2

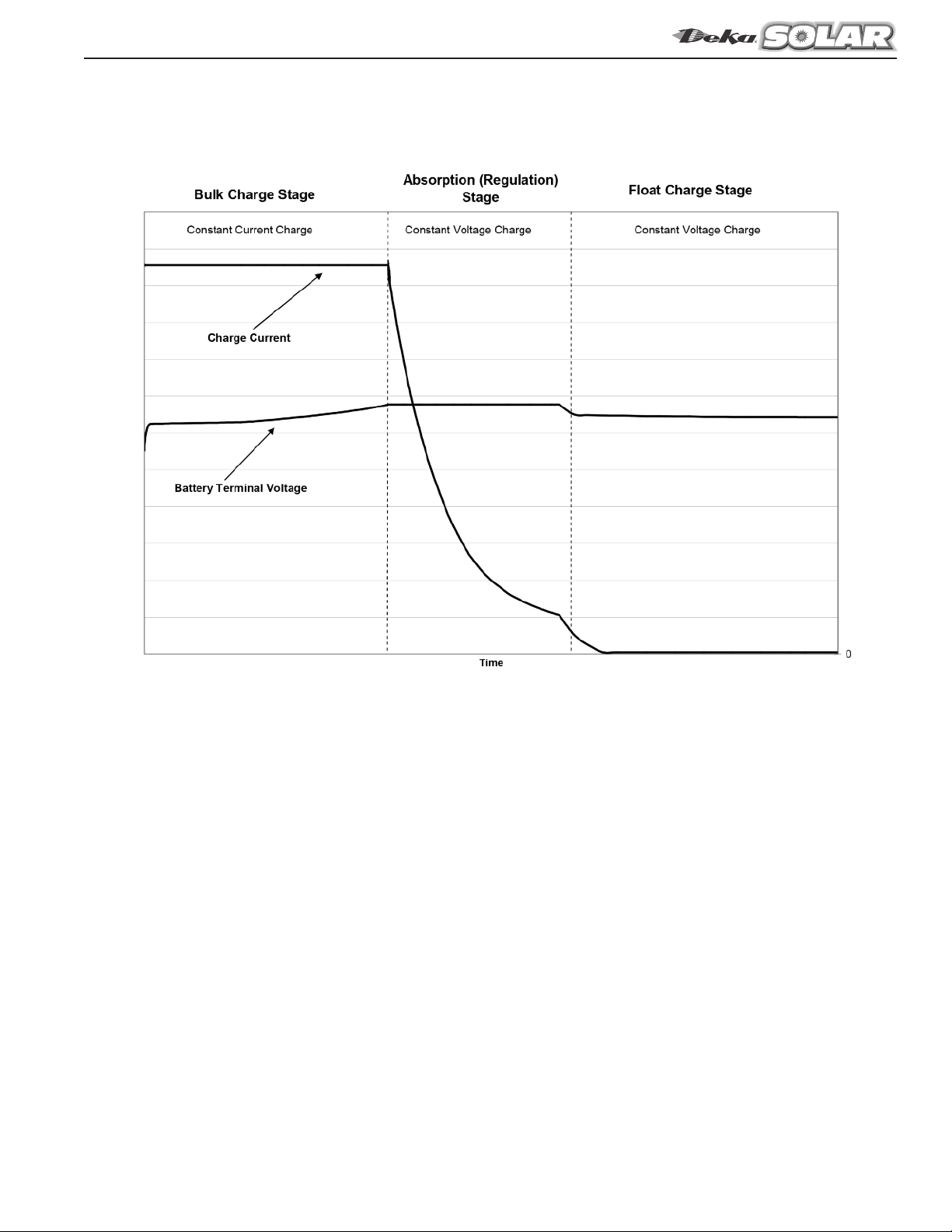

Bulk continued

internal charge capacity. The charger current is flat (constant)

and the battery voltage is rising.

Maximum allowable charge voltage & current allowed by

the battery manufacturer should be used to ensure the most

energy is returned within the bulk stage.

Bulk Charge Stage Time Calculation:

Max Time (Hr) = (Ahr x 1.2)/Avg. Current (A)

Ahr = Amp hours removed during discharge.

1.2 = Recharge multiplier

Avg. Current = Average current available

to battery from charger.

Note: Avg. current should be < maximum current limits

for installed battery. Charge current limits available

from your East Penn representative.

Max Time (Hr) – Maximum charge time for battery to

reach 80% - 85% state of charge

Absorption

The charger will attempt to hold its output voltage constant

while the battery continues to absorb charge (draw charging

current) from the charger. The rate at which the battery con-

tinues to absorb charge in this mode gradually slows down.

The amplitude of the charger current is gradually decreasing.

The charge current is falling and the battery voltage is flat

(constant).

Some Inverter/Charge Controllers can either use time or

current to determine the length of the absorption stage.

Time regulated absorption is based on a predetermined time

after the battery has completed the bulk stage (charge voltage

has reached its maximum set point). A lead-acid battery is said

to be at 80% to 85% SOC (State of Charge) when the voltage

set point is met and the current starts to taper; considered the

start of absorption. The remaining time required to reach

100% SOC is based on ever changing factors: solar isolation

(summer vs. winter), ambient temperature, battery type

(flooded, VRLA), and battery age.

Absorption stage time should be set to optimize the available

sun hours during the winter and/or cloudy months. If improp-

erly set, there is a risk of undercharging the battery system.

It is recommended to set the absorption time to the maxi-

mum time setting possible to take advantage of all available

charging light regardless of time of year or weather issues.

Using this method, the sun availability will determine the

absorption time. Following this recommendation, there is no

risk of overcharging if the battery charge voltage is set within

the recommended settings.

The amount of available power (current) to the batteries is

important for getting a battery charged. Available power

(current) to the batteries is the remaining power (current) after

connected loads are satisfied. Maximum charge voltage and

current allowed by the battery manufacturer should be used to

ensure the most energy is returned to the batteries.

The below calculation will assist in identifying the necessary

maximum charge current for the system. If the calculation

shows the absorption time is greater than the minimum

average peak sun hours for the installation location, the

amount of available current to the batteries should be

increased, which could be accomplished by a larger array

or a secondary power source such as a generator.

Charge Current Verification:

FLOODED

C20 x 0.44/charge current available

Example:

Maximum Charge Current

Battery Rating: 1186Ah (C20)

237A – Charge current (maximum)

1186Ah x 0.44 / 237 = 2.20 hrs

Minimum Charge Current

Battery Rating: 1186Ah (C20)

118A – Charge Current (minimum)

1186Ah x 0.44 / 118A = 4.42 hrs

VRLA (AGM & GEL)

C20 x 0.39/charge current available

Example:

Maximum Charge Current

Battery Rating: 183Ah (C20)

55A – Charge current (maximum)

183Ah x 0.39 / 55A = 1.30 hrs

Minimum Charge Current

Battery Rating: 183Ah (C20)

18.3A – Charge Current (minimum)

183Ah x 0.39 / 18.3A = 3.90 hrs

Current regulated absorption is using the charge current

to determine battery state of charge, which eliminates a

majority of the variables previously mentioned with time

based absorption (solar isolation, ambient temperature,

battery type). Charging in constant voltage, when a

battery/battery system reaches the absorption voltage setting

the current will start to taper. The point at which the current

stops tapering or declining is referred to as the stabilizing

current. This is an indication that the battery is fully charged

and the current the battery/battery system is drawing is only

needed to keep the battery at the set voltage. This minimum

or stabilizing current will change based on the charge voltage

setting. Battery manufacturer should be consulted for current

settings.

An additional option for determining the SOC of a battery is

monitoring the Ah (amp hour) removed from a battery

during a discharge and the amount of Ah returned during

charge; similar to a gas gauge in a car. The Ah in and out

should be monitored on a continuous basis to keep track of

the overall SOC not just from day to day.

Float

The voltage at which the battery is maintained after being

charged to 100% SOC (State of Charge) to maintain capacity

by compensating for self-discharge of the battery.

Equalize

A charge, at a level higher than the normal float voltage,

applied for a limited period of time, to correct inequalities of

voltage, specific gravity, or state of charge that may have

developed between the cells during service.

Note: Equalize charging not required on VRLA (AGM/Gel)

as part of a daily charge setup. Based on PV applications,

unpredictable recharge availability, periodic equalize may

be required.