Page 4 of 6

.draperinc.com (765) 987-7999

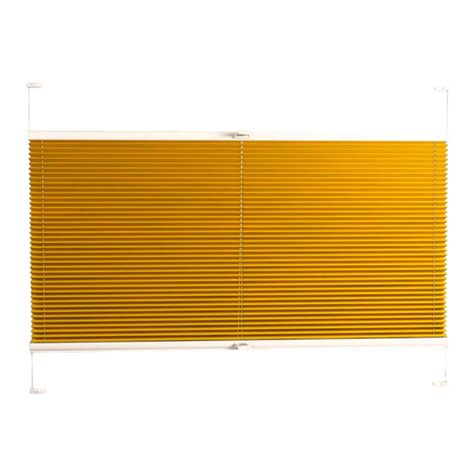

Lightbloc FlexShade®—Small Hardware by Draper

Limit Switch Adjustments—Standard and Quiet Motors

Push Button Limits

1Fully depress both limit switch push buttons, then operate wall switch to

make sure system works properly.

2Raise shade to desired “up” stop position.

3Set upper limit by depressing and releasing the proper (back) push button.

4Lower shade to desired “down” stop position.

5Set lower limit by depressing and releasing the proper (front) push button.

CAUTION: Be sure all switches are in “off” position before adjusting limit

switches. Always be prepared to shut off manually when new adjustment is

being tested. Do not allow the shade roller to become exposed by run-

ning the shade fabric too far down. Shade may be severely damaged if

allowed to run too far up or down. Eachshade’slimitswitchmustbesetifus-

inggroupcontrolsystem.Motor should be installed so limit switches are

pointed down or accessible.

Electrical Connections

Motorized shade operates on 110-120V, 60 Hz. current. Shade is shipped with

internal wiring complete and control switch(es) fully boxed, and standardly

supplied with a 6' cable lead. Longer lead can be substituted by removing

two screws in motor end of roller, removing lead, plugging new lead in, and

replacing screws. Wire to connect shade to switch(es) and switch(es) to power

supply should be furnished by installer. Connections should be made in accor-

dance with attached wiring diagram, and wiring should comply with national

and local electrical codes.DO NOT wire motors in parallel without written

permission from Draper.

All operating switches should be “off” before power is connected.

Cleaning and Maintenance

Idlers on motorized shades may occasionally need lubrication. If lubrica-

tion is required, apply a small amount of a lithium based grease direct to the

idler pin.

Most of Draper’s standard fabrics may be cleaned at the window by

vacuuming with a soft brush attachment. They may also be cleaned by using

a sponge or soft cloth and mild solution of warm soapy water. A dishwashing

liquid, such as Ivory liquid, is recommended. A clean dry cloth is recommend-

ed for the metal finish. Exceptions are Flocké, Roc-Rol and Phifer SW7000

fabrics, which must be cleaned with a dry art sponge.

Please Note: Forlowvoltagewiringrequirements,Draperrecommendscon-

sultingwithaprofessionallowvoltageelectricalcontractor.Itisveryimportant

that shielded and stranded CAT 5 cable be used to prevent any electrical

interference.

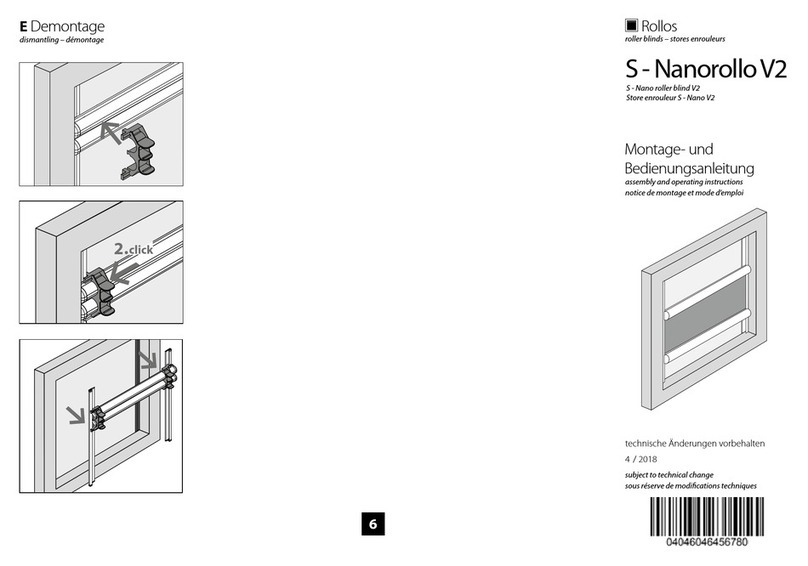

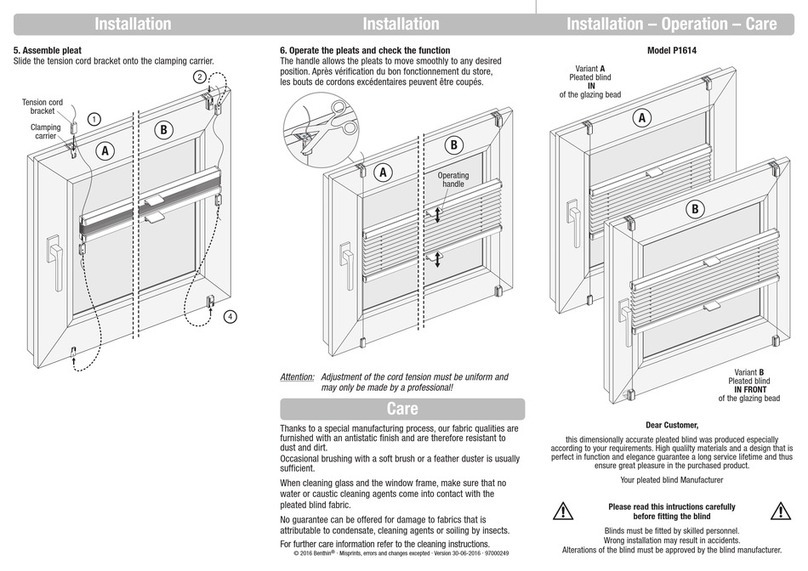

Figure 15

Slat Bar

Catch

Sill Channel

NOTE: Opaque caulking around perimeter of cover, side channels, and

sill may be necessary for complete light block—especially for jamb

mounts where window openings are not square.

P-Clip Cord Tension Device

Figure 16

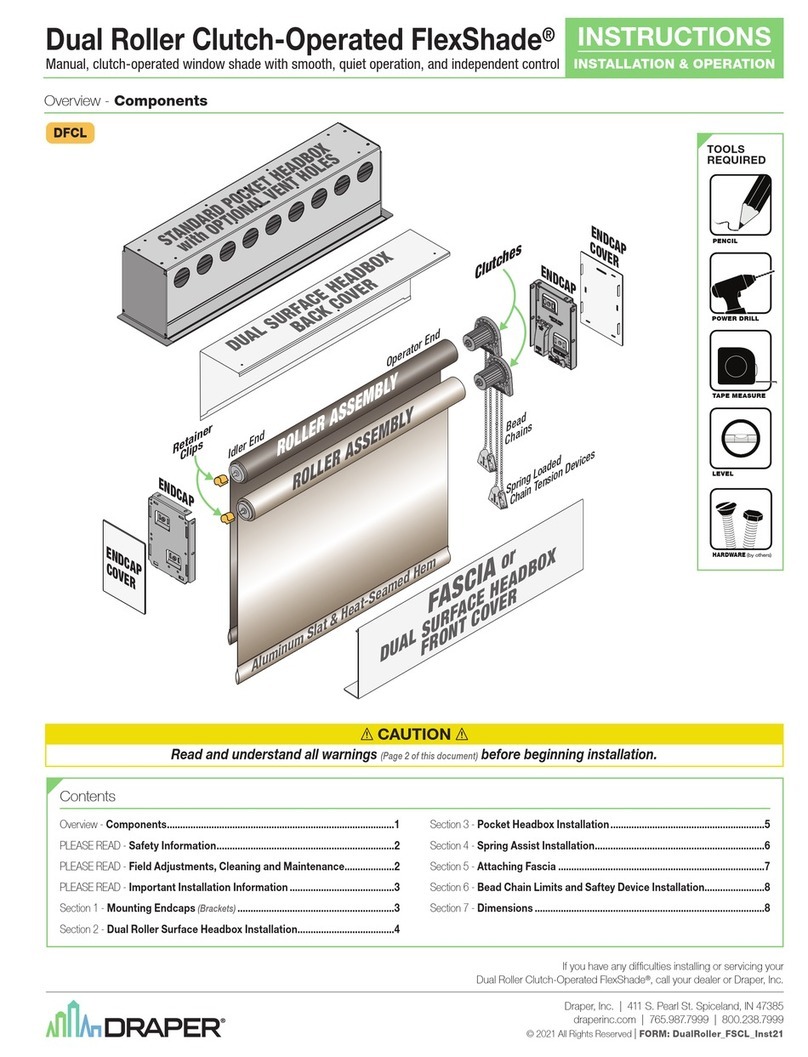

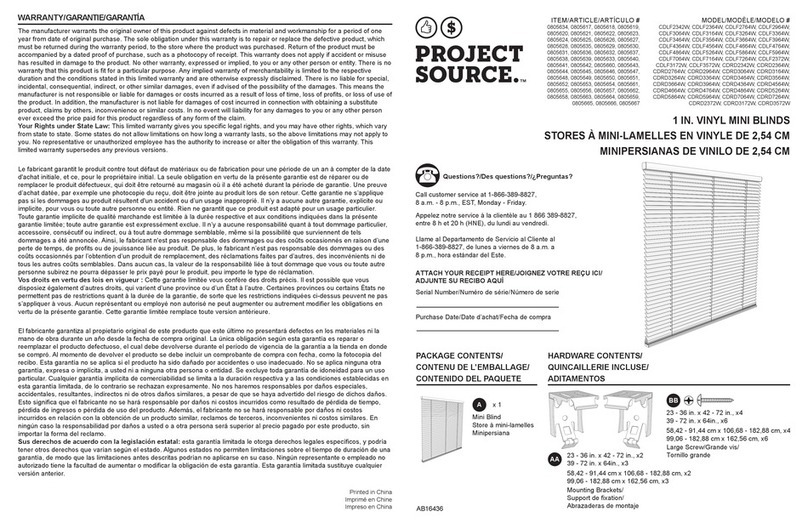

8Draper Bead Chain Clutch Operated shades that do not comply with

WMCA/ANSI Standard A100.1-2012 come with a cord tension device pre-

attached to bead chain (see Fig. 16). This device must be attached to wall,

jamb or sill so that the bead chain is held taut enough that children cannot

pull it away from the wall or fit their head into the loop. See safety note on

page 1.

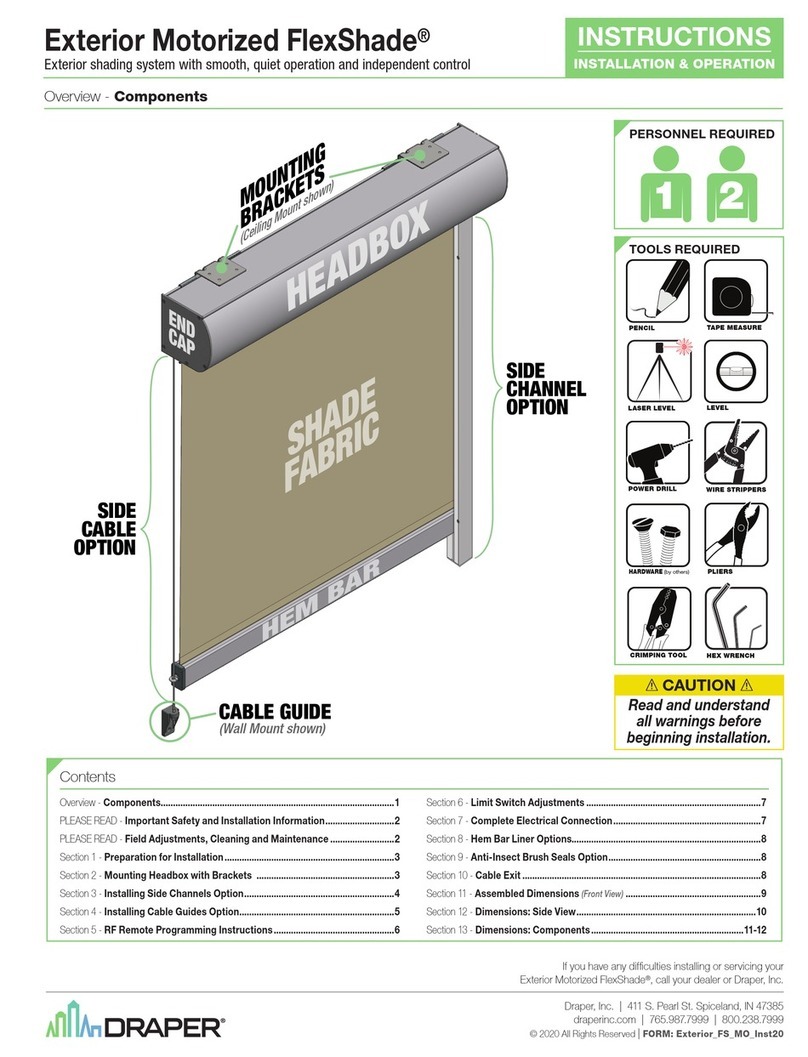

Spring-Loaded Cord Tension Device

If your Draper Clutch FlexShade

®

complies with WMCA/ANSI Standard

A100.1-2012, a Spring-Loaded Cord tension device comes installed on bead

chain (see Fig. 17). An approved permanent warning label is attached, and

approved mechanical fasteners (wood screws) are included. Install cord ten-

sion device to wall, jamb or sill. To install, pull tensioner down so that the bead

chain is held taut and use the mounting hardware to keep it taut. The bead

chain should be taut enough so it will move smoothly through the device. If

there is not enough tension, the device will not allow the bead chain to pass

through and operate the shade. This device is designed so that children can-

not pull the bead chain away from the wall or fit their head into the loop. See

safety note on page 1. The installer is responsible for selecting mount-

ing hardware appropriate for site conditions. For more information, visit:

http://www.draperinc.com/WindowShades/WCMAcompliance.asp.

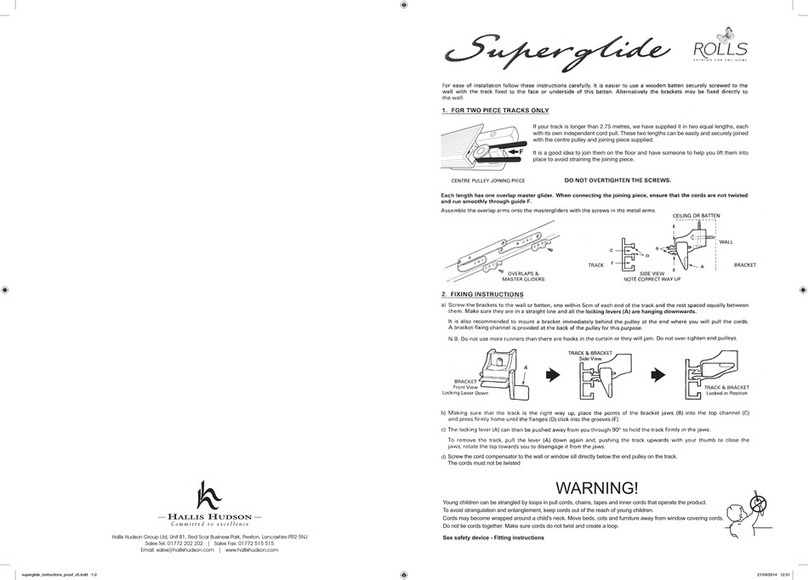

Attaching to Wood or Metal

1For attaching to wood, two #8-18 x 1.5" Zinc HWH TEK Type AB wood

screws are provided. For attaching to metal, choose fasteners with a mini-

mum fastener manufacturer-rated or tested release force of 20 lb (89 N),

and make sure they are long enough for the threads to catch and hold.

2Mark mounting hole locations with a pencil.

3Drill pilot holes smaller than the screw size.

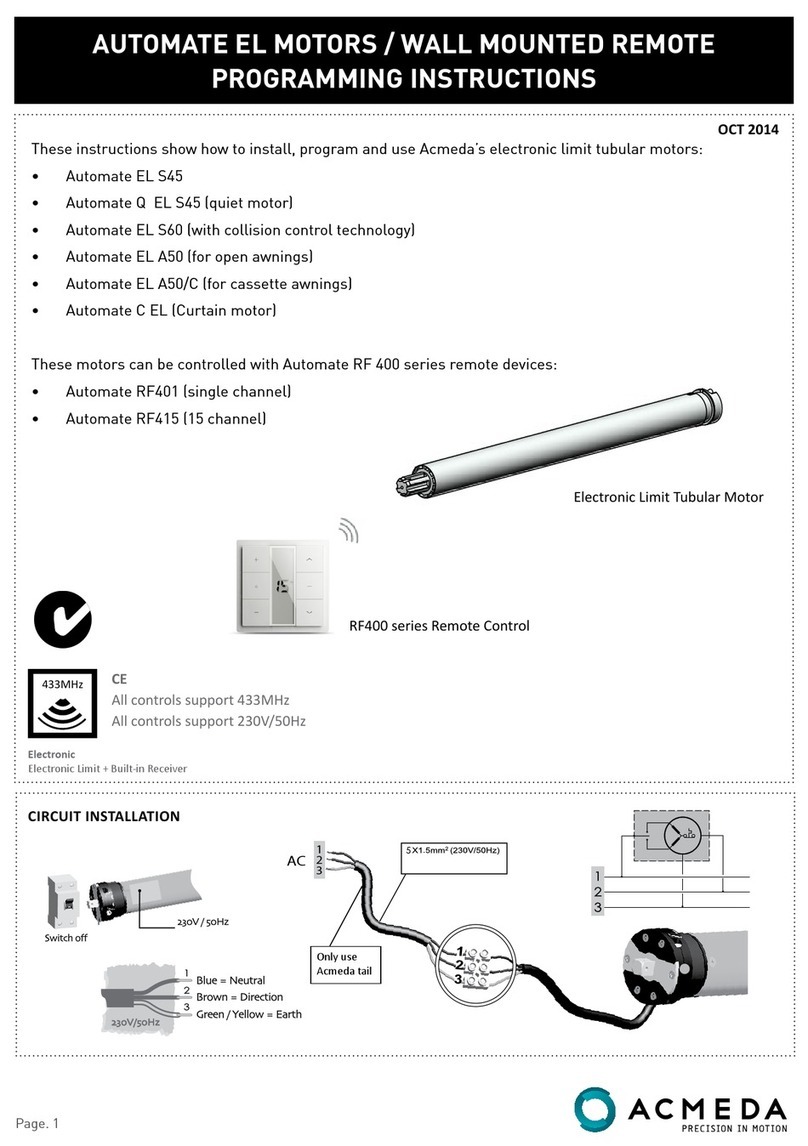

Figure 17

JAMB MOUNT SILL MOUNT

Spring-Loaded

Clamp

JambMount SillMount

Tensioner

Installation through Drywall

1Make sure that screws are long enough for the threads to catch and hold

joist or stud.

2Locate the stud and mark it with a pencil.

3Mark mounting hole locations.

Please note: Ifyouareunabletomountonastud,useMollyBoltsorToggle

Bolts.Thefastenersshallhaveaminimumfastenermanufacturer-ratedor

tested release force of 20 lb (89 N).

4Drill shallow pilot holes smaller than the screw size.

5Pass screws through the Spring Loaded Tension Device. Turn the screws

into the pilot hole, starting by hand. The fasteners shall have a minimum

fastener manufacturer-rated or tested release force of 20 lb (89 N).

4Pass screws through the Spring Loaded Tension Device. Turn the screws

into the pilot hole, starting by hand.

Please Note: Tighten screws so that the Spring Loaded Tension Device

maintainsenoughtensiononthebeadchainforshadetooperatewithout

working loose, but not tight enough that the Spring Loaded Tension Device is

damagedbyovertightenedscrews.

Please Note: Tighten screws so that the Spring Loaded Tension Device

maintainsenoughtensiononthebeadchainforshadetooperatewithout

working loose, but not tight enough that the Spring Loaded Tension Device is

damagedbyovertightenedscrews.