bedknifeontherightsideofthecuttingunit.Putting

anidentifyingmarkonthisbladewillmakesubsequent

adjustmentseasier.Insertthe0.05mm(0.002inch)

shimbetweenthemarkedreelbladeandthebedknife

atthepointwherethebladecrossesthebedknife.

4.Turntherightbedbaradjusterclockwiseuntilyoufeel

lightpressure(i.e.,drag)ontheshim,thenbackoffthe

bedbaradjuster2clicksandremovetheshim.(Since

adjusting1sideofthecuttingunitaffectstheother

side,the2clicksprovidetheclearancethatyouneed

forwhenyouadjusttheotherside.)

Note:Ifthereisalargegap,drawbothsidescloserby

alternatelytighteningtherightandleftsides.

5.Slowlyrotatethereelsothatthesamebladethatyou

checkedontherightsideiscrossingthebedknife

approximately25mm(1inch)infromtheendofthe

bedknifeontheleftsideofthecuttingunit.

6.Turntheleftbedbaradjusterclockwiseuntilyoucan

slidetheshimthroughthereeltobedknifegapwith

lightdrag.

7.Returntotherightsideandadjustasnecessarytoget

lightdragontheshimbetweenthesamebladeand

bedknife.

8.Repeatsteps6and7untilyoucanslidetheshim

throughbothgapswithslightdrag,but1clickinon

bothsidespreventstheshimfrompassingthroughon

bothsides.Thebedknifeisnowparalleltothereel.

Note:Youshouldnotneedtoperformthisprocedure

fordailyadjustments,butaftergrindingordisassembly.

9.Fromthisposition(i.e.,1clickinandashimnot

passingthrough)turnthebedbaradjustersclockwise2

clickseach.

Note:Eachclickturnedmovesthebedknife0.018

(0.0007inch).Donotovertightentheadjusting

screws.

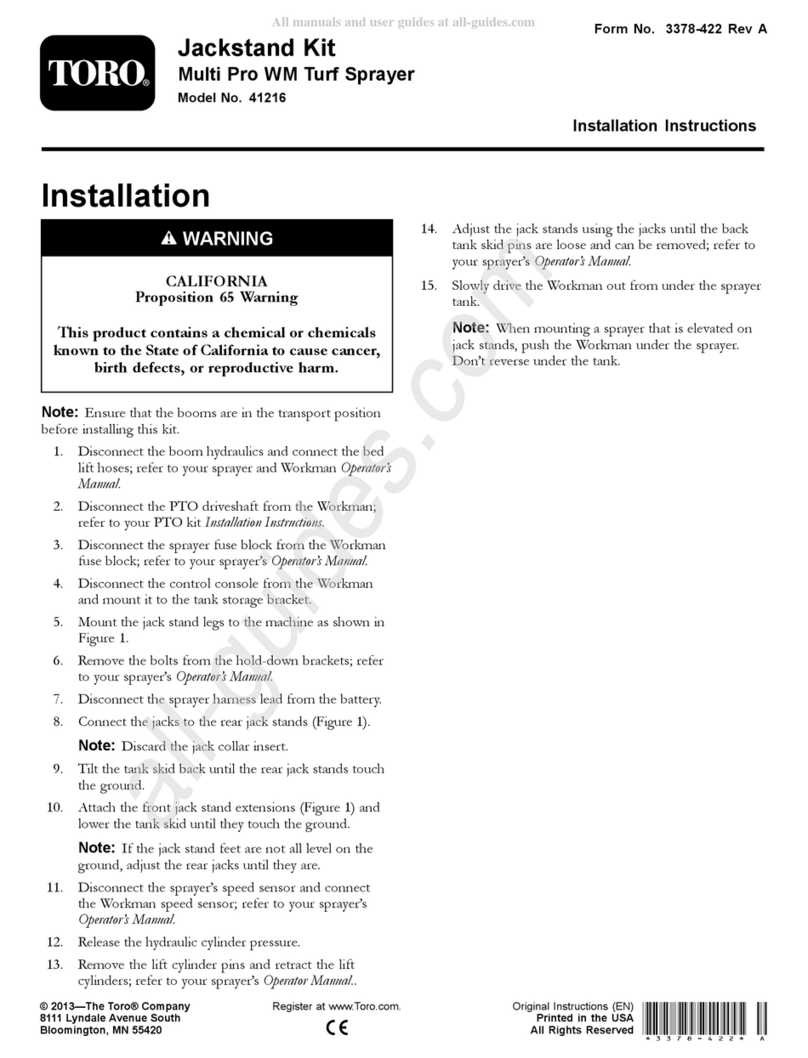

10.Testthecuttingperformancebyinsertingalongstripof

cuttingperformancepaper(ToroPartNo.125-5610)

betweenthereelandthebedknife,perpendiculartothe

bedknife(Figure10).Slowlyrotatethereelforward;it

shouldcutthepaper.

Figure10

Note:Ifthereisexcessivereeldrag,eitherbacklap

orgrindthecuttingunittoachievethesharpedges

neededforprecisioncutting.

AdjustingtheRearRoller

1.Adjusttherearrollerbrackets(Figure11)tothedesired

height-of-cutrangebypositioningtherequiredamount

ofspacersbelowtheside-platemountingange(Figure

11)pertheHOCChart.

Figure11

1.Spacer3.Side-platemountingange

2.Rollerbracket

2.Raisetherearofthecuttingunitandplaceablock

underthebedknife.

3.Removethe2nutssecuringeachrollerbracketand

spacertoeachside-platemountingange.

4.Lowertherollerandthescrewsfromtheside-plate

mountingangesandspacers.

5.Placespacersontoscrewsonrollerbrackets.

6.Securetherollerbracketandspacerstotheunderside

oftheside-platemountingangeswiththenuts

previouslyremoved.

7.Verifythatthebedknife-to-reelcontactiscorrect.Tip

themowertoexposethefrontandrearrollersandthe

bedknife.

Note:Thepositionoftherearrollertothereel

iscontrolledbythemachiningtolerancesofthe

assembledcomponentsandparallelingisnotrequired.

Alimitedamountofadjustmentispossiblebysetting

thecuttingunitonasurfaceplateandlooseningthe

side-platemountingbolts(Figure12).Adjustand

tightenthebolts.Torquetheboltsto37to45N∙m

(27to33ft-lb).

Figure12

1.Side-platemountingbolts

8