ŸAfter a Fall Arrest: Inspect the impact indicator on the snap hook of the SRL and look for an exposed red color band. Do not

attempt to reset the impact indicator. Remove the retractable from service immediately and return to TheHarnessDepot or an authorized

repair center. If using a retractable with a webbed lifeline, then inspection of the shock pack is required. Remove retractable from

service if there are any deformation, elongation or other signs of the shock pack being torn or deployed. If inspection reveals an

unsafe condition, remove unit from service immediately and destroy, or contact an authorized service center for repair.

ŸInspecting The Self Retracting Lifeline:

STEP 1: Inspect for loose screws and bent or damaged parts.

STEP 2: Inspect housing for distortion, cracks or other damage Ensure

the swivel eye is not damaged or distorted in anyway. Make sure

the swivel eye turns freely.

STEP 3: The lifeline must fully extend and retract without hesitation or

creating a slack line condition.

STEP 4: Ensure the device locks up when lifeline is jerked sharply.

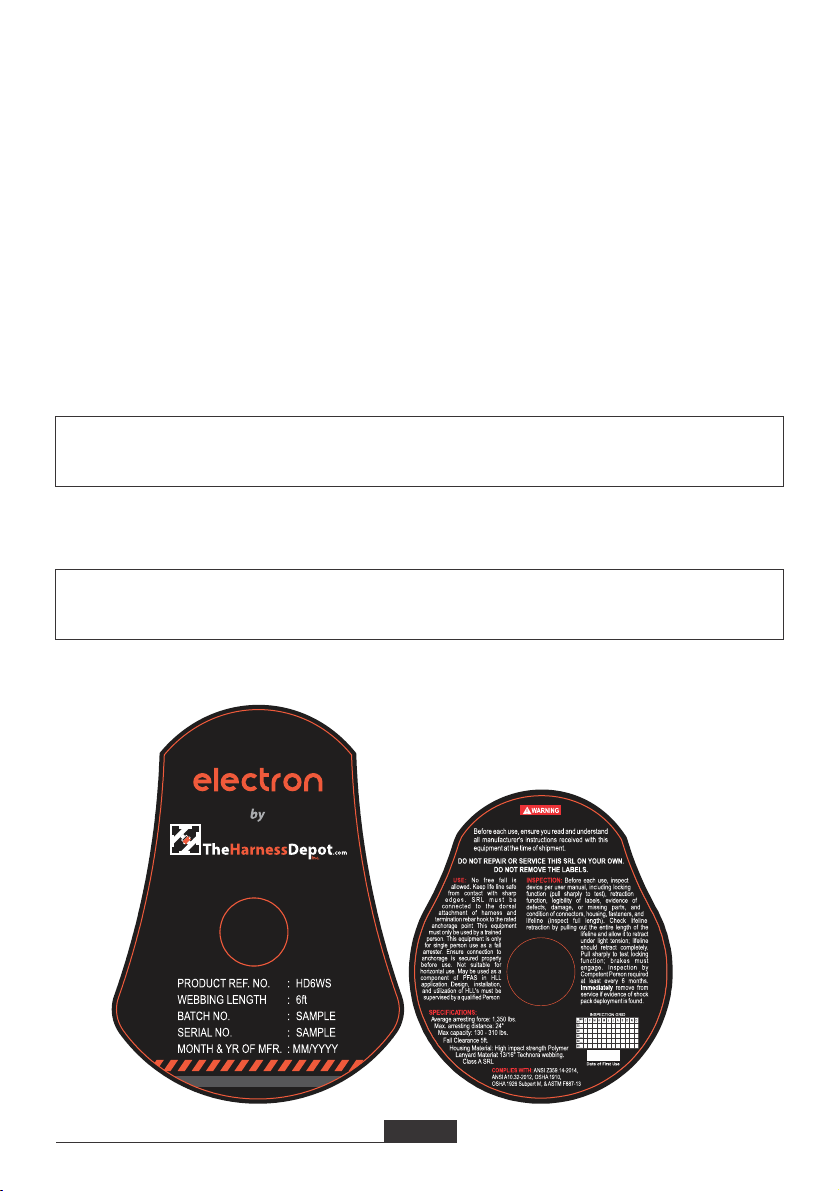

STEP 5: Ensure the labels must be present and fully legible with

inspection log information completed.

STEP 6: Look for signs of corrosion on the entire unit.

STEP 7: Wire rope inspection must include identifying cut kinks, broken

wires, bird-caging, corrosion, welding splatter, chemical

damage, or severely abraded areas. Check all thimbles etc…

for excessive wear including cracks or separation of metal

components.

STEP 8: Webbed lifeline inspection must include identifying frayed

strands, broken webbing, burns, cuts, and abrasions. Inspect

for excessive heat, paint build-up, soiling rust, or chemical

damage indicated by brown or discolored areas.

STEP 9: Inspect connecting hooks or Karabiners for signs of damage,

corrosion or excessive wear.

STEP 10: Record inspection results in the inspection and maintenance

log found in this manual. Clearly check off month the SRL was

inspected on the label of the housing.

17. CABLE INSPECTION: When inspecting SRL's that utilize cable lifelines, it is critical

to look for the following damages and deterioration that will result in malfunction of

the unit and potentially unsafe conditions.

Ÿ Crushing: The cable will often get crushed or bent while being used on a job

site. Cable that is crushed or bent will damage the retractable and thus the

unit should be immediately taken out of service and returned to

TheHarnessDepot or authorized repair center.

ŸCutting: Movement over sharp edges or other objects while the cable is under tension results in damaged strands and broken

wires. If, through inspection of the retractable lifeline prior to each use, it is found to have any broken strand, immediately remove

from service and return to TheHarnessDepot or an authorized repair center.

ŸAbrasion: Abrasion can result from normal wear. Particular attention must be paid to the outer wire strands as they with each

use, it is found have damage or deterioration from abrasion, immediately remove from service and return to TheHarnessDepot or an

authorized repair center.

ŸKinking: Any deformation in the cable whereas the lifeline appears to be bent, requires the retractable to be immediately removed

from service and returned to TheHarnessDepot or an authorized repair center.

ŸCorrosion, Arc or Heat Damage: Extreme caution must be taken to avoid any potential damage as a result of using a retractable

within an environment where corrosive compounds, welding, or high heat may exist. Corrosive damage could cause the cable to

crack. Welding damage would result in fused wires and thus change the characteristics of the strength with regards to the wire. If

the retractable is used in these environments, the retractable lifeline needs to be closely examined for damage.

18. PLAN THE FALL PROTECTION SYSTEM: Before installation plan your system. Consider all factors that will affect your safety during use

of this equipment. The following list gives important points to consider when planning your system:

ŸAnchorage: Select a rigid anchorage capable of supporting the loads no less than 5,000 lbs per worker attached.

ŸSharp Edges: Avoid working where system components may be in contact with, or abrade against, unprotected sharp edges.

11