CONTENT

1 SAFETY....................................................................................................................................................1

1.1 SIGNAL EXPLANATION..........................................................................................................................1

1.2 ARC WELDING DANGERS.................................................................................................................... 1

1.3 THE KNOWLEDGE OF ELECTRIC AND MAGNETIC FIELDS......................................................................5

2 SUMMARY.............................................................................................................................................6

2.1 BRIEF INTRODUCTION........................................................................................................................ 6

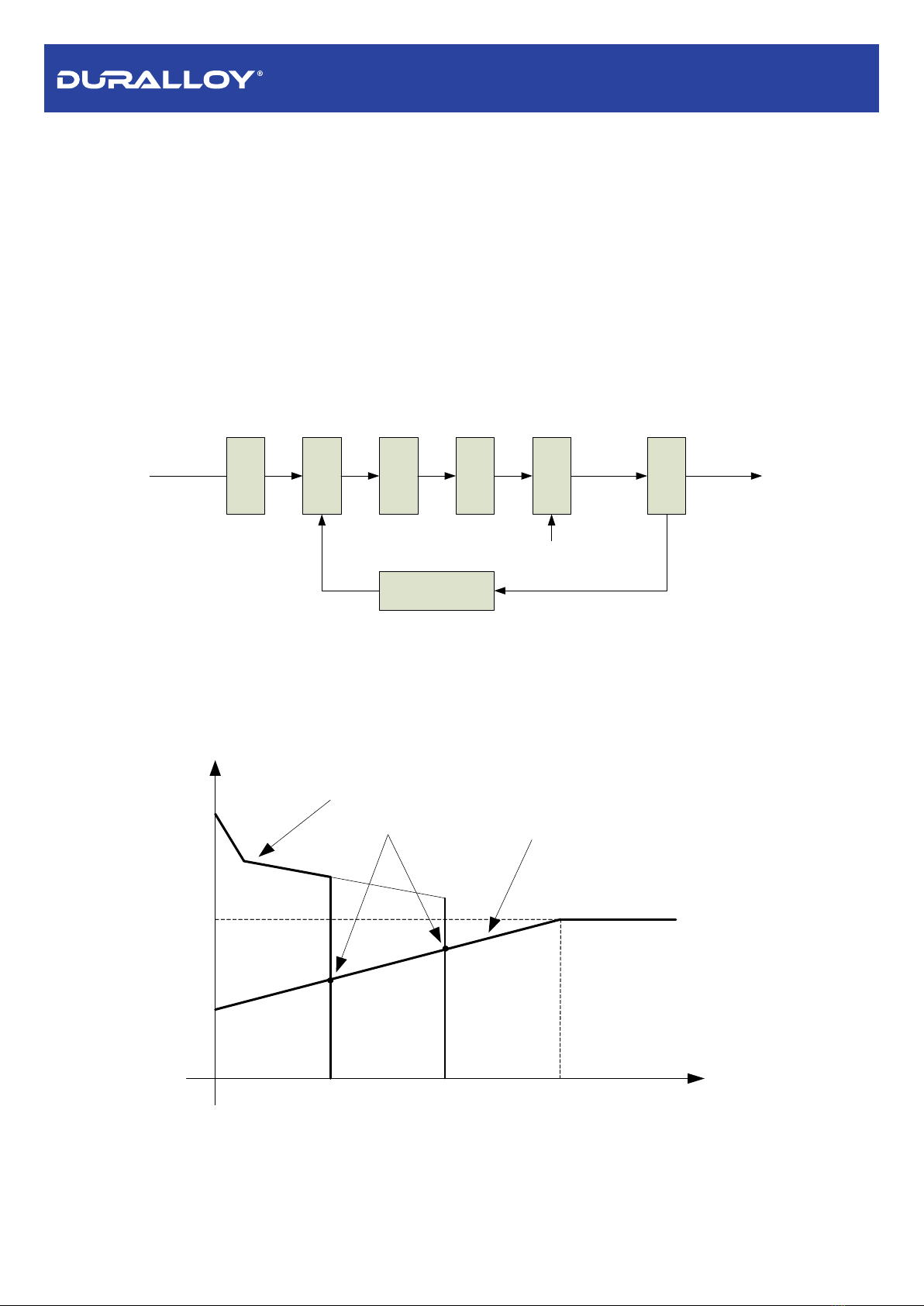

2.2 WORKING PRINCIPLE.........................................................................................................................8

2.3 VOLT-AMPERE CHARACTERISTIC....................................................................................................... 8

3 INSTALLATION AND ADJUSTMENT..................................................................................................9

3.1 PARAMETERS..................................................................................................................................... 9

3.2 DUTY CYCLE & OVER HEAT.............................................................................................................10

3.3 MOVEMENT AND PLACEMENT...........................................................................................................10

3.4 POWER SUPPLY INPUT CONNECTION................................................................................................. 11

3.5 POLARITY CONNECTION(MMA).................................................................................................. 11

3.6 ASSEMBLING THE EQUIPMENT (TIG).................................................................................................12

4 OPERATION......................................................................................................................................... 13

4.1 LAYOUT FOR THE PANEL...................................................................................................................13

4.2 CONTROL PANEL.............................................................................................................................. 14

4.4 ARGON ARC WELDING OPERATION................................................................................................. 18

4.4.1 TIG welding (4T operation)

...................................................................................................

18

4.4.2 TIG welding (2T operation)

.................................................................................................

19

4.5 WELDING PARAMETERS................................................................................................................... 21

4.5.1 Joint forms in TIG/MMA

........................................................................................................

21

4.5.2 The explanation of welding quality

....................................................................................

21

4.5.3 TIG Parameters Matching

....................................................................................................

21

4.6 OPERATION ENVIRONMENT.............................................................................................................24

4.7 OPERATION NOTICES......................................................................................................................24

5 MAINTENANCE & TROUBLESHOOTING........................................................................................25

5.1 MAINTENANCE.................................................................................................................................25

5.2 TROUBLESHOOTING........................................................................................................................26

5.3 ELECTRICAL PRINCIPLE DRAWING.....................................................................................................29

6 EXPLODED VIEW DRAWING............................................................................................................ 30

TIG191P AC/DC OWNER’S MANUAL

www.duralloy.net.au | 1300 369 456