__________________________________________________________________________________________________________________

European

Safety

Systems

Ltd.

Impress House, Mansell Road, Acton, London W3 7QH [email protected] Tel: +44 (0)208 743 8880 www.e2s.com Fax: +44 (0)208 740 4200

Document No. D211-00-611-IS-SC Issue: E 02-03-2020 Sheet 2 of 13

Ex nA IIC Gc X T4 Ta -40°C to +50°C

Ex tc IIIC 75°C Dc X Ta -20°C to +50°C

Installation must be carried out in compliance with the

Canadian Electric Code

2.6 ATEX / IECEx certification

The D2xC2LD2 LED beacon complies with the following

standards:

EN60079-0:2012+A11:2013 / IEC60079-0: ed. 6.0 (2011-06)

EN60079-15:2010 / IEC60079-15: ed. 4.0 (2010-01)

EN60079-31:2014 / IEC60079-31:2013 ed. 2.0 (2013-11)

Certificate No. DEMKO 14 ATEX 4786493904X

IECEx ULD 14.0004X

The D2xC2LD2 LED beacon is rated as follows:

CE Marking

Zones, Gas / Dust Groups and Temperature Classification

When connected to an approved system the D2XC2LD2 LED

beacon may be installed in:

Zone 2 explosive gas air mixture not likely to occur

in normal operation, and if it does, it will only exist for

a short time.

Zone 22 explosive dust air mixture not likely to occur

in normal operation, and if it does, it will only exist for

a short time.

May be used with gases in groups:

Group IIA propane

Group IIB ethylene

Group IIC hydrogen / acetylene

Having a temperature classification

(for Gas applications) of:

T1 450ºC

T2 300ºC

T3 200ºC

T4 135ºC

May be used with Dust types:

Group IIIA combustible flyings

Group IIIB non-conductive dust

Group IIIC conductive dust

Maximum Surface Temperature for Dust Applications:

75ºC

Installation must be carried out in compliance with the

latest issue of the following standards:

EN60079-14 / IEC60079-14: Explosive atmospheres -

Electrical installations design, selection and erection

EN60079-10-1 / IEC60079-10-1: Explosive atmospheres -

Classification of areas. Explosive gas atmospheres

EN60079-10-2 / IEC60079-10-2: Explosive atmospheres –

Classification of areas. Explosive dust atmospheres

2.7 Ingress Protection Ratings

The product is rated for ingress Protection as follows:

IP rating IP66

Type rating per UL50E / NEMA250: 4 / 4X / 3R / 13

To maintain the ingress protection rating, the cable entries must

be fitted with suitably rated, certified cable entry and/or blanking

devices during installation.

2.8 Electrical Ratings

It is important that a suitable power supply is used to run the

equipment. The power supply selected must have the

necessary capacity to provide the input current to all the units.

The input current will vary according to the voltage input level.

The current levels shown above are for the worst-case input

voltage and flash setting resulting in max. current.

For detailed current ratings of the device please see Section 13.

3) Special Conditions for Safe Use

Special Condition for safe Use as stated on the Type

Examination Certificate DEMKO 14 ATEX 4786493904X / CoC

IECEx ULD 14.0004X:

When used for a Group III application, the surface of the

enclosure may store electrostatic charge and become a source

of ignition in applications with a low relative humidity <~30%

relative humidity where the surface is relatively free of surface

contamination such as dirt, dust, or oil.

Guidance on protection against the risk of ignition due to

electrostatic discharge can be found in EN TR50404 and IEC

TR60079-32.

End user shall adhere to the manufacturer’s installation and

instruction when performing housekeeping to avoid the potential

for hazardous electrostatic charges during cleaning, by using a

damp cloth.

To maintain the ingress protection rating and mode of

protection, the cable entries must be fitted with suitably rated,

certified cable entry and/or blanking devices during installation.

If conduit is used for installation, seal conduit within 18 inches

from the enclosure.

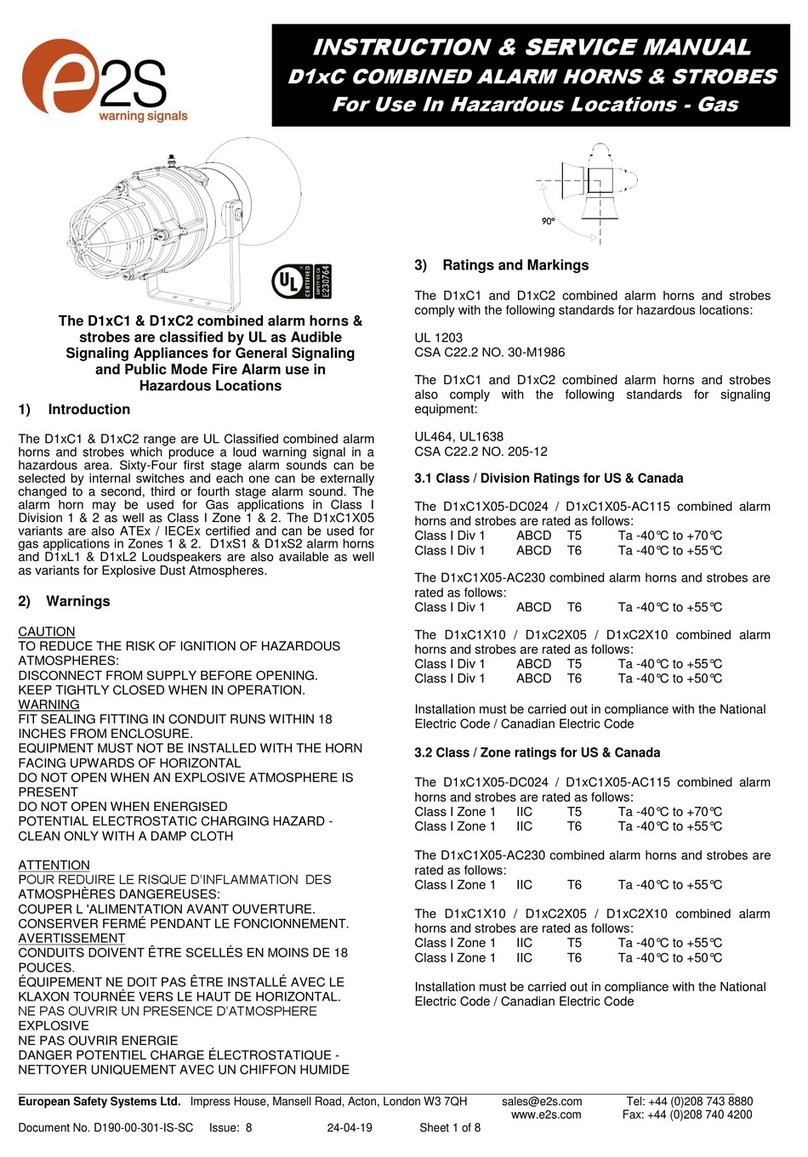

4) Location and Mounting

The location of the combined alarm horn and beacon should be

made with due regard to the area over which the warning signal

must be visible and audible. It should only be fixed to services

that can carry the weight of the unit.

DxC2 Alarm Horn and Strobe to a flat surface via the two 9.7 x

6.7mm, 147mm pitch fixing holes in the mounting feet of the

sounder section and the two 7mm fixing holes in the feet of the

base.

The equipment is not to be mounted with the horn facing

upwards.

2813

II 3G Ex nA IIC T4 Gc Ta -40°C to +50°C

II 3D Ex tc IIIC 75°C Dc Ta -40°C to +50°C