INTRODUCTION

Corn Head Clinic Guide - GT

Table of Contents

MAINTENANCE ............................................................................................................................................................3

REQUIRED FLUIDS ..................................................................................................................................................... 4

LUBRICANT PART NUMBERS ..................................................................................................................................... 4

MAINTENANCE SCHEDULE ........................................................................................................................................ 5

PRE-SEASON ........................................................................................................................................................... 5

NORMAL OPERATION ............................................................................................................................................. 5

DOWN CORN ........................................................................................................................................................... 6

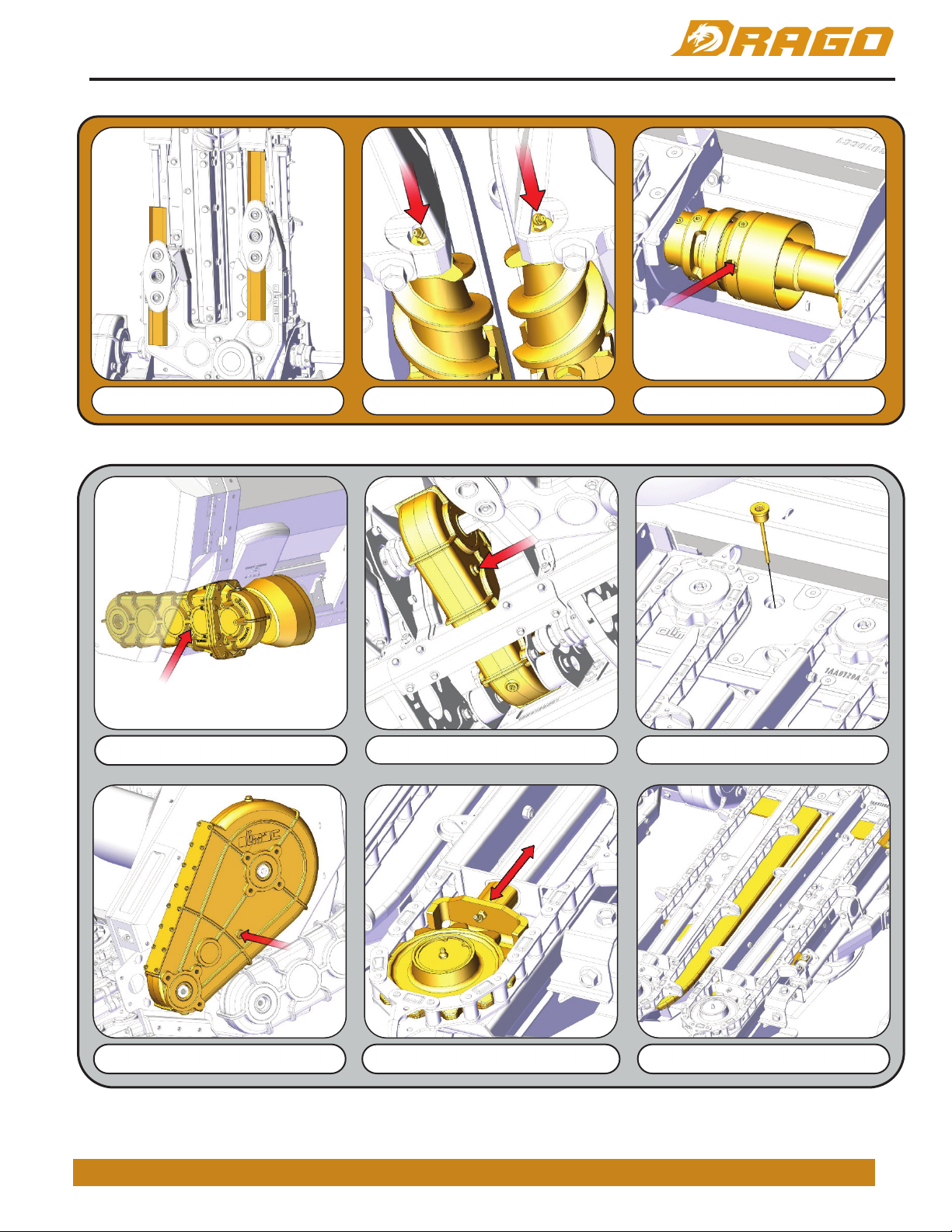

PRE-SEASON ............................................................................................................................................................... 7

20-HOUR ..................................................................................................................................................................... 8

100-HOUR ................................................................................................................................................................... 8

250-HOUR OR YEARLY ............................................................................................................................................... 9

INITIAL SETTINGS................................................................................................................................................... 11

CORN HEAD ANGLE .................................................................................................................................................... 11

HEAD SPEED ............................................................................................................................................................. 12

SNOUT ADJUSTMENTS ............................................................................................................................................. 13

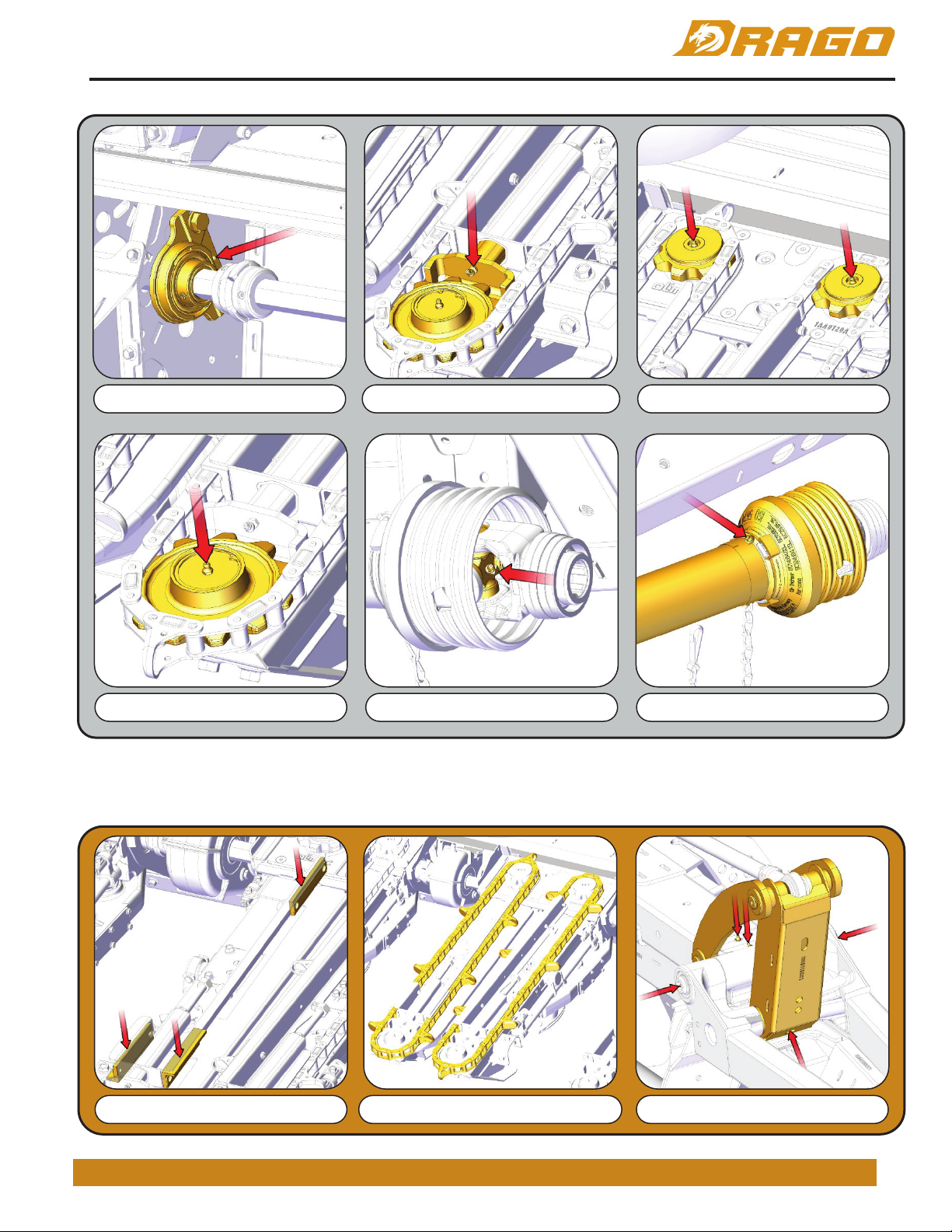

DECK PLATE GAP ...................................................................................................................................................... 13

DECK PLATE TENSION.............................................................................................................................................. 14

GATHERING CHAIN TENSION .................................................................................................................................. 14

PART REPLACEMENT ...............................................................................................................................................15

PERFORMANCE PARTS............................................................................................................................................ 17

TROUBLESHOOTING.................................................................................................................................................18

NOTES..........................................................................................................................................................................21

SERVICE VIDEOS ..................................................................................................................................................... 23