FURTHER CONTROLS EXPLAINED

Overload/ Error Indicator (3)

Lights when over voltage, over current or electrical

overheating (due to exceeding duty cycle) is detected and

protection is activated.

When protection is activated, welding output will be disabled until

the safety system senses the overload has reduced suciently

and indicator lamp goes out. May also trigger if machine

experiences an internal power circuit failure.

Torch System Error Indicator (4)

Lights when issue with torch system or air supply detected

and cutting output is disabled as a result. Flashing light means

that torch shield cap is not installed. Continuous light means

likely damaged or missing torch consumables or insucient air

pressure supply to the torch.

Compressed Air Testing/Setting Switch (6)

When positioned as ‘set’ compressed air control valve is open

continuously. This is useful for testing and setting the air pressure

without having to activate the trigger circuit. ‘Run’ position is

normal operation.

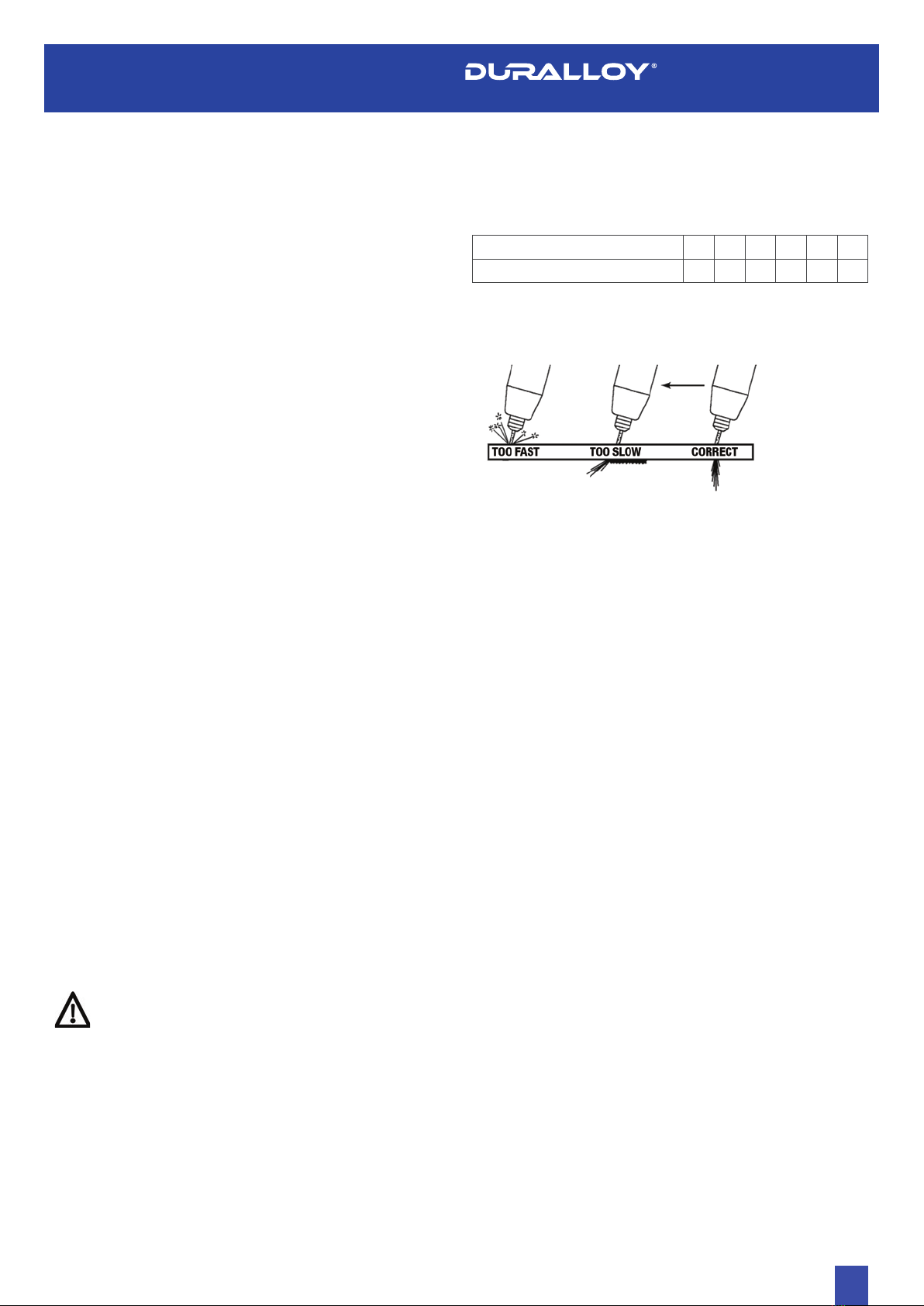

TIPS & TRICKS

Air Regulator Pressure Adjustment

Correct air pressure is critical for plasma cutting. Incorrect air

pressure will cause poor cut quality, lack of cutting power,

damage to the plasma torch and consumables and potentially

damage the power source. Optimum air pressure is between 0.45

and 0.5 MPa (65-75psi). Air pressure should be set with the air

flowing through the torch, as the pressure with the air flowing will

normally be less than static pressure, due to flow losses through

the torch system. To unlock the pressure regulator knob in order

to adjust it, pull the knob upwards. Once the pressure is set

correctly, push the knob down again to lock it into place.

Air Filter/ Water Separator

As with correct air pressure, clean, dry air is also critical for

plasma cutting machine performance and reliability. The

DURALLOY CUT 40PFC MV is supplied with an air filtration/

moisture separator to assist with providing suitable air supply.

The moisture separator is self-draining, the water drain tube exits

out the bottom of the clear condensate bowl. It is normal to see

moisture coming from this tube periodically. If excessive amounts

of water or oil are being produced in the condensate bowl and

drain line, the compressed air supply should be checked for

issues.

www.duralloy.net.au | 1300 369 456

Pilot Arc System

The DURALLOY CUT 40PFC MV use a pilot arc system to

establish the main cutting arc. A pilot arc system is a circuit where

the return is back through the torch head and cable. This means

it can create a small arc with some cutting power without making

any electrical connection with the main machine earth. This is

especially useful for starting cuts on material that does not have a

good initial earth connection, such as paint, rust, scale.

Once the pilot arc is established and power is flowing back

through the main earth, the pilot arc is switched o and the main

arc started. Please note the pilot arc circuit is only designed to

operate for short periods of time as an auxiliary starting system,

so it has a safety protection that only allows the pilot arc to run for

short periods at a time. In addition to this, these models also have

a plot arc controller system if the main arc cuts out and the torch

remains to be triggered, the pilot arc will reignite. This is useful for

cutting discontinuous workpieces like mesh or grids.

It is very important to recognise that plasma torch consumables

wear as part of normal operation and should be replaced in a

timely manner. Operating a torch with worn consumables will

cause poor cutting results and possible damage to the torch

and machine itself. Damage caused by untimely replacement of

consumables will not be covered by warranty.

Use the following guidelines to determine when consumables

should be replaced:

Cutting Tips: The cutting tip has a small calibrated orifice that the

plasma passes through. If the orifice becomes partially blocked,

deformed or enlarged, the cutting tip should be replaced.

Electrodes: The electrode has a small silver ‘hafnium’ insert in the

end of the tip. This is what generates the plasma ions. Once the

hafnium insert is gone or is damaged the tip must be replaced.

Swirl Ring/Retaining Cap: These should be replaced if broken,

chipped, cracked or badly heat damaged.

Tips and electrodes: These should wear reasonably evenly and

it is normal practice to replace them both together. If a new tip

is inserted with a worn electrode the tip will wear much more

quickly than if the electrode was also replaced at that same

time. If tips or electrodes are wearing much faster than the other

component it is likely to be caused by one of the following: poor

operator technique, incorrect air supply or damaged torch head.

It is also very important to only use genuine DURALLOY

consumables and parts for the XT4000 torch. They are

engineered to suit the machine and non-genuine items may

cause lack of performance, short life span, torch and machine

damage and void warranty.

6

CUT 40PFC MV

OWNER’S MANUAL