Electrical Connection

The DURALLOY MIG 200 is designed to operate on a 15A 240V

AC power supply. If an extension cord must be used, it should be

a heavy duty version with a minimum cable core size of 2.5mm2.

Operating Environment

Adequate ventilation is required to provide proper cooling.

Ensure that the machine is placed on a stable level surface where

clean cool air can easily flow through the unit. The DURALLOY

MIG 200 has electrical components and control circuit boards

which may be damaged by excessive dust and dirt, so a clean

operating environment is important for reliable product life.

BASIC OPERATION

1. Fitting Wire Spool & Loading Wire Feeder

1.1 Open the wire compartment cover. Unthread the wire spool

retainer. Fit the wire spool to spool holder shaft, ensuring that

the wire exits the spool towards the bottom the spool.

1.2 Set the spool brake tension by adjusting the spool tension

adjustment screw before replacing the wire spool retainer.

The spool brake tension should be set so that the spool can

rotate freely, but does not continue to rotate once the wire

feed stops. This may need to be adjusted as the wire is used

up and the spool weight decreases.

WARNING! Excessive spool brake tension will

cause wire feeding issues and aect welding performance

as well as premature failure/ wear of

wire feed components.

1.3 Feed the wire from the spool through the wire drive inlet

guide into the wire feeder.

1.4 Release the wire feed tension arms by pivoting the wire feed

tension adjustment lever from the vertical to the horizontal

position.

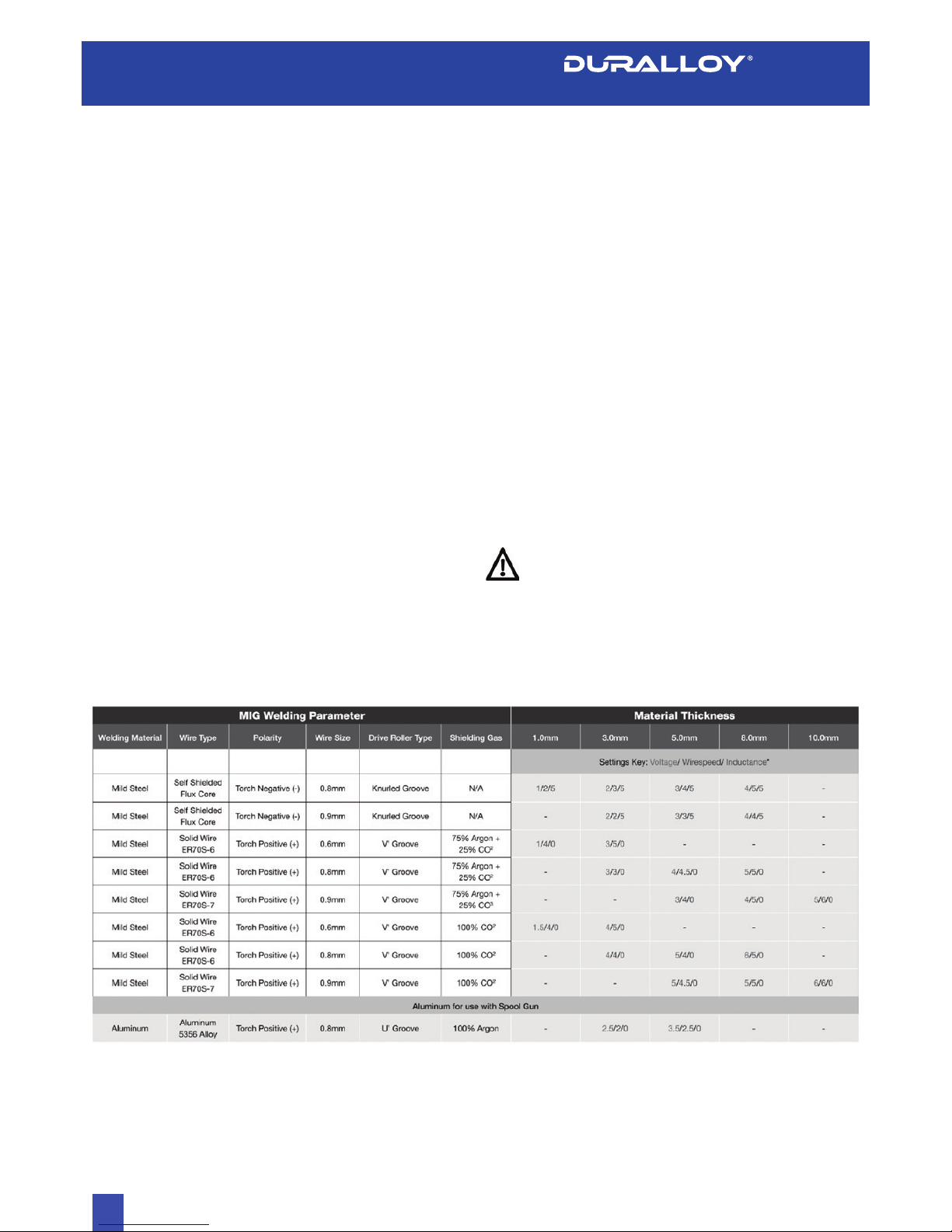

1.5 Check the wire drive roller grooves match the selected MIG

wire type and size. The drive roller will have two dierent

sized grooves; the size of the groove in use is stamped on

the side of the drive roller. For flux cored ‘soft’ wire, such as

that used in gasless MIG welding, the drive roller groove has

a serrated profile (known as knurled). For solid core ‘hard’ MIG

wire, the drive roller groove used has a ‘V’ shaped profile. For

Aluminium solid core ‘soft’ MIG wire, the drive roller required

has a ‘u’ shaped groove. If necessary, remove and change the

drive roller by unthreading the drive roller retainer.

1.6 Once the correct drive rollers are selected and fitted, manually

feed the wire through the wire drive inlet guide through the

www.duralloy.net.au | 1300 369 456

drive roller grooves and into the brass outlet wire guide tube.

Ensuring that the wire is correctly seated in the drive roller

grooves, replace the wire feed tension arms and lock them

into place by rotating the wire feed tension adjustment lever

back to the vertical position.

Adjusting wire feed tension: this is accomplished by winding the

knob on the tension adjustment lever. Clockwise will increase

tension, anti-clockwise will decrease drive tension. Ideal tension

is as little as possible, while maintaining a consistent wire feed

with no drive roller slippage.

Check all other causes of excess wire feeding friction causing

slippage first, such as; incorrect/ worn drive roller, worn/ damaged

torch consumables, blocked/damaged torch wire guide liner,

before increasing wire feed tension. There is a number scale on

the tension adjustment lever to indicate the adjustment position.

The higher the number indicated, the higher the tension that is

set.

WARNING! Before changing the feed roller or wire

spool, ensure that the mains power is switched o.

WARNING! The use of excessive feed tension will cause

rapid and premature wear of the drive roller, the support

bearing and the drive motor/ gearbox.

1.7 Connect the MIG Torch Euro Connector to the MIG torch Euro

connection socket (12) on the front of the machine. Secure by

firmly hand tightening the threaded collar on the MIG Torch

connector clockwise.

1.8 Check that the correct matching MIG wire, drive rollers and

MIG torch tip are fitted.

1.9 Connect the machine to suitable mains power using the

mains input power lead. Switch the mains power switch to ‘on’

to power up the machine. Adjust the wire feed speed control

(1) to maximum.

1.10 You are now ready to feed the wire through the torch. With

the wire feeder cover open, pull the trigger of the MIG torch

to check that the wire is feeding smoothly through the feeder

and into the torch.

1.11 With the tip removed from the torch and the torch laid out as

straight as possible, activate the torch trigger until the wire

feeds out through the end of the MIG torch. Replace the tip on

the MIG torch and trim o any excess wire.

QUICK START GUIDE - WELDER INSTALLATION

7

MIG 200

OWNER’S MANUAL