TX3 SERIES

ON

S2

S1

SHT

HHH

TemperatureController

TX3

ON

S2

S1

1

TemperatureController

TX3

ON

S2

S1

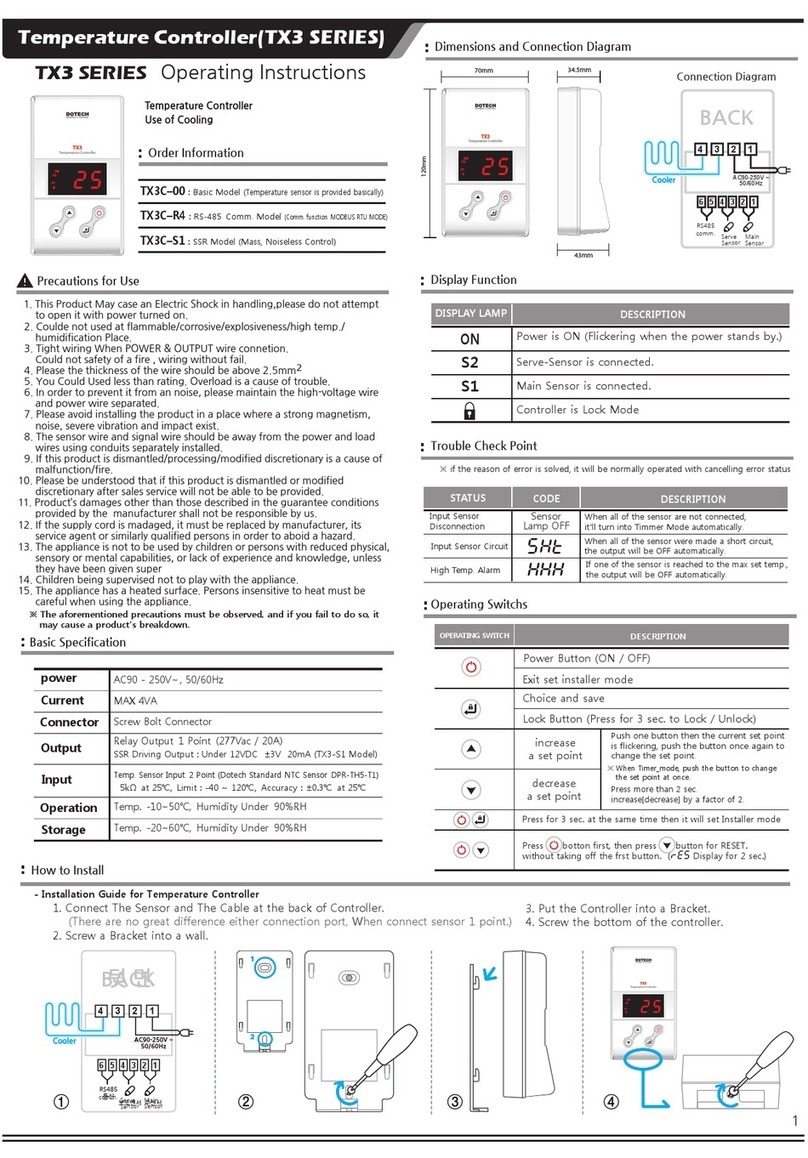

70mm

120mm

TemperatureController

TX3

34.5mm

43mm

ON

S2

S1

AC90-250V ~

50/60Hz

6 5 4 3 2 1

4 3 2 1

1

2

④③②①

AC90-250V ~

50/60Hz

6 5 4 3 2 1

4 3 2 1

Cooler

Heater

Cooler

Heater

Precautions for Use

Temperature Controller(TX3 SERIES)

Basic Specification

Order Information

TX3–00

: Basic Model

(Temperature sensor is provided basically)

TX3–R4

: RS-485 Comm. Model

(Comm. function MODBUS RTU MODE)

TX3–S1

: SSR Model (Mass, Noiseless Control)

Output

Input 5kΩ at 25℃, Limit : -40 ~ 120℃, Accuracy : ±0.3℃ at 25℃

Connector

Dimensions and Connection Diagram

How to Install

Display Function

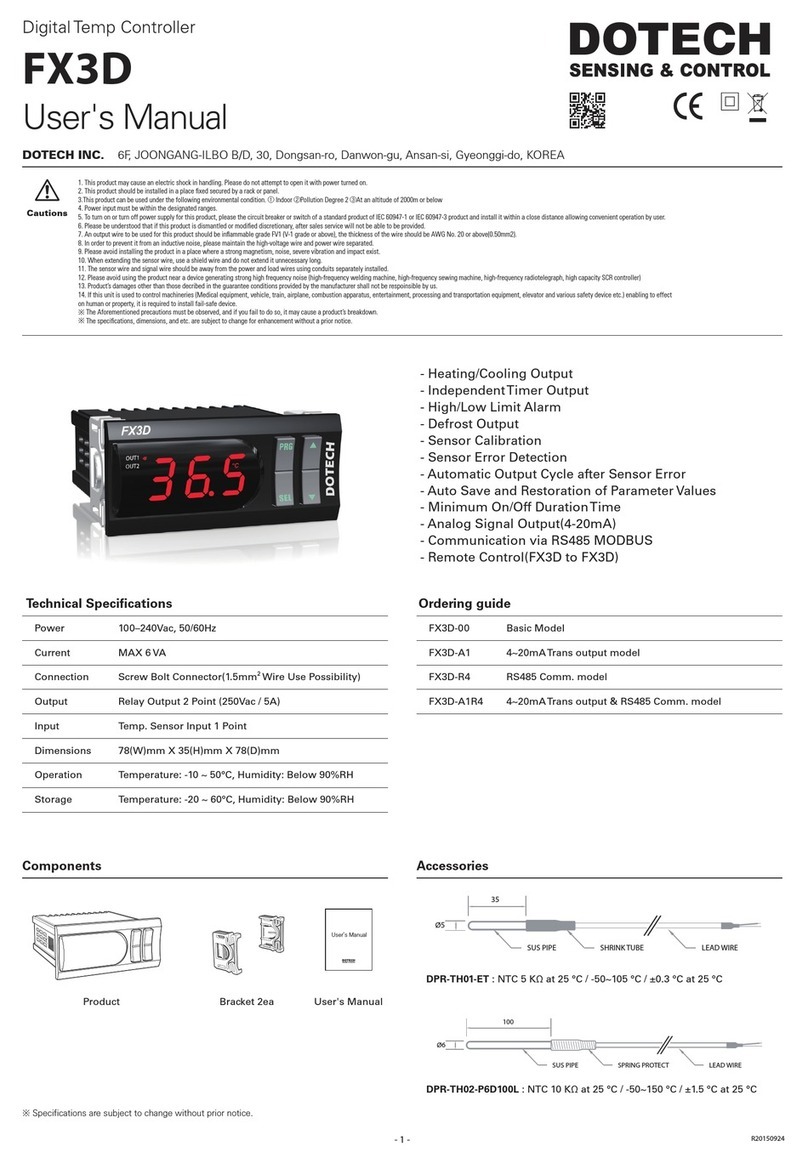

Temperature Controller is multi-functional thermometer

for both cooling and heating to control temperature in

construction site, fashion, factories, offices, etc.

Operation

Storage

SSR Driving Output : Under 12VDC ±3V 20mA (TX3-S1 Model)

DISPLAY LAMP DESCRIPTION

Power is ON (Flickering when the power stands by.)

Main Sensor is connected.

Serve-Sensor is connected.

Controller is Lock Mode

※ The aforementioned precautions must be observed, and if you fail to do so, it

may cause a product’s breakdown.

Trouble Check Point

STATUS DESCRIPTION

When all of the sensor are not connected,

it’ll turn into Timmer Mode automatically.

Input Sensor

Disconnection

Input Sensor Circuit

High Temp. Alarm

※ if the reason of error is solved, it will be normally operated with cancelling error status

CODE

Sensor

Lamp OFF

When all of the sensor were made a short circuit,

the output will be OFF automatically.

If one of the sensor is reached to the max set temp.,

the output will be OFF automatically.

Connection Diagram

Serve

Sensor

RS485

comm. Main

Sensor

- Installation Guide for Temperature Controller

1. Connect The Sensor and The Cable at the back of Controller.

(There are no great difference either connection port, When connect sensor 1 point.)

2. Screw a Bracket into a wall.

1. This Product May case an Electric Shock in handling,please do not attempt

to open it with power turned on.

2. Coulde not used at flammable/corrosive/explosiveness/high temp./

humidification Place.

3. Tight wiring When POWER & OUTPUT wire connetion.

Could not safety of a fire , wiring without fail.

4. Please the thickness of the wire should be above 2.5mm

2

5. You Could Used less than rating. Overload is a cause of trouble.

6. In order to prevent it from an noise, please maintain the high-voltage wire

and power wire separated.

7. Please avoid installing the product in a place where a strong magnetism,

noise, severe vibration and impact exist.

8. The sensor wire and signal wire should be away from the power and load

wires using conduits separately installed.

9. If this product is dismantled/processing/modified discretionary is a cause of

malfunction/fire.

10. Please be understood that if this product is dismantled or modified

discretionary after sales service will not be able to be provided.

11. Product’s damages other than those described in the guarantee conditions

provided by the manufacturer shall not be responsible by us.

12. If the supply cord is madaged, it must be replaced by manufacturer, its

service agent or similarly qualified persons in order to aboid a hazard.

13. The appliance is not to be used by children or persons with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given super

14. Children being supervised not to play with the appliance.

15. The appliance has a heated surface. Persons insensitive to heat must be

careful when using the appliance.

Operating Instructions

Temp. -10~50℃, Humidity Under 90%RH

Temp. -20~60℃, Humidity Under 90%RH

Temp. Sensor Input 2 Point (Dotech Standard NTC Sensor DPR-TH5-T1)

Relay Output 1 Point (277Vac / 20A)

Screw Bolt Connector

MAX 4VA

AC90 - 250V~ , 50/60Hz

power

Current

Operating Switchs

OPERATING SWITCH DESCRIPTION

Power Button (ON / OFF)

Choice and save

Lock Button (Press for 3 sec. to Lock / Unlock)

increase

a set point

decrease

a set point

Push one button then the current set point

is flickering, push the button once again to

change the set point.

Press for 3 sec. at the same time then it will set Installer mode

Exit set installer mode

※ When Timer_mode,

push the button to change

the set point at once.

Press more than 2 sec.

increase[decrease] by a factor of 2.

3. Put the Controller into a Bracket.

4. Screw the bottom of the controller.

BACK

BACK

Press botton first, then press button for RESET.

without taking off the frst button. (RES Display for 2 sec.)

Serve

Sensor

Main

Sensor

RS485

comm.