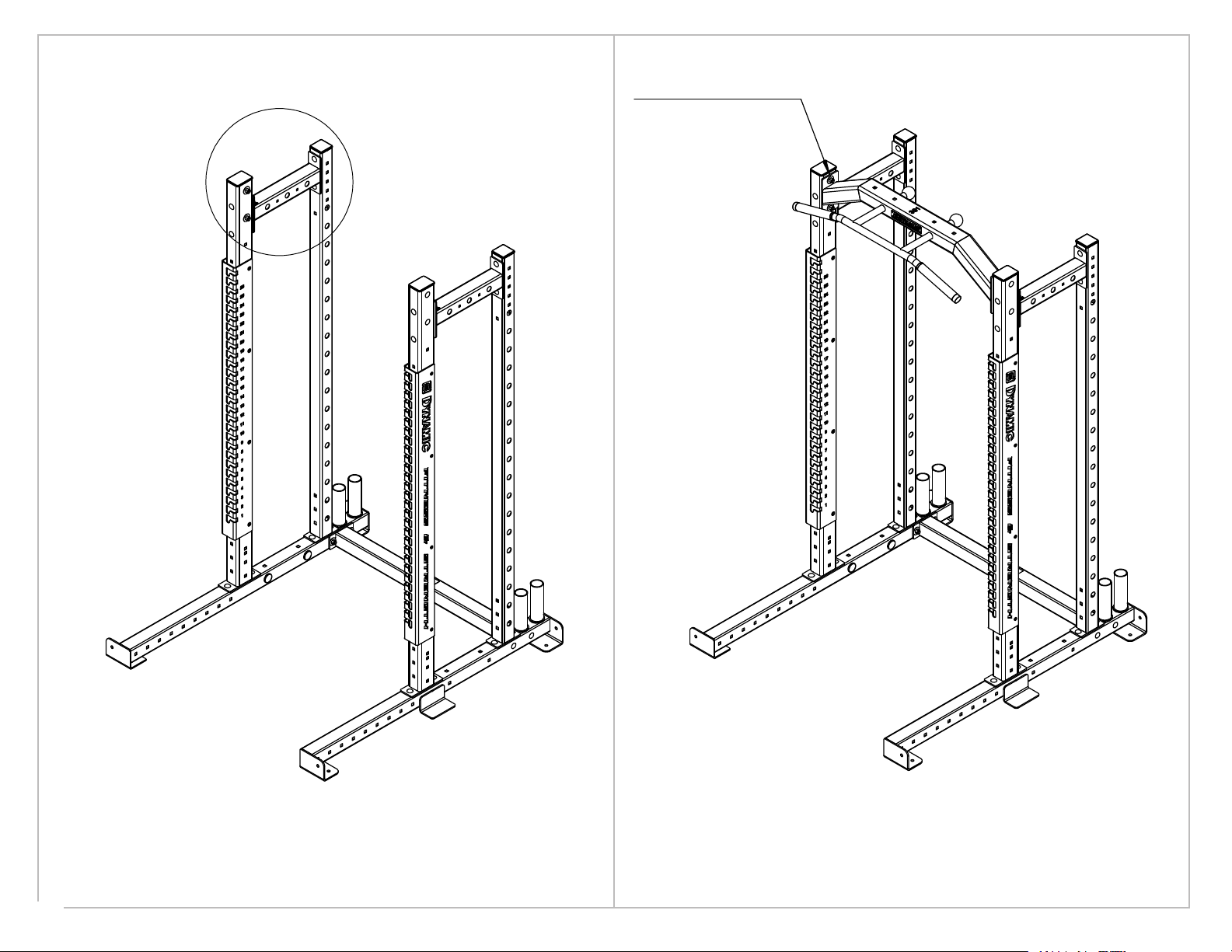

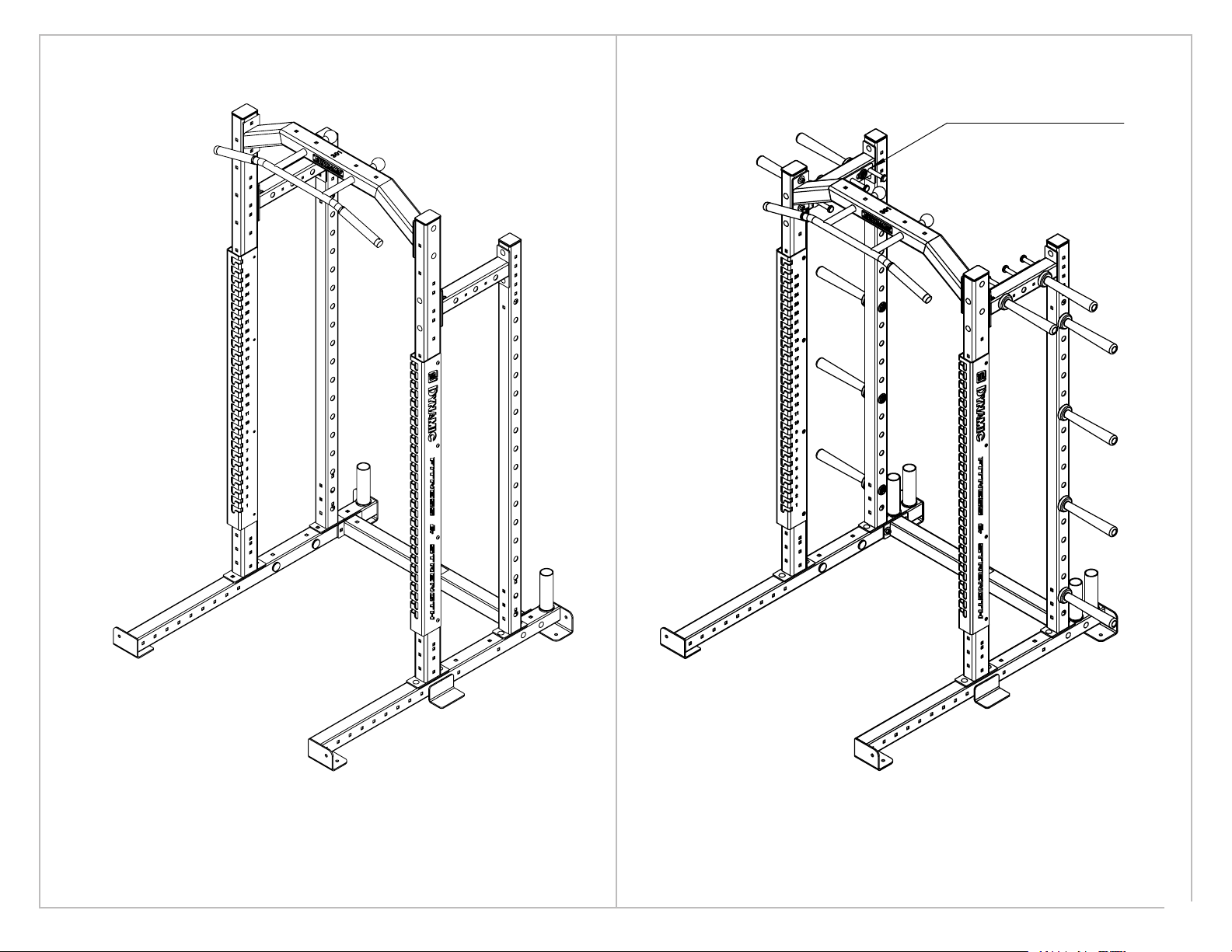

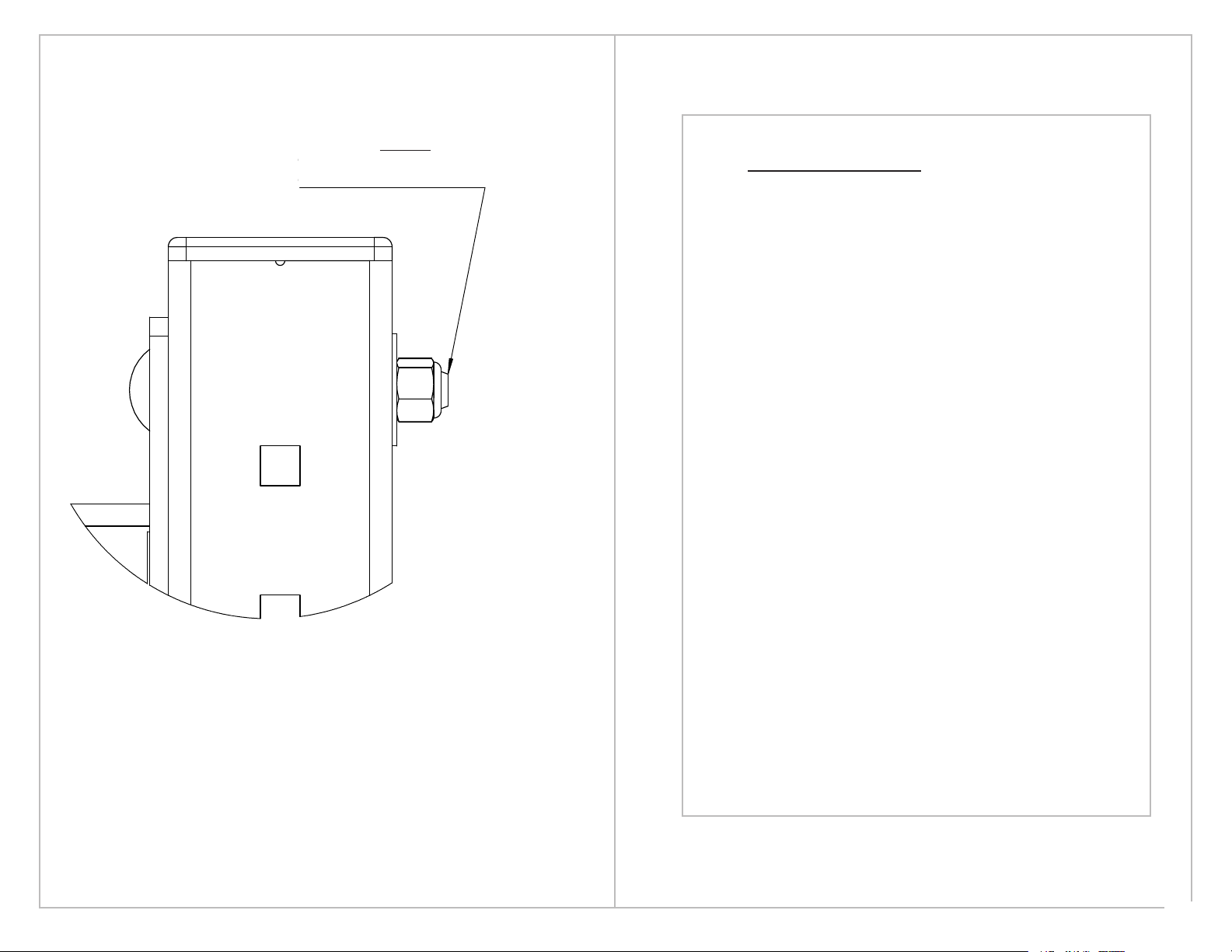

All parts have a part number.

Position the part number to be

covered by its mating component

or up as shown in this view.

74.57

63.48

SCALE 1 : 10

A

DETAIL

The mounting access for bar

catch and safety must be to inside

of rack as shown.

Note: Titan G2 Series will not have an

upright wrap as shown

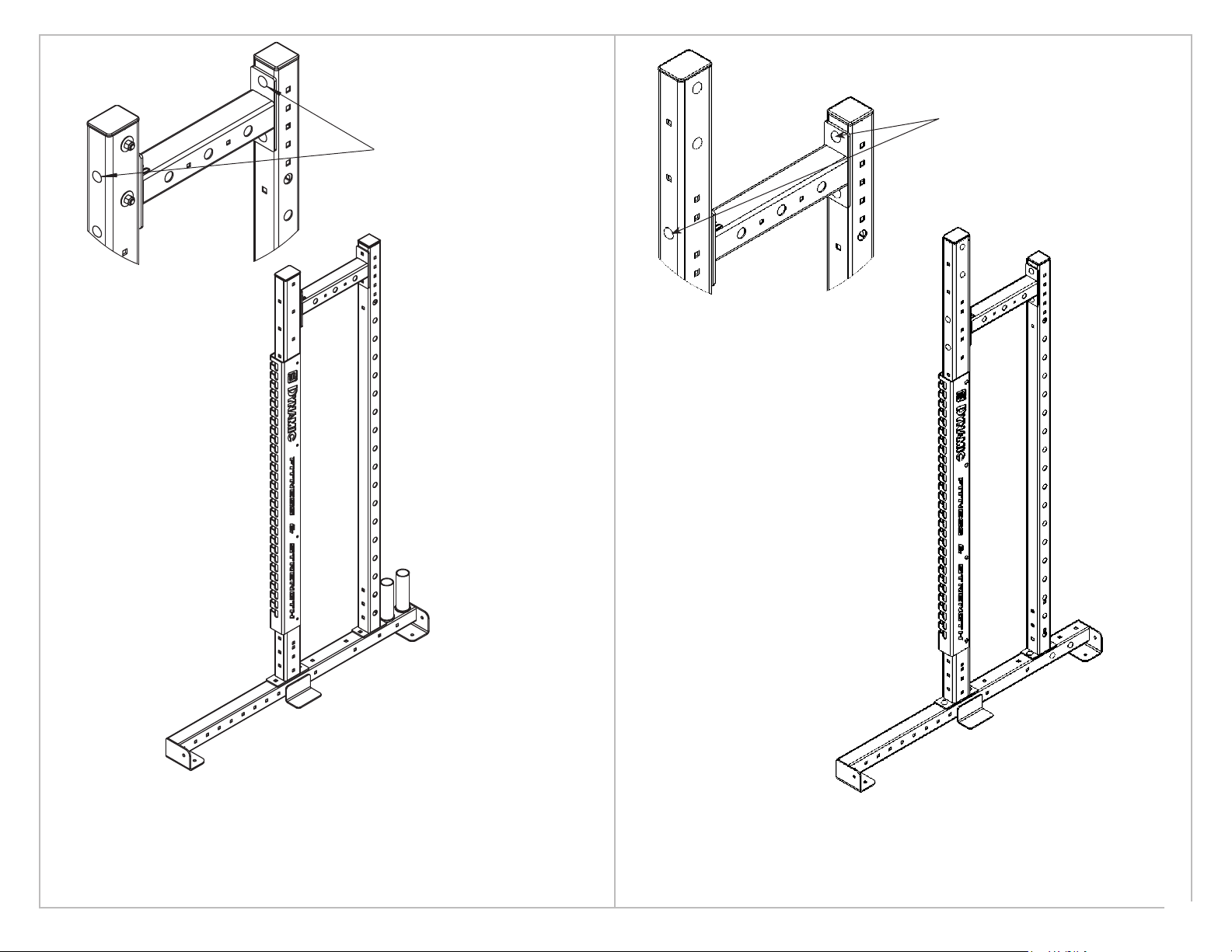

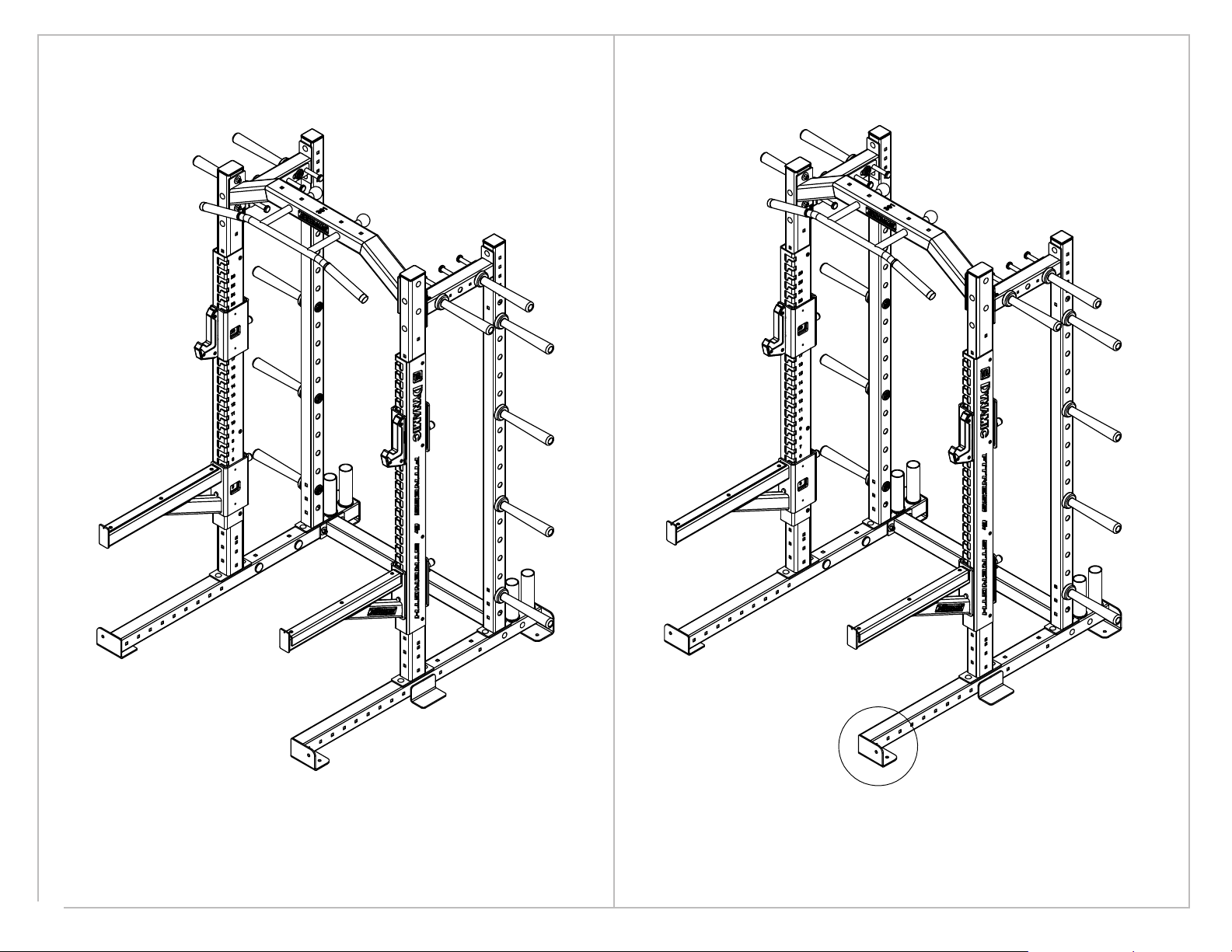

Step one

Attach bar holders to ends of each base as shown.

Depending on the build of your rack the bar holder

number may vary. (Max two per side)

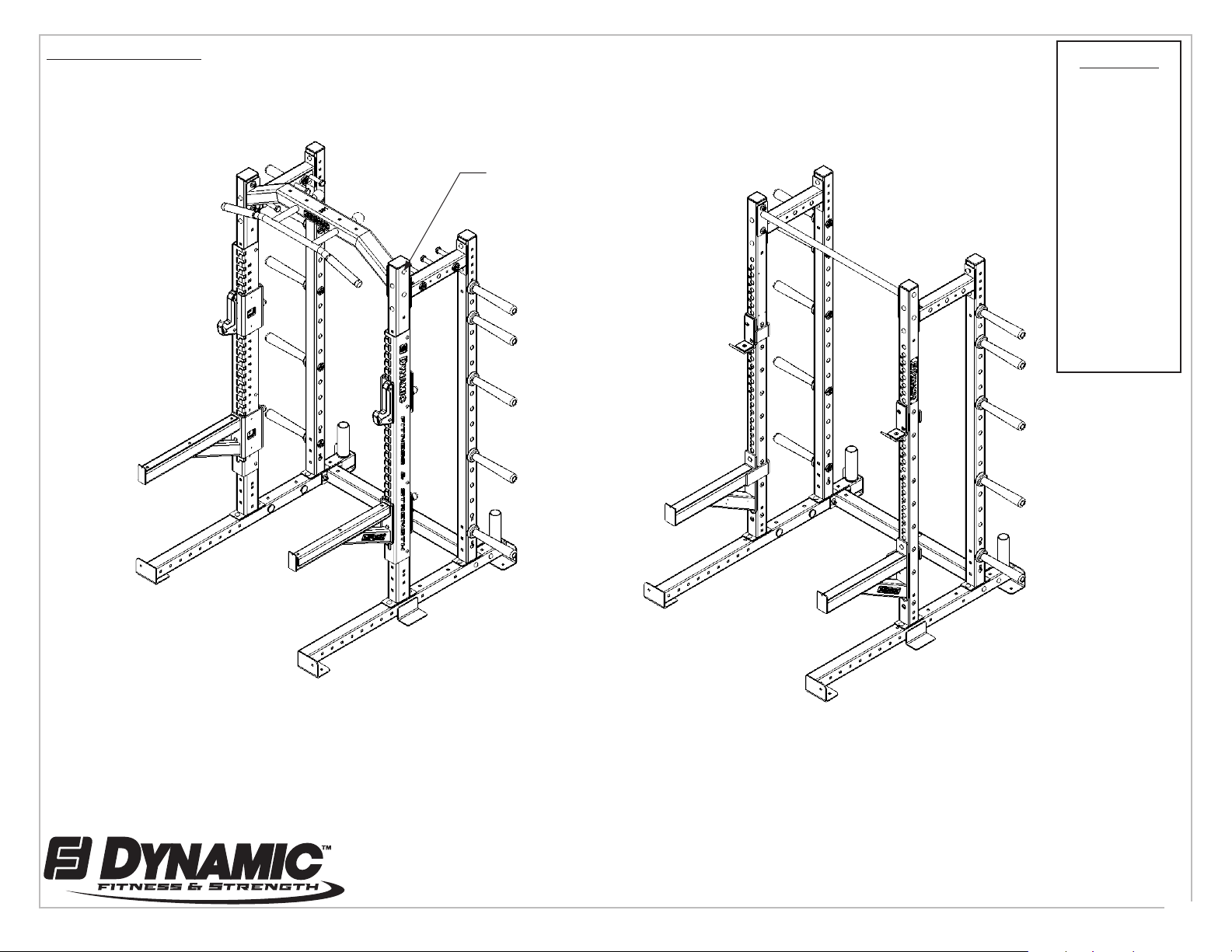

Before Assembling this rack:

Consider how much space will be

required around the unit to access weights

and not interfere with other equipment.

Step Two

Attach storage post and front upright to right

base as shown. Repeat for left side.

Note: The base mounting flanges must face outward

A

All parts have a part number.

Position the part number to be

covered by its mating component

or up as shown in this view.

74.57

63.48

SCALE 1 : 10

A

DETAIL

The mounting access for bar

catch and safety must be to inside

of rack as shown.

Note: Titan G2 Series will not have an

upright wrap as shown

Step one

Attach bar holders to ends of each base as shown.

Depending on the build of your rack the bar holder

number may vary. (Max two per side)

Before Assembling this rack:

Consider how much space will be

required around the unit to access weights

and not interfere with other equipment.

Step Two

Attach storage post and front upright to right

base as shown. Repeat for left side.

Note: The base mounting flanges must face outward

A

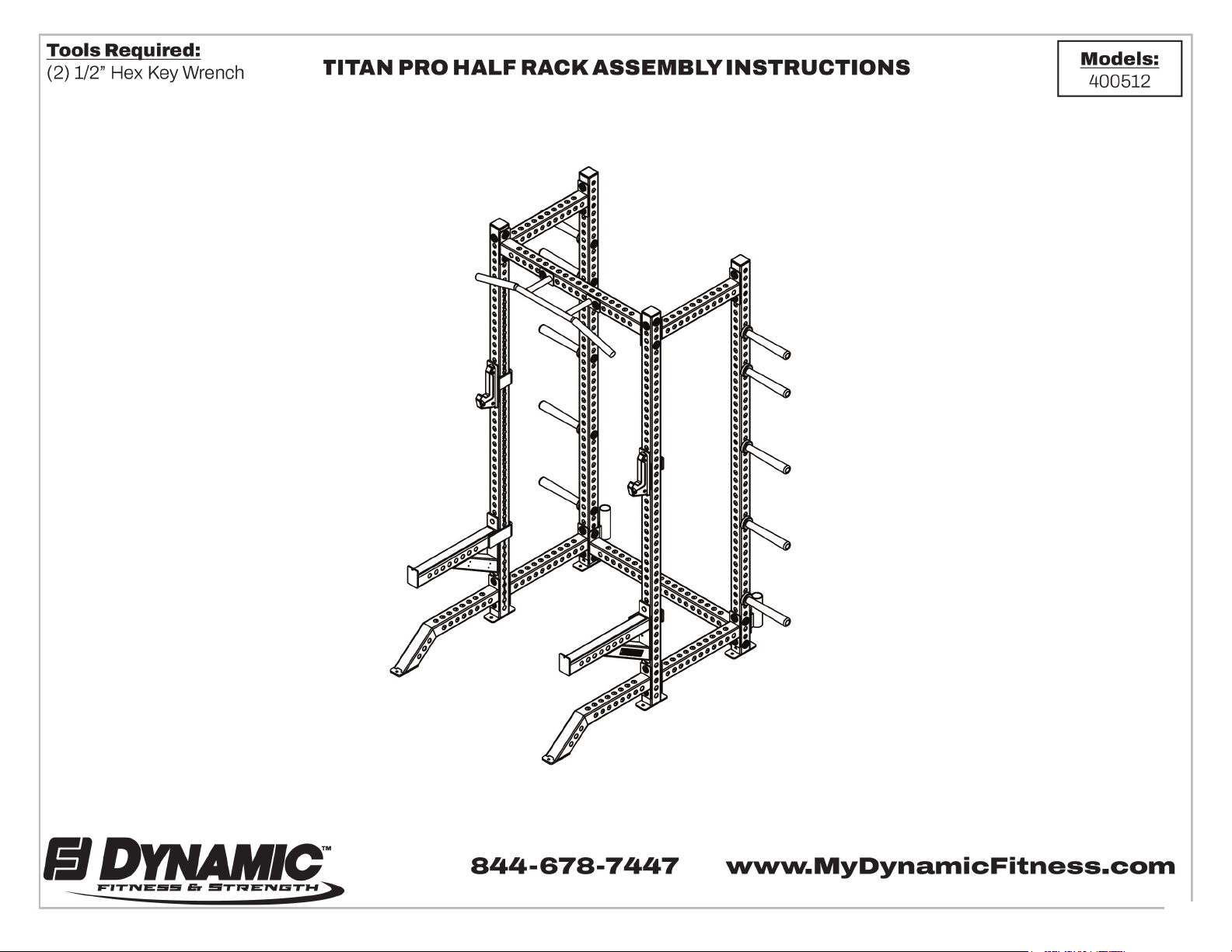

All parts have a part number.

Position the part number

to be covered by its mating

component or up as shown

in this view.

Before assembling this rack:

Consider how much space will be

required around the unit to access weights

and not interfere with other equipment.

The mounting access for bar

catch and safety must be to inside

of rack as shown.

Note: Titan G2 Series will not have an

upright wrap as shown

Step 2

Attach storage post and front upright to right

base as shown. Repeat for left side.

Note: The base mounting anges must face outward

Step 1

Attach bar holders to ends of each base as shown.

Depending on the build of your rack the bar holder

number may vary. (Max two per side)

6