3

1: INTRODUCTION

1:1 Training

This manual is meant to assist with Deka Ready Power troubleshooting

and service. All topics covered in the following sections are taught

in the Deka University DRP Technician class. It is recommended

that DRP technicians participate in this class to receive a complete

understanding of DRP operation, troubleshooting, and service

of lithium batteries and their approved chargers. Work with you

branch management to enroll in an upcoming class.

1.2 How to Use This Manual

For easier navigation, the digital version of this manual contains links

to each section in the table of contents on page 2. Use these to quickly

navigate to the desired section.

The symbols below are used throughout this manual to indicate

important information.

NOTE: Indicates information that may affect product performance or

actions that would void the product warranty.

CAUTION: Indicates information that involves operator safety or

potential product damage.

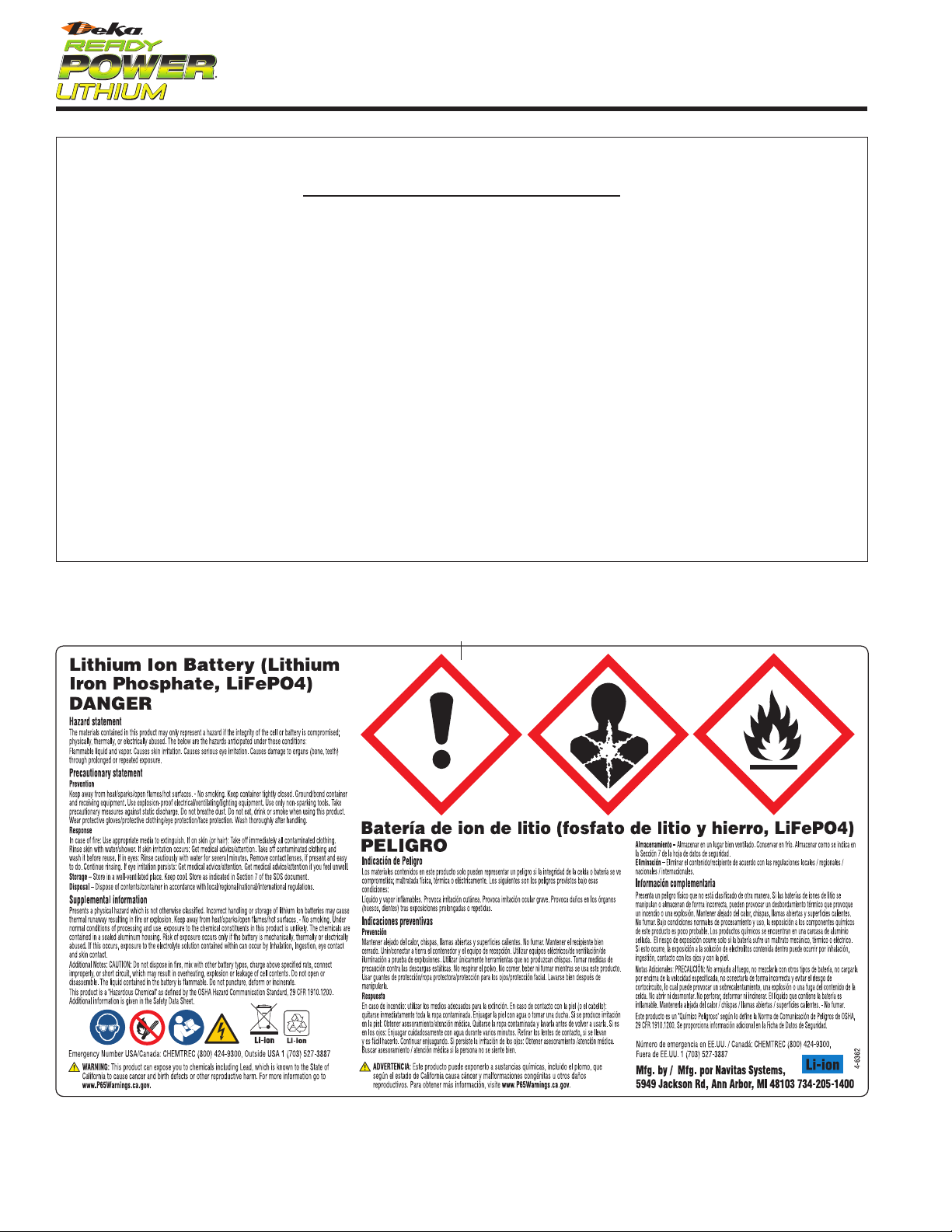

2: SAFETY

2.1 General

When used properly, the Deka Ready Power Li-ion motive power

battery is a safe, dependable source of electrical power. However, the

materials contained within this product may present a hazard or haz-

ardous condition if the integrity of the cell or battery is compromised.

Only trained and QUALIFIED personnel should install, use, or service

this equipment.

Consult the Safety Data Sheet (SDS) for additional precautions and first

aid measures. The SDS can be obtained at www.dekareadypower.com

2.2 Elements of Concern

There are five main potential hazards when not used and maintained

as designed in a Deka Ready Power Li-ion battery: electrolyte,

off-gassing, arc flash and shock potential, and weight.

1.

Electrolyte:

The electrolyte in a Li-ion battery plays a key role in

transporting the positive lithium ions between the cathode and anode.

The most common electrolyte is comprised of lithium salt, such as

LiPF6 (an organic solvent), containing ethylene carbonate, dimethyl

carbonate, and diethyl carbonate. Electrolyte can be a safety hazard

since it contains flammable solvents and if the Deka Ready Power

is damaged or incorrectly charged, it may lead to explosion and fire.

Electrolyte in the presence of water will also produce Hydrofluoric acid.

Consult SDS for additional precautions and first aid measures.

2.

Off-Gassing:

Cells have one time use pressure relief vents to allow

excessive pressure out. Excessive pressure is due to the breakdown

of the electrolyte. This breakdown may produce an “organic” smell

(similar to a permanent marker). Allow off-gassing to dissipate before

servicing a battery and contact the local Deka Representative for

further guidance.

3.

Electricity:

An electric shock hazard exists for persons who contact

live parts of batteries when the voltage is over 60 volts DC. The higher

the voltage, the greater the electric shock hazard. Do not touch battery

terminals while the Deka Ready Power is operating.

4.

Arc Flash:

The light and heat produced as part of an

arc fault

, a

type of electrical explosion or discharge that results from a connec-

tion through air to ground or another voltage phase in an electrical

system. Be sure to consult a hazard category classification table, like

that found in NFPA 70E. Table 130.7(C)(15)(a) lists a number of typical

electrical tasks by various voltage levels and recommends the category

of PPE that should be worn. The second method of selecting PPE is

to perform an arc flash hazard calculation to determine the available

incident arc energy. An industry manual from the Institute of Electrical

and Electronical Engineers (IEEE) labeled IEEE 1584 provides a guide

to perform calculations given the maximum fault current, duration

of faults, and other general equipment information is known. Once

the incident energy is calculated, the appropriate Personal Protective

Equipment (PPE) can be selected. Only personnel trained in NFPA 70E

and the Deka Ready Power should service the Deka Ready Power.

5.

Weight:

The average lift truck battery weighs more than 2,000 lbs.

(900kg). It can cause serious injury if it isn’t handled carefully during

installation, removal, and transport. Always use proper lifting equip-

ment and techniques.

2.3 Proper PPE, Tool, and Equipment

1.

Wearing Protective Clothing:

Technicians working on or near Deka

Ready Power batteries should always wear proper protective clothes

including safety glasses, gloves, and safety toed shoes. Remove all

metal jewelry to prevent an electric shock. Consult with the National

Electrical Code (NEC), National Fire Protection Association (NFPA)

NFPA 70E, and local codes when working with exposed and/or

energized electrical conductors.

2.

Lifting Batteries:

Always use the proper lifting equipment to reduce

the risk of tray damage, shorting and possible injury. An insulated

battery lifting beam of the proper weight capacity rating with an

overhead hoist is the safest way to move a battery. An insulated lifting

beam, with hooks that fit properly into the lifting ears in the tray, can

be used with almost any type of overhead hoist. Be sure the lifting

hooks align perfectly with the battery lifting ears. Misaligned hooks

can cause battery lifting ear damage and could disengage while the

battery is being lifted.

3.

Using the Battery as a Counterweight:

For most lift trucks to

operate safely, the battery is part of the counterweight system of the

forklift truck. The battery must be within the recommended battery

weight range specified on the forklift truck’s nameplate. The battery’s

service weight is noted on the ID label affixed to the battery counter-

weight (refer to section 5.8.2). A battery that is too heavy or too light

can change the truck’s center of gravity and cause it to be unstable.

It is the user’s responsibility to be sure the battery is within weight

specifications of the forklift truck.

4.

Charging Areas – Proper Equipment:

The Deka Ready Power

should be charged using only approved charging equipment in

designated charging areas.

5.

Fire Fighting Equipment:

Hand-operated fire extinguishers should

be available in all charging areas even if the areas are equipped with

automatic sprinkler systems. For information on extinguisher class,

size, and mounting locations, consult local fire authorities and your

insurance carrier.

6.

Disconnecting Charger:

Always press the “Stop” button on

the charger prior to disconnecting a battery that is being charged.

Not using the “Stop” button will damage the battery and charger

receptacles.

3