D+H GVL 8408-M-UL User manual

GVL 8408-M-UL

en Original instructions . . . . . . . . . . . . . . . . . . . . . . . Page . . . . . . . 2

99.828.04 1.0/06/19

GVL 8408-M-UL GVL 8408-M-UL

99.828.04 1.0/06/1999.828.04 1.0/06/19

2/12 3/12

English

English

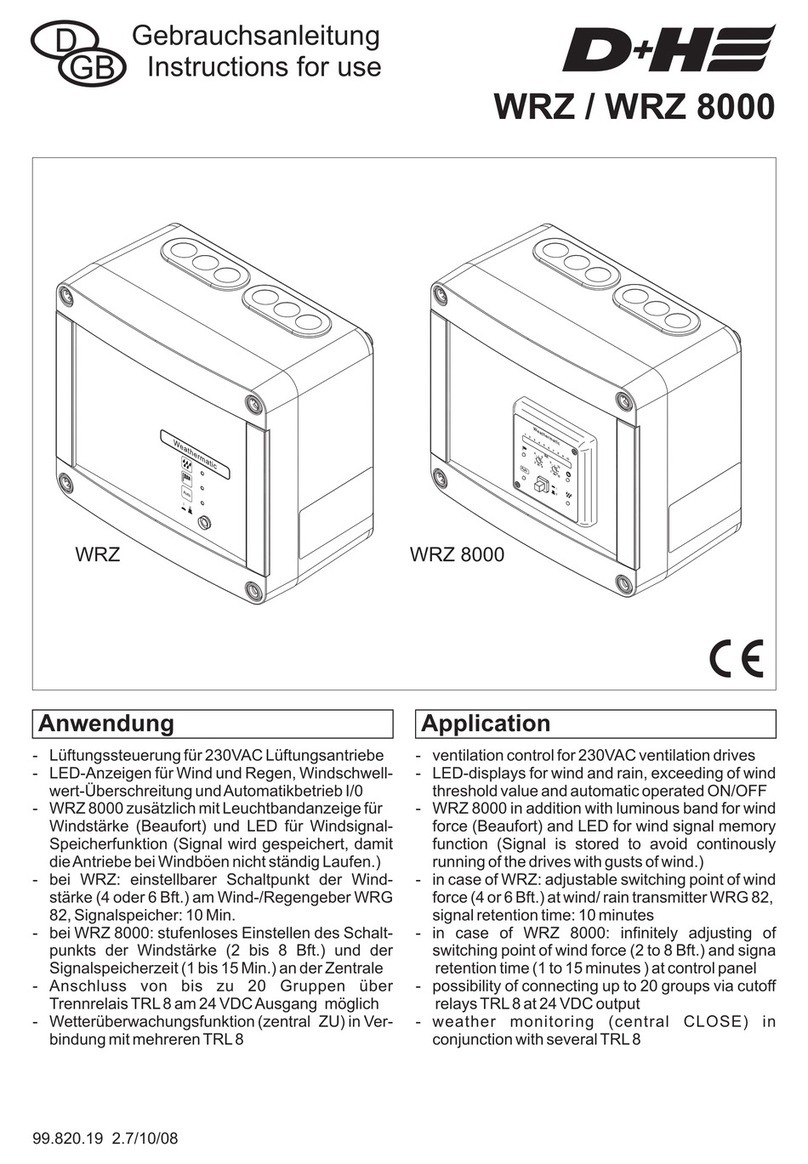

Intended use

- Ventilation control for small to medium sized

building objects

- For triggering of 24 V DC drives

- 5 ventilation groups

- 8 A total actuating current - stabilized

- Only for indoor mounting

Example for Application

* optional function extension (separate components, retrofitable!)

This instruction includes descriptions and connection plans of components which are not part of

scope of supply of control panel. You can order these parts and many more separately from your

D+H distributor. Further connecting plans are available there as well.

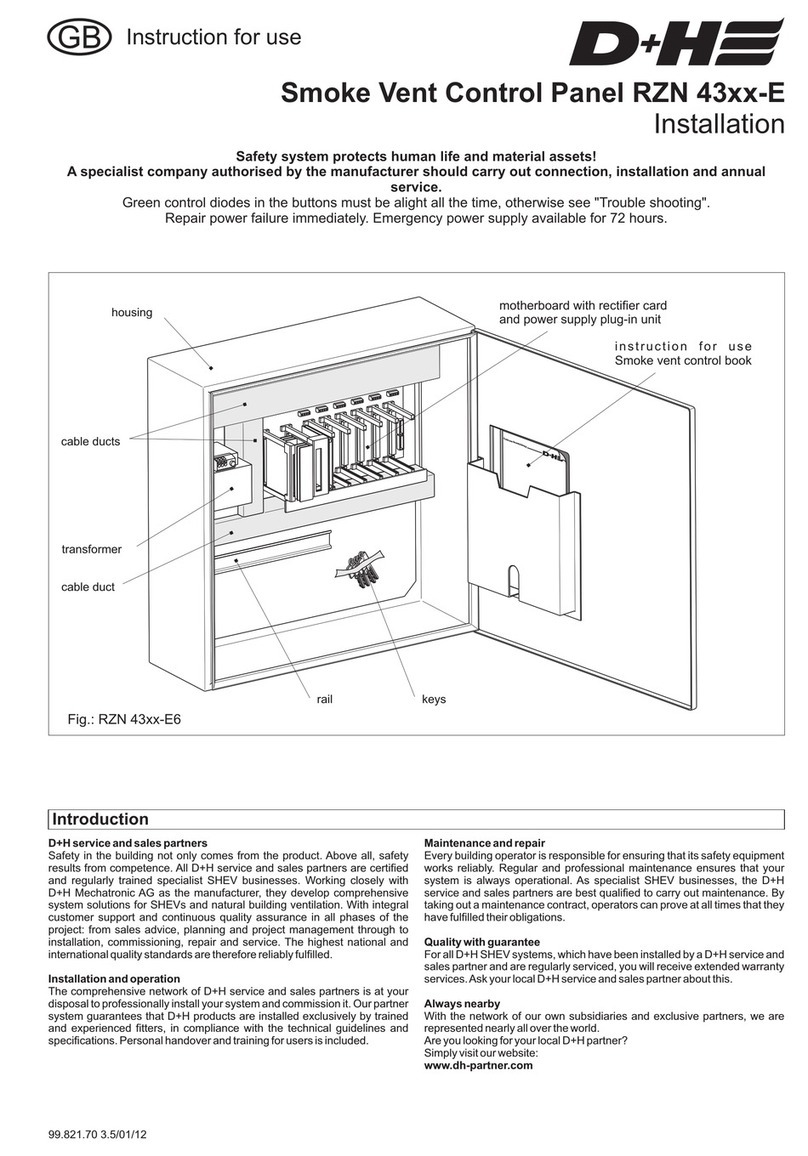

WARNING

Performance features

- Ventilation safety function (key operation

OPEN/CLOSE), can be free encoded

- Weather automatic for single groups,

can be switched on and off

- Entry for external control, e.g. timer

- Possibility of connecting rain detector or wind/ rain

detector without supplementary module

- Plastic housing, surface mounted type with

lockable steel sheet door

Delivery contents

Ventilation control panel including control Board,

plastic housing, replacement fuses and instructions

for use.

groups

window drives*

vent button* room temp. control* Control panel (GVL 8408-M-UL) rain sensor*

external control*

Safety notes:

- Read all safety warnings, instructions, illustrations and specifications provided with this

product.

- Failure to follow all instructions listed below may result in electric shock, fire and/or serious

injury.

- Save all warnings and instructions for future reference.

- When installing the Ventilation Control Panel (GVL 8304-K-UL), basic safety precautions should

always be followed to reduce risk of fire, electric shock, and personal injury.

- Operating voltage 115 V AC!

- Prior to installation, maintenance and installation of additional assemblies to the control panel,

the control panel must be separated from the supply voltage and all electrical parts nearby there

are powered, must be covered.

- Connection has to be carried out only by an authorized electrical specialist.

- Mounting of the control panel should be carried out by a D+H distributor, whose qualification

and experience is ensured by regular in-house training.

- Only listed cable types for Class 2 circuits may be used:

a) Type CL2, CL2P, CL2R, or CL2X complying with the Standard for Power-Limited Circuit

Cables, referenced in Annex A, Ref. No. 12, or

b) Other cable with equivalent or better electrical, mechanical, and flammability ratings; or

c) Cable that is a factory-connected integral part of a Class 2 power supply complying with the

Standard for Class 2 Power Units, referenced in Annex A, Ref. No. 13, or a Class 2 transformer

complying with the Standard for Low Voltage Transformers - Part 3: Class 2 and Class 3

Transformers, referenced in Annex A, Ref. No. 11, or an LPS (Limited Power Source) supply

complying the Standard for Information Technology Equipment - Safety - Part 1: General

Requirements, referenced in Annex A, Ref. No. 14.

- All wiring must be installed by a qualified electrican according to e.g. National Electrical Codes,

NFPA 70 and local codes.

- For continued protection against fire, replace only with the same type and rating of fuse.

- Each control unit has provision for permanent connection to the supply source by means of

rigid or flexible conduit or equivalent in accordance with the National Electrical Code.

- The conduit openings shall be provided an shall be for conduit entry 22.2-mm (7/8 in.) in

diameter or equivalent metric cable glands.

- To create the cable entry:

A suitable tool with depth stop must be used to create the cable entry.

The depth stop must be set so that the central Board cannot be damaged.

- Duty cycle: After 2 minutes operation time, 8 minutes pause.

- Only for indoor mounting.

- Just use unchanged original D+H parts

For North America:

The International Building Codes have to be observed

GVL 8408-M-UL GVL 8408-M-UL

99.828.04 1.0/06/1999.828.04 1.0/06/19

2/12 3/12

English

English

Intended use

- Ventilation control for small to medium sized

building objects

- For triggering of 24 V DC drives

- 5 ventilation groups

- 8 A total actuating current - stabilized

- Only for indoor mounting

Example for Application

* optional function extension (separate components, retrofitable!)

This instruction includes descriptions and connection plans of components which are not part of

scope of supply of control panel. You can order these parts and many more separately from your

D+H distributor. Further connecting plans are available there as well.

WARNING

Performance features

- Ventilation safety function (key operation

OPEN/CLOSE), can be free encoded

- Weather automatic for single groups,

can be switched on and off

- Entry for external control, e.g. timer

- Possibility of connecting rain detector or wind/ rain

detector without supplementary module

- Plastic housing, surface mounted type with

lockable steel sheet door

Delivery contents

Ventilation control panel including control Board,

plastic housing, replacement fuses and instructions

for use.

groups

window drives*

vent button* room temp. control* Control panel (GVL 8408-M-UL) rain sensor*

external control*

Safety notes:

- Read all safety warnings, instructions, illustrations and specifications provided with this

product.

- Failure to follow all instructions listed below may result in electric shock, fire and/or serious

injury.

- Save all warnings and instructions for future reference.

- When installing the Ventilation Control Panel (GVL 8304-K-UL), basic safety precautions should

always be followed to reduce risk of fire, electric shock, and personal injury.

- Operating voltage 115 V AC!

- Prior to installation, maintenance and installation of additional assemblies to the control panel,

the control panel must be separated from the supply voltage and all electrical parts nearby there

are powered, must be covered.

- Connection has to be carried out only by an authorized electrical specialist.

- Mounting of the control panel should be carried out by a D+H distributor, whose qualification

and experience is ensured by regular in-house training.

- Only listed cable types for Class 2 circuits may be used:

a) Type CL2, CL2P, CL2R, or CL2X complying with the Standard for Power-Limited Circuit

Cables, referenced in Annex A, Ref. No. 12, or

b) Other cable with equivalent or better electrical, mechanical, and flammability ratings; or

c) Cable that is a factory-connected integral part of a Class 2 power supply complying with the

Standard for Class 2 Power Units, referenced in Annex A, Ref. No. 13, or a Class 2 transformer

complying with the Standard for Low Voltage Transformers - Part 3: Class 2 and Class 3

Transformers, referenced in Annex A, Ref. No. 11, or an LPS (Limited Power Source) supply

complying the Standard for Information Technology Equipment - Safety - Part 1: General

Requirements, referenced in Annex A, Ref. No. 14.

- All wiring must be installed by a qualified electrican according to e.g. National Electrical Codes,

NFPA 70 and local codes.

- For continued protection against fire, replace only with the same type and rating of fuse.

- Each control unit has provision for permanent connection to the supply source by means of

rigid or flexible conduit or equivalent in accordance with the National Electrical Code.

- The conduit openings shall be provided an shall be for conduit entry 22.2-mm (7/8 in.) in

diameter or equivalent metric cable glands.

- To create the cable entry:

A suitable tool with depth stop must be used to create the cable entry.

The depth stop must be set so that the central Board cannot be damaged.

- Duty cycle: After 2 minutes operation time, 8 minutes pause.

- Only for indoor mounting.

- Just use unchanged original D+H parts

For North America:

The International Building Codes have to be observed

GVL 8408-M-UL GVL 8408-M-UL

99.828.04 1.0/06/1999.828.04 1.0/06/19

4/12 5/12

English English

View motherboard

For continued protection against fire, replace only with the same type

and rating of fuse or equivalent, adjacent to the fuse holders.

WARNING

Class 2 supply, 24 V shall be used.

Wiring plan (Paragon)

Output voltage 24 V DC!

Do not run cables together with power lines!

In case of a cable with ground wire

(e.g. green / yellow) this must not be used!

total current

0.5

787

1312

2100

1

394

656

1050

1.5

262

427

699

2

197

328

525

2.5

157

262

420

3

131

213

351

3.5

112

180

299

4

98

164

262

ft

ft

ft

type

2x AWG 16

2x AWG 14

2x AWG 12

total current

0.5

240

400

640

1

120

200

320

1.5

80

130

213

2

60

100

160

2.5

48

80

128

3

40

65

107

3.5

34

55

91

4

30

50

80

m

m

m

type

2x 1,5 mm²

2x 2,5 mm²

2x 4 mm²

115 V AC, 60 Hz

to further ones

see line lenghts and cross sections

window drive control panel

vent button

ca. 4 ft above

upper edge

firm flooring

external

control

4x AWG 20

4x AWG 20

2x AWG 20

4x AWG 20

rain sensor

3x AWG 14

room temperature

control

Line lenghts and cross sections

fuse mains LED Power ON

28 - 14 AWG

max. 4.5 lb-in

22 - 12 AWG

max. 6 lb-in

mains connector

S1

F3.15A

T2.5A

S2

F3.15A

S3

F3.15A

S4

F3.15A

S5

F3.15A

Power

115 VAC

www.dh-partner.com

Ventilation control panel

GVL 8408-M-UL

Group 1 Group 2 Group 3 Group 4 Group 5

WARNING

For continued protection against fire,

replace only with the

same type and rating of fuse.

fuse drive

group 1

DIP-switch S1

fuse drive

group 2

DIP-switch S2

fuse drive

group 3

DIP-switch S3

fuse drive

group 4

DIP-switch S4

fuse drive

group 5

DIP-switch S5

group 1-5: 22 - 12 AWG / max. 4.5 lb-in

Encoding of group – DIP switches S1 - S5

Following functions can be adjusted for each group separately with DIP switches S1 - S5 on

motherboard of control panel and on group plug-in unit, if available.

The delivery state of all DIP-switches is OFF.

1 = ON Drives CLOSE up to final position by single pressing on respective vent button.

1 = OFF Drives are closing only so long as the vent button is pressed.

2 = ON Drives OPEN up to final position by single pressing on vent button.

2 = OFF Drives are opening only so long as the vent button is pressed.

3 = ON Drives are automatically closed by trigger of function „Central CLOSE",

e.g. by rain detector or room temperature control.

3 = OFF Drives can be closed only by pressing the respective vent button.

4 = ON Drives are automatically opened by trigger of function „Central OPEN",

e.g. by room temperature control.

4 = OFF Drives can be opened only by pressing the respective vent button.

GVL 8408-M-UL GVL 8408-M-UL

99.828.04 1.0/06/1999.828.04 1.0/06/19

4/12 5/12

English English

View motherboard

For continued protection against fire, replace only with the same type

and rating of fuse or equivalent, adjacent to the fuse holders.

WARNING

Class 2 supply, 24 V shall be used.

Wiring plan (Paragon)

Output voltage 24 V DC!

Do not run cables together with power lines!

In case of a cable with ground wire

(e.g. green / yellow) this must not be used!

total current

0.5

787

1312

2100

1

394

656

1050

1.5

262

427

699

2

197

328

525

2.5

157

262

420

3

131

213

351

3.5

112

180

299

4

98

164

262

ft

ft

ft

type

2x AWG 16

2x AWG 14

2x AWG 12

total current

0.5

240

400

640

1

120

200

320

1.5

80

130

213

2

60

100

160

2.5

48

80

128

3

40

65

107

3.5

34

55

91

4

30

50

80

m

m

m

type

2x 1,5 mm²

2x 2,5 mm²

2x 4 mm²

115 V AC, 60 Hz

to further ones

see line lenghts and cross sections

window drive control panel

vent button

ca. 4 ft above

upper edge

firm flooring

external

control

4x AWG 20

4x AWG 20

2x AWG 20

4x AWG 20

rain sensor

3x AWG 14

room temperature

control

Line lenghts and cross sections

fuse mains LED Power ON

28 - 14 AWG

max. 4.5 lb-in

22 - 12 AWG

max. 6 lb-in

mains connector

S1

F3.15A

T2.5A

S2

F3.15A

S3

F3.15A

S4

F3.15A

S5

F3.15A

Power

115 VAC

www.dh-partner.com

Ventilation control panel

GVL 8408-M-UL

Group 1 Group 2 Group 3 Group 4 Group 5

WARNING

For continued protection against fire,

replace only with the

same type and rating of fuse.

fuse drive

group 1

DIP-switch S1

fuse drive

group 2

DIP-switch S2

fuse drive

group 3

DIP-switch S3

fuse drive

group 4

DIP-switch S4

fuse drive

group 5

DIP-switch S5

group 1-5: 22 - 12 AWG / max. 4.5 lb-in

Encoding of group – DIP switches S1 - S5

Following functions can be adjusted for each group separately with DIP switches S1 - S5 on

motherboard of control panel and on group plug-in unit, if available.

The delivery state of all DIP-switches is OFF.

1 = ON Drives CLOSE up to final position by single pressing on respective vent button.

1 = OFF Drives are closing only so long as the vent button is pressed.

2 = ON Drives OPEN up to final position by single pressing on vent button.

2 = OFF Drives are opening only so long as the vent button is pressed.

3 = ON Drives are automatically closed by trigger of function „Central CLOSE",

e.g. by rain detector or room temperature control.

3 = OFF Drives can be closed only by pressing the respective vent button.

4 = ON Drives are automatically opened by trigger of function „Central OPEN",

e.g. by room temperature control.

4 = OFF Drives can be opened only by pressing the respective vent button.

GVL 8408-M-UL GVL 8408-M-UL

99.828.04 1.0/06/1999.828.04 1.0/06/19

6/12 7/12

English English

Connection – 115 V AC supply

Mot.b

Mot.a

–

OPEN

CLOSE

L (open signal, only LT 84-U-SD)

Vent button

(e.g. LT 84-U-SD)

LP

Mot.b

Mot.a

24 V DC

Window Drives

Mot.b

Mot.a

+G

Az

Zz

–

External contact

for central closing

(e.g. rain detector)

X

Line lengths and

cross sections

see page 5

The input current

of the connected

window drives

shall not exceed

4 Amp.

Connection – Vent button and window drives

NOTICE

cable tie for

strain relief

L

N

PE

115 V AC, 60 Hz

GVL 8408-M-UL

Drive group

1 ... 5

GVL 8408-M-UL

GVL 8408-M-UL GVL 8408-M-UL

99.828.04 1.0/06/1999.828.04 1.0/06/19

6/12 7/12

English English

Connection – 115 V AC supply

Mot.b

Mot.a

–

OPEN

CLOSE

L (open signal, only LT 84-U-SD)

Vent button

(e.g. LT 84-U-SD)

LP

Mot.b

Mot.a

24 V DC

Window Drives

Mot.b

Mot.a

+G

Az

Zz

–

External contact

for central closing

(e.g. rain detector)

X

Line lengths and

cross sections

see page 5

The input current

of the connected

window drives

shall not exceed

4 Amp.

Connection – Vent button and window drives

NOTICE

cable tie for

strain relief

L

N

PE

115 V AC, 60 Hz

GVL 8408-M-UL

Drive group

1 ... 5

GVL 8408-M-UL

GVL 8408-M-UL GVL 8408-M-UL

English English

99.828.04 1.0/06/1999.828.04 1.0/06/19

8/12 9/12

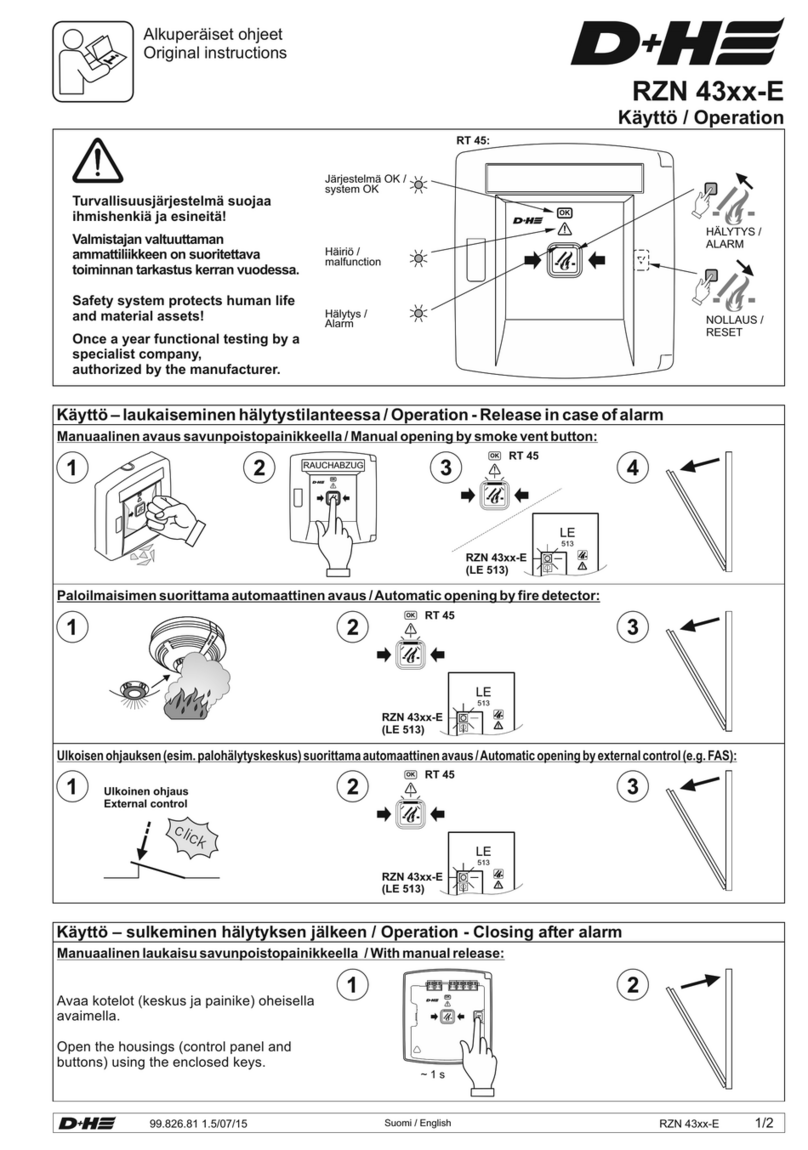

Operation - Day-to-day ventilation

Open: Close: Stop:

Vent button required.

ST OP

STOP

ST OPST OP

Connection – Vent button, window drives and weather sensor

* Connect lead directly when no automatic switch available.

In this case the manual operation is out of function.

Mot.b

Mot.a

–

OPEN

CLOSE

L (open signal, only LT 84-U-SD)

Vent buttons

(e.g. LT 84-U-W + LT 84-U-SD)

LP

Mot.b

Mot.a

24 V DC

Window Drives

Mot.b

Mot.a

+G

Az

Zz

–

GVL 8408-M-UL

X

Line lengths and

cross sections

see page 5

< optional >

rain

Wind

–

+

124357689

R

W

S 1/1

S 1/2

P3 P4

PS

rain

–

–

+24V

21 3 4 5 6

R

insert

bridge!

insert

bridge!

Automatic

on/off

WRG 82

(Wind and Rain sensor)

VRS 10

(Rain sensor) The input current

of the connected

window drives

shall not exceed

4 Amp.

Only if wind detector or rain detector available:

If the weather automatic is switched on via vent button LT 84-U-W

(optional), the system will automatically close in case of wind or rain.

The system will not automatically open again, if wind or rain has

stopped. Opening of the system for ventilation via vent button.

The weather automatic can be switched-off at vent button LT 84-U-W

(optional), if gap ventilation is required in case of bad weather.

Gap ventilation is not possible in case of bad weather, if no vent

button LT 84-U-W available.

Operation - Weather automatic

Automatic

on/off

LT 84-U-W

NOTICE

Drive group

1 ... 5

GVL 8408-M-UL GVL 8408-M-UL

English English

99.828.04 1.0/06/1999.828.04 1.0/06/19

8/12 9/12

Operation - Day-to-day ventilation

Open: Close: Stop:

Vent button required.

ST OP

STOP

ST OPST OP

Connection – Vent button, window drives and weather sensor

* Connect lead directly when no automatic switch available.

In this case the manual operation is out of function.

Mot.b

Mot.a

–

OPEN

CLOSE

L (open signal, only LT 84-U-SD)

Vent buttons

(e.g. LT 84-U-W + LT 84-U-SD)

LP

Mot.b

Mot.a

24 V DC

Window Drives

Mot.b

Mot.a

+G

Az

Zz

–

GVL 8408-M-UL

X

Line lengths and

cross sections

see page 5

< optional >

rain

Wind

–

+

124357689

R

W

S 1/1

S 1/2

P3 P4

PS

rain

–

–

+24V

21 3 4 5 6

R

insert

bridge!

insert

bridge!

Automatic

on/off

WRG 82

(Wind and Rain sensor)

VRS 10

(Rain sensor) The input current

of the connected

window drives

shall not exceed

4 Amp.

Only if wind detector or rain detector available:

If the weather automatic is switched on via vent button LT 84-U-W

(optional), the system will automatically close in case of wind or rain.

The system will not automatically open again, if wind or rain has

stopped. Opening of the system for ventilation via vent button.

The weather automatic can be switched-off at vent button LT 84-U-W

(optional), if gap ventilation is required in case of bad weather.

Gap ventilation is not possible in case of bad weather, if no vent

button LT 84-U-W available.

Operation - Weather automatic

Automatic

on/off

LT 84-U-W

NOTICE

Drive group

1 ... 5

GVL 8408-M-UL GVL 8408-M-UL

English English

99.828.04 1.0/06/1999.828.04 1.0/06/19

10/12 11/12

Usable window drives by D+H Mechatronic AG

Technical Data

Type GVL 8408-M-UL

Rated voltage 115 V AC ± 10%, 60 Hz

Rated power 388 VA

Stand-by operating ca. 2.5 W

Protection class I

Temperature range -5 ... +40 °C (23...104°F)

Ingress protection IP 30

Class of rating short-time duty, 20%

Output voltage 24 V DC / residual ripple 10%<

Safe output: *

Running current of drives 6.4 A

Rated current of drives 8 A

Housing plastic

colour of housing white

Housing dimensions 12.1'' x 12.1'' x 3.9''

310 x 310 x 100 mm

* Please observe:

The output current of the groups 1 ... 5 amounts max. 4 A.

The total output current of the control panel, is limited up to 8 A.

Electrical devices, accessories and packaging should

be sorted for environmental-friendly recycling.

Do not dispose electrical devices into household waste!

Disposal

To avoid accidents always disconnect the ventilation

control from the power supply before cleaning or

performing any maintenance.Inspection and

maintenance has to be carried out according to

D+H maintenance notes. Only original D+H spare

parts may be used. Repair is to be carried out

exclusively by D+H.

Wipe away debris or contamination with a dry, soft

cloth.

Do not use cleaning agents or solvents.

Maintenance and cleaning

Mounting of drive:

Because of varied possiblilties for choosing drives,

Please take mounting informations from relevant

instructions for use of the respective drive.

Moving direction of drives:

Change poles of wires of the drive supply

(„Mot.a" and „Mot.b"), when moving direction is wrong.

Window drives (Accessories)

The control unit may only be operated with the following drives of which representative samples of the

product series as specified on the respective certificate were tested according to the current UL

requirements:

Series: VCD

Certificate Number 20150923-E222052

Models VCD 22/yyy, VCD 22/yyy-BSY, VCD 22/yyy-BSY+, MA 25 N-V2, VCD 204/yyy, VCD 203/yyy, and

ZEL MA 25 G3/yyy.

Note: where yyy represents the stroke length up to 350 mm, MA 25 N-V2 UL with a stroke of 250 mm.

Series: CDC

Certificate Number 20170207-E222052

Models CDC-0252-0350-1-ACB, CDC-0252-0500-1-ACB, CDC-0252-0600-1-ACB, CDC-0252-0800-1-

ACB, CDC-0252-1000-1-ACB, CDC-TW-0502-0350-1-ACB, CDC-TW-0502-0500-1-ACB, CDC-TW-0502-

0600-1-ACB, CDC-TW-0502-0800-1-ACB, CDC-TW-0502-1000-1-ACB, may be followed by several digits

refering to optional data signals and connections configurations.

Series: KA

Certificate Number 20150923-E222052

Models KA, followed by -TW or Blank, followed by 16, 34, 54, 66, or 106, followed by “/”, followed by yyyy,

followed by Blank or -BSY+, may be followed by -SA, -SZ, -SGI or any alternate digits, where yyyy

represents the stroke length in millimeters, from 0100 to a maximum of 1500

Series: CDP

Certificate Number 20150923-E222052

Models CDP 800/yyyy-BSY+, CDP 1000/yyyy-BSY+, CDP 1500/yyyy-BSY+, CDP-TW 1600/yyyy-BSY+,

CDP-TW 2000/yyyy-BSY+, CDP-TW 3000/yyyy-BSY+,, may be followed by several digits refering to

optional data signals and connections configurations, with "yyyy" three of four digits for length of stroke

from 600 to 1500 mm

Series: LDx/VLD

Certificate Number 20160629-E222052

Models LDE or LDCO 1000/yyy, LDF 100/yyy, LDS 100/yyy, LDH 800/yyy,

and linear drive for locking and unlocking motor-operated window models VLD 51/yyy-BSY+, VLD 51/yyy.

May be followed by various other suffixes.

Series: ZA/DXD-BSY

Certificate Number 20150923-E222052

Models ZA 35/yyyy-BSY+, ZA 85/yyyy-BSY+, ZA 105/yyyy-BSY+, ZA 155/yyyy-BSY+, may be followed by

„-HS”, SXD 800/yyyy-BSY+, SXD 1000/yyyy-BSY+, SXD 1500/yyyy-BSY+;

Double motor - Models DXD 150/yyyy-BSY+, DXD 300/yyyy-BSY+, may be followed by „-HS”, may be

followed by various other suffixes.

Louver operator drive - Models LA 35/yyyy-BSY+, LA 85/yyyy-BSY+, LA 105/yyyy-BSY+, LA 155/yyyy-

BSY+, may be followed by various other suffixes

Note: yyyy defines the stroke length in millimeters

Series: ZA-PLP

Certificate Number 20180207-E222052

Models ZA 35/yyyy, ZA 85/yyyy, ZA 105/yyyy, ZA 155/yyyy, ZA-0300-yyyy-1-PLP, ZA-0800-yyyy-1-PLP,

ZA-1000-yyyy-1-PLP, ZA-1500-yyyy-1-PLP,

Louver operator drive - Models LA 35/yyyy, LA 85/yyyy, LA 105/yyyy, LA 155/yyyy, LA-0300-yyyy-1-PLP,

LA-0800-yyyy-1-PLP, LA-1000-yyyy-1-PLP, LA-1500-yyyy-1-PLP. May be followed by various other

suffixes. May be followed by ,–HS”, may be followed by various other suffixes.

Note: yyyy defines the stroke length in millimeters.

GVL 8408-M-UL GVL 8408-M-UL

English English

99.828.04 1.0/06/1999.828.04 1.0/06/19

10/12 11/12

Usable window drives by D+H Mechatronic AG

Technical Data

Type GVL 8408-M-UL

Rated voltage 115 V AC ± 10%, 60 Hz

Rated power 388 VA

Stand-by operating ca. 2.5 W

Protection class I

Temperature range -5 ... +40 °C (23...104°F)

Ingress protection IP 30

Class of rating short-time duty, 20%

Output voltage 24 V DC / residual ripple 10%<

Safe output: *

Running current of drives 6.4 A

Rated current of drives 8 A

Housing plastic

colour of housing white

Housing dimensions 12.1'' x 12.1'' x 3.9''

310 x 310 x 100 mm

* Please observe:

The output current of the groups 1 ... 5 amounts max. 4 A.

The total output current of the control panel, is limited up to 8 A.

Electrical devices, accessories and packaging should

be sorted for environmental-friendly recycling.

Do not dispose electrical devices into household waste!

Disposal

To avoid accidents always disconnect the ventilation

control from the power supply before cleaning or

performing any maintenance.Inspection and

maintenance has to be carried out according to

D+H maintenance notes. Only original D+H spare

parts may be used. Repair is to be carried out

exclusively by D+H.

Wipe away debris or contamination with a dry, soft

cloth.

Do not use cleaning agents or solvents.

Maintenance and cleaning

Mounting of drive:

Because of varied possiblilties for choosing drives,

Please take mounting informations from relevant

instructions for use of the respective drive.

Moving direction of drives:

Change poles of wires of the drive supply

(„Mot.a" and „Mot.b"), when moving direction is wrong.

Window drives (Accessories)

The control unit may only be operated with the following drives of which representative samples of the

product series as specified on the respective certificate were tested according to the current UL

requirements:

Series: VCD

Certificate Number 20150923-E222052

Models VCD 22/yyy, VCD 22/yyy-BSY, VCD 22/yyy-BSY+, MA 25 N-V2, VCD 204/yyy, VCD 203/yyy, and

ZEL MA 25 G3/yyy.

Note: where yyy represents the stroke length up to 350 mm, MA 25 N-V2 UL with a stroke of 250 mm.

Series: CDC

Certificate Number 20170207-E222052

Models CDC-0252-0350-1-ACB, CDC-0252-0500-1-ACB, CDC-0252-0600-1-ACB, CDC-0252-0800-1-

ACB, CDC-0252-1000-1-ACB, CDC-TW-0502-0350-1-ACB, CDC-TW-0502-0500-1-ACB, CDC-TW-0502-

0600-1-ACB, CDC-TW-0502-0800-1-ACB, CDC-TW-0502-1000-1-ACB, may be followed by several digits

refering to optional data signals and connections configurations.

Series: KA

Certificate Number 20150923-E222052

Models KA, followed by -TW or Blank, followed by 16, 34, 54, 66, or 106, followed by “/”, followed by yyyy,

followed by Blank or -BSY+, may be followed by -SA, -SZ, -SGI or any alternate digits, where yyyy

represents the stroke length in millimeters, from 0100 to a maximum of 1500

Series: CDP

Certificate Number 20150923-E222052

Models CDP 800/yyyy-BSY+, CDP 1000/yyyy-BSY+, CDP 1500/yyyy-BSY+, CDP-TW 1600/yyyy-BSY+,

CDP-TW 2000/yyyy-BSY+, CDP-TW 3000/yyyy-BSY+,, may be followed by several digits refering to

optional data signals and connections configurations, with "yyyy" three of four digits for length of stroke

from 600 to 1500 mm

Series: LDx/VLD

Certificate Number 20160629-E222052

Models LDE or LDCO 1000/yyy, LDF 100/yyy, LDS 100/yyy, LDH 800/yyy,

and linear drive for locking and unlocking motor-operated window models VLD 51/yyy-BSY+, VLD 51/yyy.

May be followed by various other suffixes.

Series: ZA/DXD-BSY

Certificate Number 20150923-E222052

Models ZA 35/yyyy-BSY+, ZA 85/yyyy-BSY+, ZA 105/yyyy-BSY+, ZA 155/yyyy-BSY+, may be followed by

„-HS”, SXD 800/yyyy-BSY+, SXD 1000/yyyy-BSY+, SXD 1500/yyyy-BSY+;

Double motor - Models DXD 150/yyyy-BSY+, DXD 300/yyyy-BSY+, may be followed by „-HS”, may be

followed by various other suffixes.

Louver operator drive - Models LA 35/yyyy-BSY+, LA 85/yyyy-BSY+, LA 105/yyyy-BSY+, LA 155/yyyy-

BSY+, may be followed by various other suffixes

Note: yyyy defines the stroke length in millimeters

Series: ZA-PLP

Certificate Number 20180207-E222052

Models ZA 35/yyyy, ZA 85/yyyy, ZA 105/yyyy, ZA 155/yyyy, ZA-0300-yyyy-1-PLP, ZA-0800-yyyy-1-PLP,

ZA-1000-yyyy-1-PLP, ZA-1500-yyyy-1-PLP,

Louver operator drive - Models LA 35/yyyy, LA 85/yyyy, LA 105/yyyy, LA 155/yyyy, LA-0300-yyyy-1-PLP,

LA-0800-yyyy-1-PLP, LA-1000-yyyy-1-PLP, LA-1500-yyyy-1-PLP. May be followed by various other

suffixes. May be followed by ,–HS”, may be followed by various other suffixes.

Note: yyyy defines the stroke length in millimeters.

D+H Mechatronic AG

Georg-Sasse-Str. 28-32

, Germany22949 Ammersbek

: +49 239Tel. 40-605 65

: +49Fax 40-605 65 254

E-Mail: info@dh-partner.com

www.dh-partner.com

© 2018 D+H Mechatronic AG, Ammersbek

Technische Änderungen vorbehalten. /

Rights to technical modifications reserved. 99.828.04 1.0/06/19

This manual suits for next models

1

Table of contents

Other D+H Control Panel manuals

Popular Control Panel manuals by other brands

Fire-Lite

Fire-Lite MS-2410BC Programming, installation, maintenance and operating instruction manual

Profelmnet

Profelmnet 3433 quick start guide

UniPOS

UniPOS FS5200 instruction manual

Beijer Electronics

Beijer Electronics X2 web manual

Digital Vision

Digital Vision element manual

Cooper Controls

Cooper Controls Greengate CK4-120NO Installation sheet