The majority of conventional hanging choir microphones suffer from several similar design aws. Some

have the microphone electronics installed in the ceiling with unbalanced microphone cable going to the

microphone. Such designs are often susceptible to radio frequency interference (RFI) or picking up hum

from nearby electrical lines. Another common aw is the use of small, lightweight microphone housings that

do not have enough weight to pull the cable straight when suspended from the ceiling. These lightweight

microphone housings sometimes move due to the air blowing on them from the air conditioning system.

Another problem is the use of cables that will move or rotate due to temperature or humidity changes. These

microphones may be perfectly positioned, then a few days later may be pointed a different direction as the

cable has rotated due to temperature or humidity changes.

The Earthworks ChoirMic is larger in size than most conventional choir microphones, however, all of the

electronics are housed inside the microphone body and the output is low impedance and balanced. This

greatly reduces the likelihood of RFI problems. In addition, high quality Canare™ Star Quad™ microphone

cable is used which provides greater insurance against RFI. This premium microphone cable is also

guaranteed not to rotate or move due to temperature or humidity changes. The heavy microphone body also

provides enough weight to pull the microphone cable straight down for a good cosmetic appearance.

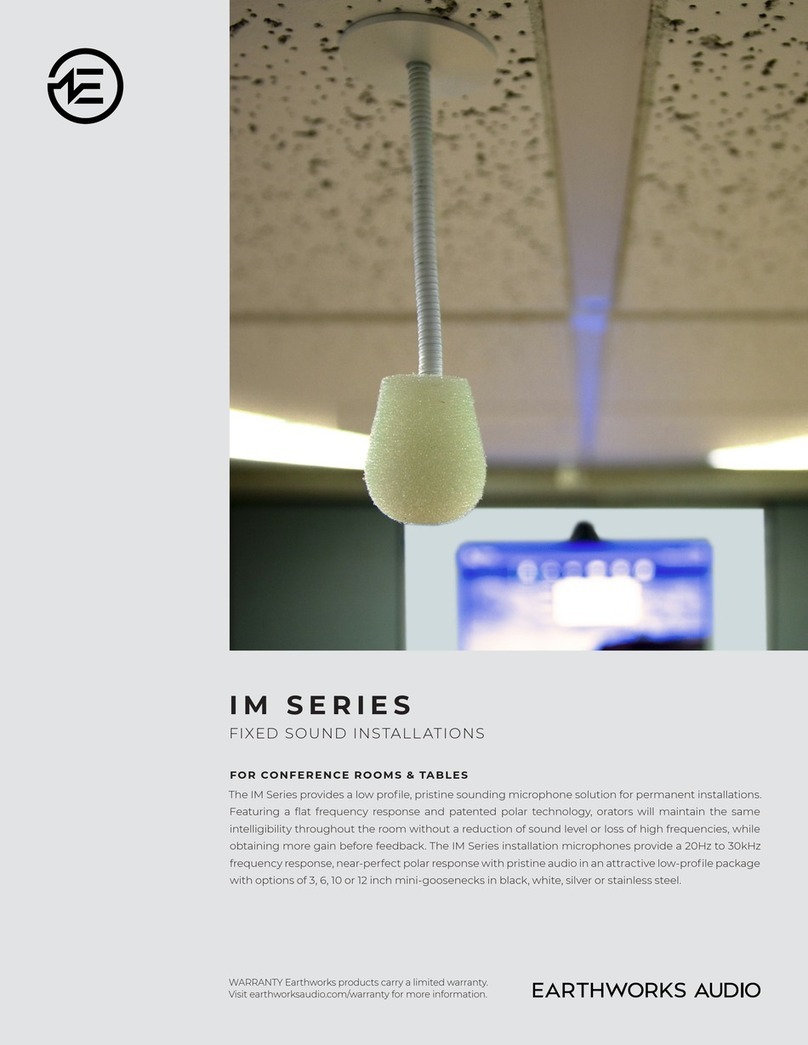

Installers will love the mini-gooseneck on the ChoirMic, as it allows easy positioning of the microphone

head. Many conventional choir microphones require a wire spring type element on the cable to position the

microphone. Not much fun for an installer on top of a tall step ladder. These types of microphones usually

require many trips up and down the ladder to position each microphone. Installers will quickly appreciate the

simplicity and ease of positioning of the Earthworks ChoirMic which hangs straight and stable, and can be

easily positioned with the mini-ex gooseneck.

Other important design features of the ChoirMics is their high SPL handling up to 145dB SPL. Their

extended high frequency response to 30kHz will improve intelligibility and sound quality. The very

short diaphragm settling time of the ChoirMic will allow the listeners to hear detail never before

possible (which is masked by conventional microphones). The use of high current, Class A, low

distortion electronics maintain the quality and integrity of the sound and allow high frequency

information to be sent easily through long lengths of cable without loss of high frequency content.

The ChoirMic™ microphone cable is eld replaceable in the event that a microphone cable becomes

damaged, or the use of a longer cable becomes necessary. To replace the cable, loosen the set screw

on the cap at the cable end of the microphone with an Allen wrench. With the set screw loosened,

hold the microphone body in one hand and rotate the top cap with the other hand to remove the top

cap. With the top cap removed, pull on the microphone cable and the connector will come out. This

connector is a Neutrik model NC3FX-SPEC with gold contacts. You can solder it like a standard XLR-3

microphone connector.

To replace the top cap, rst replace the locking push-button under the rubber grommet then push

the reassembled connector back into the microphone body, mating the connectors. Then hold down

the locking push-button and slide the top cap over it and screw the top cap back on. Once the top cap

is screwed on, the locking push-button will lock the connector into place. If you have any difculty in

replacing the microphone cable, please contact the Earthworks factory for assistance.

MICROPHONE CABLE IS

FIELD REPLACEABLE

CHOIRMIC™ DESIGN

PHILOSOPHY

Earthworks ChoirMics with a mini-ex gooseneck can be

positioned quite easily

Conventional Choir microphones with wire clips are extremely

difcult to position