3

Earthworks High Definition Microphones™

the New Science in Microphones

David Blackmer, the brilliant engineer who invented the innovative

technologies of dbx, is also the inventor and founder of Earthworks.

In the last few years of his life, David developed a number of revolu-

tionary technologies that dramatically improve the sound quality and

performance of microphones. In short, Earthworks High Definition

Microphones™ pick up sounds more accurately and with more detail

than conventional microphones. These dramatic improvements are in

the areas of impulse response, diaphragm settling time and advanced

polar technologies. Those who have heard Earthworks High Definition

Microphones™ say they have more rear rejection and more gain before

feedback in addition to hearing more detail of the attack, more subtle

detail from low level signals thereby providing a more pristine sound

quality than any conventional microphones can provide, regardless of

price.

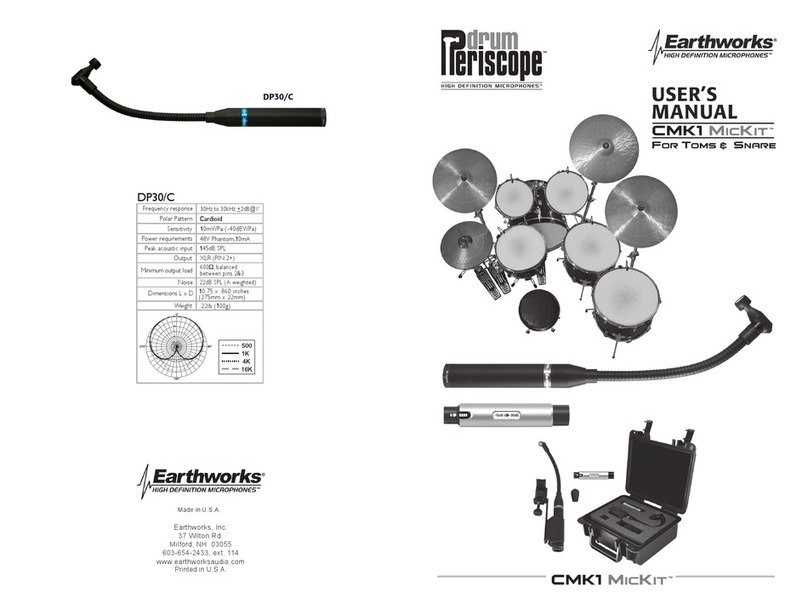

Miking Drums

There are many ways to mic drums and it seems that most every record-

ing or live sound engineer has their own way of doing this. Our objective

is not to indicate which drum miking approach is better, but to make sug-

gestions and look at the advantages and disadvantages of each. Every

engineer or producer uses their own methods to obtain the results they

desire, and that’s what matters.

Multi-microphone Method

The objective in multi-microphone drum miking is to place a separate

microphone on most or all the elements of a drum set. Typically, sep-

arate mics are used on snare, toms, hi-hat and kick drum, along with

one or two overhead microphones. The overhead mics pick up the

overall sound of the drum set including cymbals (which are typically

not miked separately). By this method, the mixing engineer can control

the level, and signal processing (limiting, EQ, etc.) for each element of

the drum set (toms, snare, hi-hat, etc.). This provides a great deal of

control over the sound of the entire drum set and allows bringing out

certain patterns on hi-hat, snare, etc. Multi-miked drums are desirable

for live sound, providing more control and increased gain before feed-

back, and when recording in a large room with high ambient sound this

reduces the amount of unwanted room sound and provides greater

control of the drum mix.