ON

ON

REVERSE

SENSITIVITY

REVERSE

LOOP

EXIT

LOOP

FULL OPEN

DOORKING

4602-010

SW1

SW3

SW2

OPEN

TIMER

NC

NO

1

2

3

4

5

6

7

8

9

10

1

ON

2 3 4

UL 325 LEDs

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

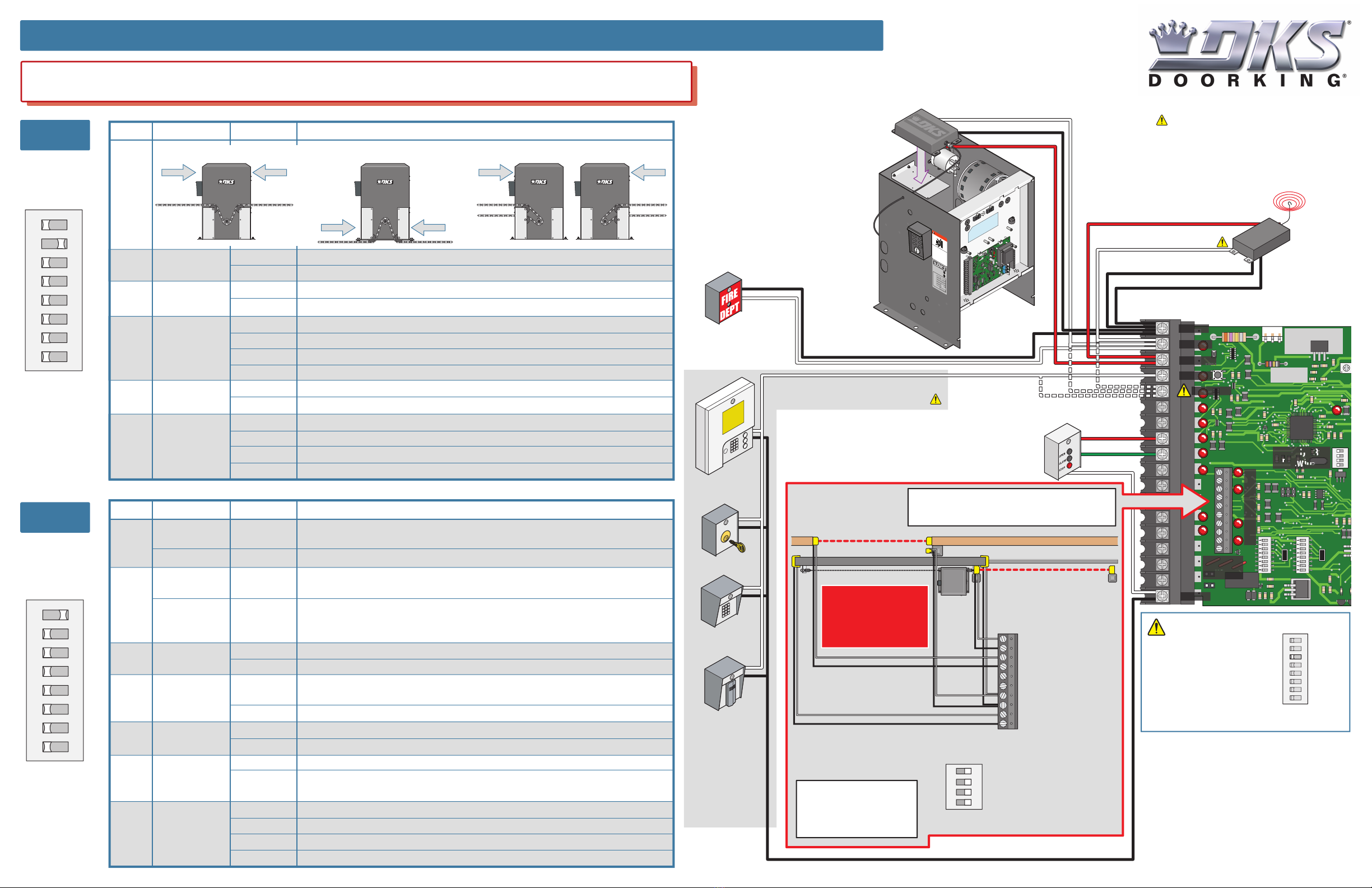

Full Open

Common

Common

Full Open

24 V Power

Partial Open

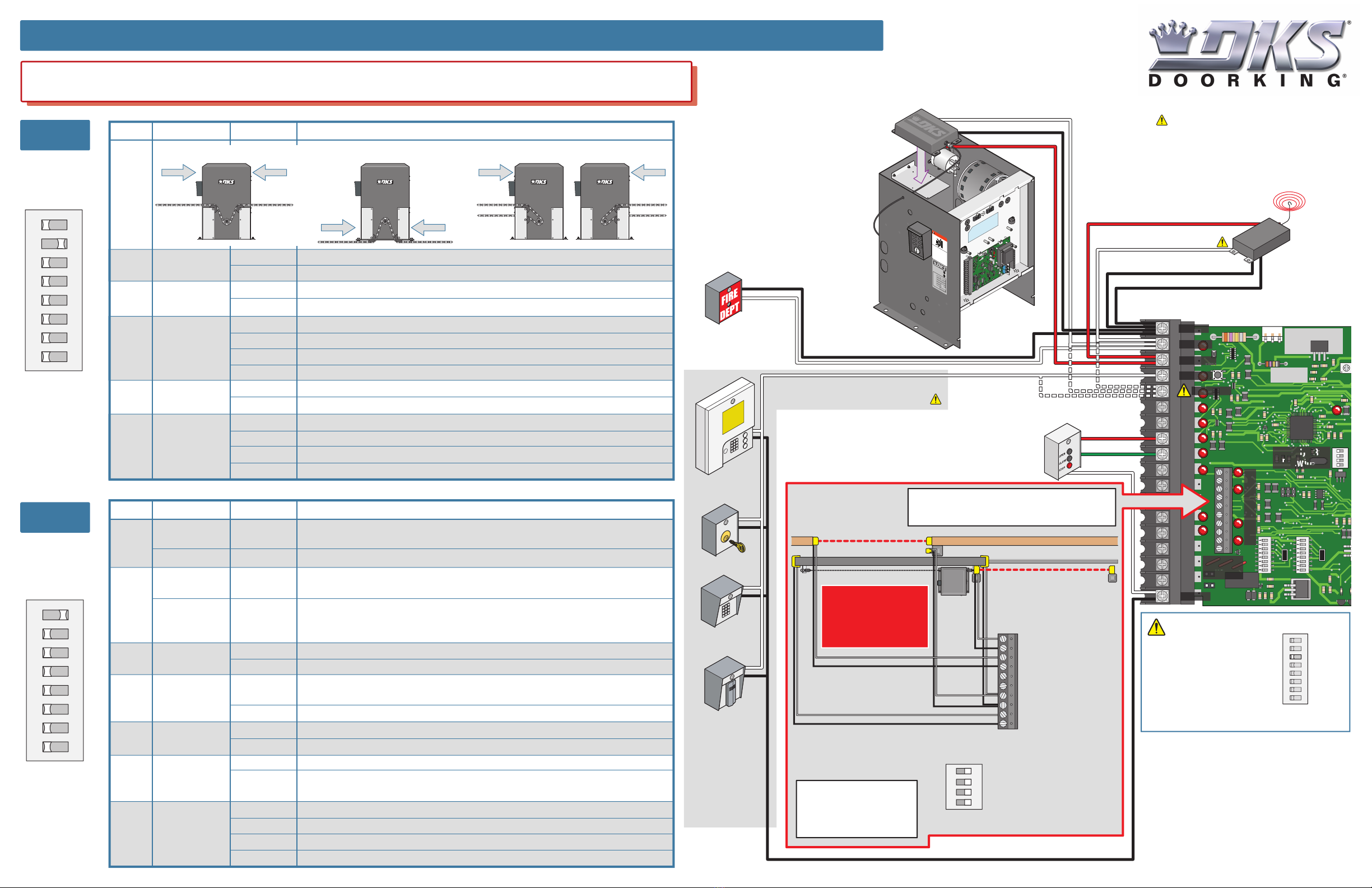

SW 1

SW 2

7-OFF

7-OFF

7-ON

7-ON

8-OFF

8-ON

8-OFF

8-ON

Gate Open

Back-Off

Position

Normal Setting. Gate fully opens.

Gate stops short 1” from full open position. Used for a reversing edge device.

Gate stops short 2” from full open position. Used for a reversing edge device.

Gate stops short 3” from full open position. Used for a reversing edge device.

Switch Function Setting Description

OFF

ON

4-OFF

4-OFF

4-ON

4-ON

5-OFF

5-ON

5-OFF

5-ON

Auto-Close

Timer

Relay Activation

and

LED Indicator

Light Activation

2

1

Motor

Hold

OFF

ON

3

4 and 5

7 and 8

Normal Setting. No voltage to motor when gate is stopped (Level gate).

Voltage applied to motor always. Keeps inclined gate from coasting when stopped.

Auto-close timer is OFF. Manual input required to close gate.

Auto-close timer is ON. Adjustable from 1-23 seconds to close gate.

OFF

ON

Self-Test

6Normal Setting.

Runs self-test. Caution: Bench testing ONLY!

Relay activates and LED is ON when the gate is fully open.

Relay activates and LED is ON when the gate is not closed.

Relay activates and LED is ON when the gate is opening and open.

Relay activates and LED is ON when the gate is opening and closing.

Changes the direction the operator will open/close the gate depending on the different chain configurations.

Opening

direction

using OFF

setting.

Opening

direction

using ON

setting.

Post

Mounts

Center or

Opens

with

ON

setting.

Mounts

Right

All Rear

Opens

with

OFF

setting.

Mounts

Left

All Rear

Opening

direction

using ON

setting.

Opening

direction

using OFF

setting.

Mount

Front

ON

12345678

SW 2

ON

12345678

SW 1

OFF

ON

Operator Model

Select

5

7-OFF

7-OFF

7-ON

7-ON

8-OFF

8-ON

8-OFF

8-ON

Gate Close

Back-Off

Position

Normal Setting. Gate fully closes.

Gate stops short 1” from full close position. Used for a reversing edge device.

Gate stops short 2” from full close position. Used for a reversing edge device.

Gate stops short 3” from full close position. Used for a reversing edge device.

Switch Function Setting Description

2

7 and 8

Built-in

Solenoid

Lock

OFF

ON

4

Normal Setting. Fail-safe logic. Lock engages only if attempt is made to force gate

open (Factory setup).

Fail-secure logic. Lock engages after each gate cycle (2600-865 Lock kit required).

Normal Setting. Switch must be OFF for Model 9150.

DO NOT use ON setting for Model 9150.

OFF

ON

Partial Open

(14 Ft)

3Normal Setting. Switch must be OFF for terminal #5 input to open gate 14 Ft.

DO NOT use ON setting. NOT associated with partial open feature for the 9150.

OFF

ON

OFF

ON

Normal Setting. Input to terminal #6 and/or reverse loops will reverse gate

during close cycle.

Input to terminal #6 and/or reverse loops will stop gate during close cycle – gate

will continue to close after input to terminal #6 and/or reverse loops are cleared

(Helps prevent tailgating vehicles from unauthorized entry).

OFF

ON

6

Normal Setting. Timer will function normally.

Opening gate will stop and begin to close as soon as all reversing inputs (Reverse

loops, photo sensors) are cleared regardless of the distance the gate has opened.

1

Quick-Close

Timer Override

Exit Loop Port

Output

Full Open Input

A plug-in exit loop detector plugged into the EXIT Loop port will partially open single

operator or fully open dual operators depending on type of loop detector used).

Normal Setting. Plug-in exit loop detector will fully open gate (Single operator).

Reverses Gate

Stops Gate

WARNING

MOVINGGATE CAN CAUSE

Operategate only when gate area is in sight

andfree of people and obstructions.

Donot allow children to play in gate area

oroperate gate.

Donot stand in gate path or walk through

pathwhile gate is moving.

Readowner’s manual and safety instructions.

SERIOUSINJURY OR DEATH

CLASS

CERTIFIEDTO

CAN/CSAC22.2 NO. 247

CONFORMSTO

ANSI/UL-325

VEHICULARGATE OPERATOR

HP

53382

MODEL

SERIAL

VOLTS PHASE

AMPS 60Hz

MAXGATE LOAD

DoorKing,Inc., Inglewood, CA

ON

ON

REVERSE

SENSITIVITY

REVERSE

LOOP

EXIT

LOOP

KEYSWITCH

DOORKING

4602-010

SW1 SW2

OPEN

TIMER

NC

1

2

3

4

5

NO

Red Full Open

Green Close

White Com

Key Switch

Stand-Alone

Keypad

Stand-Alone

Card Reader

Telephone

Entry

Fire Box

3-Button

Control Station DoorKing ONLY

Note:

All stand-alone

and telephone

entry devices

must use a

separate power

source.

#4-Connected device fully opens gate.

#5-Connected device opens gate 14-feet.

#2-Full Open

Com

Com

Com

Relay - #2 - Full Open.

#5 - Opens gate 14-feet.

Relay N.O. - #2 - Full Open.

#5 - Opens gate 14-feet.

250 mamp.

max.

3-Wire Radio Receiver

ON

12345678

SW 2

SW 2,

switch 3

must be

OFF.

Relay Com

24 Volt Com

24 Volt - 250 mamp. max.

4-Wire

Receiver

#5 Terminal Note (Single

Operator Only): Any opening

device connected to terminal #5 will

open the gate to the partial open

14-ft setting. External entrapment

protection devices will also open the

gate to the partial open setting. If the

Inherent Reverse Sensor gets

activated during the close cycle, it

will always fully open the gate.

24 volt

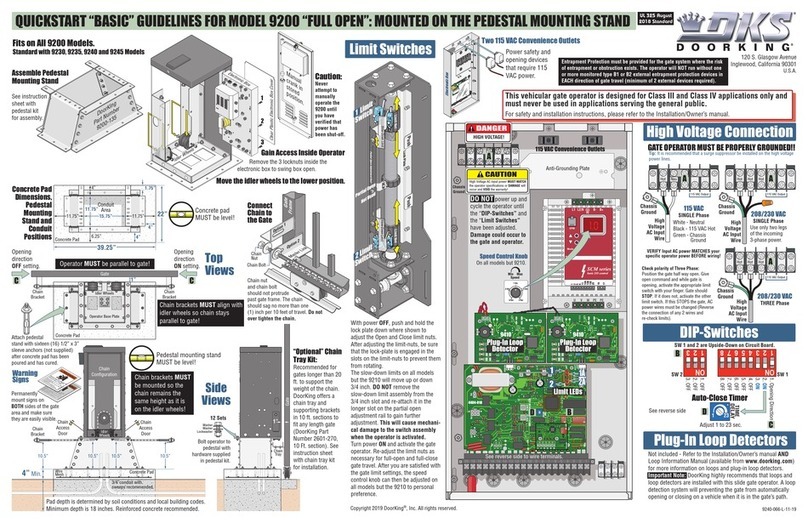

Note: After a DIP-switch setting is changed, power must be turned OFF and then turned back on for the new setting to take affect.

Jumper Wire

Needed

See Manual

Important: Controls intended for user activation must be located at least six (6) feet away from any moving part

of the gate and where the user is prevented from reaching over, under, around or through the gate to operate the

controls. Emergency access controls only accessible by authorized personnel (e.g., fire, police, EMS) may be

placed at any location in the line-of-sight of the gate.

N

UL 325

Terminal

UL 325

DIP-Switches

Closed Gate

Wall

Close Beam

Open Beam

Filler Post If necessary

Open Edge

IMPORTANT: Photo sensors

must use Normally Closed (NC)

contacts with the beam set for

light operate (relay activated

when beam is not obstructed).

External Entrapment

Protection Devices

IMPORTANT: Only 1 monitored Device can be connected

to each input. An OPTIONAL Expansion Kit (sold

separately) will allow connection for additional devices.

UL 325 Terminal

Close Edge

Open Edge

DIP-switches MUST be turned ON for each device wired to terminal.

At least ONE external

entrapment protection

device MUST be installed

or the operator will NOT

function.

UL 325 DIP-Switches

N.C.

N.C.

N.C.

N.C.

N.C.

Connect ONLY MONITORED

Devices

1

ON

2 3 4

1 - OPEN Beam STOP

2 - Ground (Common)

3 - CLOSE Beam REVERSE

4 - Ground (Common)

5 - 24 VAC 250 ma. Max

6 - Ground (Common)

7 - OPEN Edge/Beam REVERSE

8 - Ground (Common)

9 - CLOSE Edge/Beam REVERSE

10 - Ground (Common)

1 - OPEN Beam (UL 325 Terminal 1)

2 - CLOSE Beam (UL 325 Terminal 3)

3 - OPEN Edge (UL 325 Terminal 7)

4 - CLOSE Edge (UL 325 Terminal 9)

(See Installation/Owner’s manual for more information)

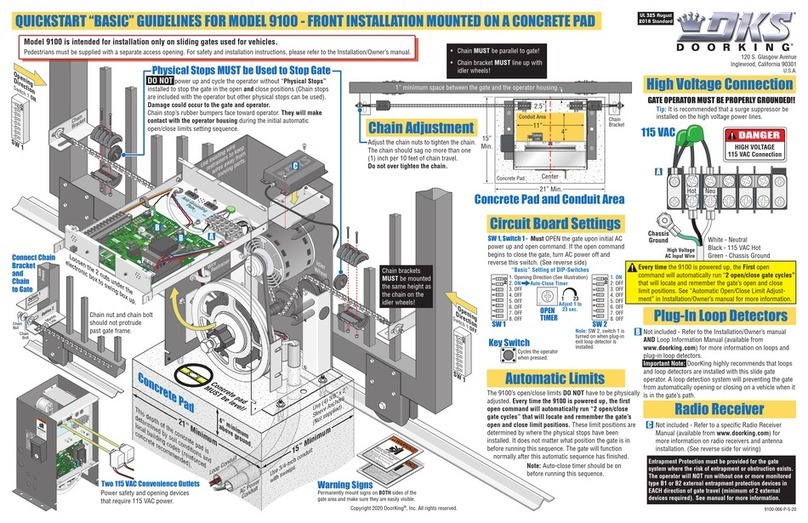

QUICKSTART “BASIC” GUIDELINES FOR MODEL 9150 - DIP-SWITCH AND WIRING REFERENCE

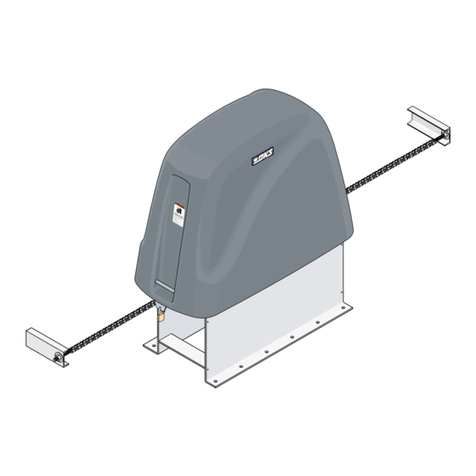

Model 9150 is intended for installation only on sliding gates used for vehicles.

Pedestrians must be supplied with a separate access opening. For safety and installation instructions, please refer to the Installation/Owner’s manual. 120 S. Glasgow Avenue

Inglewood, California 90301

U.S.A.