7

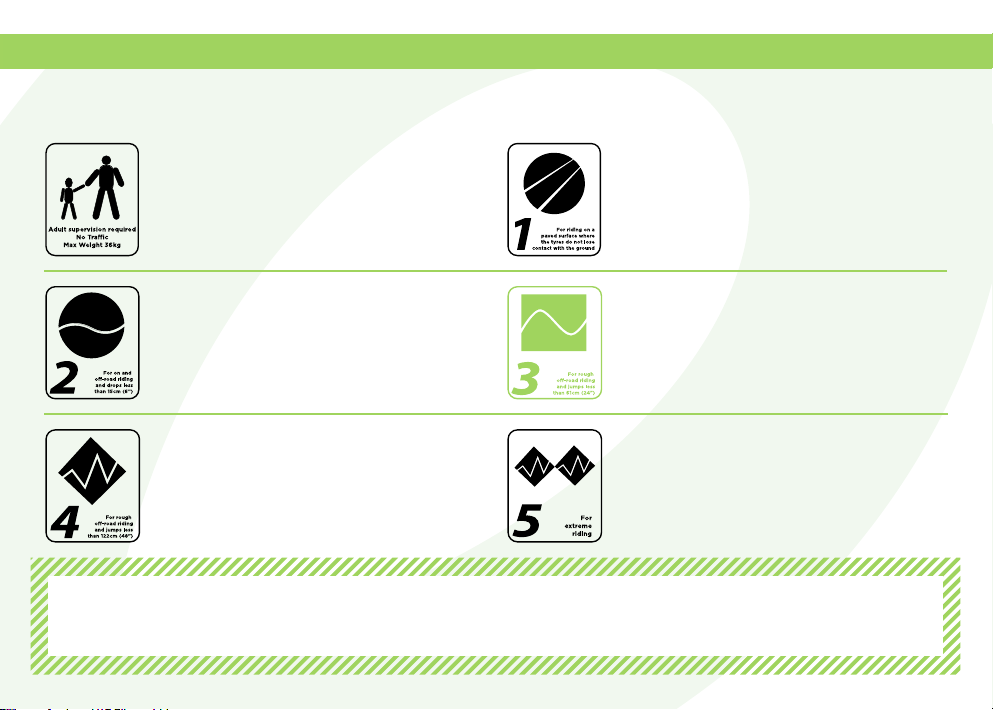

INTENDED USE

The Hellion X20 and Hellion X24 are children’s bikes. As such, they are not intended for use by an adult. Incorrect use could result

in damage to parts on the bike including, but not exclusive to, the frame, forks, cranks and wheel set.

Intended Use: Condition 3

This is a set of conditions for the operation of

a children’s bicycle under appropriate parental

supervision in a manner consistent with the

child’s bicycling skills.

This is a set of conditions for the operation of

a bicycle on a regular paved surface where the

tires are intended to maintain ground contact.

This is a set of conditions for the operation of

a bicycle that includes Condition 1 as well as

unpaved and gravel roads and trails with mod-

erate grades. In this set of conditions, contact

with irregular terrain and loss of tire contact

with the ground may occur. Drops are intended

to be limited to 15cm (6”) or less

This is a set of conditions for operation of a

bicycle that includes Condition 1 and Condition

2 as well as rough trails, rough unpaved roads,

and rough terrain and unimproved trails that

require technical skills. Jumps and drops are

intended to be less than 61cm (24”).

This is a set of conditions for operation of a

bicycle that includes Conditions 1, 2, and 3, or

downhill grades on rough trails at speeds less

than 40km/h (25 mph), or both. Jumps are

intended to be less than 122cm (48”).

This is a set of conditions for operation of a

bicycle that includes Conditions 1, 2, 3, and 4;

extreme jumping; or downhill grades on rough

trails at speeds in excess of 40km/h (25 mph);

or a combination thereof.

Although we test our bikes beyond their intended usage and weight, the maximum safe combined weight for rider + luggage

is as follows: Hellion X20: 40kg Hellion X24: 50kg

Note: The bike is NOT suitable for the fitting of a luggage carrier, child seat or bicycle trailer.

It is not recommended to to fit stabilisers to the bike