K239 Issue No.11

General

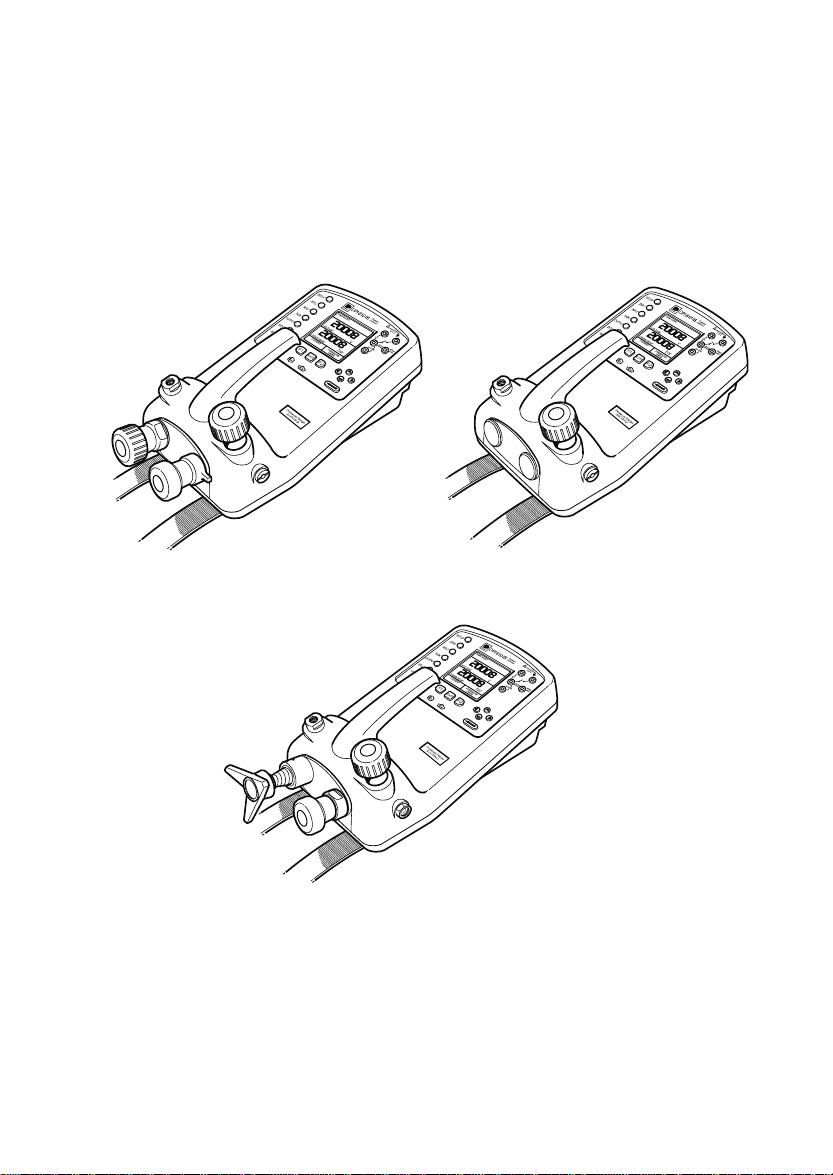

The DPI 610 is a rugged, portable precision instrument available either as an indicator

or calibrator for use in hazardous areas. Additionally, an intrinsically safe hydraulic

calibrator version (HC) is available.

The instrument is primarily used for calibrating instrumentation and systems over the

range -1 to 20 bar, (HC version to 400 bar). Used in conjunction with external transducers,

the range of the standard calibrator/indicator can be extended up to 700 bar.

The instrument is also capable of sinking an externally supplied current loop up to a

maximum current of 24 mA and measuring dc input voltages of ± 30V and dc currents

of ± 55 mA. Ambient temperature measurement is also provided.

The DPI 610 is powered by six alkaline C-cells and has an RS232 interface.

Important Notice

Zinc-carbon and zinc-chloride cells should NOT be used in this instrument.

Use only the battery types as shown in theTable on page 7.

Description of Procedures

In the procedures outlined in this User Guide, hard (fixed function) and soft (variable

function) key operations are shown in bold type (e.g.) TASK and F1. These statements

mean press the TASK key and press the F1 key. Soft key operations can be allocated

to both the F1 and F2 keys. Where a specific soft function is referred to it is written in

bold italics (e.g.)

PROCESS

.

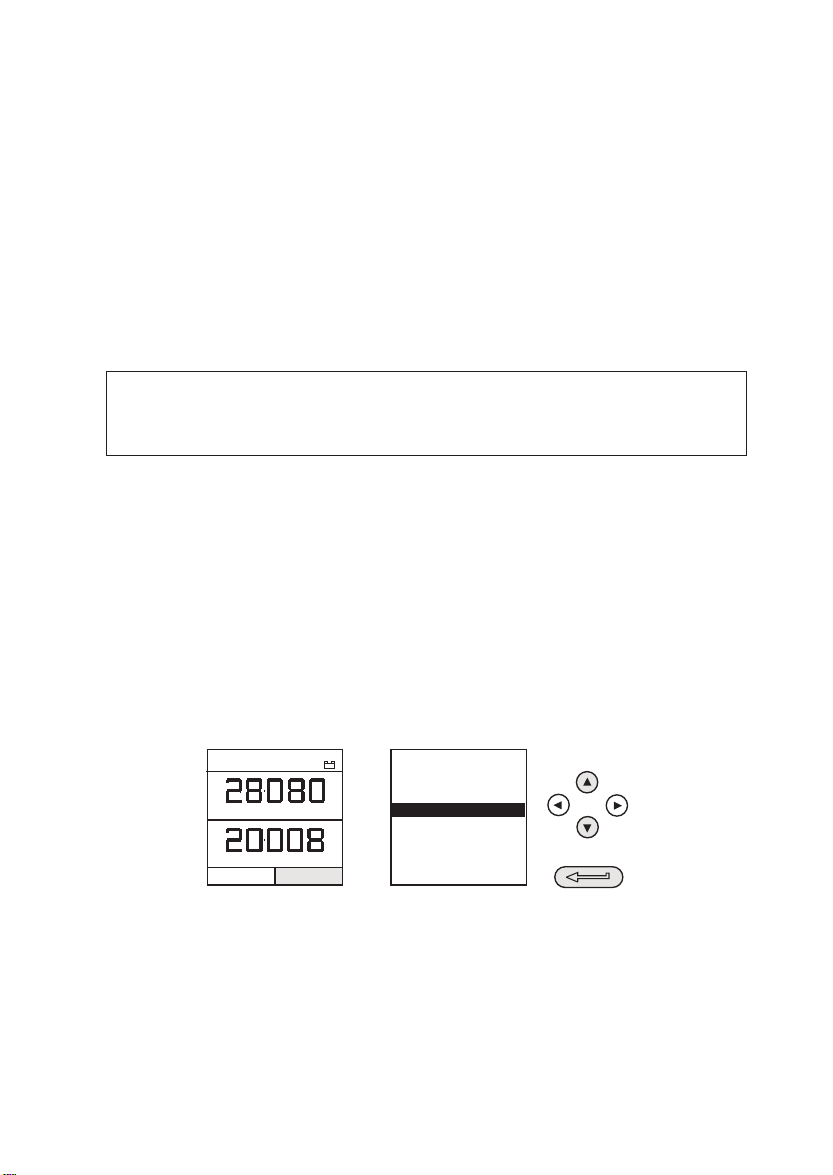

This instrument has a number of operating modes which are described in simplified

form in the following sections. Diagrams accompanying the procedures give typical

selection sequences and shaded controls indicate that this control key should be

pressed in the appropriate sequence. Diagrams should be read from left to right, top to

bottom where appropriate. A shaded display soft box indicates that the function key

immediately below that soft box should be pressed (either F1 for the left hand soft box

or F2 for the right). A typical diagram is shown below (e.g.).

In the above diagram the following key sequence is indicated.

(a) Press the F2 key (the key immediately below the

UNITS

soft box).

(b) Use the Up and Down cursor keys (only) to select the required option.

(If all keys shaded, use all these keys to select or enter data).

(c) Press the ENTER key.

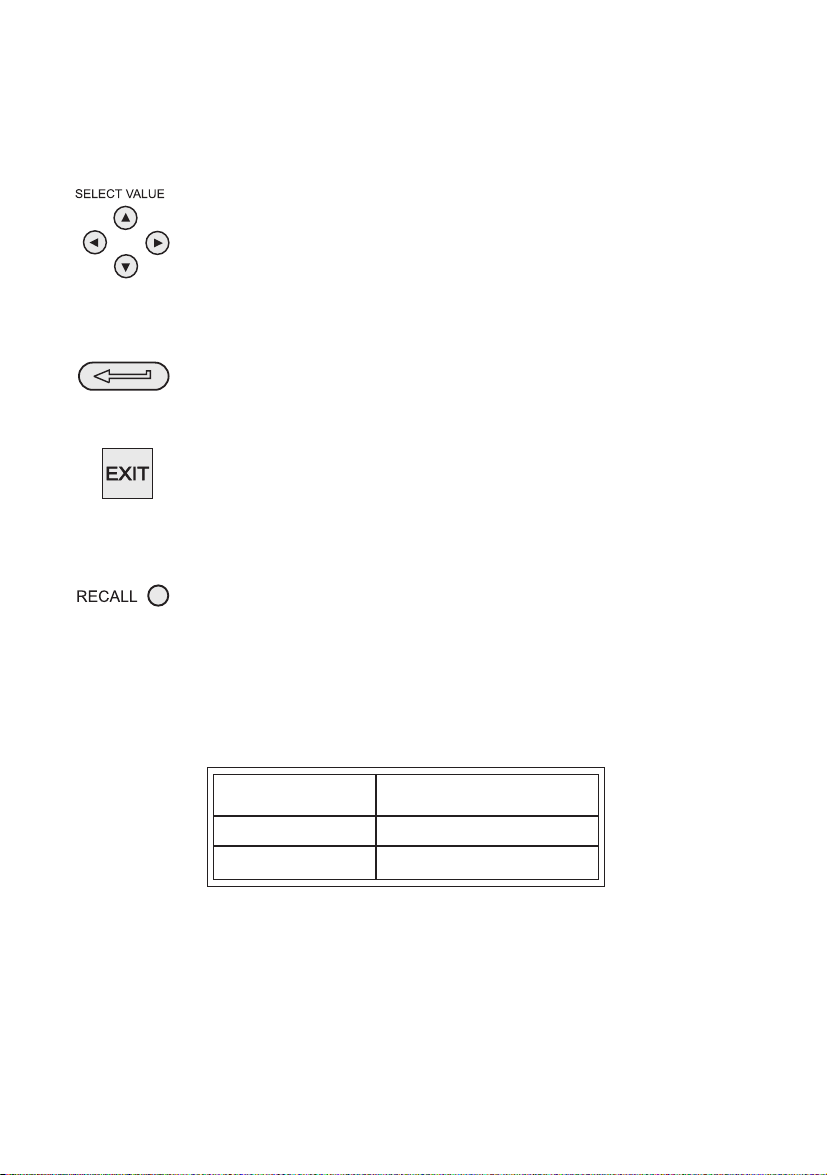

INTRODUCTION Summary of Functions

SELECT UNITS

SELECT UNITS

OF PRESSURE

inHg

bar

hPa

Pa

PRESSURE INT

bar

VOLTAGE

V

CURRENT

UNITS

PRESSURE

TASK: BASIC

+

-

IS1_1_B.p65 23/03/99, 10:371