Contents

1 INTRODUCTION .................................................................................................................... 1

1.1 ABOUT THIS MANUAL –SUPPORTING DOCUMENTS........................................................................................................1

1.2 GLOSSARY..............................................................................................................................................................1

1.3 INITIAL INSPECTION OF MATERIAL LIST .......................................................................................................................1

1.4 SPECIAL TOOLS &HARDWARE ..................................................................................................................................2

1.5 FUNCTIONAL OVERVIEW ...........................................................................................................................................2

1.5.1 Grid Connected Solar plus Storage ........................................................................................ 2

1.5.2 Backup Solar plus Storage ................................................................................................... 3

1.5.3 Backup Solar PV curtailment method: Frequency Shift Power Control (FSPC)............................... 3

1.5.4 Circuit and system sizing for 100 / 125 / 150 Amp electrical panels ............................................. 3

1.5.5 Circuit and system sizing for 200+ Amp electrical panels .......................................................... 3

1.5.6 Over-sized PV systems ....................................................................................................... 3

1.6 INTERNAL COMPONENT OVERVIEW ............................................................................................................................4

1.6.1: Energy management controller (EMC) ................................................................................. 4

2 INSTALLATION PLANNIN ....................................................................................................... 5

2.1 INSTALLATION CLEARANCES BETWEEN THE DURACELL HUB AND THE BATTERY SYSTEM ..............................................5

2.2 INSTALLATION CONDUIT PLAN –POWER AND COMMUNICATION CIRCUITS.........................................................................6

2.3 SLD -AC COUPLED PV SYSTEM WITH BACK-UP POWER OPERATION...........................................................................7

3 INSTALLATION INSTRUCTIONS ................................................................................................ 8

4 ELECTRICAL WIRIN INSTRUCTIONS ......................................................................................... 8

4.1 EMC CABLE CONNECTION .......................................................................................................................................8

4.2 AK1 CABLE CONNECTION.........................................................................................................................................8

4.3 AC POWER CONNECTIONS .......................................................................................................................................8

4.3.1 Phase Orientation in Split Phase 120/240 Systems ................................................................... 9

4.3.2 Main Electrical Panel Connection ......................................................................................... 9

4.3.3 Backup Panel Connection .................................................................................................. 10

4.3.4 ESS: PCS Grid Port Connection ........................................................................................... 10

4.3.5 ESS: PCS Load Port Connection .......................................................................................... 10

4.4 CTCONNECTIONS .................................................................................................................................................11

4.4.1 Main Electrical Panel CT Connections .................................................................................. 11

4.4.2 Solar PV CT Connection ..................................................................................................... 11

4.4.3 PCS CT Connections ......................................................................................................... 11

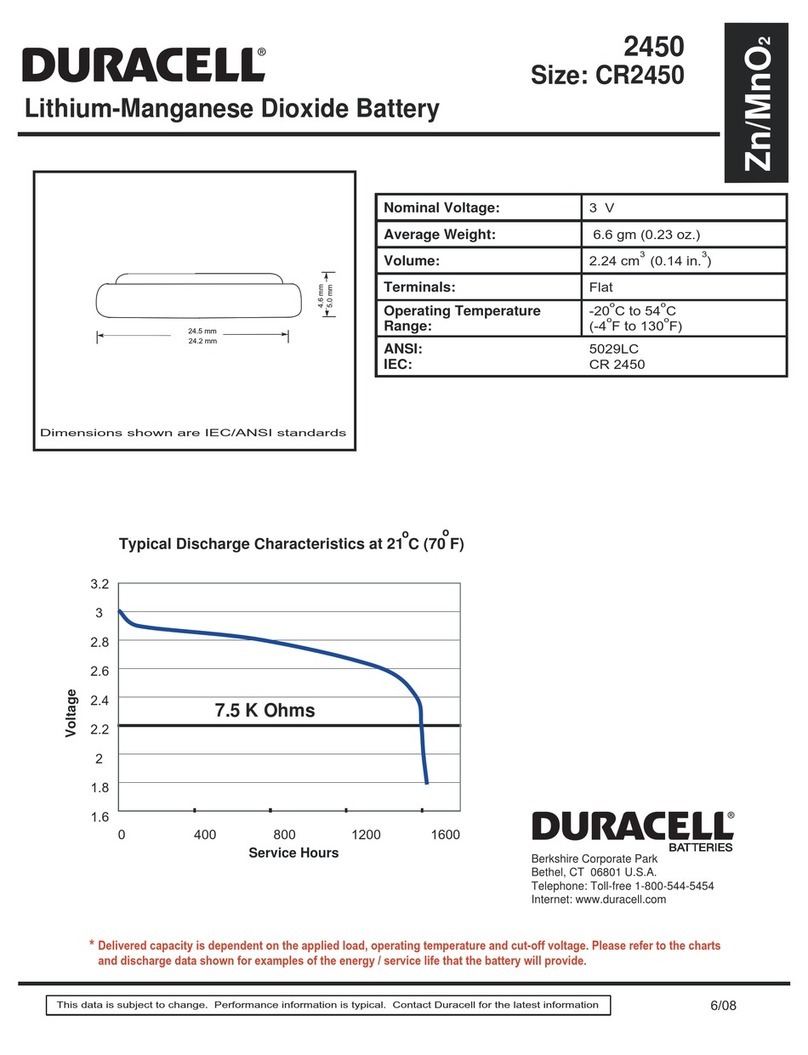

4.5 12V BACKUP BATTERY CONNECTION.......................................................................................................................11

5 OPERATION ........................................................................................................................ 12

5.1 EMC SELECTOR SWITCH ........................................................................................................................................12

5.2 PRE-STARTUP CHECKLIST....................................................................................................................................... 12

5.3 STARTUP ..............................................................................................................................................................12

5.4 POST-STARTUP CHECKLIST .....................................................................................................................................12

5.5 PERMISSION TO OPERATE CHECKLIST....................................................................................................................... 13

6 MAINTENANCE .................................................................................................................... 13

7 TROUBLESHOOTIN ............................................................................................................. 13

8 TECHNICAL DATA ............................................................................................................... 14

8.1 ELECTRICAL SPECIFICATIONS ..................................................................................................................................14

8.2WIRE AND TORQUE RATINGS ...................................................................................................................................14

APPENDIX A: ELECTRICAL BLOCK DIA RAM OF INTERNAL COMPONENTS ............................................ 15

APPENDIX B: MULTI-MODE TRANSFER / BYPASS RELAY OPERATION ................................................... 16

KX:DURACELL HUB BYPASS /TRANSFER RELAY......................................................................................................... 16

K3: PCS TRANSFER RELAY ..........................................................................................................................................16

K1: PCS ISLANDING RELAY .......................................................................................................................................... 17

PCS AND HUB RELAY STATE MAP..................................................................................................................................17

BACKUP SUPPLY INTERRUPTION PERIOD DURING GRID OUTAGE /RETURN TO GRID ..............................................................17

APPENDIX C: INTERNET CONNECTION OPTIONS ...........................................................................18

C.

1HARD-WIRED ETHERNET........................................................................................................................................18