Select Operation Mode:

The operating modes and ranges are controlled by a shorting

jumper on jumper block J2. This jumper block is shown in Fig. 5.

Figure 5, Mode Programming Jumpers

Jumper block J2 primary function is to control the operating mode.

There are two operating modes, Normal and Velocity. The Normal

operating mode provides for zero pressure to correspond to 0 V or

4 mA output. This mode is selected by placing the supplied short-

ing jumper for J2 on the pins next to the letter “N”. The jumper for

J2 is factory installed to the Normal Mode. If no jumper is installed

on J2, the device defaults to the “N” selection.

The Velocity mode provides the ability for the unit in conjunction

with a Pitot tube or similar flow sensor with known K factor to give

a direct output in air velocity. This mode is selected by placing the

supplied shorting jumper for J2 on the pins next to the letter “V”.

If the optional display is present, this mode prompts the display to

read in air velocity. The current or voltage output is modified such

that full scale output is 4004* K* √(ΔP) feet per minute or its met-

ric equivalent in meters per second depending upon which units

are selected. The factory programming for the K factor is 1.00 but

may be adjusted (see Adjust K Factor). The velocity displayed for

the various models can be found in Table 1.

Velocity Displayed

Model English Metric

MS-X3X K* 12.66 x 1000 fpm K* 57.7 m/s

MS-X4X K* 15.51 x 1000 fpm K* 70.7 m/s

MS-X5X K* 20.02 x 1000 fpm K* 91.2 m/s

Table 1

SETUP

Set Measurement Units:

MagnesenseTM transmitters can be easily set to operate in either

English or metric units.

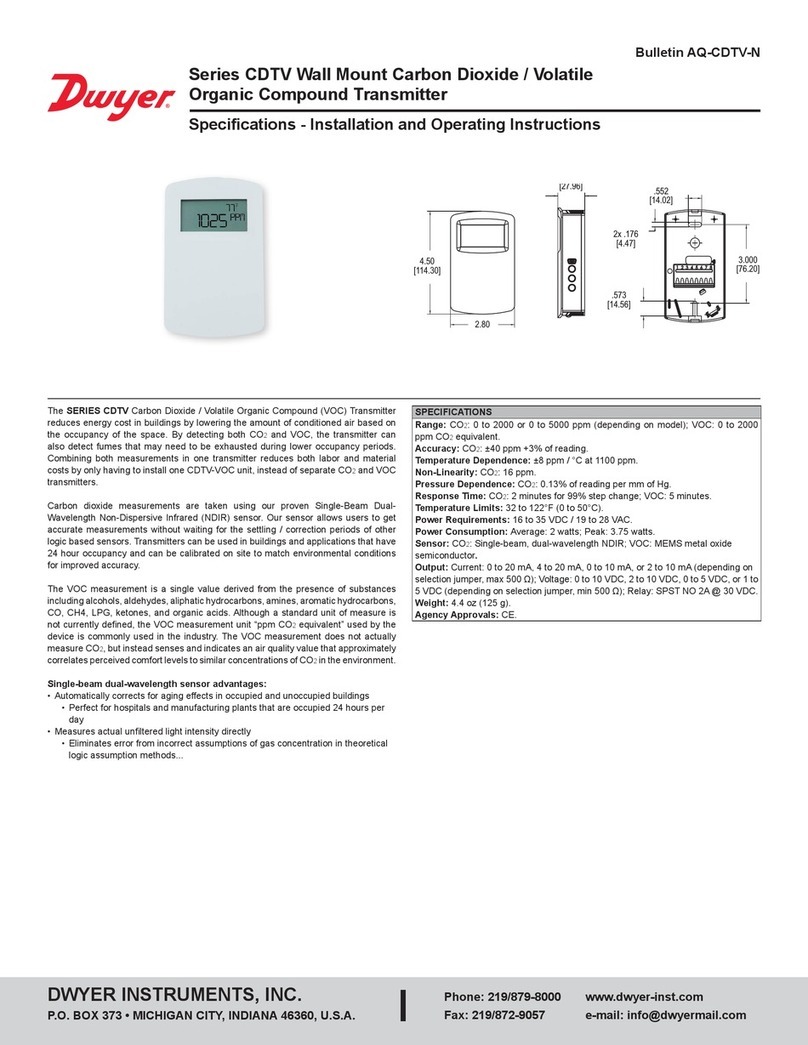

The programming jumper is CONN3. A representation of this

jumper is shown in Fig. 6. English units are selected by placing the

provided shorting jumper on the lower two pins of the block. Metric

units are selected by placing the provided shorting jumper on the

upper two pins of the block. If no jumper is present English units

are selected by default.

Figure 6, Measurement Units Programming Jumper

In addition to the obvious change in the scale of the LCD display,

the full scale range and corresponding analog outputs are also

affected by the measurement units selection. The analog output

goes to full scale output (10 volts or 20 mA depending on model)

of the selected range and units. See Table 2.

FULL SCALE ANALOG OUTPUT

Model English Metric

MS-X31 10 in w.c. 2 kPa

MS-X41 15 in w.c. 3 kPa

MS-X51 25 in w.c. 5 kPa

Table 2

Install Optional Display:

The A-435 LCD conversion kit allows any non display model to

have the LCD added at a later time. The kit contains an LCD dis-

play and replacement cover with LCD window. The optional dis-

play may be set to read pressure either in Inches Water Column or

Kilopascal. The optional display can be also set to display air

velocity in X1000 feet per minute or meters per second when used

with a Pitot tube or similar flow sensor with a known K factor.

The optional display for the Magnesense®is mounted on the main

board by connectors CONN4 and CONN5. The display is proper-

ly mounted when CONN4 and CONN5 on the display are con-

nected to the corresponding CONN4 and CONN5 on the main

board. See Fig. 4. Installing the display upside down causes no

harm the display or the main board. The display just simply reads

upside down.

Label (Included with display):

The optional LCD display does not contain engineering unit indica-

tion. So that the display may be appropriately marked, four adhe-

sive labels have been provided with the units. The unit labels are

INWC, kPa, X1000 fpm, and M/S. Attach the appropriate provid-

ed units label above the display window on the cover of the device

to indicate to which units the display has been set.

Adjust K Factor:

If the optional display is present, the K factor used in velocity mea-

surements may be adjusted. This is done by activating the K fac-

tor adjustment function of the unit. To activate the K factor adjust-

ment function, take the shorting jumper from programming block

J2 and place it on the upper two terminals next to the letter “K”.

See Fig. 5. The display will now show the programmed Pitot tube

K factor. The K factor can be adjusted up and down by using the

up and down buttons as up and down buttons. Once the desired

K factor has been set, replace the shorting jumper on J2 to its

velocity position (“V”). The shorting jumper must not be left in the

“K” position for proper operation of the unit. The factory setting for

the K factor is 1.0 and it is adjustable from 0.5 to 3.

One button pressure calibration – Leaving the hose barbs vent-

ed, press and hold the “Zero/Up” switch for about 4-5 seconds.

The zero point should now be set and if the display is present, the

display will read zero. Span is also simultaneously adjusted at the

time the zero is set. No further calibration is required. It does not

matter if in metric or English unit made when performing this “one

button” calibration of both zero & span.

Bulletin A-26P

Page 3

English

CONN3

Metric

A-26P 1/9/07 2:33 PM Page 3