04 05

W W W . D Y E P A I N T B A L L . C O M W W W . D Y E P A I N T B A L L . C O M

QUICK START UP GUIDE

Before playing with your new RIZE ™ paintball marker there are a few

important steps to take.

STEP 1. BATTERY INSTALLATION

A . Remove three right hand sid e grip p anel screws with a 3/ 32” allen key.

B. Open grip panel and install 9V battery into the connector inside the frame. Start

by inserting the top of the battery into the recess and aligning the battery terminals

with the contacts on the board, then pushing the bottom of the battery fully into

place. Ensure that the battery removal ribbon leaves a small tail accessible from

under battery when installed to aid for easy battery removal. Note the markings

above the battery housing which indicate which of the board contacts are positive

and negative and install the battery accordingly.

C. Close g rip p anel and tig hten the three screws back. W hile closing the p anel

ob serve that no wires g et caug ht b etween the frame and the g rip p anel.

STEP 2. BARREL INSTALLATION

A . Screw on the b arrel to the front of the RIZE ™. Make sure it thread s all the

way in and is secure.

B. Attach the b arrel p lug so that it covers the tip o f the b arrel and secure

the g un.

STEP 4 . ATTACHING GAS SOURCE

Screw on a preset air system into the airp ort located on the b ottom of the grip frame.

Be sure the air system is screwed in all the way into the A irp ort. If there is a leak

from the airport when screwing in the air system, replace the o- ring on the p reset reg ulator.

STEP 5. TURNING ON THE RAIL™ AND CHECKING THE VELOCITY

A . Make sure yo u and everyb ody around you is wearing A STM / CE ap p roved

paintb all masks.

B. Press and hold the top b utton located b ehind the grip frame until the RA IL™

turns on. WARNING, THE RAIL™ IS LIVE. MAKE SURE BARREL PLUG IS IN PLACE

AND DO NOT POINT THE RAIL™ AT ANYTHING YOU DON’T INTEND TO SHOOT.

C. F ill up the loader with .68 calib er paintb alls.

D. Shoot the RA IL™ over a chronograp h to check the velocity. If ad justment is

need ed , adjust the velocity b y turning the Hyper3™ velocity ad justment screw with

a 3/ 16” allen key. In ( clockwise) will red uce the velo city and out ( co unter clockwise)

will increase the velo city. A fter each ad justment it takes a few shots befo re the

change can b e seen on the chronog rap h. Never adjust the RA IL™ to shoo t faster

than 30 0 fps or what the field rules / local laws p ermit.

Q UIC K REF ERENC E

USI NG YO UR MAR KER

Q UIC K REF ERENC E

USI NG YO UR MAR KER

STEP 3. LOADER INSTALLATION

When screwing the air system into the airport, always check that the threads on

the air system and the airport are clean and not worn out. If you think the thread s

are not in g ood condition, contact DY E Precision o r a p rofessional store b efore

screwing in the air system.

The RIZE ™ airp o rt will work with bo th 30 0 0 psi, 450 0 p si air systems and CO2

tanks fitted with an anti - sip hon.

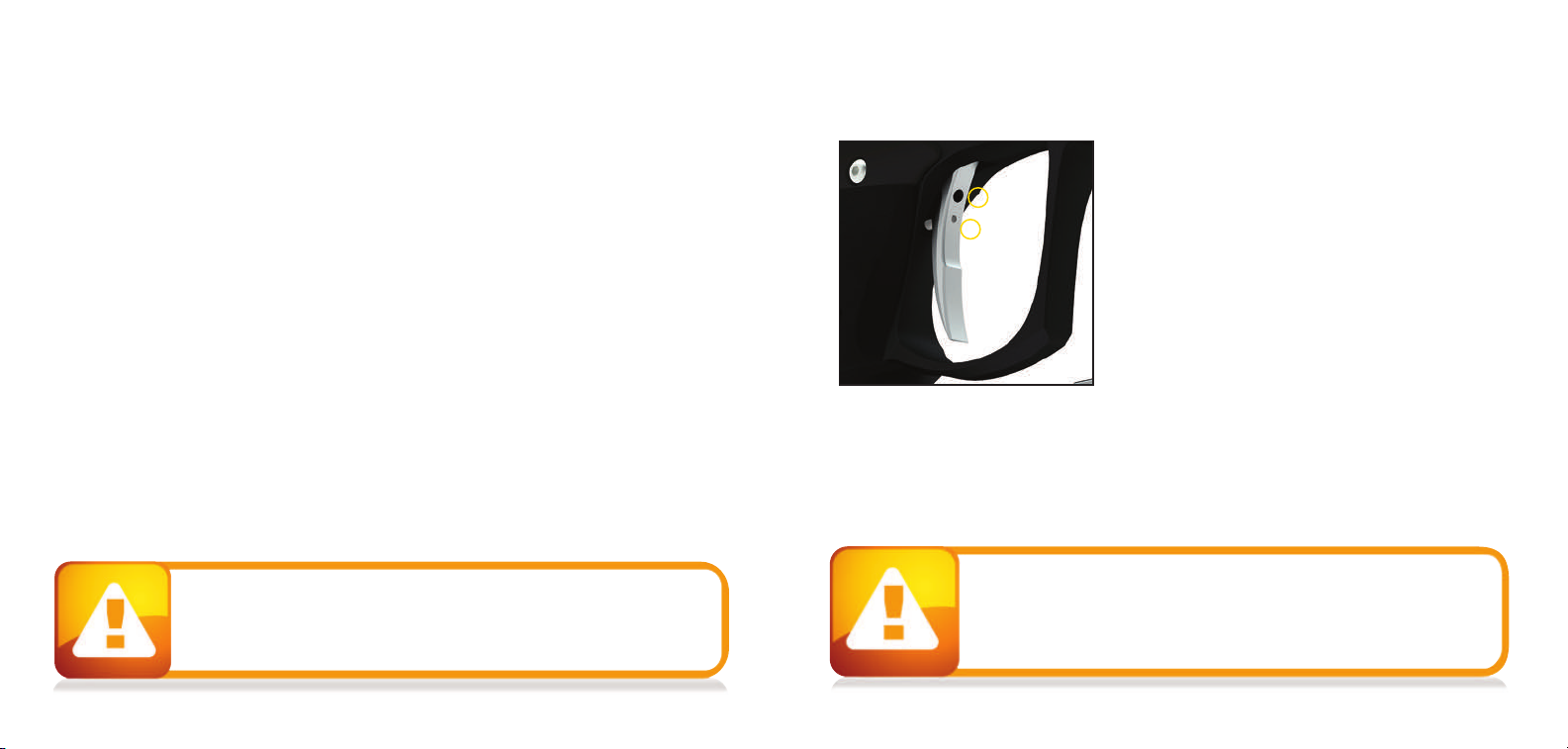

With the clamp lever lifted away from the feed neck press your hopper into the feed

neck collar. Then lower the lever down to secure the loader. If the collar’s grip needs

to be adjusted turn the upper screw with a 3/32” hex tool. If the grip is too tight turn

the screw counter- clockwise. If the grip is not tight enough turn the screw clockwise. For

best results use a force feeding motorized loader, preferably a DYE Rotor Loader.