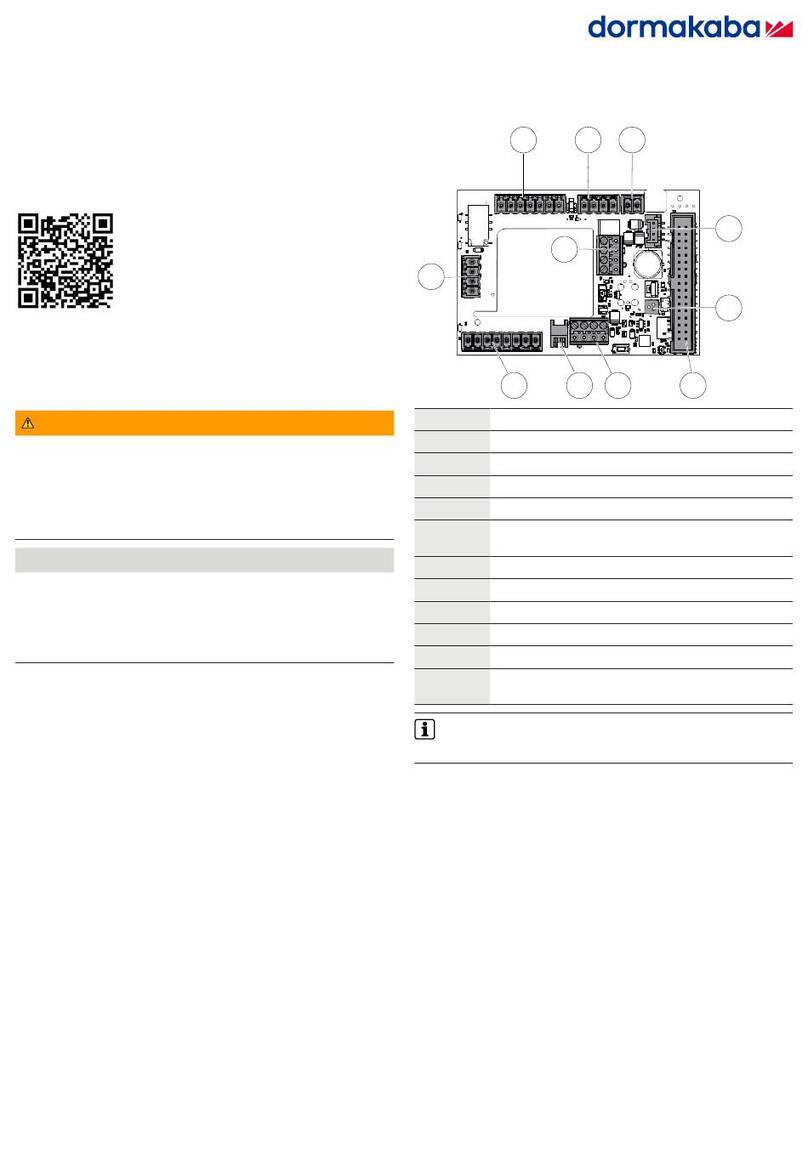

10 Multi Floor Controller PK3661 03-19

4.0 System Installation Overview

A

U

T

S

X

Figure 6 OR

Step 5: Mounting the Quantum RFID ECU reader

Figure 7

1. Remove the back plate and use it to mark the

holes for the cables and screws.

NOTE: Refer to annex H of this manual for elevator

panel preparation for mounting reader.

2. Drill the holes in the wall according to the

diameters indicated on the drilling template

in Annex H, based on the type of surface the

reader is being installed on.

Refer to RCU/ECU installation instructions

Step 6: Connect peripheral wiring

CAUTION

Do not exceed the maximum cable length indicated

by the manufacturer of the products being

connected. In addition, the wire used to connect the

peripherals to controller PCB must be of the proper

gauge and type as specified by the manufacturer.

IMPORTANT

Every wire must pass through a strain relief as

connected in step 3

IMPORTANT

dormakaba does not provide technical or field

support for 3rd party locking devices. Please

consult the device manufacturer for support.

NOTE: The Maximum Recommended Wire Length

is the approximate wire length that causes

a 5% voltage loss in the wire, using a 12-volt

locking device at the rated current included.

1. Fire Alarm Panel

Refer to Annex A, Figure 10 for detailed wiring.

Remove the jumper wire connected between pins

3 and 4 of connector J18 on the controller PCB

and complete the fire panel installation as per

manufacturer’s indications.

2. Tamper Switch to Premise Alarm

System

To wire the tamper switch to the premise alarm

system disconnect the wires on controller PCB

connector J7 pins 1 & 2, and run a 2-connector cable

from the switch to the premise alarm system.

IMPORTANT

The tamper alarm switch’s polarity is such that

when the door is closed the switch itself is also in a

closed state. Ensure that the wiring to the premise

alarm system is done accordingly to prevent false

alarms.

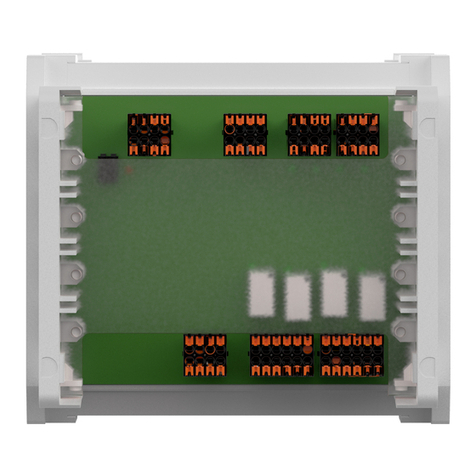

Step 7: Relay Expansion Board outputs wiring

Refer to Annex B, for sample wiring diagram.

The relay expansion board provides 8 relay contacts

for wiring & control of relay-enabled elevator. The

board only provides normally open or normally

closed dry contacts, so no power is provided by the

board.

As wiring of relay-controlled equipment may vary

between products please refer to the product

manufacturer’s instruction booklet for proper

instructions.

NOTE: Refer to Annex B, table 4 for specific relay

expansion board bypass switches.

- If bypass switches are ‘ON’, the relays are

bypassed and the green LED associated with

that relay is turned OFF.

- If bypass switches are ‘OFF’ the controller PCB

can activate the relays. The associated LEDs

turn OFF during relay activation.

NOTE: When the power to the MFC-X is too low

(power failure, the controller PCB stops

functioning and the relays on the controller

PCB or the expansion board will return to

their normal state. Any peripheral connected

to the relays will then be either in a normally

open (NO) or normally closed (NC) state,

dependent on the wiring.