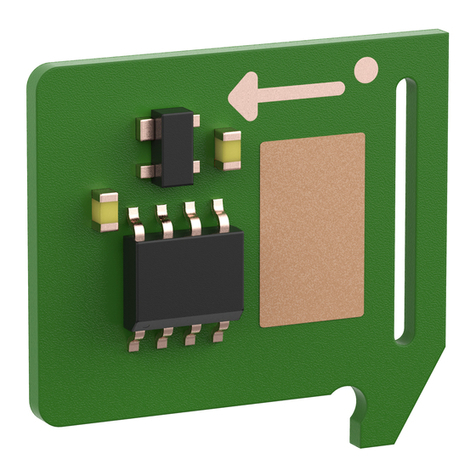

Assembly Instruction Product description

060636 45532/16923 - 2023-04 ED connection board CAN 5

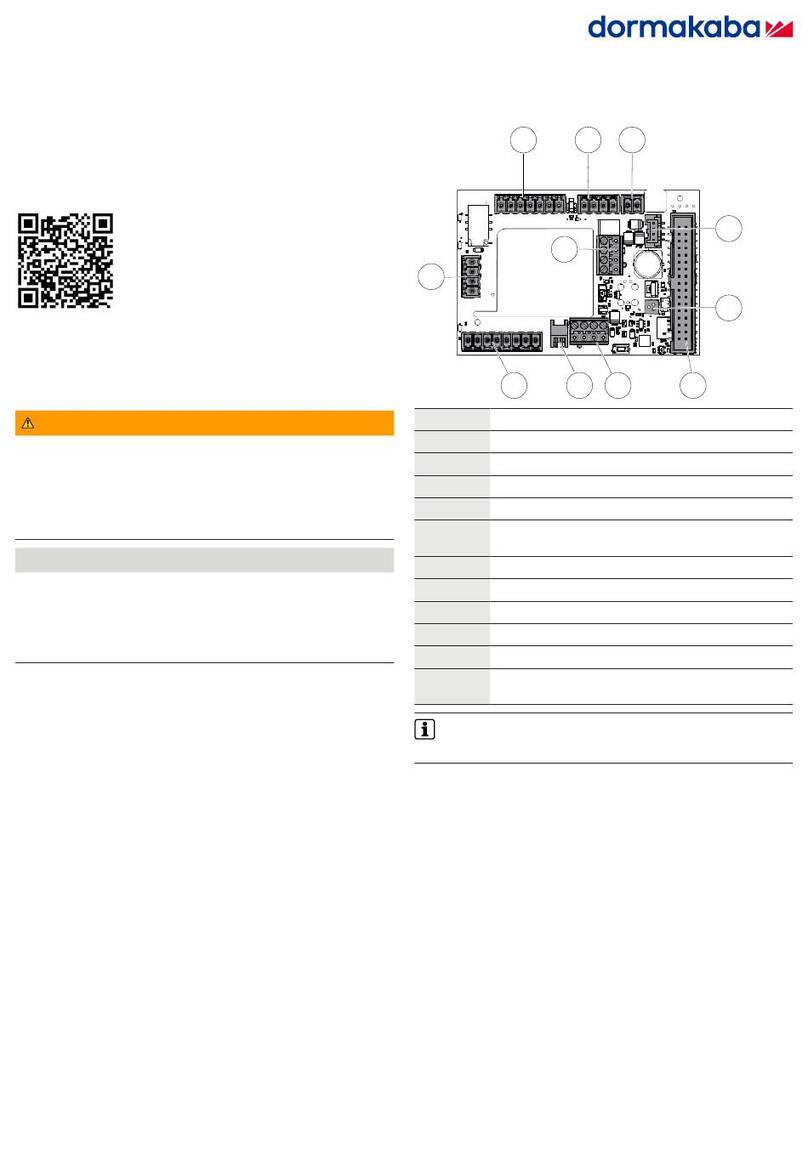

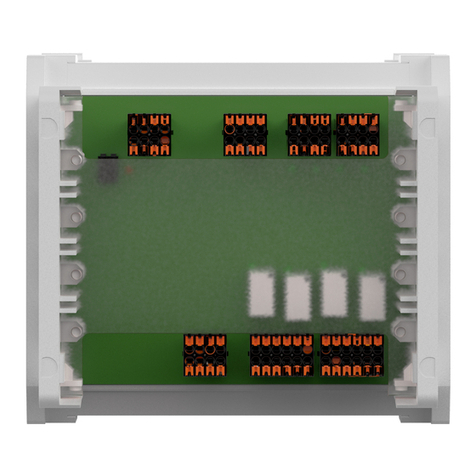

Position Layout

7 Ribbon cable connection socket

8 CAN connection cable EntriWorX connection terminals

9 CAN connection cable EntriWorX connection plug

10 Safety sensors

11 Signal inputs for night/bank, impulse outside and impulse inside

The operating conditions specified in the mounting and commissioning instructions

for ED 100/250 operators apply to the ED connection board CAN.

3.4 LED display

The RGB LED function display on the ED connection board CAN is defined as a

secondary function display. The RGB LED function display uses signal colors to

show the current operating status or a fault.

To see the signal colors of the RGB LED function display, remove the ED 100/250

operators’ cladding.

Signal no. Color Description Meaning

1 permanently

red

Self-test error display Self-test error occurred or

CAN device detection is

faulty.

2 Flashing

green

Identification display The device identification is

activated.

3 Flashing yel-

low

CAN device mapping The device assignment is ac-

tive after a CAN reset. De-

vice assignment ends when

the assignment is com-

pleted without errors or

when an error occurs.

4 Flashing red Error display One or more errors are

pending. Error number with

the highest priority is indi-

cated by the number of

flashes.

See “Evaluate errors and rectify faults”.

Signal no. Color Description Meaning

5 Glowing white TMS initialization TMS bus initialization for

sensor and ED connection

board CAN running.

6 Green light: Display operating status

OK

The system is working with-

out errors.