9) Cable Selection

When selecting the cable size consideration must be given to

the input current that each unit draws (see table above), the

number of beacons on the line and the length of the cable

runs. The cable size selected must have the necessary

capacity to provide the input current to all of the beacons

connected to the line.

SAFETY WARNING: If the BExBG05D beacons are used at

high ambient temperatures, i.e. over +40ºC, then the cable

entry temperature may exceed +70ºC and therefore suitable

heat resisting cables must be used, with a rated service

temperature of at least 95ºC.

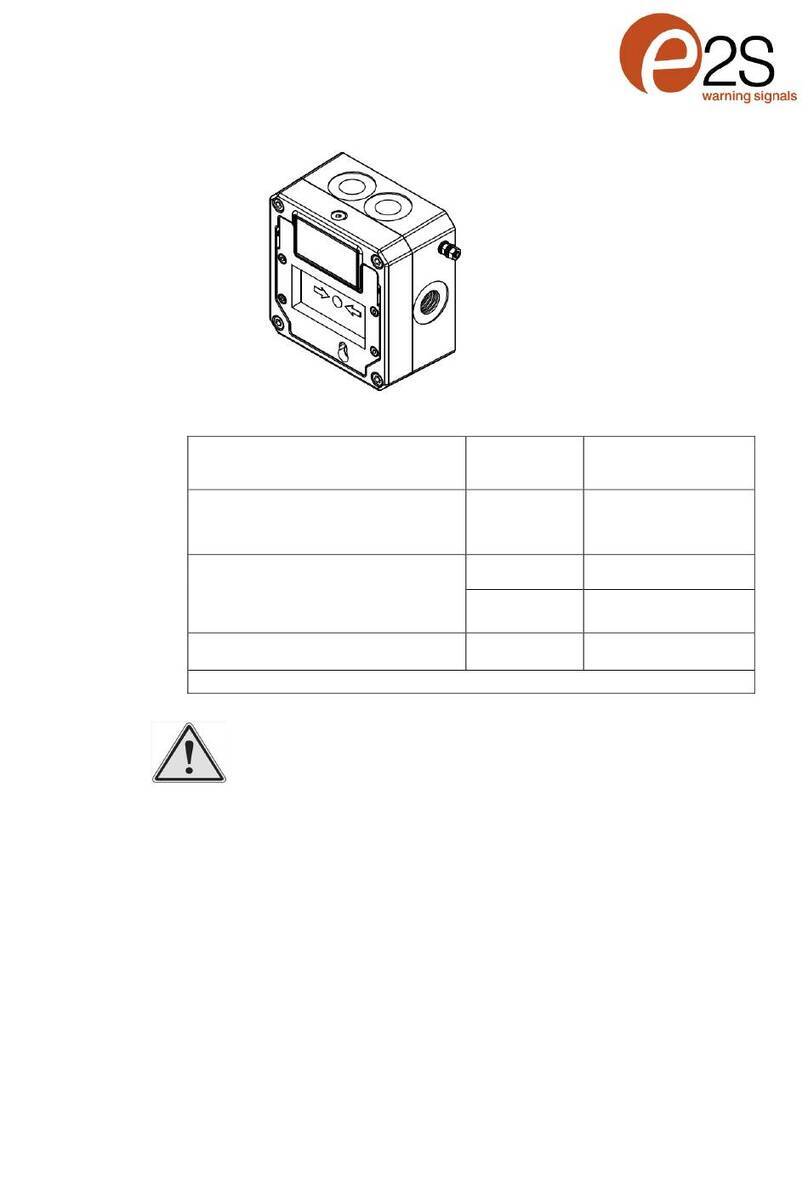

10) Earthing

Both AC and DC beacon units must be connected to a good

quality earth. The units are provided with internal and

external earthing terminals which are both located on the

terminal chamber section of the unit (see figures 2 and 3).

When using the external earth terminal a cable crimp lug

must be used. The cable lug should be located between the

two M5 stainless steel flat washers. The M5 stainless steel

spring washer must be fixed between the outer flat washer

and the M5 stainless steel nut to ensure that the cable lug is

secured against loosening and twisting.

The internal earth bonding wire ensures that a good quality

earth is maintained between the flameproof chamber casting

and the flameproof cover casting.

11) Cable Glands

The BExBG05D beacons have dual cable gland entries which

have an M20 x 1.5 entry thread as standard. Only cable

glands approved for Ex ‘d’ applications can be used, which

must be suitable for the type of cable being used and also

meet the requirements of the Ex ‘d’ flameproof installation

standard BS EN 60079-14 : 1997.

When only one cable entry is used the other one must be

closed with an Ex ‘d’ flameproof blanking plug, which must be

suitably approved for the installation requirements.

For combustible dust applications, the cable entry device and

blanking elements shall be in type of explosion protection

increased safety "e" or flameproof enclosure "d" and shall

have an IP 6X rating according to EN 60529.

SAFETY WARNING: If the BExBG05D beacons are used at

high ambient temperatures, i.e. over +40ºC, then the cable

entry temperature may exceed +70ºC and therefore suitable

heat resisting cable glands must be used, with a rated service

temperature of at least 95ºC.

12) Cable Connections

The cable connections are made into the terminal blocks on

the electronic pcb assembly located in the flameproof

enclosure. See section 7 of this manual for access to the

flameproof enclosure. A four-way terminal block is provided

on both AC and DC beacons. Therefore there are two live

terminals and two neutral terminals for the input and output

wiring on AC units. On the DC units there are two +ve

terminals and two -ve terminals for the input and output

wiring.

Wires having a cross sectional area of up to 2.5mm² can be

connected to each terminal way. If an input and output wire is

required a 2.5mm² wire can be connected to each terminal

way. When connecting wires to the terminals great care

should be taken to dress the wires so that when the cover is

inserted into the chamber the wires do not exert excess

pressure on the terminal blocks. This is particularly important

when using cables with large cross sectional areas such as

2.5mm².

13) Synchronised Operation

All BExBG05D beacons that are connected to the same

supply line will have a synchronised flash rate at one flash

every second. To ensure that the units will be synchronised

check that the pin header is not fitted, i.e. the two header pins

are not shorted together (see Figure 4).

2offM20

Cable Entries

Internal Earth Terminal

Figure 3

Internal

Bonding Wire

Terminal

BExBG05D Beacon Cover Internal View

Figure 4

BExBG05D 5 Joule Beacons

Suppl