning

●Provide safe workplaces for those using the

formwork (e.g. for when it is being erected/dis-

mantled, modified or repositioned etc). It must be

possible to get to and from these workplaces via

safe access routes!

●If you are considering any deviation from the

details and instructions given in this booklet, or

any application which goes beyond those

described in the booklet, then revised static cal-

culations must be produced for checking, as well

as supplementary assembly instructions.

Rules applying during all phases of

the assignment:

●The customer must ensure that this product is

erected and dismantled, reset and generally used

for its intended purpose under the direction and

supervision of suitably skilled persons with the

authority to issue instructions.

●Doka products are ONLY to be used in accord-

ance with the Doka User Information booklets or

other technical documentation provided by

Doka.

●The stability of all components and units must be

ensured during all phases of the construction

work!

●The functional/technical instructions, safety

warnings and loading data must all be strictly

observed and complied with. Failure to do so can

cause accidents and severe (even life-threaten-

ing) damage to health, as well as very great

material damage.

●Fire-sources are not permitted anywhere near

the formwork. Heating appliances are only

allowed if properly and expertly used, and set up

a safe distance away from the formwork.

●The work must take account of the weather con-

ditions (e.g. risk of slippage). In extreme weather,

steps must be taken in good time to safeguard

the equipment, and the immediate vicinity of the

equipment, and to protect employees.

●All connections must be checked regularly to

ensure that they still fit properly and are function-

ing correctly.

It is very important to check all screw-type con-

nections and wedge-clamped joins whenever the

construction operations require (particularly

after exceptional events such as storms), and to

tighten them if necessary.

Assembly

●The equipment/system must be inspected by the

customer before use, to ensure that it is in suita-

ble condition. Steps must be taken to rule out the

use of any components that are damaged,

deformed, or weakened due to wear, corrosion or

rot.

●Combining our formwork systems with those of

other manufacturers could be dangerous, risking

damage to both health and property. If you

intend to combine different systems, please con-

tact Doka for advice first.

●The assembly work must be carried out by suita-

bly qualified employees of the client's.