e-motion add-e NEXT User manual

Page 1

add-eNEXT User Manual

EN

Vers. 3.6

e-motion your bike

with add-e

Page 2

Table of ConTenTs: User ManUal

Table of conTenTs: User ManUal p. 2

foreword & iMporTanT inforMaTion p. 3

legal inforMaTion p. 4

safeTy insTrUcTions p. 5

warranTy/disclaiMer p. 6

explanaTion of syMbols p. 7

scope of delivery p. 8

add-enexTinsTallaTion ManUal p. 9

Table of contents: Installation Manual p. 10

Section 1: Determining which variant is right for you p. 11

Section 2: Assembling the kit p. 14

Section 3: Drive unit & mechanical setting p. 25

Section 4: Special notes to the installation process p. 31

add-enexToperaTing ManUal p. 33

Table of contents: Operating Manual p. 34

1. add-e NEXT drive unit p. 36

2. add-e NEXT battery p. 41

3. add-e NEXT chargers & docking station p. 50

4. add-e NEXT sensors p. 53

5. add-e NEXT remote control p. 58

6. add-e NEXT sport mapping p. 62

7. add-e NEXT smartphone app p. 63

8. add-e NEXT software update p. 64

9. Tipps & tricks for troubleshooting p. 79

Page 3

foreword & iMporTanT inforMaTion

Thank you for purchasing your add-e NEXT retrofit kit. This manual contains instal-

lation information.

Before you start, it is important that you familiarise yourself with the various instal-

lation variants.

This manual should be kept in a safe place by the customer and given to the new

owner if the conversion kit is eventually passed on.

Our add-e NEXT auxiliary drive unit is designed to be easily retrofitted to almost

any bike. You do not need any particular prior knowledge for this. Nevertheless,

we do recommend that you only carry out the initial installation yourself if you

have already had some experience doing manual work on a bike. If you encounter

difficulties or deviations from this user manual, our partners are at your disposal to

help you. Use the store locator on our website at www.add-e.at/haendlersuche. You

can also find more information, pictures and videos through our homepage at

www.add-e.at.

All directions given in this manual refer to the normal direction of travel. The chain

ring is on the right-hand side in the direction of travel and the saddle is located

above the bottom bracket.

The add-e NEXT retrofit kit can be used on a wide range of bike types (MTB, racing

bike, trekking bike, city bike, etc.). However, we cannot rule out the possibility that

highly different frame shapes and/or additional equipment may make it impossib-

le to install the add-e NEXT retrofit kit. In particular, pressed-in bottom brackets

(Pressfit) and full-suspension bikes (Fullys) may make it impossible to use the instal-

lation kit. Further information on this subject can be found on our website at

www.add-e.at/faq.

In some cases, you may need special tools to work to a professional standard.

These make the work a lot easier, do not cost much and can be ordered from our

online shop at www.add-e.at/shop.

Although the graphics and text in this user manual have been produced with the

greatest care, we cannot accept liability for any errors, inconsistencies and the

consequences thereof.

We update this manual continuously. You can download the latest version from our

website at www.add-e.at/montage.

Page 4

legal inforMaTion

According to pedelec standard EN 15194/2017, the max. assistance speed is 25

km/h with a nominal continuous power of 250W. The add-e NEXT Sport is equip-

ped with mapping 2. This means that it has a max. assistance speed of 25 km/h

and a max. power of 600W. This corresponds to the above standard, because the

600W indicates the peak power.

The add-e NEXT Sport Edition allows travel at an average higher speed (max. up to

45 km/h). In order to use the add-e NEXT Sport in the European Union in com-

pliance with the law, it is factory delivered with mapping 2 (25 km/h, 600W peak

power). These parameters can only be modified if a dongle is fitted to the drive

unit. If you disconnect this dongle after modification, no risk of tampering exists,

even if there is an accident, and the set maximum speed (25 km/h) also applies to

add-e NEXT Sport as the maximum design speed in accordance with the registrati-

on-free pedelec standard EN 15194/2017.

The parameters can be changed by the user at own request with the dongle, both

for the motor power and for the maximum speed, but this no longer complies with

the EN 15194/2017 standard.

If the configuration chosen does not comply with the applicable legal regulations

in the country of use, the add-e NEXT is only allowed to be used with a special

license and/or for racing purposes and/or on private property.

Different countries have different regulations for the use of e-drive units on bikes.

Generally, the overall bike is used for assessment. Whether other regulations also

apply when an e-motor is retrofitted, e.g. for lighting, depends on the country in

question and compliance is the responsibility of the user.

The user is responsible to inform himself about the legal regulations that apply in each

case and for complying with them accordingly. Off-road restrictions regarding electrical

power, maximum speed and pedal assistance also need to be complied with.

Page 5

safeTy insTrUCTions

Before putting the unit into operation, the user should read through the complete

manual, since it provides important information about correct operation and mini-

mises the risks. If damage does occur due to failure to observe these instructions,

the manufacturer accepts no liability, and the guarantee/warranty is void.

Proper functioning of the bike and the add-e NEXT retrofit kit is essential and

reduces the risk of injury or accidents with potentially fatal consequences for the

cyclist and others.

For your own safety, please ensure that you wear the proper protective clothing

and a helmet. First, practice with care on a suitable track to get used to the new

handling behaviour with the add-e.

Depending on the frequency of use, you should inspect and may need to clean the

add-e NEXT retrofit kit and its parts on a regular basis.

Before each journey, check the bike for the correct motor setting, tyre pressure/

condition and the secure fit of the add-e, and adjust if necessary!

Ensure that no moving parts, e.g. cables of the drive unit or other objects, can get

caught between the drive unit and the tyre, otherwise unexpected problems may

ensue, including the rear wheel jamming.

The motor swing arm must always remain mobile, do not let objects get wedged

in it. Otherwise, this may result in the motor no longer disengaging from the rear

wheel and/or unwanted damage.

The motor of the drive unit can get very hot while travelling. Avoid touching it

directly after use, as this could lead to burns and injuries.

Page 6

In the area covered by EU law, the vendor is liable for material defects for at least

the first two years after the date of purchase. For battery cells, this is limited to 6

months from the date of purchase.

This covers defects that already existed at the time of delivery. In the first six

months, it is assumed that the defect already existed at the time of purchase. A

requirement for the purchaser to make a claim is that all specified conditions were

complied with during installation, use and maintenance.

These regulations only apply to states that are subject to EU law. In Switzerland and

other non-EU countries, liability is limited to one year after the date of purchase.

Wearing parts, such as the battery casing (scratches, falls, impact, etc.), friction

roller, scratches and damage attributable to the user's personal negligence are

excluded from the warranty.

Any form of manipulation or modification not expressly permitted in the installa-

tion or operating manual, assembly video or by written permission from GP Motion

GmbH invalidates the warranty .

Damage to the add-e NEXT battery caused by a complete discharge (e.g. due to

prolonged lack of use) or by using a different charger is excluded from the warran-

ty. If the add-e NEXT battery is not used for a longer period of time, it should be

removed from the battery holder.

In the case of a warranty claim, please contact the respective retailer. The ma-

nufacturer or specialist retailer will repair or replace the defective parts. For the

purpose of processing the warranty claim, the customer is required to send in the

defective parts or the add-e NEXT kit.

The "Repair Order" form is available online at www.add-e.at/montage or from

[email protected]. This form needs to be filled in carefully and enclosed with the

delivery. Warranty claims without a correctly completed form may result in higher

costs and a delay in the repair. The customer is responsible for ensuring that the

parts sent in are suitably wrapped to avoid damage in transit. The manufacturer ist

not liable for damage that occurs during transport.

Removing the serial number from the add-e NEXT battery or the add-e NEXT drive

unit voids the warranty.

Spare parts are available from the retailer.

Failure to observe the information provided in this manual, improper use or use for

purposes other than those the product is intended will result in GP Motion GmbH

rejecting the claim for damage to and caused by the product. Liability for conse-

quential damage to elements of any kind or persons is excluded.

The manufacturer accepts no responsibility for and will not refund any costs incur-

red as a result of improper use.

warranTy/disClaiMer

Page 7

explanaTion of syMbols

PLEASE NOTE!

This symbol stands for special instrucons which need to be follo-

wed during use or installaon.

TIP!

This symbol stands for special ps that make use or installaon

easier.

ATTENTION!

This symbol stands for IMPORTANT informaon and instrucons

for assembly or use. It is imperave that you observe these in order

to avoid hazards.

This marking means that the parts are not allowed to be disposed

of in household waste

CLEANLINESS!

Secons marked with this symbol indicate that special aenon

needs to be paid to cleanliness here.

Page 8

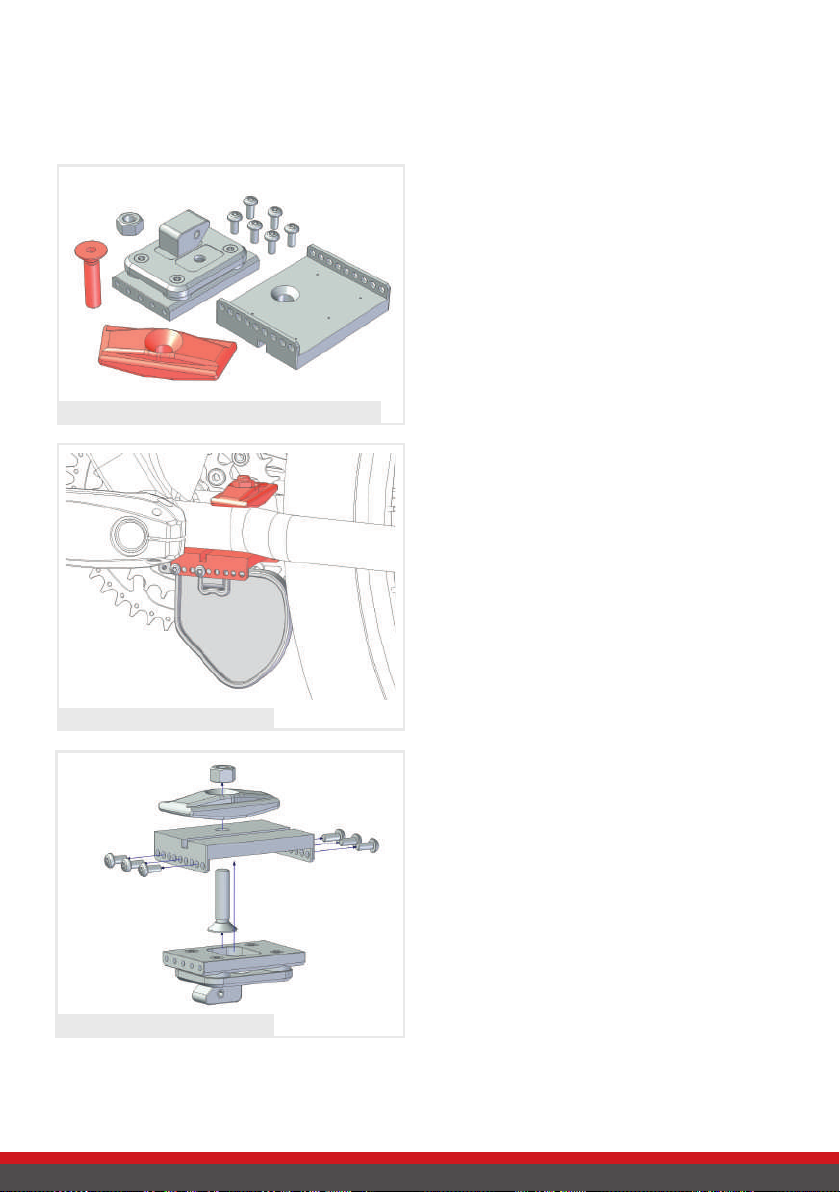

add-e NEXT battery

add-e NEXT drive unit add-e NEXT charger

add-e NEXT Sensors

Assembly arms

short

Stand plate Damper plate Assembly arms

long

Setting gauge

Battery holder

6x M4 Torx screws

3x M4 Torx screws

long

Spacer

Dongle

size 3 Allen key

size 4 Allen key

size 6 Torx key

size 20 Torx key

Cable ties

long

Button cell

CR 2032 3V

sCope of deliVery

Docking station

size 20 Torx key

O-rings & rubbers

add-e NE

add-e NE

X

X

T Sensors

T Sensors

CR 2032 3V

2x Steel straps

4x M6 grub screws

2x M5 Allen

screws

1x 8mm Washer

1x M8 Nut

1x M8 Screw

Page 9

add-eNEXT Instalation Manual

EN

Vers. 3.6

e-motion your bike

with add-e

Page 10

Table of ConTenTs: insTallaTion ManUal

secTion 1: idenTificaTion of insTallaTion varianT p. 11

Variant 1: Installation at the side stand p. 12

Variant 2: Installation at the bottom bracket p. 13

Variant 3: Installation with the Hebie counterplate p. 13

secTion 2: asseMbling The KiT p. 14

Step 1: Attaching the damper plate p. 14

1.1. Variant 1: Installation at the side stand mount p. 14

1.2. Variant 2: Bottom bracket installation with assembly arms p. 16

1.2.1. Dismantling the cranks and removing the bottom bracket p. 16

1.2.2. Assembling the damper plate p. 18

1.2.3. Attaching the damper plate to the bottom bracket p. 19

1.3. Variant 3: Installation with the Hebie counterplate p. 20

Step 2: Attaching the battery holder p. 21

2.1. Variant 1: Standard attachment of the battery holder p. 21

2.2. Variant 2: Attaching the battery holder with steel straps p. 22

2.3. Variant 3: Attaching the battery holder with screw & steel strap p. 23

Step 3: Attaching the add-e NEXT sensors p. 24

secTion 3: drive UniT & Mechanical seTTing p. 25

Preparation p. 26

Setting 1: Upper stop p. 27

Setting 2: Contact pressure p. 28

Setting 3: Freewheel p. 29

Setting 4: Lower stop p. 30

secTion 4: special noTes To insTallaTion process p. 31

4.1. Moving the wedge if it is too close to the chain p. 31

4.2. Installation with a bottom bracket width of 73 mm p. 32

4.3. Bottom bracket installation with Italian bottom bracket p. 32

Page 11

inTrodUCTion

This part of the manual deals mainly with fitting the add-e NEXT retrofit kit to

your bike. A detailed description of the each of the parts, as well as their opera-

tion, technical data and functions can be found in the second part, the Operating

Manual.

Installing your new add-e NEXT retrofit kit may involve the use of special tools

which are not included in the set. These tools can be purchased from our online

shop at www.add-e.at/shop or from a specialist bike retailer.

Read the operating and installation manuals carefully before assembling the drive.

The steps need to be followed in their exact order. Only original parts from the

manufacturer or accessories recommended by the manufacturer should be used.

seCTion1: idenTifiCaTion of insTallaTion VarianT

Preparation

The following factors need to be considered to get the most out of your new add-e

NEXT retrofit drive:

• The rear tire should not have a rough/knobble profile. It is important that it has

a continuous centre rib, like the Continental Travel Contact, Schwalbe Hurricane

or Schwalbe Land Cruiser.

• At the position on your bike where you intend to fit the battery, adequate space

should be available so it can be inserted and removed from the holder easily.

• Standard installation is not possible with a Pressfit bottom bracket (i.e. a pres-

sed-in bottom bracket, not a screwed-in bottom bracket). In this case, please

• On a full-suspension MTB (Fully) the drive can only be installed if the rear wheel

suspension can be locked completely or the drive can be fitted directly to the

rear wheel struts. In this case, please contact our support team at

Due to different bike tipes available, fitting the drive unit with the damper plate

may vary from bike to bike. This also depends on factors such as the cable pull,

available space, bottom bracket models, etc.

Prior to the installation of the drive you should check which variant is suitable for

your bike.

Page 12

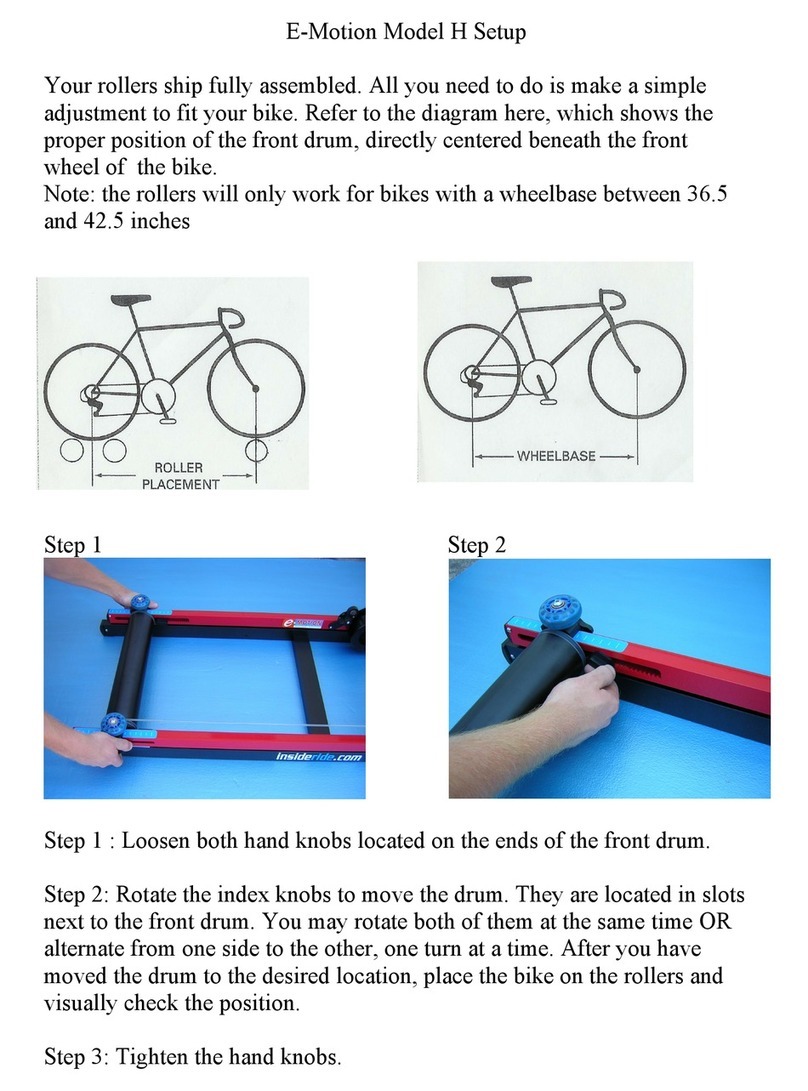

1. Place the damper plate in the stand

plate and attach the setting gauge.

2. The damper plate can be moved along

the stand plate so that the distance

between the setting gauge and the

rear wheel can be adjusted. Slide the

damper plate towards the rear wheel

until the setting gauge rests against

the tyre.

3. Ideally, it should be possible to tighten

three, but at least two M4 Torx screws

on each side in order to continue

installing the drive unit with the side-

stand mounting plate. - See p. 14.

If this is not possible, another installa-

tion variant will have to be used.

The setting gauge is touching the rear wheel

Variant1 1: Installation at the side stand

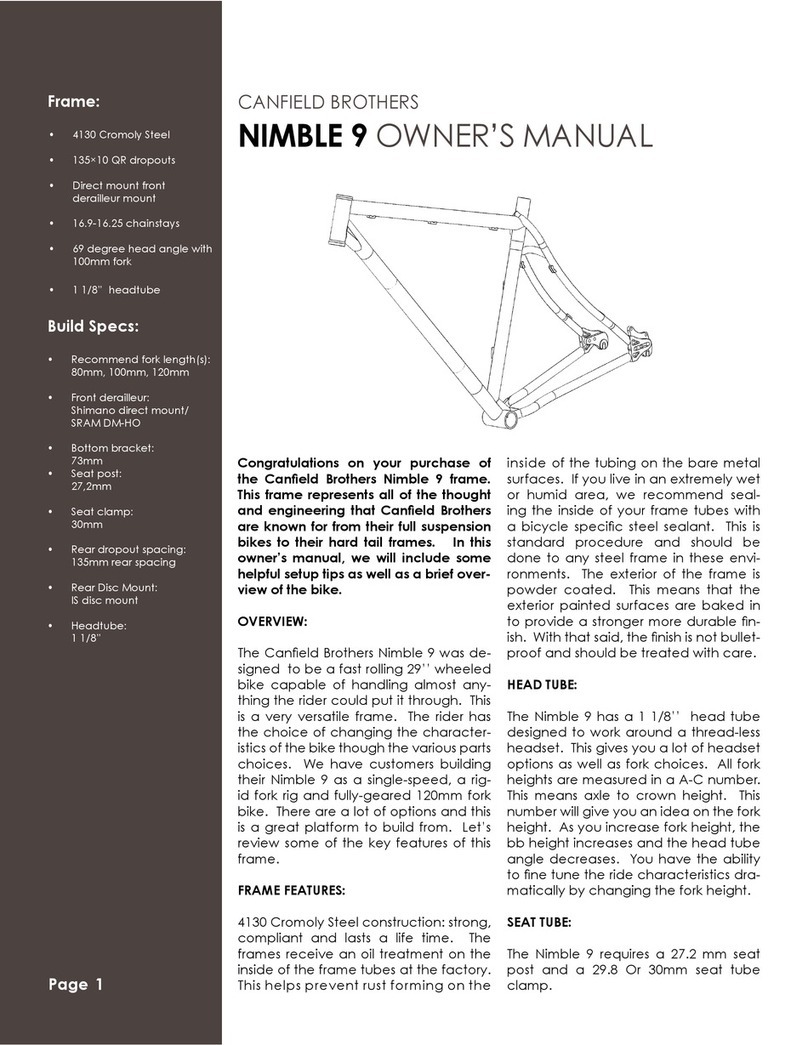

If your bike has a side stand mounting, it can be used to install the drive. Make sure

that the side-stand mounting is sufficiently far away from the rear wheel and at a

suitable angle to the rear wheel hub. You can check this as follows:

ATTENTION!

If the angle is not correct, you can adjust it by using an underlay for

the stand plate. You can use aluminium or plasc plates or similar for

this purpose. See p. 15.

PLEASE NOTE!

The shape of the frame may prevent the seng gauge from coming

into contact with the rear wheel. If this is the case, rotate the stand

plate for 180°.

Page 13

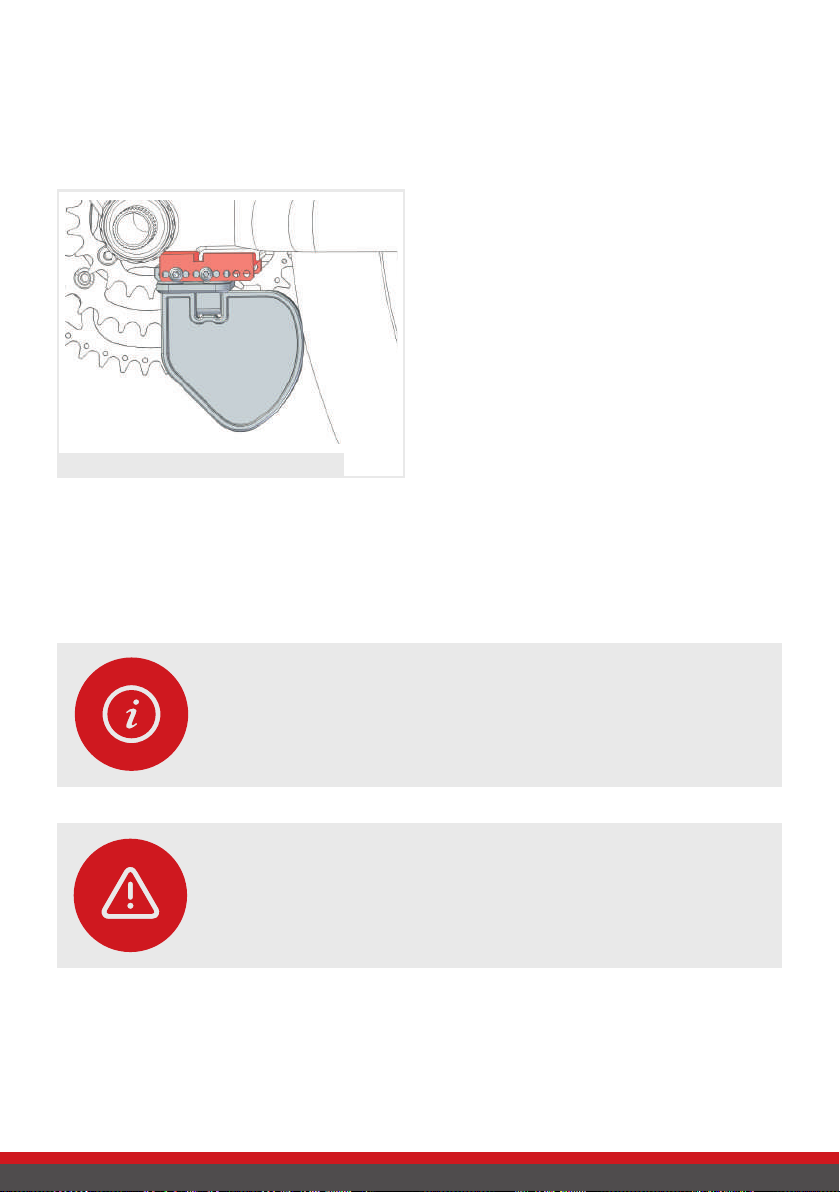

Variant 2: Installation at the bottom bracket

When fitting the drive unit to the bot-

tom bracket, the short assembly arms

should preferably be used. If the distan-

ce to the tyre is too great, the included

long assembly arms may be used.

This installation variant is not suitable

for bikes with pressfit bottom brackets.

With screwed-in bottom brackets, you

can continue the bottom bracket instal-

lation variant. See p. 16.

The installation at the bottom bracket should be choosen if the bike does not have

a side-stand mounting plate or if cable pulls or limited space conditions do not

allow any other installation variant.

Variant 3: Installation with the Hebie counterplate

The drive unit is fitted by using the Hebie

counterplate if neither Variant 1 nor Va-

riant 2 can be used. Particular attention

needs be paid to ensuring that there is

sufficient space. For a detailed descrip-

tion see p. 20.

The Hebie counterplate is not included

in the installation kit, but can be bought

in our online shop at www.add-e.at/shop

or from your local specialist retailer.

PLEASE NOTE!

In some cases the le bearing shell has no ange or is made of

plasc. In the case of plasc boom bracket shells, the distance

between the motor and the rear wheel can change/increase over

me. For a safe and durable installaon, metal bearing shells with

a ange on both sides should be used. A suitable selecon can be

found in our online shop at www.add-e.at/shop.

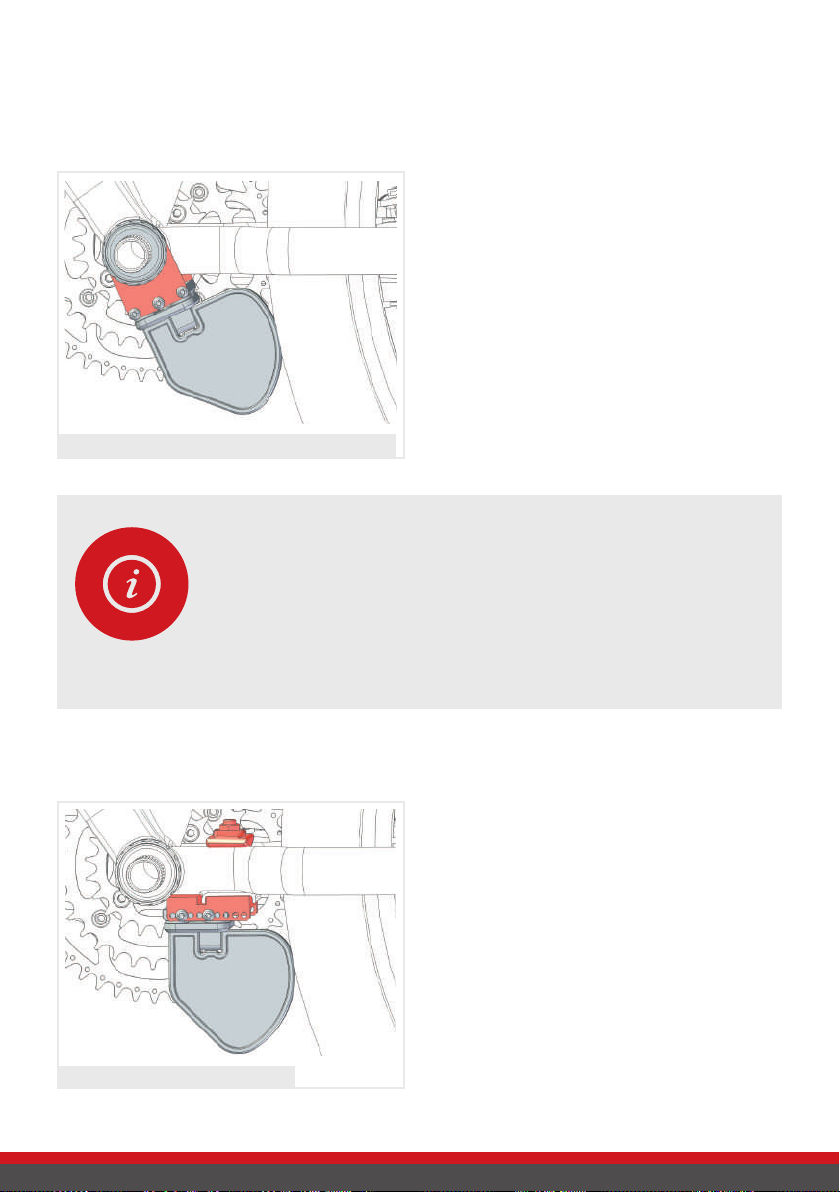

Bottom bracket assembly with short assembly arms

Fitting with the Hebie counterplate

Page 14

seCTion 2: asseMbling The KiT

After checking which installation variant is suitable, you can start assembling the

installation kit.

Step 1: Attaching the damper plate

The following describes all three installation variants for attaching the damper plate.

Depending on your bike type one of the three variants can be used.

1.1. Variant 1: Installation at the side stand mount

Parts needed:

• Damper plate

• Stand plate

• 6x M4 Torx screws, short

• 1x M8 Allen Screw

• M8 nut

• Washer

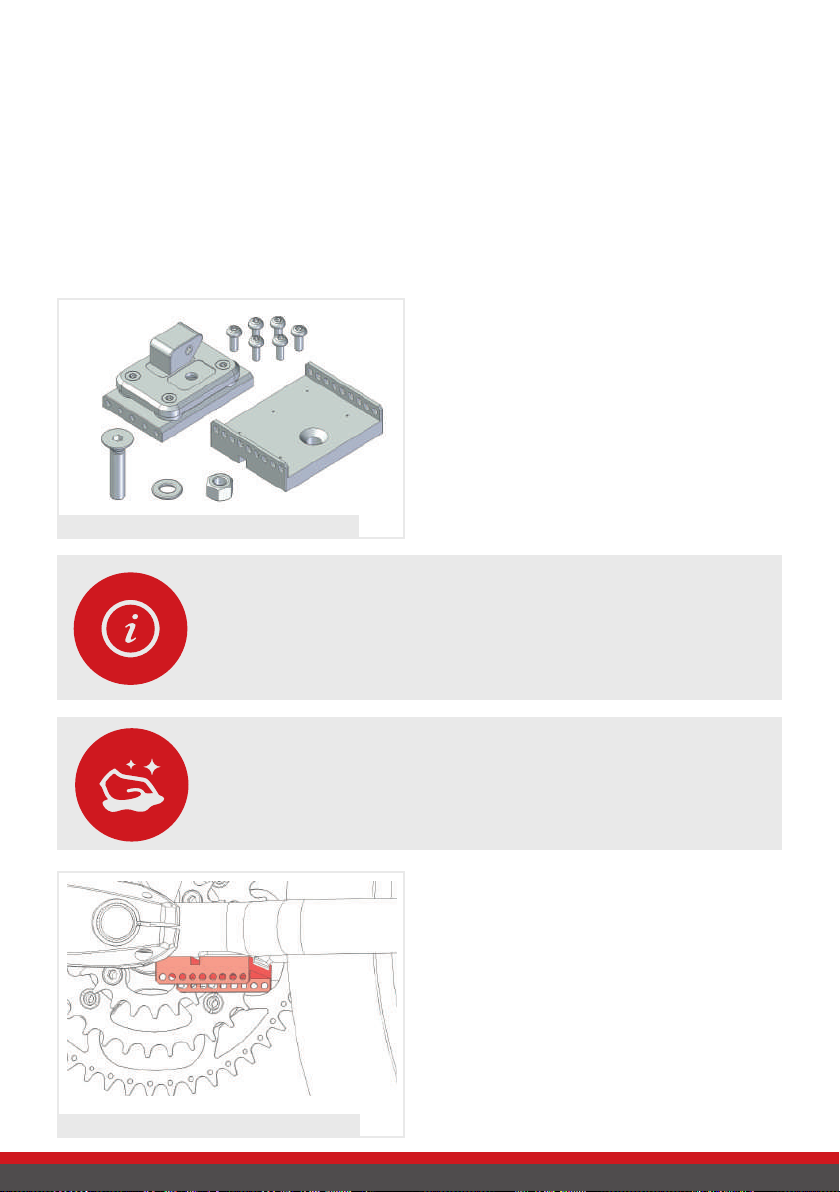

Parts needed for installation at side stand mount

CLEANLINESS!

Before aaching the stand plate, the side stand mount needs to be

thoroughly cleaned!

PLEASE NOTE!

If your bike has a side stand, remove it and switch to a rear stand if

needed. A rear stand can be purchased in our online shop at

www.add-e.at/shop or from a specialist bike retailer.

Stand plate attached to the side stand mount

1. Attach the stand plate below the side

stand mount. Insert the M8 Allen

screw from below and fasten it from

above with the washer and the M8

nut.

2. Slide the damper plate onto the stand

plate with the wedge facing the chain

ring and attach the setting gauge with

the curve facing the rear wheel.

Page 15

3. Slide the damper plate back and

forth along the stand plate until the

setting gauge rests against the rear

wheel.

If there is not enough space due to the

shape of the bike, the stand plate can

be rotated fo 180° to gain more space.

Setting gauge is touching the rear wheel

p

PLEASE NOTE!

In order to be able to adjust the drive unit opmally aferwards, the

angle from the stand plate to the rear wheel hub may need to be

adjusted.

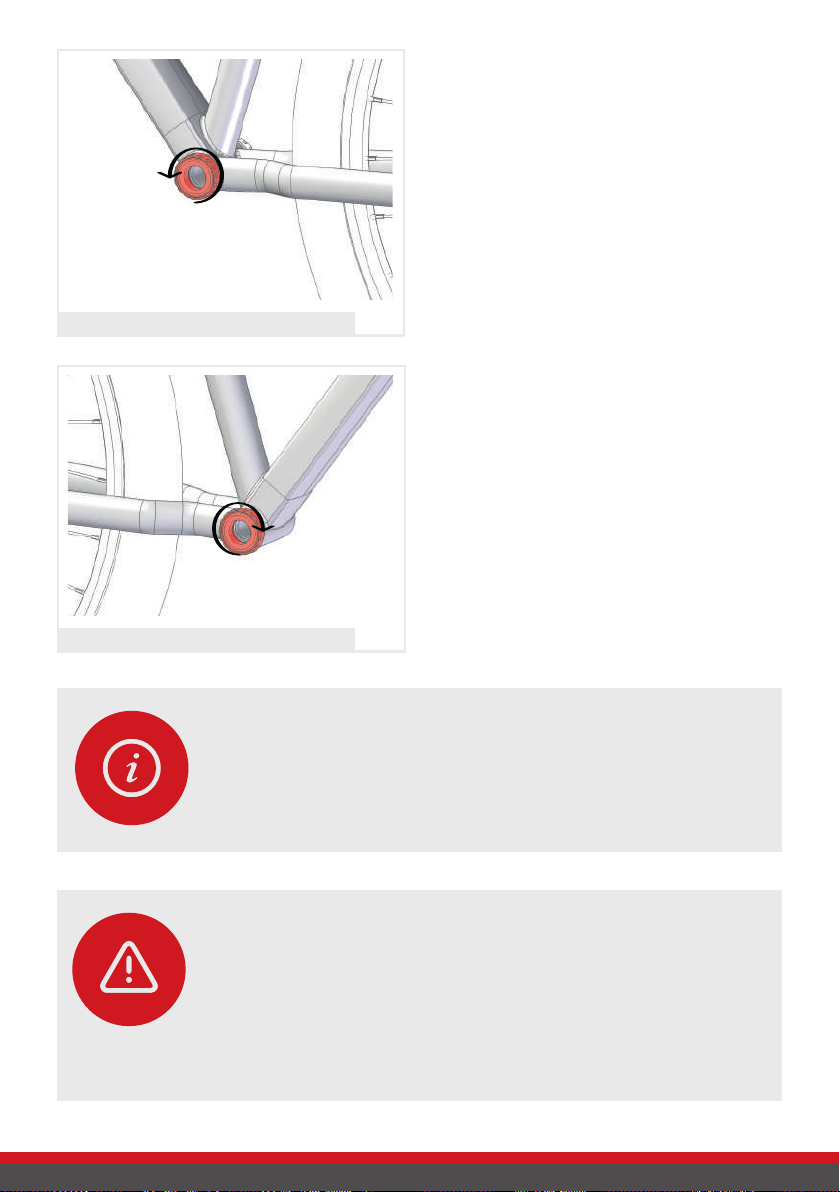

The angle needs to be adjusted so that

the extended line of the stand plate

extends to at least the centre or slightly

above the rear wheel hub.

Underlaying the stand plate

Adjust the stand plate angle

If you cannot set the right angle, you can

adjust it by underlaying the stand plate.

For example, aluminium or plastic plates

can be used as an underlay.

4. If the damper plate setting is appro-

priate, attach it to the stand plate using

six M4 Torx screws (ideally three, but at

least two screws on each side).

Mounting the damper plate to stand plate

Page 16

1.2. Variant 2: Bottom bracket installation with assembly arms

Parts needed:

• 1x Damper plate

• 2x Assembly arms, short

• 2x assembly arms, long (optional)

• 6x M4 Torx screw, short

Parts needed for bottom bracket installation

PLEASE NOTE!

To t the drive unit to the boom bracket special bike tools are nee-

ded. These can be ordered in our online shop at www.add-e.at/shop.

The following steps should only be done by experienced installers.

1. Loosen the two screws on the clamp

of the left pedal crank.

Remove the locking screw on the

pedal crank and then pull the crank

off the shaft.

1.2.1. Dismantling the cranks and removing the bottom bracket

Depending on the model and manufacturer, your bike may be equipped with diffe-

rent bottom brackets and cranksets.

The following describes the installation using a Shimano Hollowtech II bottom bra-

cket as an example. This procedure may vary considerably depending on bike type.

Disassembly of the left pedal crank

2. Pull the right-hand pedal crank out

of the bottom bracket.

It may be need to loosen the shaft by

gently tapping on it.

3. Remove the bike chain from the

chainring.

Disassembly of the right pedal crank

Page 17

PLEASE NOTE!

Some Italian and French frame manufacturers are an excepon,

and have both right-hand threads. If you cannot loosen a boom

bracket, heang the frame with a hot air gun in this area helps.

4. Unscrew and remove the left bottom

bracket shell.

Disassembly of the left bottom bracket shell

5. Unscrew and remove the right bot-

tom bracket shell.

The chain ring side thread for the

bottom bracket is a left-hand thread.

Disassembly of the right bottom bracket shell

ATTENTION!

In some cases the le bearing shell has no ange or is made of

plasc. In the case of plasc boom bracket shells, the distance

between the motor and the rear wheel can change/increase over

me. For a safe and durable installaon, metal bearing shells with

a ange on both sides should be used. A suitable selecon can be

found in our online shop at www.add-e.at/shop

Page 18

1. Attach the short assembly arms to

each side of the stand plate using the

six M4 Torx screws supplied.

1.2.2. Assembling the damper plate

When fitting the drive unit to the bottom bracket, preferably the short assembly

arms should be used. Check whether the bike's frame allows this as follows:

Assembling the damper plate

2. Place the setting gauge on the as-

sembled damper plate and point the

wedge on the damper plate towards

the chain ring.

Loosely attach the assembly arms to

the bottom bracket using the bottom

bracket shells.

The setting gauge should rest against

the rear wheel. If this is not the case,

use the long assembly arms.

Short assembly arms - right lenght

p

ATTENTION!

If the distance between the seng gauge and the rear wheel is too

large, use the long assembly arms! However, if these are too long,

the stand plate angle for ng the drive unit will be too acute.

Right ng later on is not possible.

Short assembly arms too short Long assembly arms too long

Page 19

1.2.3. Attaching the damper plate to the bottom bracket

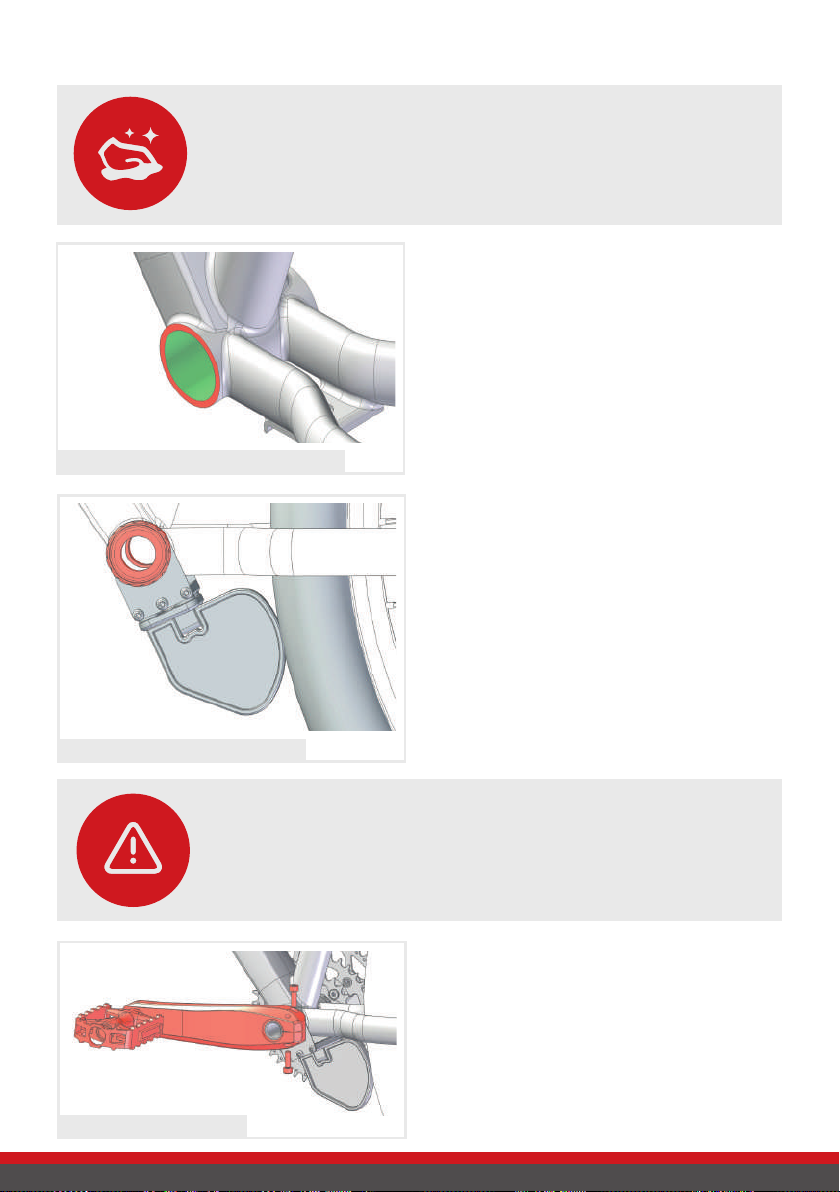

CLEANLINESS!

Before aaching the damper plate, thoroughly clean the area around

the boom bracket. There should be no dirt or grease between the

assembly arms and the frame.

1. To improve the grip of the assembly

arms, some assembly paste can be

applied to the contact surfaces on

the bottom bracket.

For this purpouse, apply a thin layer

of paste to the frame, making sure

that it does not enter inside the

frame.

Thin layer of assembly paste on the frame

2. Pre-fix the damper plate to the frame

with the appropriate assembly arms

and the two bottom bracket shells.

Press the setting gauge against the

tyre. Before alternately tightening the

bottom bracket shells, make sure that

the extended line of the damper plate

extends to at least the centre of the

rear wheel hub or slightly above it.

See p. 15.

Tightening the bottom bracket shells

3. Replace the pedal cranks in reverse

order.

See p. 16.

Make sure that everything is tight-

ened securely.

Mount the pedal cranks

ATTENTION!

When ghtening the boom bracket, make sure that the seng

gauge does not slip out of place and remains in contact with the

tyre! Tighten the boom bracket shells alternately.

Page 20

1.3. Variant 3: Installation with the Hebie counterplate

Parts needed:

• Hebie counterplate (not included in

standard delivery)

• Damper plate

• Stand plate

• 6x M4 Torx screws

• 1x M8 Allen screw

• M8 cap nut

Fitting the drive unit with Hebie counterplate is done when weather the side stand

nor bottom bracket variants are suitable. Particular attention needs to be paid that

there is sufficient space.

Parts needed for Hebie counterplate installation

Attaching the Hebie counterplate

1. Insert the stand plate between the

rear wheel struts with the M8 bolt

inserted.

2. Attach the Hebie counterplate from

above and tighten it with the M8 cap

nut.

3. Slide the damper plate with the set-

ting gauge attached along the stand

plate towards the rear wheel until it

rests against the tyre.

4. Tighten the damper plate with at

least 2 screws on each side, making

sure the wedge is pointing towards

the chainring, and the setting gauge

is resting against the tyre.

Attaching the Hebie counterplate

With installation variant 3, the stand

plate is attached to the frame with the

Hebie counterplate.

For a detailed description of how to

attach the stand plate, refer to the inst-

ructions for fitting the drive unit to the

side-stand mounting. See p. 14.

Table of contents

Other e-motion Bicycle Accessories manuals