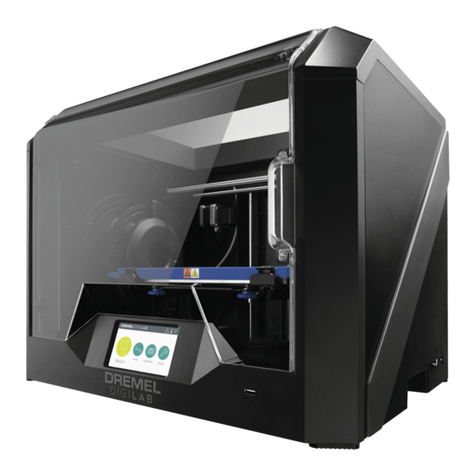

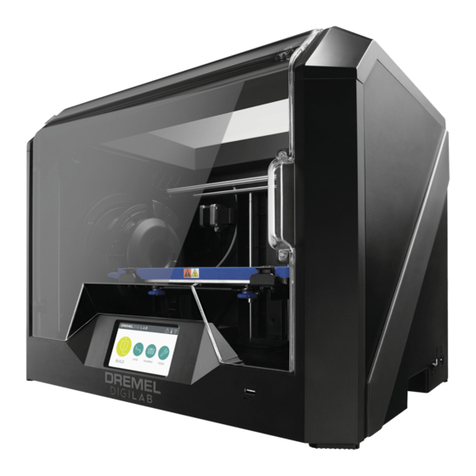

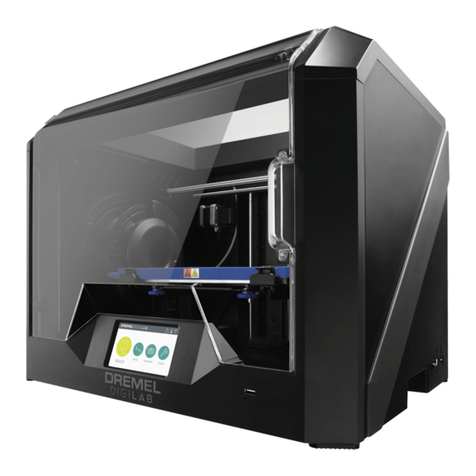

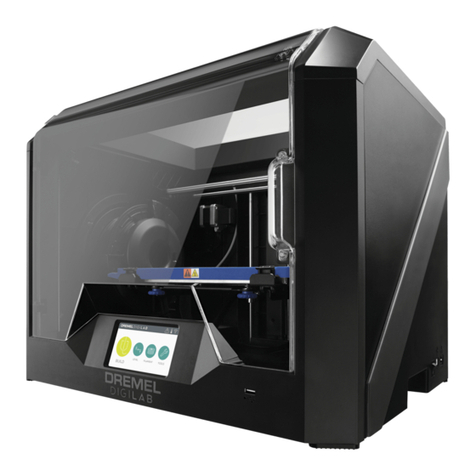

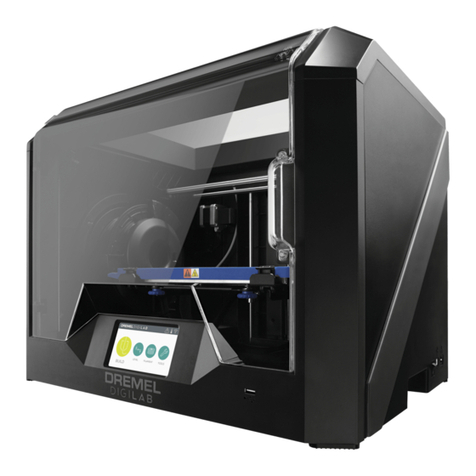

Dremel DigiLab 3D45 Use and care manual

Other Dremel 3D Printer manuals

Dremel

Dremel DigiLab 3D45 Assembly instructions

Dremel

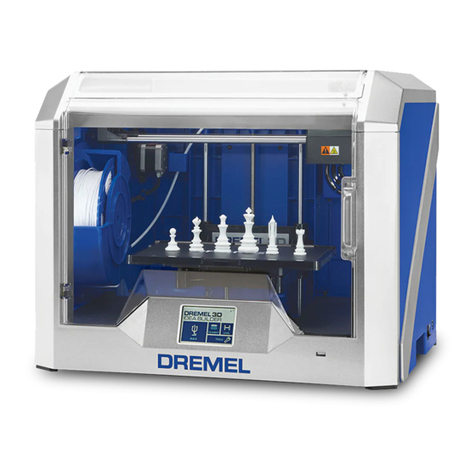

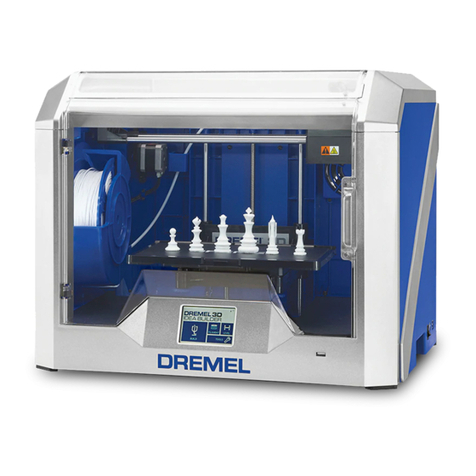

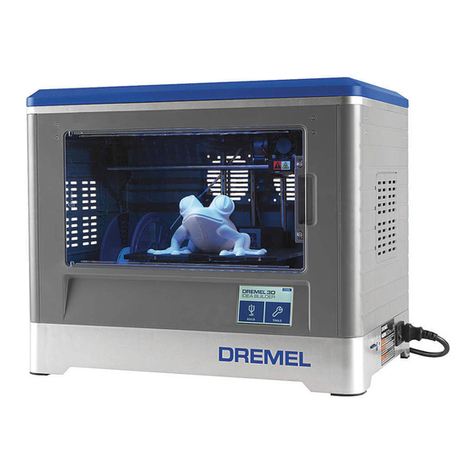

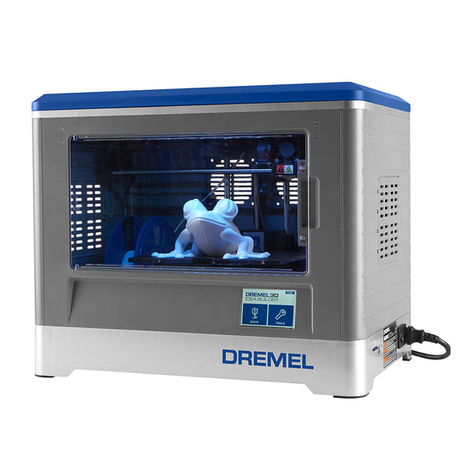

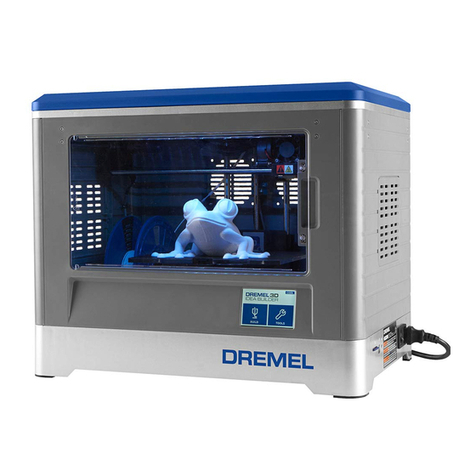

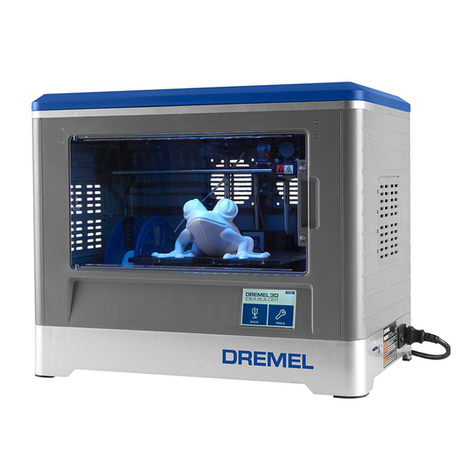

Dremel Idea Builder 3D20-01 User manual

Dremel

Dremel DigiLab 3D45 User manual

Dremel

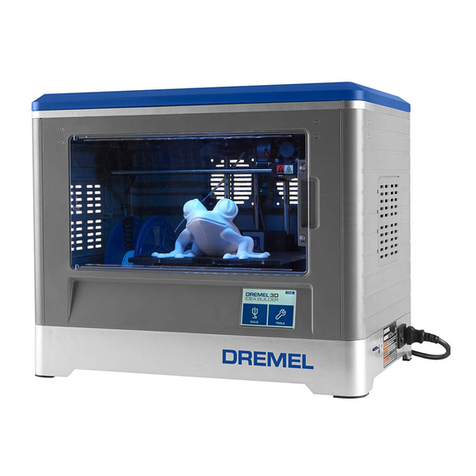

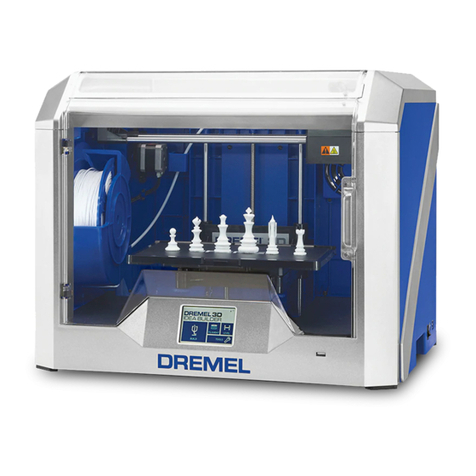

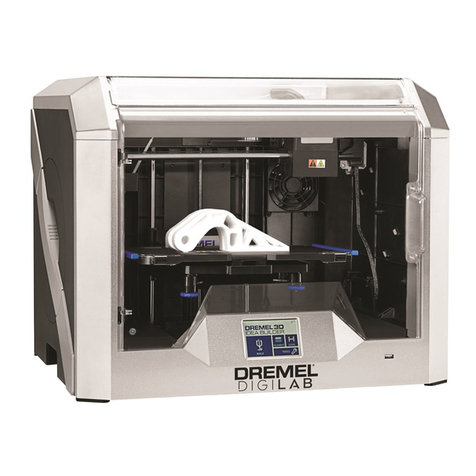

Dremel 3D40 Idea Builder Operating instructions

Dremel

Dremel 3D40 Idea Builder User manual

Dremel

Dremel 3D40 Idea Builder Quick guide

Dremel

Dremel Idea Builder 3D20-01 Assembly instructions

Dremel

Dremel DigiLab 3D45 User manual

Dremel

Dremel 3D20 Idea Builder User manual

Dremel

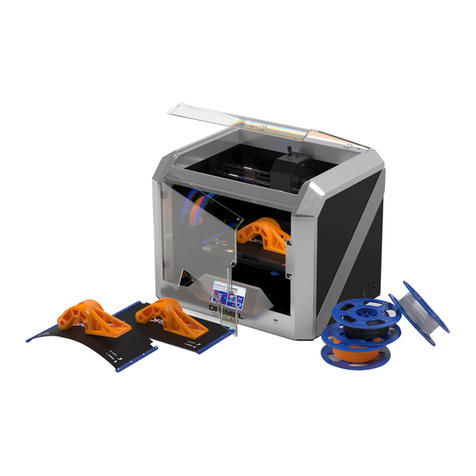

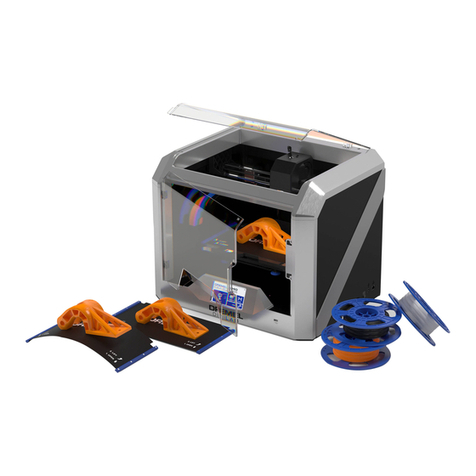

Dremel DigiLab 3D40 FLEX User manual

Dremel

Dremel DigiLab 3D45 User manual

Dremel

Dremel 3D20 Idea Builder User manual

Dremel

Dremel 3D20 Idea Builder User manual

Dremel

Dremel 3D20 Idea Builder User manual

Dremel

Dremel 3D20 Idea Builder User manual

Dremel

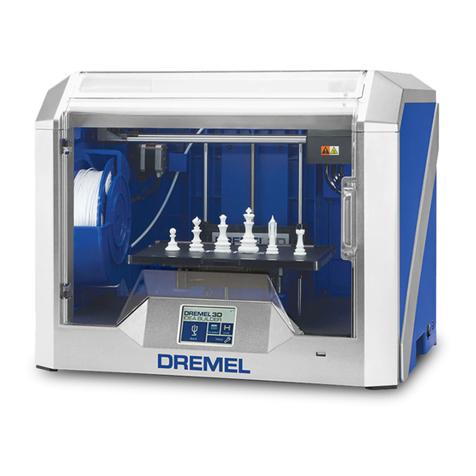

Dremel DIGILAB 3D40 User manual

Dremel

Dremel DigiLab 3D45 Quick guide

Dremel

Dremel 3D40 FLEX User manual

Dremel

Dremel 3D20 Idea Builder User manual

Dremel

Dremel DigiLab 3D45 Operating instructions